How To Weld Sheet Metal With A Wire Feed Welder

Welding sheet metal can be a challenging task, but with the right technique and equipment, it can be accomplished successfully. One of the most popular tools for welding sheet metal is a wire feed welder. This type of welder uses a continuous wire electrode that is fed through a welding gun, which creates an electric arc that melts and fuses the metal pieces together.

Before you begin welding, it is important to prepare the sheet metal properly. Clean the surface of the metal to remove any dirt, oil, or rust that may be present. Use a wire brush or sandpaper to achieve a smooth and clean surface. Additionally, make sure to wear proper safety gear, including welding gloves, a welding helmet, and protective clothing, to protect yourself from sparks and UV radiation.

Once the sheet metal is prepared, you can begin the welding process. Position the metal pieces in the desired configuration and secure them in place using clamps or magnets. It is crucial to maintain a proper joint gap between the metal pieces to ensure a strong and durable weld. A joint gap of about 1/16 to 1/8 inch is typically recommended for sheet metal welding.

When using a wire feed welder, it is important to choose the right settings for the thickness of the sheet metal. Adjust the voltage and wire speed according to the manufacturer’s guidelines or welding chart. Start with lower settings and make test welds to ensure proper penetration and fusion. It is also essential to maintain a consistent welding speed to achieve a uniform and smooth weld.

In conclusion, welding sheet metal with a wire feed welder requires proper preparation, the right technique, and suitable equipment. By following these guidelines and practicing on scrap metal beforehand, you can master the art of sheet metal welding and achieve strong and professional results.

What is a wire feed welder?

A wire feed welder, also known as a MIG welder (Metal Inert Gas), is a type of welding machine that uses a continuously fed wire electrode to create an electric arc for joining two pieces of metal together. This process is also known as gas metal arc welding (GMAW).

Wire feed welders are commonly used for welding sheet metal due to their versatility and ease of use. They are especially beneficial for beginners or hobbyists as they require less skill and expertise compared to other types of welding machines.

Wire feed welders work by feeding a thin wire electrode through a welding gun. The wire electrode is coated with a flux material that melts and shields the weld from impurities. The welding machine also releases an inert gas, such as argon or carbon dioxide, to further protect the weld from contamination.

This welding process is efficient and allows for high-quality welds on thin sheet metal without the need for extensive cleanup or post-weld treatments. The wire feed welder’s ability to control the amperage and speed of the wire feed makes it ideal for working with different thicknesses of sheet metal.

Advantages of wire feed welders:

- Easy to learn and use, making them suitable for beginners

- Higher deposition rates compared to other types of welding machines

- Can be used on various metal types, including stainless steel, aluminum, and mild steel

- Produces clean and precise welds with minimal splatter

- Less cleanup and post-weld treatments required

Disadvantages of wire feed welders:

- Not suitable for heavy-duty or structural welding

- Requires a constant supply of electricity

- Limited to flat or horizontal welding positions

- Can be affected by wind or drafts

- May require additional equipment for welding in outdoor or windy conditions

Advantages of using a wire feed welder for welding sheet metal

When it comes to welding sheet metal, using a wire feed welder can offer several advantages over other welding methods. Here are some of the key benefits:

1. Speed and efficiency: Wire feed welders are known for their fast welding speed, making them a great choice for working with thin sheet metal. The continuous wire feed allows for a steady and efficient welding process, reducing the time required to complete a weld.

2. Ease of use: Wire feed welders are relatively easy to operate, even for beginners. With the proper settings and technique, you can achieve clean and precise welds on sheet metal without much difficulty. This makes wire feed welders a popular choice among DIY enthusiasts and hobbyists.

3. Lower heat output: Sheet metal is highly sensitive to heat, and excessive heat can cause warping, distortion, or burn-through. Wire feed welders produce a lower heat output compared to other welding methods, reducing the risk of damaging the sheet metal. This allows for more controlled welding and minimizes the need for additional heat management techniques.

4. Versatility: Wire feed welders offer a wide range of applications, making them suitable for welding different types of sheet metal, including steel, aluminum, and stainless steel. They can be used for various projects, from automotive repairs to HVAC installations.

5. Cost-effective: Wire feed welders are generally more affordable compared to other types of welding equipment. Additionally, the wire feed consumables, such as welding wire and shielding gas, are less expensive than electrodes and other welding materials. This makes wire feed welding a cost-effective option for welding sheet metal.

