What Kind of Nail Gun Do I Need? A Comprehensive Guide

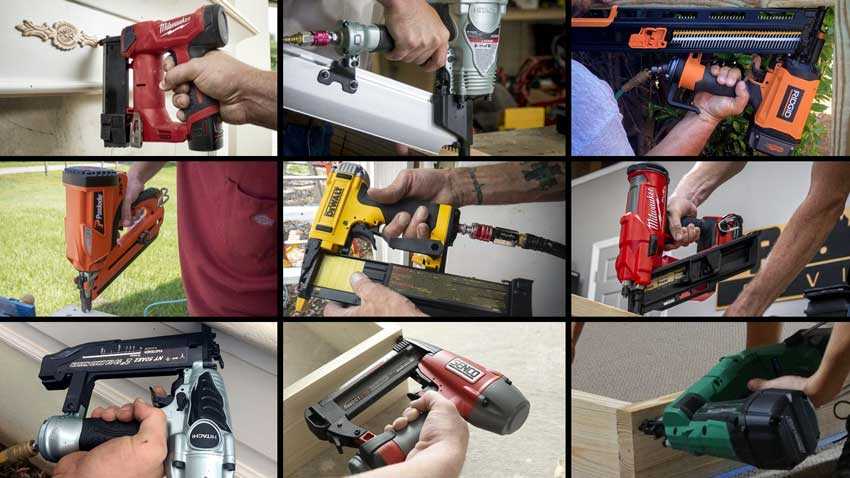

If you’re planning a DIY project that involves working with wood, chances are you’ll need a nail gun. But with so many different types available, how do you know which one to choose? In this comprehensive guide, we’ll walk you through the different types of nail guns and their uses, so you can make an informed decision.

First, it’s important to understand that there isn’t a one-size-fits-all nail gun. The type of nail gun you’ll need depends on the specific project you’re working on and the materials you’re using. For example, if you’re working on a small craft project, a brad nailer might be the best choice. On the other hand, if you’re building a deck or framing a house, you’ll need a framing nailer.

Each type of nail gun is designed to drive a specific type and size of nail. Brad nailers are used for small, delicate projects and can drive nails up to 2 inches long. Finish nailers, also known as trim nailers, can drive larger nails up to 2.5 inches long and are used for finishing work. Framing nailers, as the name suggests, are used for heavy-duty framing applications and can drive nails up to 3.5 inches long.

In addition to the type of nail gun, you’ll also need to consider the power source. Nail guns can be powered by air, electricity, or batteries. Pneumatic nail guns are powered by compressed air and are known for their power and accuracy. Electric nail guns are more portable and don’t require an air compressor, but they may lack the power of their pneumatic counterparts. Battery-powered nail guns are the most portable option but may have limited power and battery life.

Before making your final decision, it’s a good idea to research the specific nail gun models available and read customer reviews. You’ll want to consider factors such as durability, ease of use, and reliability. Ultimately, the best nail gun for you will be one that meets your specific needs and budget.

Remember, safety should always be your top priority when using a nail gun. Be sure to read and follow all manufacturer’s instructions and wear appropriate safety gear, such as safety glasses and gloves.

So, whether you’re building a bookshelf, installing baseboards, or working on a home improvement project, choosing the right nail gun is crucial. With the information provided in this comprehensive guide, you’ll be well-equipped to make an informed decision and select the perfect nail gun for your project.

Choosing the Right Nail Gun for Your Project

When it comes to completing your project, choosing the right nail gun is essential. The type of nail gun you need will depend on the specific requirements of your project, including the type of material you are working with and the size and type of nails you plan to use. Here are some factors to consider when deciding on the appropriate nail gun for your project.

Consider the Type of Material

First, consider the type of material you will be working with. Different nail guns are designed for specific materials such as wood, drywall, or concrete. Using the wrong type of nail gun for your material can cause damage or result in an ineffective connection. Be sure to choose a nail gun that is designed for the material you are working with.

