When was the nail gun invented? Discover the history of this revolutionary tool

The nail gun is a modern marvel that has revolutionized the construction industry. It has made the once tedious and time-consuming task of hammering nails a thing of the past. But when exactly was this ingenious tool invented and how did it come to be?

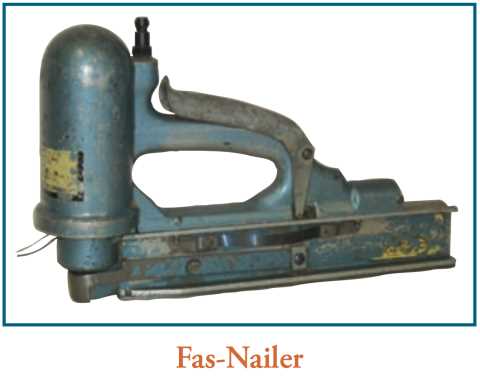

The history of the nail gun dates back to the 1950s when it was first developed and introduced as an alternative to traditional hammering. The exact inventor and the precise date of invention are unclear, as there were several individuals and companies involved in the development of the nail gun. However, it is widely believed that the first nail gun was created by engineers looking to improve productivity and efficiency in the construction industry.

Early nail guns were typically pneumatic, meaning they used compressed air to drive nails into various materials. These early models were often bulky and required a separate air compressor to function. However, as technology advanced, nail guns became more compact and portable, making them easier to use in a variety of applications.

Today, nail guns come in a variety of types and sizes, including pneumatic, electric, and cordless models. They are used extensively in construction, carpentry, and woodworking projects. The nail gun has truly transformed the way we build, allowing for faster and more precise nail placement, increased productivity, and reduced physical strain on workers.

In conclusion, the invention of the nail gun has had a profound impact on the construction industry. It has streamlined the building process, making it faster, more efficient, and less physically demanding. So the next time you see a nail gun in action, take a moment to appreciate the ingenuity and innovation that went into its creation.

When was the nail gun invented?

Nail guns have become an essential tool in the construction industry, making the process of nailing faster and more efficient. But when exactly was the nail gun invented?

The first nail gun was actually invented in the early 1950s by a man named Morris Pynoos. Pynoos, an engineer from Los Angeles, realized the need for a tool that could quickly and easily drive nails into various surfaces. He set out to create a device that would revolutionize the construction industry.

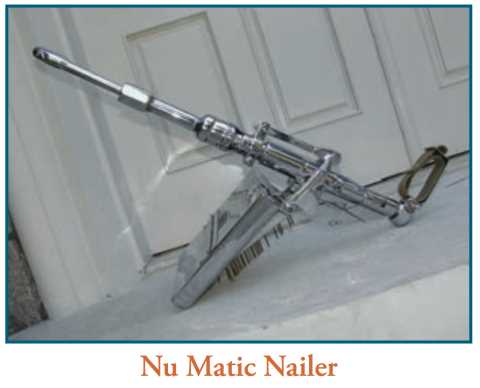

Pynoos created the first nail gun by modifying a machine gun. He converted the barrel to hold nails, and with the pull of a trigger, the nails would be driven into the desired surface. This early version of the nail gun was primarily used for industrial purposes, such as roofing and construction.

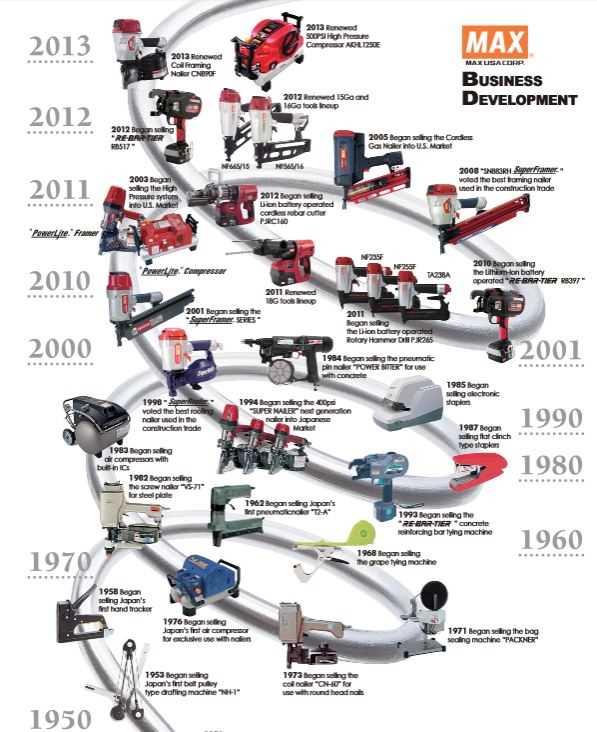

Over the years, nail guns continued to evolve and improve. In the 1970s, the pneumatic nail gun was introduced, which utilized compressed air to drive the nails. This innovation made it even easier and faster to complete construction projects.