6. Clean welds: When properly executed, wire feed welding can produce clean and aesthetically pleasing welds on sheet metal. The continuous wire feed ensures a consistent weld bead, resulting in smooth and uniform welds that require minimal cleanup or post-welding finishing.

In conclusion, using a wire feed welder for welding sheet metal offers several advantages, including speed and efficiency, ease of use, lower heat output, versatility, cost-effectiveness, and clean welds. Whether you are a professional welder or a DIY enthusiast, a wire feed welder can be a valuable tool for working with sheet metal.

Preparing for Welding

Before you start welding sheet metal with a wire feed welder, it is important to properly prepare both the sheet metal and your work area.

Clean the Sheet Metal

The first step in preparing for welding is to clean the sheet metal surface. This is essential to remove any dirt, grime, grease, or rust that may be present. Use a wire brush or sandpaper to scrub the surface thoroughly, ensuring a clean and smooth welding surface.

Remove any Coating

Some sheet metal comes with protective coatings or paint that should be removed before welding. These coatings can produce harmful fumes when heated, and can also interfere with the quality of the weld. Use a grinder or a solvent to remove any coating, being careful not to damage the sheet metal underneath.

Secure the Sheet Metal

It is important to securely hold the sheet metal in place before welding. This can be done using clamps or magnets to ensure that the metal does not move during the welding process. Make sure the sheet metal is positioned correctly and securely before proceeding with the welding.

Prepare the Work Area

Before starting the welding process, it is important to prepare your work area to ensure safety and efficiency. Clear any clutter or flammable materials from the area and make sure there is enough space for you to maneuver around the welding equipment. It is also advisable to have a fire extinguisher nearby in case of any accidents.

By properly preparing the sheet metal and your work area, you can ensure that your welding process goes smoothly and that you achieve high-quality welds.

Cleaning the sheet metal surface

Before starting the welding process, it is essential to ensure that the sheet metal surface is clean and free from contaminants. Proper cleaning will help improve the quality and durability of the weld.

1. Remove any existing coatings or paints

If the sheet metal has any existing coatings or paints, it is crucial to remove them before welding. These coatings can create a barrier between the metal and the welding wire, affecting the weld quality. Use a paint stripper or abrasive tool to carefully remove the coatings, ensuring not to damage the sheet metal surface.

2. Clean off dirt, rust, and oxidation

Use a wire brush or abrasive pad to remove any dirt, rust, or oxidation from the sheet metal surface. Gently scrub the metal, paying attention to any areas that may have accumulated debris or corrosion. This step helps achieve better weld penetration and prevents porosity in the welding bead.

Note: If the sheet metal is heavily rusted or oxidized, consider using a chemical rust remover or a grinder equipped with a wire wheel attachment to remove the stubborn rust and corrosion.

3. Degrease the surface

Grease and oils can hinder the welding process and lead to poor weld quality. Use a commercial degreaser or a mixture of water and mild detergent to thoroughly clean the sheet metal surface. Wipe the surface with a clean cloth or rag to remove any residue.

4. Allow the surface to dry completely

After cleaning and degreasing, it is crucial to let the sheet metal surface dry completely before welding. Moisture or residual cleaning agents can cause welding defects, such as porosity or weld contamination. Ensure the surface is free from any moisture or residue by using a clean, dry cloth or compressed air.

By properly cleaning the sheet metal surface, you can ensure optimal welding conditions and achieve high-quality welds with a wire feed welder.

Setting up the wire feed welder

Before you begin welding sheet metal with a wire feed welder, it’s important to properly set up the machine to ensure optimal performance and accuracy. Here are the steps to follow:

1. Select the appropriate wire and gas

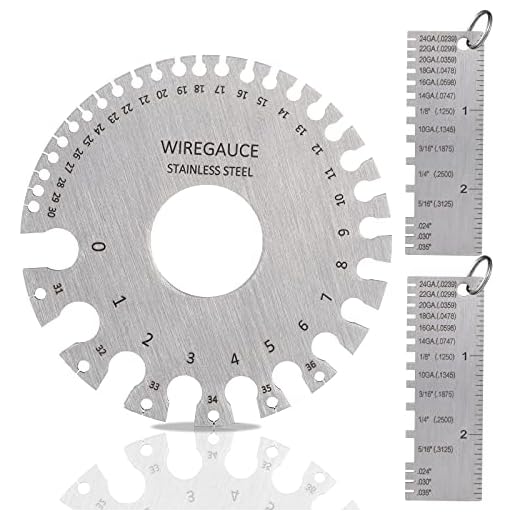

Choose a wire that is suitable for welding thin sheet metal. Generally, a wire with a diameter of 0.023 inches or 0.030 inches is recommended. It’s also important to select the appropriate shielding gas, such as 100% argon or a mix of argon and carbon dioxide, depending on the type of metal being welded.