Determine the Size and Type of Nails

The size and type of nails you plan to use is another important consideration. Nail guns are designed to accommodate different sizes and types of nails, including brad nails, finish nails, and framing nails. Ensure that the nail gun you choose is compatible with the size and type of nails you need for your project.

Consider the Power Source

Nail guns can be powered by various sources, including air compressors, battery packs, or fuel cells. The power source you choose will depend on your specific needs and preferences. Air-powered nail guns, also known as pneumatic nail guns, are popular due to their consistent power and reliability. Battery-powered and fuel-powered nail guns offer more portability and convenience but may have limited power and runtime.

Evaluate the Job Requirements

Consider the requirements of your project, including the size and complexity of the job. For smaller, lighter projects, a brad nailer or finish nailer may be sufficient. For larger construction projects or heavy-duty applications, a framing nailer or roofing nailer may be necessary. Assessing the job requirements will help you determine the appropriate nail gun for your project.

Consider Safety Features

Safety should always be a top priority when choosing a nail gun. Look for nail guns with safety features such as trigger locks, depth adjustment, and anti-dry fire mechanisms. These features can help prevent accidents and ensure the safety of yourself and others on the job site.

Research and Compare Brands and Models

Before making your final decision, it is advisable to research and compare different brands and models of nail guns. Look for reputable brands known for their quality and durability. Read customer reviews and consider the warranty offered by the manufacturer. Comparing different options will allow you to make an informed decision and choose a nail gun that meets your needs and budget.

Conclusion

Choosing the right nail gun for your project is crucial for achieving the best results. Consider the type of material, size and type of nails, power source, job requirements, safety features, and compare different brands and models. By doing so, you will be equipped to make an educated decision and select the perfect nail gun for your specific project.

Different Types of Nail Guns and Their Uses

1. Brad Nailers

Uses: Brad nailers are commonly used for trim work, such as attaching baseboards, crown molding, and window casings. They are also suitable for attaching thin and delicate materials.

2. Finish Nailers

Uses: Finish nailers are ideal for heavier trim work, installing cabinets, and assembling furniture. They are commonly used for attaching thicker materials, such as door jambs and baseboards.

3. Framing Nailers

Uses: Framing nailers are designed for heavy-duty applications, such as framing walls, constructing decks, and building fences. They are suitable for attaching large and thick pieces of wood together.

4. Roofing Nailers

Uses: Roofing nailers are used specifically for installing roofing materials, such as asphalt shingles. They are designed to quickly and efficiently drive nails into roofing surfaces.

5. Flooring Nailers

Uses: Flooring nailers are used for installing hardwood flooring. They are designed to drive nails into the tongue of each flooring board, ensuring a secure and hidden attachment.

6. Upholstery Staplers

Uses: Upholstery staplers are used for attaching fabric or upholstery materials to furniture frames. They are designed to drive staples into the materials, providing a strong and secure hold.

7. Palm Nailers

Uses: Palm nailers are small, handheld nail guns that are used for tight or hard-to-reach spaces. They are commonly used in cramped areas or for nailing in between studs.

8. Pin Nailers

Uses: Pin nailers are used for delicate woodworking projects, such as attaching small trim pieces and veneer. They leave barely visible holes and are often used in conjunction with other adhesives.

9. Staple Guns

Uses: Staple guns are versatile tools that can be used for a variety of purposes, such as attaching fabric, upholstery, insulation, and thin materials like plastic or cardboard.

10. Concrete Nailers

Uses: Concrete nailers, also known as concrete nail guns or concrete nail guns, are used for attaching materials to concrete or masonry surfaces. They are commonly used in construction and remodeling projects.

11. Siding Nailers

Uses: Siding nailers are designed specifically for installing siding materials, such as vinyl or fiber cement siding. They are capable of driving nails through the materials and into the underlying structure.

