How to mix screed by hand

Screed is a mixture of sand, cement, and water that is used to level out floors and other surfaces. It is a crucial step in the construction process, as it creates a smooth and even foundation for flooring materials. While there are machines available to mix screed, mixing it by hand is a cost-effective alternative that can be done with minimal tools and equipment. In this guide, we will walk you through the steps of mixing screed by hand, ensuring that you achieve a high-quality mixture for your project.

Step 1: Gather Your Materials

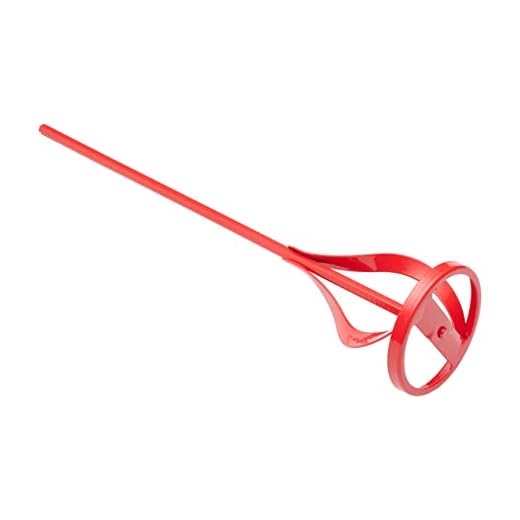

Before you begin mixing screed by hand, it’s important to gather all the necessary materials. You will need sand, cement, water, a mixing container (such as a wheelbarrow or large bucket), a shovel or trowel, and protective gear, such as gloves and a mask. Make sure that you have enough materials to complete the desired amount of screed, as running out in the middle of the project can be problematic.

Step 2: Measure the Ingredients

Next, you’ll need to measure the ingredients in the correct proportions. The typical ratio for screed is three parts sand to one part cement, although this may vary depending on the specific project requirements. Using a shovel or trowel, measure out the appropriate amounts of sand and cement and place them in the mixing container. Be sure to level the ingredients off to achieve accuracy.

Step 3: Mix the Materials

Once the ingredients are measured, it’s time to mix them together. Start by moving the dry ingredients around in the mixing container using a shovel or trowel. This process, known as dry mixing, ensures that the sand and cement are evenly distributed. Next, add water gradually while continuing to mix. The amount of water required may vary, so it’s important to add it slowly and mix thoroughly until the desired consistency is reached. The screed should be smooth and workable but not too wet.

By following these steps, you can successfully mix screed by hand. Take your time, ensure accurate measurements, and pay attention to the consistency of the mixture. Remember to use protective gear and clean your tools thoroughly after use. Now that you know how to mix screed by hand, you can confidently tackle your next construction project.

Benefits of Mixing Screed by Hand

While there are various methods available for mixing screed, mixing it by hand offers several benefits:

Cost-effective: Mixing screed by hand eliminates the need for expensive machinery, saving you money on equipment rental or purchase.

Greater control: Hand mixing allows for greater control over the consistency and quality of the screed. You can adjust the water and cement ratio as needed to achieve the desired strength and workability.

Flexibility: With hand mixing, you can mix smaller quantities of screed as and when you need it. This flexibility is particularly useful for small projects or repair work.

Adaptability: Hand mixing can be done in various locations, including areas that may be difficult to access with machinery. This makes it suitable for both indoor and outdoor projects.

Reduced waste: When mixing screed by hand, you can mix smaller amounts at a time, minimizing waste and ensuring that you only mix what you need. This can help reduce costs and environmental impact.

Improved skill development: Mixing screed by hand requires proper technique and skill. By mixing it manually, you can develop a better understanding of the material and improve your overall construction skills.

While mixing screed by hand may take longer than using machinery, the benefits it offers make it a viable option for many construction projects.

Cost-effective method

Mixing screed by hand can be a cost-effective method compared to hiring specialized equipment or professionals to do the job. Here are a few ways to keep the costs low:

1. DIY approach

Mixing the screed by hand allows you to take a do-it-yourself approach, eliminating the need to hire and pay professionals. With the right tools and materials, you can mix the screed efficiently and save on labor costs.

