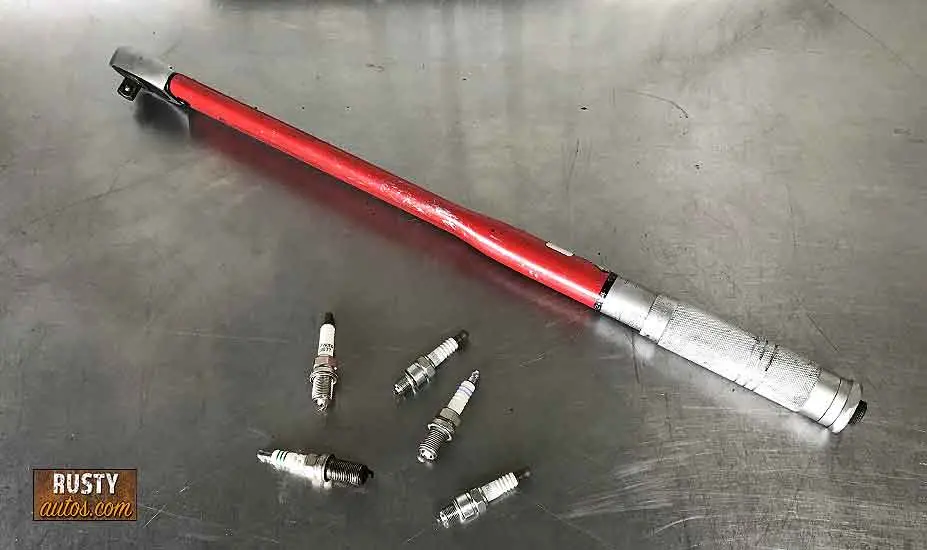

Choosing the Right Size Torque Wrench for Spark Plugs: The Ultimate Guide

When it comes to changing spark plugs, using the correct size torque wrench is essential. The torque wrench is a tool that allows you to tighten the spark plug to the manufacturer’s specified torque measurement, ensuring the plug is secure and properly sealed. However, with so many different sizes of torque wrenches available, it can be overwhelming to know which one to choose. That’s why we’ve created this ultimate guide to help you select the right size torque wrench for your spark plugs.

First and foremost, it’s important to understand that torque wrench sizes are based on the measurement of the square drive, which is the part of the wrench that connects to the socket. The most common square drive sizes for torque wrenches used in automotive applications are 1/4-inch, 3/8-inch, and 1/2-inch. The smaller the square drive size, the finer the torque control, while larger square drive sizes are better suited for higher torque applications.

When choosing the right size torque wrench for spark plugs, you need to consider the size of the spark plug socket. Most spark plugs require either a 5/8-inch socket or a 13/16-inch socket. These socket sizes correspond to the most common square drive sizes of torque wrenches. For 5/8-inch spark plugs, a 3/8-inch square drive torque wrench is recommended. For 13/16-inch spark plugs, a 1/2-inch square drive torque wrench is typically used.

It’s important to note that not all torque wrenches come in these specific square drive sizes. Some torque wrenches may have interchangeable heads or adapters, allowing you to use different socket sizes. If you already have a torque wrench with a different square drive size, you can simply purchase an adapter to match the socket size needed for your spark plugs.

Remember, using the correct size torque wrench is crucial to prevent overtightening or undertightening of spark plugs, which can lead to engine damage or poor performance. Always refer to your vehicle’s manufacturer guidelines for the specified torque measurement and choose the appropriate torque wrench accordingly.

In conclusion, choosing the right size torque wrench for spark plugs is essential for proper installation and maintenance of your vehicle’s engine. By considering the square drive size of the wrench and matching it with the socket size of the spark plug, you can ensure that the plugs are tightened to the correct torque measurement, promoting optimal engine performance and longevity.

Understanding the Importance of Using the Correct Size Torque Wrench

Using the correct size torque wrench is crucial when it comes to working on spark plugs. Ignoring this important factor can lead to various problems, including damaged spark plugs, engine inefficiency, and even engine failure.

Damaged Spark Plugs

When a torque wrench is not the right size for a spark plug, excessive force can be applied, causing the spark plug to become damaged. This can result in cracked insulators, damaged threads, and reduced overall performance. Using a torque wrench that is too large may also cause the spark plug to become loose over time, leading to misfires and engine issues.