12. Coil Nailers

Uses: Coil nailers are commonly used in construction projects that require a high volume of nails, such as framing, sheathing, and decking. They have a large magazine that can hold a continuous coil of nails, allowing for faster and more efficient work.

| Nail Gun Type | Uses |

|---|---|

| Brad Nailers | Trim work, attaching thin and delicate materials |

| Finish Nailers | Heavier trim work, installing cabinets and furniture assembly |

| Framing Nailers | Heavy-duty applications, framing walls, constructing decks |

| Roofing Nailers | Installing roofing materials, such as asphalt shingles |

| Flooring Nailers | Installing hardwood flooring |

| Upholstery Staplers | Attaching fabric or upholstery to furniture frames |

| Palm Nailers | Tight or hard-to-reach spaces, cramped areas |

| Pin Nailers | Delicate woodworking projects, small trim pieces |

| Staple Guns | Versatile for various purposes, attaching fabric, insulation, etc. |

| Concrete Nailers | Attaching materials to concrete or masonry surfaces |

| Siding Nailers | Installing siding materials, like vinyl or fiber cement siding |

| Coil Nailers | High-volume projects, framing, sheathing, and decking |

Understanding the Power Source: Pneumatic vs Cordless Nail Guns

Pneumatic Nail Guns

Pneumatic nail guns are powered by air compressors. They are the most common type of nail gun used in professional applications. The gun is connected to the air compressor via a hose, which supplies the necessary air pressure to drive the nails into the material.

One advantage of pneumatic nail guns is their power. They can deliver a high amount of force, making them suitable for heavy-duty projects and materials like hardwood or concrete. Additionally, they offer consistent power and performance, as the air pressure remains constant.

However, pneumatic nail guns require an air compressor, which can be an additional expense and may limit mobility. The hose connected to the gun can also be cumbersome and restrict movement, especially in tight spaces.

Cordless Nail Guns

Cordless nail guns, as the name suggests, do not require a cord or air compressor to function. Instead, they are powered by rechargeable batteries. These guns are highly portable and can be used in various locations without the need for a power source.

Cordless nail guns are ideal for small to medium-sized projects and are popular among DIY enthusiasts. They are lightweight, easy to maneuver, and offer greater freedom of movement compared to pneumatic nail guns.

However, cordless nail guns may not provide the same amount of power as their pneumatic counterparts. Battery life can also be a limiting factor, as it determines the number of nails a user can drive on a single charge. Additionally, the cost of batteries and chargers can add up over time.

Which One Should You Choose?

The choice between a pneumatic and cordless nail gun depends on your specific needs and preferences.

- If you require maximum power and plan to work on heavy-duty projects, a pneumatic nail gun is recommended.

- On the other hand, if portability and ease of use are more important to you, a cordless nail gun may be the better option.

Consider the type of projects you will be working on, your budget, and your mobility needs before making a decision. It’s also worth noting that some professionals may choose to have both types of nail guns in their arsenal to cover a wide range of applications.

| Pneumatic Nail Guns | Cordless Nail Guns |

|---|---|

| High power | Portability |

| Consistent performance | Lightweight |

| Requires air compressor | Uses rechargeable batteries |

| Good for heavy-duty projects | Suitable for small to medium-sized projects |

| Restricted mobility due to hose | No restriction on movement |

Factors to Consider When Selecting a Nail Gun

Selecting the right nail gun for your needs can greatly impact the efficiency and quality of your project. Here are some important factors to consider when choosing a nail gun:

- Power source: Nail guns can be powered by electricity, compressed air, or fuel cells. Each power source has its advantages and disadvantages. Electric nail guns are suitable for smaller projects and can be used indoors. Compressed air nail guns are more powerful and suitable for heavy-duty projects, but require an air compressor. Fuel-powered nail guns are portable and don’t require any cords or hoses, but can be more expensive.

- Type of nail: Different nail guns are designed to use specific types of nails. Common nail types include brad nails, finish nails, framing nails, and roofing nails. Consider the type of nails you will be using for your project and ensure that the nail gun is compatible with them.

