Find Local Torque Wrench Calibration Services Near Me | Trusted Professionals

When it comes to torque wrench calibration, finding a reliable and trusted professional is crucial. A torque wrench is a precision tool used to apply a specific amount of torque to a fastener such as a bolt or nut. Over time, these tools can lose their accuracy and may require calibration to ensure they are measuring torque correctly.

Whether you are a professional mechanic or a do-it-yourself enthusiast, having a properly calibrated torque wrench is essential to prevent under or over tightening of fasteners. This not only ensures the proper functioning of mechanical systems but also helps avoid accidents and injuries caused by loose or overtightened connections.

Fortunately, finding local torque wrench calibration services near you is easier than ever. With a quick search online or by asking for recommendations from fellow professionals or friends, you can locate trusted professionals who offer calibration services for torque wrenches. These experts have the knowledge, equipment, and experience to accurately calibrate your torque wrench to meet industry standards.

Why is Torque Wrench Calibration Important?

Calibration is an essential aspect of maintaining the accuracy and reliability of torque wrenches. Torque wrenches are used in various industries, such as automotive, aerospace, and manufacturing, where precision is crucial. Here are some key reasons why torque wrench calibration is important:

1. Accuracy and Reliability:

Calibrating torque wrenches ensures that they provide accurate and reliable torque measurements. Over time, torque wrenches can experience wear and tear, affecting their performance. Calibration helps identify any deviations and errors in the torque readings, allowing for necessary adjustments or repairs to be made, ensuring accurate torque application.

2. Compliance with Standards:

Torque wrench calibration is necessary to comply with industry standards and regulations. Many industries, such as aerospace and manufacturing, have specific requirements for torque precision. By calibrating torque wrenches, businesses can adhere to these standards and ensure the safety and quality of their products or services.

3. Preventing Over-tightening or Under-tightening:

Incorrectly applied torque can lead to various issues, such as loose or damaged fasteners, component failures, and safety hazards. Torque wrench calibration helps prevent over-tightening or under-tightening, ensuring that fasteners are properly secured without exceeding their recommended torque specifications. This helps prevent damage to equipment, reduces the risk of accidents, and improves overall product performance.

4. Cost Savings:

Regular torque wrench calibration can help businesses avoid costly rework, repairs, or product failures caused by improperly applied torque. By ensuring the accuracy of torque wrenches, businesses can minimize the risk of errors and reduce expenses associated with warranty claims, equipment damage, or product recalls.

5. Increased Productivity:

Calibrated torque wrenches provide consistent and accurate torque readings, enabling technicians or operators to work efficiently. With accurate torque values, workers can confidently and quickly apply the correct amount of torque, saving time and improving overall productivity.

6. Equipment Longevity:

Regular calibration helps identify and address any issues or wear in torque wrenches before they cause significant damage. By maintaining the accuracy and performance of torque wrenches through calibration, businesses can extend the lifespan of their equipment, reducing the frequency of repairs or replacements.

7. Documentation and Audit Trails:

Torque wrench calibration provides documented evidence of the accuracy and reliability of torque measurements. This documentation can be crucial during audits, quality control inspections, or compliance assessments. It helps businesses prove that they are following proper procedures and maintaining their equipment to the required standards.

Overall, torque wrench calibration is vital for ensuring accurate torque application, compliance with industry standards, preventing damage or failures, and improving overall productivity and cost-efficiency. Regular calibration helps businesses maintain the reliability and performance of their torque wrenches, leading to better quality products or services.

Factors to Consider when Choosing a Local Torque Wrench Calibration Service

1. Certification and Accreditation

When selecting a local torque wrench calibration service, it is important to consider their certification and accreditation. Look for service providers that have the necessary certifications and accreditations from recognized organizations. This ensures that they have the skills and expertise to calibrate torque wrenches accurately and up to industry standards.