Engine Inefficiency

Using an incorrect torque wrench can also lead to engine inefficiency. If the spark plug is not tightened properly, it can cause air and fuel leaks. This can lead to a poor combustion process and decreased fuel efficiency. Additionally, a loose or damaged spark plug may not produce a strong enough spark to ignite the air and fuel mixture, resulting in misfires and reduced power output.

Engine Failure

In extreme cases, using the wrong size torque wrench can eventually lead to engine failure. If a spark plug is not tightened enough, it can become dislodged from the cylinder head while the engine is running. This can cause severe damage to the engine, including bent valves, damaged pistons, and even catastrophic engine failure.

Proper Torque Specifications

Using the correct size torque wrench helps ensure that spark plugs are tightened to the manufacturer’s recommended torque specifications. Each spark plug has a specific torque requirement to ensure proper sealing and to prevent overtightening or undertightening. Following the correct torque specifications is essential for safety, performance, and longevity of the engine.

Conclusion

Understanding the importance of using the correct size torque wrench for spark plugs is vital to the overall performance and reliability of the engine. By using the appropriate torque wrench, you can avoid damaging the spark plugs, maintain engine efficiency, and prevent potentially catastrophic engine failure. Always refer to the manufacturer’s specifications and guidelines when selecting and using a torque wrench for spark plug installation.

Factors to Consider When Selecting the Size of Torque Wrench

When it comes to choosing the right size torque wrench for spark plugs, there are a few important factors to consider. These factors will help ensure that you have the correct torque wrench for the job and can safely tighten the spark plugs to the manufacturer’s specifications. Here are the key factors to consider:

- Spark Plug Size: The first and most obvious factor to consider is the size of the spark plugs you will be working with. Spark plugs come in various sizes, such as 14mm, 16mm, and 18mm. It is important to choose a torque wrench that can accommodate the specific size of spark plugs you will be working with.

- Torque Range: The torque range of the wrench is another crucial factor to consider. Different spark plug manufacturers may have different torque specifications for their plugs. It is essential to select a torque wrench that can provide the correct torque levels within the specified range. This will ensure that the spark plugs are tightened to the appropriate level without causing any damage.

- Accuracy: Accuracy is paramount when working with torque wrenches. It is crucial to choose a torque wrench that offers a high level of accuracy to ensure that the spark plugs are properly tightened. Look for torque wrenches that have been calibrated and meet the recommended industry standards for accuracy.

- Handle Length: The length of the torque wrench handle is another factor to consider. A longer handle will provide more leverage and make it easier to apply the necessary torque. However, it is important to consider the space constraints in your engine and ensure that the torque wrench handle can fit comfortably without obstruction.

- Type of Spark Plug: Lastly, consider the type of spark plug you will be working with. Some spark plugs, such as those with a tapered seat, may require a specific type of torque wrench. Be sure to choose a torque wrench that is compatible with the specific type of spark plug you will be working with.

By considering these factors, you can select the right size torque wrench for spark plugs and ensure that you have the proper tool for the job. Remember to always follow the manufacturer’s recommendations for torque specifications to avoid damaging the spark plugs or the engine.

Types of Torque Wrenches Available for Spark Plugs

When it comes to tightening spark plugs, it is important to use the right size torque wrench. There are several types of torque wrenches available that are specifically designed for spark plugs. Here are some of the most common types:

1. Click-Type Torque Wrench

A click-type torque wrench is the most commonly used type of torque wrench for spark plugs. It has a click mechanism that produces an audible click sound when the desired torque level is reached. This makes it easy to use and ensures that the spark plug is tightened to the correct specification.

2. Beam-Type Torque Wrench

A beam-type torque wrench uses a beam or rod to indicate the torque being applied. It does not have a click mechanism like the click-type torque wrench. Instead, it relies on the user to visually read the torque level from the scale on the wrench. This type of torque wrench is generally less expensive than click-type wrenches, but it requires more careful observation during use.

