What is a Turret Lathe? A Comprehensive Guide

A turret lathe is a type of machine tool used in metalworking applications. It is specifically designed for the machining of cylindrical workpieces and is known for its high precision and productivity. The main feature that sets a turret lathe apart from other types of lathes is its turret, which holds multiple cutting tools that can be automatically indexed into the workpiece.

The turret lathe was first developed in the 19th century and has since become an essential tool in the manufacturing industry. It is commonly used for turning, boring, drilling, threading, and facing operations. The ability to quickly change cutting tools allows for the efficient production of complex parts with minimal downtime.

One of the key advantages of a turret lathe is its versatility. It can be used for both small-scale and large-scale production runs and can handle a wide range of materials, including metals, plastics, and composites. Additionally, turret lathes can be equipped with automated features, such as bar feeders and part catchers, to further enhance productivity.

Overall, a turret lathe is a powerful machine that offers high precision, efficiency, and flexibility in metalworking applications. Whether it is used in a small job shop or a large manufacturing facility, a turret lathe can help manufacturers produce high-quality parts in a cost-effective manner.

What is a Turret Lathe?

A turret lathe is a type of lathe machine that is used for machining cylindrical parts. It is named after its turret, which holds various tools and can be rotated to bring different tools into the cutting position. Turret lathes are known for their versatility and ability to perform multiple machining operations without the need for manual tool changes.

The turret lathe was first developed in the late 19th century and quickly became popular due to its ability to quickly and accurately produce complex parts. It revolutionized the manufacturing industry by increasing productivity and reducing the need for skilled operators.

One of the key features of a turret lathe is its ability to automate tool changes. The turret, which is mounted on the lathe carriage, holds multiple tool holders. These tool holders can be indexed and rotated to bring the desired tool into position. This eliminates the need for manual tool changes and reduces setup time, making turret lathes highly efficient machines.

Turret lathes can perform a wide range of machining operations, including turning, facing, drilling, threading, and boring. Their ability to hold multiple tools allows for complex and intricate parts to be machined with ease.

In addition to their versatility, turret lathes are also known for their high accuracy and precision. The ability to rapidly change tools and accurately position them ensures that parts are machined to the required specifications. This makes turret lathes ideal for manufacturing industries that require precise and consistent parts.

Overall, a turret lathe is a valuable machine in the manufacturing industry. Its ability to automate tool changes, perform multiple machining operations, and achieve high accuracy makes it an essential tool for producing complex parts efficiently.

History of Turret Lathe

A turret lathe is a type of lathe machine that is designed to perform various machining operations with high precision and efficiency. It is known for its ability to automatically change tools, allowing for the production of complex parts with minimal human intervention. The development of turret lathes has been instrumental in the advancement of the manufacturing industry.

Early Development

- The concept of a turret lathe can be traced back to the early 19th century when there was a growing demand for machines that could perform repetitive tasks with high accuracy.

- One of the earliest recorded designs of a turret lathe was patented by Stephen Fitch in 1845. His machine featured a revolving turret that held multiple tools, allowing for quick tool changes.

- Throughout the 19th century, various improvements were made to turret lathe designs, with inventors like Joseph R. Brown and Christopher Miner Spencer making significant contributions.

Industrial Revolution

The industrial revolution in the late 19th century brought about a rapid expansion of manufacturing capabilities. Turret lathes played a crucial role in this expansion by increasing production efficiency and reducing labor costs.

- The introduction of electric motors and other technological advancements led to the development of more advanced turret lathe designs.

- Companies such as Warner & Swasey and Lodge & Shipley became prominent manufacturers of turret lathes during this period.

- Turret lathes were widely utilized in industries such as automotive, firearms, and machinery manufacturing.

Computer Numerical Control (CNC)

The development of computer numerical control (CNC) technology in the mid-20th century revolutionized the manufacturing industry, including the operation of turret lathes.

- With the introduction of CNC controls, turret lathes became even more efficient and versatile. CNC allows for precise control of the machine’s movements and tool changes.

- Modern turret lathes are often equipped with advanced features such as automatic tool changers, live tooling, and multi-axis capabilities.

- These advancements have made turret lathes essential machines in many industries, especially in the production of complex parts.