2. Experience and Expertise

Another important factor to consider is the experience and expertise of the local torque wrench calibration service. Look for service providers that have been in the industry for a significant amount of time and have a track record of delivering high-quality calibration services. Experienced professionals are more likely to have encountered a wide range of torque wrenches and can handle any calibration needs effectively.

3. Reputation and Reviews

Check the reputation and reviews of the local torque wrench calibration service before making a decision. Look for feedback and testimonials from previous customers to get insights into the quality of their services. Also, consider checking online review platforms to see what other customers have to say about their experience with the service provider. A reputable and well-reviewed calibration service is more likely to provide reliable and accurate calibrations.

4. Turnaround Time

The turnaround time for the calibration service is an important factor to consider, especially if you require quick and efficient calibration. Inquire about the estimated time it takes for the service provider to calibrate torque wrenches and ensure that it aligns with your timeline. Prompt calibration services are essential to minimize any downtime in your operations.

5. Cost

Consider the cost of the local torque wrench calibration service and ensure that it fits within your budget. However, do not solely base your decision on the cost alone. It is important to strike a balance between cost and the quality of the calibration service. Remember that accurate calibration is crucial for the performance and safety of torque wrenches, so prioritize quality over cost.

6. Additional Services

Check if the local torque wrench calibration service offers any additional services that may be beneficial to you. This can include the provision of calibration certificates, repair services, or the option for on-site calibrations. Having access to these additional services can save you time and effort by consolidating multiple needs into one service provider.

7. Location and Convenience

Consider the location and convenience of the local torque wrench calibration service. Choosing a service provider that is easily accessible and close to your location can save you time and transportation costs. Additionally, inquire about their availability and the possibility of scheduling appointments to ensure that their services align with your operational needs.

| Factors to Consider | Description |

|---|---|

| Certification and Accreditation | Ensure the service provider has the necessary certifications and accreditations from recognized organizations. |

| Experience and Expertise | Look for service providers with extensive experience in torque wrench calibration. |

| Reputation and Reviews | Check the service provider’s reputation and read reviews from previous customers. |

| Turnaround Time | Inquire about the estimated time it takes to calibrate torque wrenches. |

| Cost | Consider the cost of the calibration service while prioritizing quality. |

| Additional Services | Check if the service provider offers additional services such as calibration certificates or repair services. |

| Location and Convenience | Choose a service provider that is easily accessible and convenient for your needs. |

Benefits of Hiring a Trusted Professional for Torque Wrench Calibration

1. Accurate and Reliable Calibration

By hiring a trusted professional for torque wrench calibration, you can ensure that your wrench is accurately calibrated. Professionals have the knowledge and expertise to calibrate wrenches with precision, taking into account all necessary variables.

2. Compliance with Industry Standards

Trusted professionals are well-versed in industry standards and guidelines for torque wrench calibration. They will ensure that your wrench meets all the required specifications and complies with safety regulations.

3. Equipment Expertise

Professionals have the necessary equipment to calibrate torque wrenches accurately. They are familiar with different types of wrenches and can handle them accordingly. They have access to specialized tools, ensuring a thorough and comprehensive calibration process.

4. Time and Cost Efficiency

By hiring a trusted professional, you can save time and money. Instead of attempting to calibrate the wrench yourself or using an unreliable service, a professional will efficiently and effectively calibrate your torque wrench, minimizing downtime and avoiding costly errors.

5. Documentation and Certification

Trusted professionals provide documentation and certification for the calibration service. This documentation serves as proof of compliance and can be valuable for audits, quality control, and warranty requirements.

6. Peace of Mind

Knowing that your torque wrench has been calibrated by a trusted professional gives you peace of mind. You can rely on the accuracy and reliability of your wrench, ensuring the safety and quality of your work.

7. Maintenance and Support

Trusted professionals can provide ongoing maintenance and support for your torque wrench. They can offer guidance on proper usage, storage, and maintenance practices, ensuring the longevity and optimal performance of your wrench.

