Can A Gasless Mig Welder Weld 6mm Steel

When it comes to welding thick steel, many welders wonder if a gasless MIG welder is up to the task. The answer is not a simple yes or no, but rather depends on a variety of factors.

First and foremost, it’s important to understand how a gasless MIG welder works. Unlike traditional MIG welders that use a shielding gas to protect the weld pool from atmospheric contamination, gasless MIG welders use a flux core wire to create a protective shield. This flux core wire contains flux compounds that vaporize during the welding process, creating a protective gas. This process is known as “self-shielding.”

When it comes to welding 6mm steel, a gasless MIG welder can certainly get the job done. However, there are some considerations to keep in mind. The thickness of the steel, the type of flux core wire, and the welding technique used all play a role in determining the success of the weld.

It’s important to choose the right flux core wire for the job. Generally, a flux core wire with a higher tensile strength is recommended for welding thicker steel. Additionally, adjusting the welder’s settings, such as the wire feed speed and voltage, can also help achieve a successful weld on 6mm steel.

While a gasless MIG welder can weld 6mm steel, it may not produce the same quality of weld as a welder that uses shielding gas. The absence of shielding gas can result in more spatter and a less clean weld. However, with the right technique and setup, a gasless MIG welder can still create strong and reliable welds on 6mm steel.

Benefits of Using a Gasless Mig Welder

Gasless MIG welders, also known as flux-cored MIG welders, offer several benefits that make them a popular choice for welding projects:

- No need for shielding gas: One of the main advantages of gasless MIG welders is that they do not require the use of shielding gas. Instead, they use a flux-cored wire that contains a flux compound. This compound produces a shielding gas when it melts, protecting the weld from contamination and oxidation.

- Portability: Gasless MIG welders are often more portable than traditional MIG welders that require a gas cylinder. This makes them ideal for on-site welding projects or situations where mobility is important.

- Ease of use: Gasless MIG welders are generally considered easier to use than traditional MIG welders. The absence of a gas cylinder means there is no need to worry about gas flow rate, gas mixtures, or adjusting gas regulators.

- Cost-effective: Gasless MIG welders can be a cost-effective option for amateur or occasional welders. They eliminate the need for purchasing and refilling gas cylinders, which can be an additional expense.

- Welding outdoors: Gasless MIG welders are better suited for welding outdoors or in windy conditions. The flux-cored wire creates its own shielding gas, reducing the risk of weld contamination caused by wind blowing away the shielding gas.

- Versatility: Gasless MIG welders can be used on a wide range of materials, including mild steel, stainless steel, and aluminum. This versatility makes them a convenient option for general welding tasks.

While gasless MIG welders offer numerous advantages, it is important to note that they may not be suitable for all welding applications. The choice between using a gasless MIG welder or a traditional MIG welder depends on factors such as the thickness of the material being welded and the desired welding quality.

Versatility for Welding Different Thicknesses of Steel

A gasless MIG welder can be a versatile tool when it comes to welding different thicknesses of steel. While there are limitations to the thicknesses that can be effectively welded, a gasless MIG welder can generally handle steel measuring up to 6mm in thickness.

When choosing a gasless MIG welder for welding thicker steel, it is important to consider the power and capabilities of the machine. Higher voltage and amperage settings are typically needed for thicker steel, so make sure the welder you choose has a suitable power output. Additionally, a welder with adjustable wire speed control will allow you to fine-tune the welding process for different thicknesses of steel.

It is also important to consider the type of wire and shielding gas that you use with a gasless MIG welder. Flux-cored wire is commonly used with gasless MIG welders, as it provides its own shielding gas when it melts. This can be particularly beneficial when welding thicker steel, as the flux-cored wire can more effectively protect the weld from contamination.

While a gasless MIG welder can handle welds on thicker steel, it is important to remember that there are limits to its capabilities. Depending on the specific welder and its power output, there may be a point where a gasless MIG welder is not suitable for the job. In such cases, it may be necessary to consider other welding methods, such as a traditional MIG welder with shielding gas.

Overall, a gasless MIG welder can provide versatility for welding different thicknesses of steel. By choosing the right machine, adjusting settings appropriately, and using suitable wire and shielding gas, you can effectively weld steel up to 6mm in thickness.