- Nail size: Nail guns can handle different sizes of nails. It’s important to choose a nail gun that can accommodate the length and diameter of the nails you will be using. Using the wrong nail size can result in weak connections or damage to the materials.

- Trigger mechanism: Nail guns can have either a sequential trigger or a bump or contact trigger. A sequential trigger requires the user to press the trigger and then push the nose of the gun against the work surface to fire a nail. A bump or contact trigger allows the user to continuously press the trigger and fire nails as long as the contact tip is pressed against the work surface. The choice between the two trigger mechanisms depends on personal preference and the safety requirements of the project.

- Weight and ergonomics: Consider the weight and ergonomics of the nail gun, especially if you will be using it for long periods of time. A lightweight and well-balanced nail gun can reduce fatigue and improve overall comfort.

- Additional features: Some nail guns come with additional features such as depth adjustment, jam clearing mechanisms, and adjustable firing modes. These features can enhance the versatility and ease of use of the nail gun, but may also increase the cost.

By taking these factors into consideration, you can make an informed decision when selecting a nail gun that is best suited for your specific needs and preferences.

Nail Gun Features to Look for

1. Power Source

One of the first things to consider when choosing a nail gun is the power source. There are three main types of power sources: pneumatic, electric, and cordless.

- Pneumatic nail guns are powered by compressed air and require an air compressor to operate. They are typically the most powerful and versatile option but can be cumbersome due to the need for an air hose.

- Electric nail guns are plugged into an electrical outlet and require no additional power source. They are generally lightweight and easy to use but may lack the power of pneumatic models.

- Cordless nail guns are powered by rechargeable batteries. They offer the convenience of portability but may have limited power and require frequent battery changes.

2. Nail Type and Size

The next important feature to consider is the nail type and size that the nail gun can accommodate. Different nail guns are designed to handle specific nail types, such as brad nails, finish nails, or framing nails. Make sure the nail gun you choose is compatible with the type of nails you will be using for your projects. Additionally, consider the size of the nails the nail gun can handle. Some nail guns can only accommodate smaller nails, while others can handle larger, heavier-duty nails.

3. Nail Depth Adjustment

Having the ability to adjust the nail depth is essential, especially when working on different materials or thicknesses. Look for a nail gun that offers easy and precise nail depth adjustment so that you can consistently achieve the desired nail depth without damaging the surface material.

4. Jam Clearing Mechanism

A nail gun can occasionally experience jamming, where a nail gets stuck in the magazine or firing mechanism. Look for a nail gun that has a jam clearing mechanism that makes it easy to remove the stuck nail without causing damage to the tool.

5. Magazine Capacity

The magazine capacity refers to the number of nails that can be loaded into the nail gun at once. A higher magazine capacity means less frequent reloading, which can save time and increase productivity. Consider the size of the projects you will be working on and choose a nail gun with a magazine capacity that suits your needs.

6. Trigger Mechanism

The trigger mechanism determines how the nail gun fires nails. There are two common types: sequential and bump-fire. Sequential triggers require the user to depress the trigger and then push the nose of the nail gun against the material before it will fire a nail. Bump-fire triggers allow the user to hold down the trigger and continuously fire nails as long as the nose is in contact with the material. Choose a trigger mechanism that suits your preference and the safety requirements of your projects.

7. Safety Features

When working with power tools, safety should always be a top priority. Look for nail guns that have safety features such as a no-mar tip to prevent damage to the work surface, a trigger lock to prevent accidental firing, and an anti-dry fire mechanism to prevent firing when the magazine is empty.