Today, there are several different types of nail guns available, including pneumatic, electric, and battery-powered models. Each type has its own advantages and is suited for different applications.

The invention of the nail gun revolutionized the construction industry, making it possible for workers to complete projects more quickly and efficiently. Whether you’re building a house or DIYing a project at home, the nail gun is a tool that has certainly made its mark on the world.

The early origins of nail guns

The concept of a nail-driving machine dates back to ancient times. The earliest known example is the Roman balista, a large weapon used in military sieges that could launch heavy bolts with a high degree of accuracy. This type of machine operated on a similar principle to a nail gun, as it used a mechanical force to propel a projectile towards a target.

However, it wasn’t until the late 16th century that the first rudimentary nail guns were developed. These early devices were manually operated and required the user to strike the back of the tool with a hammer in order to drive the nail into the material. While not as efficient as modern nail guns, these early inventions were a step towards automating the process of fastening materials together.

Over the centuries, various inventors and craftsmen sought to improve upon the design of nail guns, experimenting with different mechanisms and sources of power. It wasn’t until the late 19th century that significant advancements were made in the form of machine-powered nail guns.

One of the key pioneers in this field was Isaac Merritt Singer, best known for his sewing machines. Singer patented a pneumatic nail gun in 1850, which used compressed air to deliver nails with exceptional speed and force. This invention revolutionized the construction industry, making it significantly faster and more efficient to join materials together.

| Year | Development |

|---|---|

| 1850 | Isaac Merritt Singer patents the pneumatic nail gun |

| 1934 | Harold M. Lyman invents the first electric nail gun |

| 1959 | T.V. Hilti improves upon the pneumatic nail gun by creating the first nail strip |

| 1981 | Hitachi introduces the world’s first cordless nail gun |

Since then, nail gun technology has continued to evolve and improve. Today, there are a wide variety of nail guns available on the market, each suited to different uses and applications. From framing nail guns to finish nailers, these tools have become indispensable in the construction industry, saving time and effort for workers around the world.

The first patent for a nail gun

In 1930, a man by the name of Albert Weekes filed the first patent for a nail gun. Weekes, a carpenter from New York, recognized the need for a more efficient and reliable method of driving nails into various materials.

The patent filed by Weekes outlined a pneumatic nail gun that utilized compressed air to propel nails into surfaces. This innovative design eliminated the need for manual hammering and significantly sped up the construction process. The patent included detailed drawings and specifications, showcasing Weekes’ ingenuity and understanding of the mechanics behind the nail gun.

Weekes’ nail gun featured a magazine that held a supply of nails, a trigger mechanism, and a compressed air chamber. When the trigger was pulled, compressed air would be released from the chamber, propelling a nail out of the magazine and into the material being worked on. This straightforward design allowed for quick and accurate nail placement.

The filing of Weekes’ patent marked a significant milestone in the development of nail guns. It laid the foundation for future inventors and engineers to build upon, ultimately leading to the wide range of nail gun models available today.

Weekes’ invention revolutionized the construction industry, providing carpenters and builders with a tool that increased efficiency and productivity. From the moment his patent was filed, it was clear that nail guns would become an essential tool in the arsenal of any construction professional.

The rise of pneumatic nail guns

The invention of pneumatic nail guns marked a significant milestone in the history of construction. These powerful tools revolutionized the way nails were driven into various materials, making it faster, easier, and more efficient than ever before.

Pneumatic nail guns utilize compressed air to propel nails into surfaces. They are designed for heavy-duty tasks and are commonly used in construction projects, woodworking, and manufacturing industries. The rise of pneumatic nail guns can be attributed to several factors:

- Efficiency: Pneumatic nail guns significantly increase productivity compared to manual hammering. They have a rapid firing mechanism that can drive nails quickly and accurately into materials, saving time and effort for construction workers.

- Precision: Unlike traditional hammers, pneumatic nail guns offer better precision and control. With adjustable depth settings and a consistent force, they ensure that nails are driven consistently and flush with the surface.

- Safety: Pneumatic nail guns have safety features that reduce the risk of injury. Most models come with a sequential trigger mechanism, requiring deliberate actuation before a nail is fired. This feature helps prevent accidental firing and reduces the likelihood of accidents on the job site.

- Versatility: Pneumatic nail guns can handle a wide range of fasteners, including nails, staples, and brads. This versatility makes them suitable for various applications and materials, from framing and roofing to finishing work and upholstery.

- Technical advancements: Over the years, pneumatic nail guns have undergone significant technical advancements. Manufacturers have improved their power, speed, and durability, making them more efficient and reliable. New features, such as adjustable exhaust and ergonomic designs, have also been introduced to maximize user comfort and convenience.