2. Set the wire feed speed

The wire feed speed determines how fast the wire will be fed through the welding gun. It is typically measured in inches per minute (IPM). The right wire feed speed will depend on the thickness of the sheet metal and the type of wire being used. It’s usually best to start with a slower feed speed and gradually increase it until you achieve a smooth and stable arc.

3. Adjust the voltage

The voltage setting controls the heat input to the weld pool. For sheet metal welding, a lower voltage is usually required to prevent burn-through or warping. Refer to the manufacturer’s recommendations or consult a welding chart to determine the appropriate voltage setting based on the thickness of the sheet metal and the wire being used.

4. Check the gun and contact tip

Inspect the welding gun and make sure it is in good condition. Clean or replace the contact tip if necessary, as a worn-out or clogged tip can lead to inconsistent wire feeding and poor weld quality.

5. Prepare the workpiece and secure it in place

Ensure that the sheet metal is clean and free from any contaminants, such as rust or paint. Place the workpiece on a stable surface or secure it in a welding clamp to prevent it from moving during the welding process.

Note: It’s always recommended to refer to the user manual of your specific wire feed welder for detailed instructions on how to set up the machine properly. Additionally, practicing on scrap pieces of sheet metal before starting any actual welding projects can help you fine-tune your settings and gain confidence in your welding abilities.

Techniques for Welding

Welding sheet metal requires careful attention to detail and a gentle touch. Here are some important techniques to consider when welding with a wire feed welder:

1. Clean the metal: Before starting the welding process, it is crucial to clean the sheet metal surface thoroughly. Use a wire brush or sandpaper to remove any dirt, rust, or paint.

2. Set the machine: Adjust your wire feed welder’s settings according to the thickness of the sheet metal. Follow the manufacturer’s guidelines to ensure the correct voltage, amperage, and wire speed for optimal welding.

3. Position the workpiece: Place the sheet metal in the desired position and secure it firmly with clamps or magnets. Ensure that there is enough clearance for the welding gun to move freely along the joint.

4. Practice proper technique: Hold the welding gun at a slight angle and maintain a consistent travel speed. Use a push technique when welding thin sheet metal to prevent burn-through. For thicker metal, a weaving motion can help distribute heat evenly.

5. Control the heat: Sheet metal is prone to warping and distortion due to high heat. To minimize this, use short bursts of welding and allow the metal to cool between welds. Weld in a sequence that prevents excessive heat buildup in one area.

6. Use tack welds: Instead of continuous welding, create tack welds along the joint to hold the metal together. This will help prevent distortion and ensure proper alignment before completing the final welds.

7. Avoid excessive heat input: It’s important to strike a balance between achieving a strong weld and avoiding excessive heat input. Excessive heat can result in burn-through, warping, or even holes in the sheet metal. Practice careful control and make adjustments as needed.

8. Inspect and clean the welds: After completing the welding process, inspect the welds for any defects or inconsistencies. Use a wire brush to clean the welds and remove any welding slag or spatter.

Remember to always prioritize safety when welding. Wear appropriate protective gear, such as gloves and a welding helmet, and work in a well-ventilated area.

Questions and answers

What is sheet metal welding?

Sheet metal welding is a process of joining thin metal sheets together by melting and fusing them using a wire feed welder.

Is it difficult to weld sheet metal with a wire feed welder?

Welding sheet metal with a wire feed welder can be challenging due to the thinness of the metal and the risk of warping or burning through. However, with the right technique and settings, it can be done successfully.

What kind of wire should I use for welding sheet metal?

For welding sheet metal, it is recommended to use a thin wire with a diameter of 0.023 inches or 0.030 inches. This ensures better control and reduces the risk of burn-through.