8. Warranty

Lastly, consider the warranty offered by the manufacturer. A longer warranty period can provide peace of mind and ensure that you are protected against any defects or malfunctions.

| Feature | Description |

|---|---|

| Power Source | Pneumatic, electric, or cordless |

| Nail Type and Size | Compatibility with specific nail types and sizes |

| Nail Depth Adjustment | Ability to adjust the depth of nails |

| Jam Clearing Mechanism | Easy removing of jammed nails |

| Magazine Capacity | Number of nails the gun can hold |

| Trigger Mechanism | Sequential or bump-fire trigger |

| Safety Features | No-mar tip, trigger lock, anti-dry fire mechanism |

| Warranty | Length and coverage of the manufacturer warranty |

Safety Tips for Using a Nail Gun

1. Wear Proper Safety Gear

Before using a nail gun, it’s important to wear the appropriate safety gear to protect yourself from potential injuries. This includes:

- Safety Glasses: Protect your eyes from flying debris.

- Ear Protection: Use earplugs or earmuffs to minimize the noise generated by the tool.

- Gloves: Wear gloves to provide extra grip and protect your hands.

- Hard Hat: If you are working on a construction site, a hard hat is essential to protect your head from falling objects.

2. Familiarize Yourself with the Nail Gun

Before using a nail gun, thoroughly read the manufacturer’s instructions and familiarize yourself with the specific features and operation of the nail gun you are using. Different nail guns may have different safety mechanisms and specific instructions, so it’s important to know how to properly use the tool.

3. Inspect the Nail Gun

Prior to using the nail gun, inspect it for any damage or defects. Check the trigger, safety mechanisms, and the overall condition of the tool. If you notice any issues, do not use the nail gun and have it repaired or replaced to ensure safe operation.

4. Properly Load and Unload Nails

When loading nails into the nail gun, follow the manufacturer’s instructions to ensure proper installation. Make sure the nails are the correct size and type for the nail gun. It is important to fully understand how to load and unload the nails safely to prevent accidental discharge.

5. Maintain a Safe Work Area

Keep your work area clear of clutter, debris, and other potential hazards. Make sure there are no obstructions or tripping hazards in the vicinity. This will help prevent accidents and injuries while using the nail gun.

6. Use Proper Technique

When using a nail gun, always hold the tool with both hands, maintaining a firm grip. Keep your fingers away from the trigger when not in use. Avoid resting your finger on the trigger unless you are ready to fire. Never point the nail gun at yourself or others.

7. Keep Others at a Safe Distance

Make sure there are no bystanders in the immediate area when operating a nail gun. Maintain a safe distance from others to prevent accidental injuries caused by nails being fired.

8. Avoid Contact with Electrical Wires

Before using a nail gun, inspect the work area to ensure there are no hidden electrical wires. Hammering a nail into an electrical wire can cause serious injury or electrical shock. Use a stud finder or other appropriate tools to detect the presence of electrical components.

9. Disconnect Power Source

Before performing any maintenance or repairs on the nail gun, disconnect it from the power source. This will prevent accidental firing or injuries while working on the tool.

10. Store Properly

After using a nail gun, store it in a safe and secure location. Keep it out of the reach of children and ensure it is not exposed to extreme temperatures or moisture that could damage the tool or its components.

Following these safety tips will help ensure the safe and proper use of a nail gun, minimizing the risk of accidents or injuries.

Maintaining and Cleaning Your Nail Gun

Proper maintenance and cleaning are essential for keeping your nail gun in good working condition. Regular upkeep will help extend the life of your tool and ensure its effectiveness. Here are some steps to follow:

1. Disconnect the Power Source

Before you start any maintenance or cleaning procedures, it’s crucial to disconnect the nail gun from its power source. This will prevent any accidental firing or mishaps.

2. Inspect and Clean the Magazine

The magazine is where the nails are loaded into the nail gun. Regularly inspect the magazine for any debris, dirt, or damaged nails. If you notice any obstructions or build-up, use a clean, dry cloth or a brush to remove them.

3. Lubricate Moving Parts

Nail guns have several moving parts that require lubrication to prevent friction and ensure smooth operation. Apply a few drops of oil to the designated lubrication points as recommended by the manufacturer. Be sure to use the appropriate oil specified for your nail gun model.