Cost-Effective Solution for Welding 6mm Steel

When it comes to welding 6mm steel, a gasless MIG welder can be a cost-effective solution. Gasless MIG welding, also known as flux-cored welding, uses a tubular wire filled with flux instead of a shielding gas to protect the weld pool from contaminants in the air. This makes it suitable for outdoor applications where wind can blow away the shielding gas from a traditional MIG welder.

One of the advantages of a gasless MIG welder is its portability. With no need for a gas cylinder, it is lighter and more compact, allowing for easy transportation to different job sites. This makes it an ideal choice for contractors or DIY enthusiasts who need to weld 6mm steel in various locations.

Another benefit of gasless MIG welding is its cost-effectiveness. By eliminating the need for a shielding gas, it eliminates the ongoing expense of purchasing and refilling gas cylinders. This can result in significant savings, especially for those who frequently weld thick materials like 6mm steel.

However, it is important to note that while a gasless MIG welder can weld 6mm steel, it may not be suitable for all applications. The strength and quality of the weld can depend on factors such as the specific welding wire used, the welding technique employed, and the expertise of the welder. It is recommended to consult with a welding professional or refer to the manufacturer’s guidelines to ensure the proper setup and parameters are followed for welding 6mm steel.

In conclusion, a gasless MIG welder can be a cost-effective solution for welding 6mm steel. Its portability and the elimination of the need for shielding gas make it a convenient option for outdoor applications and can result in savings on gas cylinder costs. However, it is important to ensure the proper setup and technique to achieve strong and high-quality welds.

Considerations for Welding 6mm Steel with a Gasless Mig Welder

When it comes to welding 6mm steel with a gasless MIG welder, there are a few important considerations to keep in mind. Gasless MIG welding, also known as flux-cored welding, can be a suitable method for welding thicker materials like 6mm steel. However, there are some factors that need to be taken into account to ensure successful and quality welds.

Wire Selection

Choosing the right wire for welding 6mm steel is crucial. It is recommended to use a flux-cored wire that is specifically designed for welding thicker materials. These wires typically have a larger diameter and can provide better penetration and weld strength. Make sure to check the manufacturer’s recommendations for the appropriate wire size and type.

Power Settings

Adjusting the power settings of the MIG welder is important when welding 6mm steel. Thicker materials require higher heat input to achieve proper penetration. You may need to increase the voltage and wire feed speed to provide sufficient heat for the weld. It is recommended to begin with conservative settings and make adjustments as needed.

However, it is important to note that welding with too much heat can lead to distortion and weak welds. Finding the right balance is crucial, and it may require some practice and experimentation to achieve the desired results.

Shielding Gas

One of the advantages of gasless MIG welding is that it does not require an external shielding gas. The flux inside the wire electrode produces a protective gas shield when heated, which prevents the weld from being contaminated. However, it is essential to ensure that the work area is well-ventilated to avoid inhaling any fumes that may be generated during the welding process.

Additionally, it is important to clean the welding surface thoroughly before starting the weld. Any contaminants, such as oil, rust, or paint, can affect the quality of the weld. Use a wire brush or a grinder to remove any debris and ensure a clean and smooth welding surface.

In conclusion, welding 6mm steel with a gasless MIG welder is possible, but it requires careful consideration of wire selection, power settings, and proper cleaning of the welding surface. With the right technique and preparation, gasless MIG welding can provide strong and reliable welds on 6mm steel.

Adequate Power and Settings

When it comes to welding 6mm steel with a gasless MIG welder, it is important to ensure that the welder has adequate power and the right settings. The power output of the welder should be sufficient to penetrate the thick steel and create a strong weld.

Most gasless MIG welders have a recommended thickness range for welding, and it is important to check if 6mm steel falls within this range. If the welder is not powerful enough, it may struggle to create a proper weld or produce weak and inconsistent welds.

Additionally, the settings on the welder should be properly adjusted for welding 6mm steel. This includes setting the wire feed speed and voltage to suitable levels. The wire feed speed determines how fast the welding wire is fed into the weld puddle, while the voltage controls the heat of the arc.

For welding 6mm steel, a higher wire feed speed and voltage may be required compared to thinner materials. This allows for better penetration and fusion of the steel, resulting in a stronger weld. However, it is important to follow the manufacturer’s guidelines and recommendations when adjusting the settings.