2. Buying materials in bulk

Purchasing the necessary materials in bulk can help reduce the overall cost of the screeding project. Buying materials like sand, cement, and additives in bulk is often cheaper than buying smaller quantities, resulting in significant savings.

3. Proper calculation of quantities

Before starting the mixing process, it’s essential to calculate the correct quantities of materials needed for the screed. This prevents wastage and excess expenses. Take accurate measurements and calculations, and consult a professional if required.

4. Efficient use of resources

When mixing screed by hand, it’s crucial to use resources wisely. Don’t mix more screed than required, as it will go to waste. Mix smaller quantities at a time, ensuring that it can be used efficiently before it dries.

By following these cost-effective methods, you can successfully mix screed by hand without breaking the bank. Remember to prioritize safety, accuracy, and proper technique as you undertake the project.

Flexibility in adjusting the consistency

One of the advantages of mixing screed by hand is the ability to adjust the consistency to meet specific needs. The consistency of the screed refers to its wetness or dryness, which can greatly impact the ease of application and final results.

To achieve the desired consistency, you can adjust the amount of water added to the mix. Adding more water will make the screed wetter and easier to spread, but it may also compromise its strength and ability to set properly. On the other hand, using less water will result in a dryer mix that requires more effort to spread, but it will be stronger and less prone to cracking.

The flexibility in adjusting the consistency allows you to tailor the screed to the requirements of the project. For example, if you are pouring a thin layer, such as a topping or a levelling coat, a wetter mix may be more suitable for achieving a smooth finish and ensuring adequate bonding with the substrate. Conversely, if you are working on a thicker layer, like a structural screed, a drier mix would be preferable to ensure its strength and durability.

| Consistency | Characteristics |

|---|---|

| Wetter mix | Easier to spread Smooth finish Faster drying time |

| Drier mix | Stronger and more durable Requires more effort to spread |

It is essential to monitor the consistency of the mix as you add water to ensure that it doesn’t become too wet or too dry. The ideal consistency should be workable and cohesive, allowing you to form it into a shape without it crumbling or being too liquid. The consistency can be adjusted gradually by adding small amounts of water or dry mix until the desired result is achieved.

By hand-mixing the screed, you have the flexibility to fine-tune the consistency according to the specific requirements of each project. This flexibility allows for better control over the application process, resulting in a higher-quality finished product.

Enhanced understanding of the material

Before you begin the process of mixing screed by hand, it’s important to have a clear understanding of the material you’ll be working with. Screed is a mixture of sand, cement, water, and sometimes additives that is used to create a smooth and level surface for flooring. It is commonly used in construction projects and provides a solid base for the installation of tiles, hardwood, or other types of flooring.

By understanding the properties and composition of the screed material, you’ll be better equipped to mix it to the correct consistency and achieve the desired results. Here are a few key factors to consider:

|

1. Grain size and type of sand: |

Sand is an essential component of screed and the grain size and type of sand you use can affect the strength and characteristics of the final mix. Ideally, you should use sharp sand with a grain size of 0-4mm for a smooth and even finish. |

|

2. Cement type and ratio: |

The type of cement you use will depend on the specific requirements of your project. Ordinary Portland cement (OPC) is commonly used, but you can also use specialized cement blends for improved performance. The ratio of cement to sand will also vary depending on the application, so be sure to check the manufacturer’s recommendations. |

|

3. Water and additives: |

The amount of water you add to the mix will have a significant impact on the workability and drying time of the screed. It’s important to add water gradually and test the consistency as you go. Additionally, you may want to consider using additives, such as plasticizers or fibres, to improve the flow and strength of the screed. |

By having a solid understanding of these factors, you’ll be able to make informed decisions when mixing screed by hand. This knowledge will help ensure that your screed is of the highest quality and meets the specific requirements of your project.