4. Check the Air Filter

If you have an air-powered nail gun, it likely has an air filter to prevent debris and dust from entering the tool. Inspect the air filter regularly and clean or replace it if necessary. This will help maintain proper airflow and prevent clogs.

5. Inspect the Nosepiece and Safety Mechanism

The nosepiece and safety mechanism are crucial components of a nail gun. Regularly inspect these parts for any damage or malfunctions. If you notice any issues, consult the manufacturer’s instructions for proper troubleshooting and potential repairs.

6. Store Properly

When you’re done using the nail gun, make sure to store it in a clean and dry area. Avoid exposing it to extreme temperatures or humidity, as this can damage the tool. Additionally, keep it out of reach of children and unauthorized users.

7. Follow Manufacturer’s Instructions

Always refer to the manufacturer’s instructions for specific maintenance and cleaning guidelines for your nail gun model. They may have additional recommendations or specific steps that are unique to your tool.

By following these maintenance and cleaning practices, you can ensure that your nail gun remains in optimal condition and performs well for years to come.

Popular Brands and Models of Nail Guns

1. DEWALT

DEWALT is a highly regarded brand in the construction industry, known for its durable and reliable nail guns. Some popular models from DEWALT include:

- DEWALT DCN692B: This cordless framing nailer is powered by a brushless motor and can handle nails up to 3-1/2 inches in length.

- DEWALT DWFP12231: This pneumatic brad nailer is lightweight and features a maintenance-free motor, making it suitable for various projects.

- DEWALT DC608K: This cordless finish nailer offers consistent nail penetration and can drive nails from 1-1/4 inches to 2-1/2 inches in length.

2. Makita

Makita is another popular brand that offers a wide range of nail guns for different applications. Some popular models from Makita include:

- Makita AF505N: This pneumatic brad nailer has a narrow nose design for improved visibility and can accommodate nails up to 2 inches in length.

- Makita AN924: This pneumatic framing nailer is designed for heavy-duty use and can drive nails up to 3-1/2 inches in length.

- Makita XNB01Z: This cordless brad nailer is powered by a lithium-ion battery and offers a tool-less depth adjustment for precise nailing.

3. BOSTITCH

BOSTITCH is a well-known brand for its high-quality nail guns and fastening tools. Some popular models from BOSTITCH include:

- BOSTITCH BCN680D1: This cordless brad nailer features a brushless motor and can drive brad nails from 5/8 inch to 2-1/8 inches in length.

- BOSTITCH LPF33PT: This pneumatic framing nailer can handle nails from 2 inches to 3-1/2 inches in length and offers a selectable trigger for sequential or contact operation.

- BOSTITCH N62FNK-2: This angled finish nailer is lightweight and offers a tool-free depth adjustment for precise nail placement.

These are just a few examples of popular brands and models of nail guns available in the market. Each brand and model may have different features and specifications, so it’s important to choose the one that suits your specific needs and budget.

FAQ

What types of nail guns are available on the market?

There are several types of nail guns available, including framing nail guns, finish nail guns, brad nail guns, roofing nail guns, and flooring nail guns.

What is the difference between a framing nail gun and a finish nail gun?

A framing nail gun is designed for heavy-duty tasks like framing and attaching large pieces of wood, while a finish nail gun is designed for more precise and delicate work such as molding and trim installation.

Can I use a brad nail gun for framing?

No, a brad nail gun is not suitable for framing as it uses thinner brad nails that do not provide enough structural support for heavy-duty tasks.

What type of nail gun should I use for roofing?

For roofing, you should use a roofing nail gun specifically designed for the task. These nail guns use coil or strip nails that are long enough to penetrate roofing materials and hold them securely in place.

Are all nail guns powered by compressed air?

No, while pneumatic nail guns are the most common and often the most affordable, there are also cordless electric nail guns and gas-powered nail guns available on the market.

What factors should I consider when choosing a nail gun?

You should consider the type of projects you will be working on, the size and length of nails required, the power source, the weight and ergonomics of the nail gun, and your budget.