How to Find Local Torque Wrench Calibration Services Near Me

If you are looking for torque wrench calibration services in your local area, there are several methods you can use to find trusted professionals. By following these steps, you can ensure that your torque wrench is properly calibrated and accurate for your needs.

- Ask for Recommendations

- Search Online Directories

- Check Professional Associations

- Read Reviews and Ratings

- Contact and Compare Services

- Visit the Facility

- Ask for Certifications

Start by asking for recommendations from friends, colleagues, or other professionals who have used torque wrench calibration services in the area. Their personal experiences can provide valuable insights and help you narrow down your options.

Use online directories or search engines to find torque wrench calibration services near you. Look for directories that specifically list calibration services or search for keywords such as “torque wrench calibration” or “calibration services” along with your location.

Many professional associations related to the engineering or automotive industries have directories or lists of accredited torque wrench calibration services. Check the websites of these associations to find local professionals who have met certain quality standards.

Once you have identified potential torque wrench calibration services, take the time to read reviews and ratings from previous customers. Websites like Google, Yelp, or Trustpilot can provide insights into the quality of service and customer satisfaction.

Reach out to the torque wrench calibration services on your list and inquire about their services, pricing, and turnaround times. Make sure to ask about their credentials, experience, and any certifications they may have. Request quotes and compare the services offered.

If possible, visit the facility of the torque wrench calibration service you are considering. This will allow you to see firsthand the equipment they use, their level of cleanliness, and the overall professionalism of their operations.

Before making a final decision, ask the torque wrench calibration service for any certifications or accreditations they may have. This can help ensure that they meet industry standards and have the necessary expertise to calibrate your torque wrench accurately.

By following these steps and conducting thorough research, you can find local torque wrench calibration services near you that you can trust for accurate and reliable calibration.

What to Expect during the Torque Wrench Calibration Process

Introduction

Calibrating a torque wrench is an essential part of ensuring its accuracy and reliability. In order to maintain the efficiency and precision of the tool, regular calibration is necessary. During the calibration process, various steps are followed to measure the torque application accuracy and make any necessary adjustments. This article will provide an overview of what you can expect during the torque wrench calibration process.

1. Initial Inspection

The calibration process starts with an initial inspection of the torque wrench. The professional calibrator will examine the overall condition of the tool, checking for any visible damage or wear. They will look for loose parts, signs of corrosion, or any other potential issues that may affect the accuracy of the measurements.

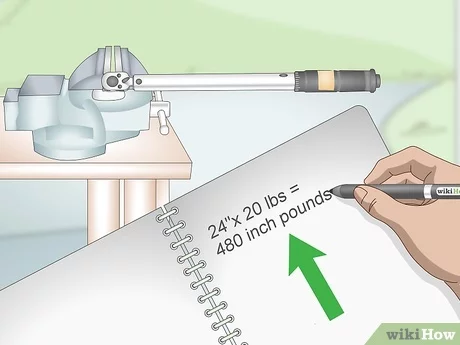

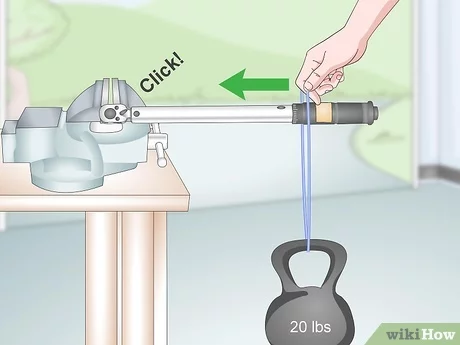

2. Applying a Known Load

In order to calibrate the torque wrench, a known load or torque is applied to the tool. This is usually done with the help of a calibrated test apparatus. The torque wrench is tightened or loosened to a specific value, and the applied torque is measured using the apparatus.

3. Measurements and Comparisons

The next step involves measuring the torque applied by the torque wrench and comparing it to the known load. The professional calibrator will use precision instruments to measure the applied torque accurately. The measured value is then compared to the known load to determine the accuracy of the torque wrench.