Today, pneumatic nail guns are an essential tool in the construction industry and have become a standard piece of equipment for many professionals. Their efficiency, precision, and versatility make them indispensable for a wide range of applications, contributing to the growth and advancement of the construction sector.

The evolution of nail gun designs

The history of nail guns dates back to ancient times when hammers were the primary tool used to drive nails. As time progressed, the need for more efficient and faster methods of joining materials arose. This led to the development and evolution of various nail gun designs.

1. Combustion-powered nail guns: In the early 20th century, combustion-powered nail guns were introduced. These nail guns utilized the power of explosive gases to drive nails into various materials. They were large and heavy, requiring the operator to wear protective gear.

2. Pneumatic nail guns: In the 1950s, the first pneumatic nail guns were invented. These tools used compressed air to generate the force needed to drive nails. They revolutionized the construction industry by increasing productivity and reducing physical strain on workers.

3. Electric-powered nail guns: In the 1980s, electric-powered nail guns were developed. These nail guns relied on electricity to generate the force required to drive nails. They were more lightweight and portable compared to their pneumatic counterparts, making them popular among DIY enthusiasts and professionals.

4. Cordless nail guns: With advancements in battery technology, cordless nail guns emerged in the late 1990s. These nail guns eliminated the need for air compressors or power cords, providing more flexibility and convenience. They are now widely used in construction and carpentry projects.

5. Innovative features and improvements: Over time, nail gun designs have incorporated various innovative features and improvements. These include depth adjustment settings, sequential and bump firing modes, ergonomic designs for improved handling, and safety mechanisms to prevent accidental firing.

Conclusion: The evolution of nail gun designs has significantly transformed the construction industry, making construction processes more efficient and reducing the time and effort required. From the ancient hammer to the modern cordless nail gun, the constant innovation in design continues to make nail guns an essential tool in the construction and carpentry fields.

The impact of nail guns on construction industry

Nail guns have had a profound impact on the construction industry, revolutionizing the way in which construction projects are completed. Their invention and widespread adoption have significantly increased the efficiency, safety, and productivity of construction workers.

Increase in productivity

One of the key advantages of nail guns is their ability to quickly drive nails into various materials, such as wood and concrete. This rapid process allows workers to complete projects at a much faster rate compared to traditional manual hammering. With the use of nail guns, construction projects can be completed in a fraction of the time, resulting in increased productivity and reduced labor costs.

Improved safety

Nail guns have also greatly improved the safety of construction workers. In comparison to manual hammering, nail guns eliminate the risk of accidental injuries caused by missed strikes or finger injuries. Additionally, nail guns have safety features such as trigger locks and sequential firing mechanisms that help prevent unintentional nail discharge. These safety measures have significantly reduced the number of workplace accidents and injuries in the construction industry.

Efficiency in large-scale projects

Nail guns have greatly streamlined the construction process, particularly in large-scale projects. These tools allow for the rapid installation of nails, making it easier to secure large structures, such as frames and roofs, in a short amount of time. With nail guns, construction workers can complete tasks that would have taken hours or even days using traditional methods, allowing them to meet deadlines more efficiently.

Cost-effectiveness

By increasing productivity and efficiency, nail guns have also contributed to cost savings in the construction industry. The reduced labor costs and faster completion of projects translate into lower expenses for construction companies. Additionally, the use of nail guns minimizes material waste as they deliver nails directly into the surface, reducing the chances of damage and the need for additional repairs.

Summary

Overall, the invention and implementation of nail guns in the construction industry have had a transformative impact. These tools have increased productivity, improved worker safety, streamlined large-scale projects, and contributed to cost savings. As technology continues to advance, nail guns are likely to undergo further enhancements and continue to play a pivotal role in construction activities.

Safety concerns and regulations

1. Accidental firing and injury

One of the main safety concerns with nail guns is the potential for accidental firing, which can lead to serious injuries. Due to the high power and speed of nail guns, a misplaced or unintentional trigger pull can result in a nail being driven into the user or a nearby person. To minimize accidental firing, many modern nail guns are equipped with safety features such as sequential triggers, which require the user to press the safety contact before pulling the trigger.

2. Flying debris

Another safety concern associated with using nail guns is the risk of flying debris. When a nail is shot into a material, it can cause fragments to become airborne. These flying debris can pose a danger to the user’s eyes or other parts of the body. To protect against this risk, it is important to wear appropriate personal protective equipment such as safety goggles or a face shield.

3. Noise exposure

Nail guns generate a significant amount of noise during operation, which can damage hearing if proper precautions are not taken. Prolonged exposure to loud noise can lead to hearing loss. To mitigate this risk, users should wear hearing protection such as earplugs or earmuffs when operating a nail gun for extended periods of time.