It is also worth noting that the type and size of welding wire can affect the welding performance. Using a wire diameter suitable for 6mm steel and a quality welding wire can contribute to achieving better results.

Overall, to successfully weld 6mm steel with a gasless MIG welder, ensure that the welder has adequate power and the settings are properly adjusted. Good penetration, fusion, and a strong weld can be achieved by using the right combination of power settings and high-quality welding wire.

Choosing the Right Wire Size and Type

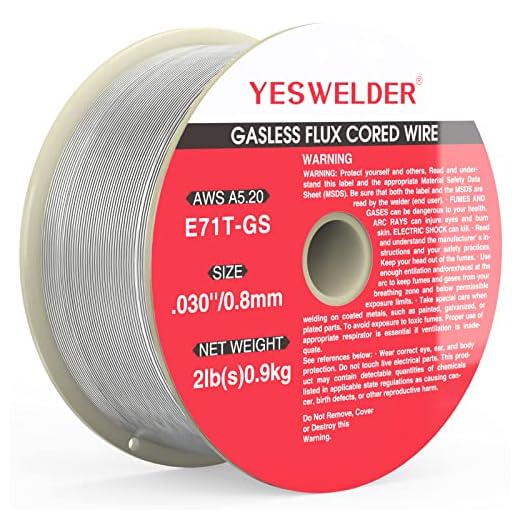

When it comes to gasless MIG welding, one of the most important factors to consider is the size and type of wire you use. The wire is the main consumable in the welding process and plays a crucial role in the quality and strength of the weld.

The wire size refers to its diameter, and choosing the right size is essential for achieving optimal results. In general, for welding 6mm steel, a thicker wire diameter is recommended. A wire size of 1.2mm or larger is often suitable for welding thicker materials. Thinner wires may not provide enough deposition rate or penetration for a strong and sturdy weld.

In addition to wire size, the wire type also affects the welding process. Gasless MIG welding typically uses flux-cored wires, which have a flux core that shields the weld from atmospheric contamination. These wires are designed to be used without external shielding gas, making them convenient for outdoor or remote welding applications.

There are different types of flux-cored wires available, such as self-shielded and dual-shielded wires. Self-shielded wires rely solely on the flux core for shielding, while dual-shielded wires use a combination of flux core and external shielding gas. When choosing the wire type, consider the specific requirements of your project, such as the weld’s strength, appearance, and environmental conditions.

It is important to note that gasless MIG welding is not suitable for all applications. While it can be effective for welding thicker steel, it may not provide the same level of control and precision as traditional MIG welding with shielding gas. For critical or precise welds, using a gas-shielded MIG welder may be more appropriate.

In conclusion, selecting the right wire size and type is crucial for achieving successful gasless MIG welding on 6mm steel. A thicker wire diameter, such as 1.2mm or larger, is typically recommended for welding thicker materials. Additionally, flux-cored wires are commonly used in gasless MIG welding, with different types available depending on the specific project requirements. Remember to consider the limitations and potential benefits of gasless MIG welding compared to traditional gas-shielded MIG welding.

Questions and answers

Can a gasless MIG welder weld 6mm thick steel?

Yes, a gasless MIG welder can weld 6mm thick steel. Gasless MIG welding, also known as flux-cored welding, uses a self-shielding wire that creates a protective slag to shield the weld from contamination. This process can handle thicker metals, including 6mm steel.

Is gasless MIG welding as effective as using gas?

Gasless MIG welding can be as effective as using gas, depending on the application and the skill of the welder. Gasless MIG welding uses flux-cored wire, which provides its own shielding, eliminating the need for an external gas supply. While it may not provide the same level of cleanliness and precision as gas welding, it can still produce strong and reliable welds on a variety of materials, including steel.

What are the advantages and disadvantages of using a gasless MIG welder?

Using a gasless MIG welder has several advantages and disadvantages. The main advantage is that it eliminates the need for an external gas supply, making it more portable and easier to use in outdoor or remote locations. Gasless MIG welding also tends to be faster and more forgiving than traditional MIG welding with gas. However, the self-shielding wire used in gasless MIG welding can create more smoke and fumes, and may not produce welds with the same level of cleanliness and precision as gas welding.