4. Adjustments if Needed

If the torque wrench is found to be inaccurate, adjustments may need to be made. The professional calibrator will make necessary adjustments to bring the torque wrench back to its specified accuracy. This may involve tightening or loosening certain components or using calibration tools to modify the settings of the torque wrench.

5. Final Verification

Once the adjustments are made, the torque wrench needs to be re-tested to ensure that it now meets the desired accuracy. The calibrated tool is once again subjected to a known load, and the applied torque is measured and compared to the expected value. If the results are within the acceptable range, the torque wrench is considered calibrated.

6. Calibration Certificate

After the torque wrench has been successfully calibrated, a calibration certificate is issued. This document provides details about the calibration process, including the date of calibration, the calibration standards used, and the results of the calibration. The certificate serves as proof that the torque wrench has been calibrated and meets the required accuracy standards.

Conclusion

Having your torque wrench regularly calibrated is crucial to ensure accurate and reliable performance. The calibration process involves careful inspection, applying a known load, measuring and comparing the applied torque, making adjustments if necessary, and final verification. By following these steps, the calibration professional ensures that the torque wrench meets the specified accuracy standards. The resulting calibration certificate provides assurance that the tool is in its optimal working condition.

Tips for Maintaining the Accuracy of Torque Wrenches

Regular Inspection

Regularly inspecting your torque wrench is essential for maintaining its accuracy. Look for signs of wear and tear, such as loose or damaged components, and fix or replace them immediately. Check that the torque settings are still accurate by comparing them with a calibrated tool.

Proper Handling

Handle your torque wrench with care to prevent any damage that could affect its accuracy. Avoid dropping it, exposing it to excessive heat or cold, and using it as a hammer or pry bar.

Calibration

Calibrating your torque wrench on a regular basis is crucial for ensuring its accuracy. Most manufacturers recommend calibration every 12 months or after 5,000 cycles, whichever comes first. It is best to have it calibrated by a professional torque wrench calibration service to ensure precision and reliability.

Storage

Store your torque wrench in a clean and dry environment, away from moisture and dust. Use a protective case or pouch to prevent any physical damage during storage or transportation.

Avoid Overloading

Avoid applying excessive force or torque beyond the wrench’s capacity. Doing so can lead to inaccurate readings and potential damage to the tool. Always use the correct torque range specified for the application.

Keep it Clean

Clean your torque wrench regularly to remove dirt, grease, and debris that can accumulate on the surface. Use a mild detergent and a soft cloth or brush to clean the tool. Make sure to dry it thoroughly before storing.

Use the Right Attachments

Ensure that you are using the correct attachments and accessories recommended by the manufacturer. Using incompatible or worn-out attachments can affect the accuracy of the torque wrench.

Proper Technique

Use the torque wrench following the manufacturer’s instructions and recommended technique. Applying force at an angle or using excessive force can lead to incorrect readings. Keep the wrench perpendicular to the fastener and apply gradual, steady force.

Regular Maintenance

In addition to regular inspections and calibration, it is important to perform routine maintenance on your torque wrench. This may include lubricating moving parts, checking for loose fasteners, and replacing any worn-out or damaged components.

By following these tips, you can ensure the accuracy and reliability of your torque wrench, allowing you to complete your projects with confidence.

FAQs about Torque Wrench Calibration Services

1. What is torque wrench calibration?

Torque wrench calibration is the process of adjusting and verifying the accuracy of a torque wrench. A torque wrench is a tool used to apply a specific amount of torque (rotation force) to a fastener, such as a nut or bolt. Over time, torque wrenches can become less accurate and require calibration to ensure they are providing the correct torque output.

2. Why is torque wrench calibration important?

Calibration is important to ensure that the torque wrench is accurate and providing the correct torque output. Using an inaccurate torque wrench can lead to under or over-tightening of fasteners, which can result in equipment failure, leaks, or other safety issues. Regular calibration helps ensure the reliability and safety of torque wrenches.