3. Digital Torque Wrench

A digital torque wrench is a modern variation of the click-type torque wrench. It features a digital display that shows the torque being applied in real-time. This type of torque wrench provides precise and accurate readings, making it ideal for professionals or those who require precise torque measurements. However, digital torque wrenches tend to be more expensive compared to other types.

4. Dial-Type Torque Wrench

A dial-type torque wrench has a dial or gauge that provides a visual indication of the torque being applied. It is similar to a beam-type torque wrench, but with a dial instead of a beam. This type of torque wrench is known for its accuracy and ease of use. However, it can be more expensive compared to other types of torque wrenches.

5. Micrometer Torque Wrench

A micrometer torque wrench is a precision instrument that allows for extremely accurate torque measurements. It features a micrometer-like scale that can be adjusted to the desired torque level. This type of torque wrench is commonly used in professional settings where precise torque measurements are critical.

Choosing the right type of torque wrench for spark plugs depends on your specific needs and budget. It is important to consider factors such as accuracy, ease of use, and cost when making your selection. Whichever type of torque wrench you choose, be sure to follow the manufacturer’s instructions and the recommended torque specifications for your spark plugs to ensure proper installation.

How to Determine the Correct Size Torque Wrench for Spark Plugs

Determining the correct size torque wrench for spark plugs is crucial to ensure the proper installation and alignment of the spark plugs. Here are some steps to help you determine the correct size torque wrench for spark plugs:

- Check the vehicle’s owner’s manual: The first step is to consult your vehicle’s owner’s manual. The manual will provide you with the recommended torque specifications for the spark plugs.

- Identify the type of spark plugs: Different types of spark plugs may require different torque settings. Common types include standard spark plugs, platinum spark plugs, and iridium spark plugs. Determine the type of spark plugs your vehicle uses.

- Consider the spark plug size: Spark plugs come in different sizes, typically measured in thread diameter and thread reach. These sizes can vary depending on the vehicle make and model. Check the size of your spark plugs to ensure you select the correct torque wrench size.

- Choose the appropriate torque range: Once you have the torque specifications and spark plug size, it is important to select a torque wrench that falls within the recommended torque range. This ensures that you can apply the right amount of torque without damaging the spark plugs.

- Consider the drive size: Torque wrenches come in different drive sizes, such as 1/4 inch, 3/8 inch, or 1/2 inch. Ensure that the torque wrench you choose has a compatible drive size with your spark plug socket.

By following these steps, you can determine the correct size torque wrench for spark plugs and ensure the proper installation of your spark plugs, preventing any potential damage or performance issues.

Common Mistakes to Avoid When Choosing the Size of Torque Wrench

Choosing the right size torque wrench for spark plugs is essential to ensure a proper and secure installation. However, there are common mistakes that people make when selecting the size of a torque wrench. Here are some mistakes to avoid:

- Using the wrong torque wrench size: One common mistake is using a torque wrench that is either too large or too small for the spark plugs. Using a torque wrench of the wrong size can lead to inaccurate torque readings and potentially damage the spark plugs or the surrounding components.

- Not considering the spark plug’s torque specification: It’s important to consider the torque specification provided by the spark plug manufacturer. Each spark plug model may have a different torque requirement, and using the wrong size torque wrench can result in under or over-tightening the spark plugs.

- Ignoring the spark plug’s reach: The reach of the spark plug refers to the length from the bottom of the thread to the seat. Ignoring the reach when choosing a torque wrench can lead to inadequate tightening or insufficient thread engagement.

- Using a torque wrench with an incompatible drive size: Torque wrenches come with different drive sizes, such as 1/4 inch, 3/8 inch, or 1/2 inch. It’s important to select a torque wrench with a compatible drive size for the spark plug’s socket. Using the wrong drive size can result in the wrench slipping or not fitting properly.

- Overlooking the torque wrench’s accuracy and calibration: It’s crucial to use a torque wrench that is accurate and properly calibrated. Overlooking the accuracy and calibration of the torque wrench can lead to incorrect torque readings and potentially cause damage to the spark plugs or other components.

By avoiding these common mistakes, you can ensure that you choose the right size torque wrench for your spark plugs and perform a proper installation without any problems.