4. Training and certification

To ensure the safe and proper use of nail guns, it is essential for users to receive adequate training and certification. This includes understanding the tool’s operation, safety features, and proper handling techniques. Training programs often cover topics such as recognizing potential hazards, selecting the appropriate nails and power settings, and maintaining the tool in good working condition.

5. Compliance with regulations

There are various regulations in place that govern the use of nail guns in different industries and jurisdictions. These regulations aim to ensure the safety of workers and prevent incidents. Users of nail guns should be familiar with the specific regulations applicable to their work environment and comply with them accordingly. This may include following guidelines on personal protective equipment, safe work practices, and equipment maintenance.

6. Workplace safety culture

Creating a strong safety culture in workplaces where nail guns are used is crucial for preventing accidents and injuries. Employers should prioritize safety by providing the necessary training, enforcing compliance with regulations, and promoting a culture of accountability and open communication. Workers, too, have a responsibility to be aware of the risks, follow safe work practices, and report any safety concerns or incidents.

The future of nail gun technology

1. Improved safety features

Nail guns have come a long way in terms of safety, but there is still room for improvement. In the future, we can expect to see nail guns with advanced safety features to prevent accidental firing. These could include pressure sensors that only allow the gun to fire when properly pressed against a surface, or even facial recognition technology to ensure that the operator is properly positioned before firing.

2. Increased efficiency

As technology continues to advance, we can anticipate nail guns becoming more efficient and powerful. With the development of stronger materials and more efficient mechanisms, future nail guns may be able to drive nails into even the toughest surfaces with ease and precision. This would save time and effort for construction workers and DIY enthusiasts alike.

3. Wireless and cordless options

Gone will be the days of tangled cords and limited maneuverability. In the future, nail guns are likely to become wireless and cordless, allowing for greater freedom of movement and ease of use. This would greatly improve productivity on construction sites and make it easier for homeowners to tackle their own home improvement projects.

4. Smart features

Just like many other tools and gadgets, nail guns have the potential to become “smart”. Imagine a nail gun that can connect to your smartphone or tablet, allowing you to track your progress, monitor usage, and even receive notifications when it’s time to refill nails or perform maintenance. This would not only make nail guns more convenient to use, but also help prevent accidents and extend the lifespan of the tool.

5. Integration with other tools

In the future, nail guns may become integrated with other tools commonly used in construction and home improvement projects. For example, a nail gun could be combined with a drill or screwdriver, allowing for seamless transitions between different tasks. This would streamline the workflow and reduce the need for multiple tools, making projects more efficient and less time-consuming.

6. Eco-friendly options

As sustainability becomes increasingly important, we can expect to see more eco-friendly nail gun options in the future. This could include nail guns that use rechargeable batteries instead of disposable ones, or even nail guns that are powered by renewable energy sources such as solar power. These eco-friendly options would not only reduce waste, but also have a positive impact on the environment.

Overall, the future of nail gun technology looks promising. With advancements in safety, efficiency, wireless capabilities, smart features, integration with other tools, and eco-friendly options, nail guns will continue to revolutionize the construction and home improvement industries. Whether you’re a professional builder or a DIY enthusiast, these future innovations will make your projects faster, easier, and more enjoyable.

FAQ

Who invented the nail gun?

The nail gun was actually invented by Morris Pynoos in 1959. He is credited with developing the first pneumatic nail gun.

What was the purpose of inventing the nail gun?

The purpose of inventing the nail gun was to make construction and carpentry work more efficient and less time-consuming. It allowed users to drive nails into surfaces quickly and accurately.

How does a nail gun work?

A nail gun works by utilizing a pneumatic system to generate force that drives nails into various surfaces. When activated, compressed air forces a piston to rapidly move, pushing the nail forward and into the material.

When did nail guns become widely used?

Nail guns became widely used in the construction industry during the 1960s. As their efficiency and ease of use became apparent, they quickly replaced traditional hammers as the primary method of driving nails.

What are some advantages of using a nail gun?

Using a nail gun offers several advantages over using a hammer. It increases productivity, as nails are driven in quickly and accurately. It also reduces physical strain on the user, as less force is required to operate a nail gun compared to swinging a hammer.

Are there different types of nail guns?

Yes, there are different types of nail guns. The most common types include pneumatic nail guns, which use compressed air, and cordless nail guns, which operate using a rechargeable battery. There are also gas-powered nail guns and electric nail guns available.

What safety precautions should be taken when using a nail gun?

When using a nail gun, it is important to wear protective eyewear and gloves to prevent any potential injuries. It is also crucial to follow the manufacturer’s instructions for operating the nail gun and to keep the tool away from children or inexperienced users.

Video