3. How often should torque wrenches be calibrated?

The frequency of torque wrench calibration depends on several factors, including the manufacturer’s recommendations, the level of usage, and the specific application. In general, torque wrenches should be calibrated at least once a year or more frequently if they are used extensively or in critical applications. It’s also important to calibrate torque wrenches after any significant impact or mechanical stress that may affect their accuracy.

4. How is torque wrench calibration performed?

Torque wrench calibration is typically performed by trained professionals using specialized equipment. The process involves applying a known calibrated force to the torque wrench and comparing its output to the expected value. Any discrepancies are then adjusted, either mechanically or electronically, to bring the torque wrench back into accurate calibration.

5. Where can I find local torque wrench calibration services?

You can find local torque wrench calibration services by searching online directories, such as Yellow Pages or Yelp, or by contacting local industrial equipment suppliers or service providers. It’s important to choose a reputable and experienced service provider to ensure accurate and reliable calibration of your torque wrenches.

6. How much does torque wrench calibration cost?

The cost of torque wrench calibration can vary depending on factors such as the type of torque wrench, the number of wrenches being calibrated, and the calibration service provider. It’s best to contact the service providers directly to get a quote based on your specific needs.

7. Can I calibrate my torque wrench myself?

While it is possible to calibrate some torque wrenches yourself using a torque tester or calibration device, it is usually recommended to have torque wrenches calibrated by trained professionals. Professional calibration ensures the accuracy and reliability of the torque wrench, and the equipment used by professionals is usually more accurate and precise than what is available to individuals.

8. Are there any regulations or standards for torque wrench calibration?

Yes, there are regulations and standards for torque wrench calibration, depending on the industry and application. For example, ISO 6789 is an international standard that specifies requirements and methods for the calibration of torque wrenches. Various industries and regulatory bodies may also have their own specific requirements for torque wrench calibration.

9. What are the consequences of using an uncalibrated torque wrench?

Using an uncalibrated torque wrench can lead to under or over-tightening of fasteners, which can result in equipment failures, leaks, or safety hazards. Under-tightening can cause bolts to loosen or fail, compromising the integrity of structures and machinery. Over-tightening can damage fasteners, strip threads, or even cause excessive stress on machinery components, leading to premature failure.

10. Can a torque wrench be recalibrated if it fails calibration?

Yes, in most cases, torque wrenches can be recalibrated if they fail calibration. However, it’s important to note that the level of adjustment allowed may depend on the specific torque wrench model and its manufacturer’s specifications. Some torque wrenches may require additional maintenance or repair if they cannot be accurately recalibrated.

FAQ

How can I find local torque wrench calibration services near me?

You can find local torque wrench calibration services near you by using online directories, such as Yelp or YellowPages, or by conducting a search on search engines like Google.

What is the importance of torque wrench calibration?

Torque wrench calibration is important to ensure that the tool is measuring torque accurately. Accurate torque measurements are crucial in many industries, such as automotive and aerospace, to ensure proper assembly and prevent any damage or failure.

How often should torque wrenches be calibrated?

The frequency of torque wrench calibration depends on the manufacturer’s recommendations and the frequency of use. In general, torque wrenches should be calibrated at least once a year or more frequently if they are used extensively.

Can I calibrate my torque wrench on my own?

While it is possible to calibrate a torque wrench on your own, it is recommended to have it calibrated by a professional calibration service. They have the necessary equipment and expertise to ensure accurate calibration.

What does torque wrench calibration involve?

Torque wrench calibration involves comparing the torque reading of the wrench to a known standard, such as a calibration machine. The wrench is adjusted if there is any deviation from the standard, ensuring accurate torque measurements.

How long does torque wrench calibration take?

The duration of torque wrench calibration can vary depending on the specific wrench and the calibration service. It can range from a few minutes to several hours, depending on the complexity of the wrench and the need for any adjustments.