Tips and Tricks for Using a Torque Wrench for Spark Plugs

1. Choose the right size torque wrench

Before you start working on your spark plugs, make sure you have the right size torque wrench. Different spark plugs may require different torque specifications, so it’s important to choose the correct tool for the job. Refer to your vehicle’s manual or the manufacturer’s specifications to determine the appropriate torque range for your specific spark plugs.

2. Use a torque wrench with a built-in ratchet

A torque wrench with a built-in ratchet is a must-have for working on spark plugs. This feature allows you to apply precise torque while preventing over-tightening. The ratchet mechanism will automatically disengage once you reach the desired torque, ensuring that you don’t damage the spark plug or the engine.

3. Start with a clean spark plug well

Before installing a new spark plug, make sure the spark plug well is clean and free of debris. Use compressed air or a small brush to remove any dirt or particles that may interfere with the proper seating of the spark plug. A clean spark plug well will ensure a secure and efficient connection.

4. Apply anti-seize lubricant

Applying a small amount of anti-seize lubricant to the spark plug threads can help prevent the spark plug from getting stuck or seizing in the cylinder head. This will make future removal of the spark plug easier and reduce the risk of damaging the threads. Be sure to follow the manufacturer’s instructions when applying the lubricant.

5. Tighten the spark plug to the specified torque

Using your torque wrench, slowly and evenly tighten the spark plug to the specified torque setting. Avoid overtightening, as this can damage the spark plug or the cylinder head. If you are unsure of the correct torque specification, refer to your vehicle’s manual or the manufacturer’s specifications.

6. Check for any leaks

After tightening the spark plug, inspect the area for any signs of leakage. A properly installed spark plug should create a tight seal, preventing any leakage of combustion gases. If you notice any leaks, remove the spark plug and check for any issues, such as a damaged gasket or improper installation.

7. Keep a torque wrench calibration schedule

To ensure the accuracy of your torque wrench, it’s important to keep a regular calibration schedule. Over time, a torque wrench can lose its accuracy, which may result in overtightening or undertightening of spark plugs. Consult the manufacturer’s guidelines or have your torque wrench professionally calibrated at regular intervals.

8. Practice proper torque wrench handling

When using a torque wrench, it’s important to handle it properly to prevent any damage or loss of accuracy. Always store the wrench in a clean and dry place, away from any excessive heat or moisture. Avoid dropping the torque wrench or using it as a lever, as this can affect its calibration.

9. Seek professional help if unsure

If you are unsure about how to properly use a torque wrench or have any concerns about working on spark plugs, it’s always best to seek professional help. A certified mechanic can guide you through the process and ensure that the spark plugs are installed correctly and functioning properly.

10. Regularly inspect and replace spark plugs

To maintain optimal engine performance, it’s important to regularly inspect and replace spark plugs as needed. Over time, spark plugs can wear out or become fouled, affecting fuel efficiency and engine performance. Consult your vehicle’s manual for the recommended inspection and replacement intervals.

By following these tips and tricks for using a torque wrench for spark plugs, you can ensure a secure and efficient connection while preventing any damage to the spark plugs or the engine.

FAQ

What is a torque wrench and why is it important for spark plugs?

A torque wrench is a tool used to apply a specific amount of torque, or rotational force, to a fastener. It is important for spark plugs because they need to be tightened to a specific torque specification in order to ensure proper performance and prevent damaging the spark plug or the engine.

How do I determine the size of torque wrench I need for spark plugs?

The size of torque wrench you need for spark plugs depends on the specific spark plug size and the torque specification provided by the spark plug manufacturer or the vehicle manufacturer. You can usually find this information in the vehicle’s manual or by contacting the manufacturer. Once you have the required torque specification, you can choose a torque wrench that has a range encompassing that specification.

What happens if I use the wrong size torque wrench for spark plugs?

If you use a torque wrench that is too small, you may not be able to apply enough torque to properly tighten the spark plug, which can result in it becoming loose and potentially causing engine misfires or other issues. If you use a torque wrench that is too big, you may over-tighten the spark plug, which can also cause damage to the spark plug or the engine.

Are there any other factors to consider when choosing a torque wrench for spark plugs?

Yes, in addition to the size, you should also consider the torque range, the type of torque wrench (such as click or beam), the quality and accuracy of the torque wrench, and any additional features or accessories that may be beneficial for your specific needs.

Video