Continued Advancements

Advancements in technology continue to push the capabilities of turret lathes further. With the integration of robotics, artificial intelligence, and additive manufacturing, turret lathes are becoming more efficient, precise, and automated.

Today, turret lathes are indispensable machines in many manufacturing processes and play a crucial role in the production of a wide range of products, from automotive components to aerospace parts.

Components of a Turret Lathe

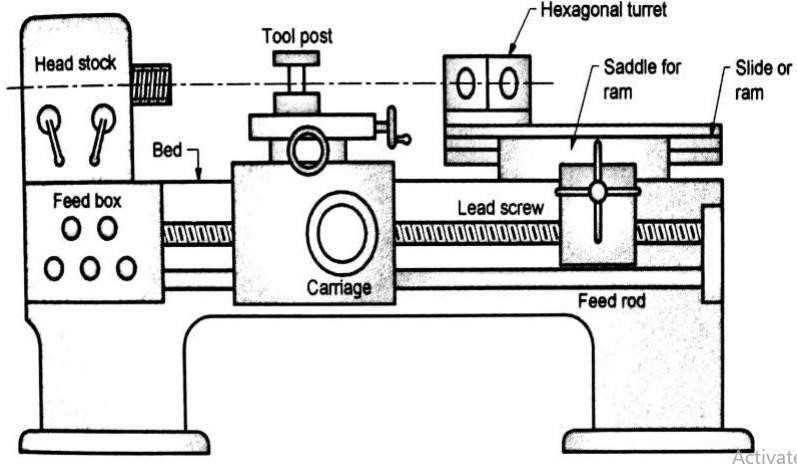

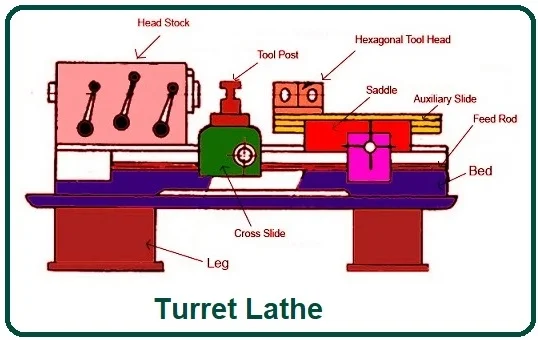

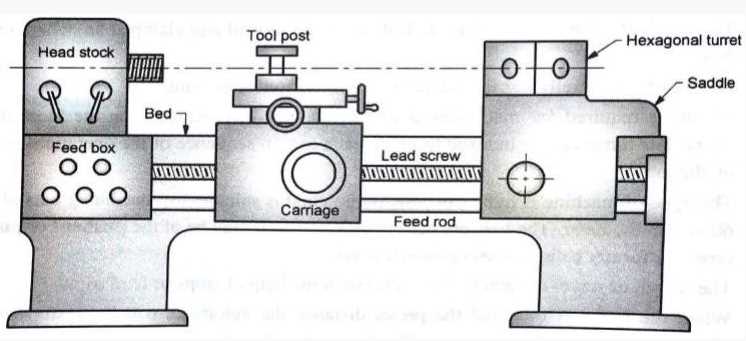

A turret lathe is a highly versatile machine tool that is used for various machining operations. It consists of several key components that work harmoniously to perform turning, drilling, and other operations with precision. The following are the major components of a turret lathe:

1. Bed

The bed is the foundation and main body of the turret lathe. It provides a rigid and stable platform for supporting all the other components of the machine. The bed is usually made of cast iron to provide strength and stability.

2. Headstock

The headstock is mounted on the bed and contains a spindle that rotates the workpiece. It houses various components such as gears, bearings, and a motor to drive the spindle. The headstock is responsible for providing the rotational motion required for turning operations.

3. Carriage

The carriage is mounted on the bed and slides along the bed’s ways. It holds the cutting tool and moves it along the workpiece for performing various machining operations. The carriage consists of several components, including the saddle, cross slide, and tool post.

4. Saddle

The saddle is a major component of the carriage and is mounted on the bed’s ways. It allows for longitudinal movement of the carriage along the bed. The saddle usually contains the handwheel and feed mechanism for controlling the movement of the carriage.

5. Cross Slide

The cross slide is mounted on the saddle and provides the tool’s lateral movement. It allows for precise positioning of the cutting tool relative to the workpiece. The cross slide is equipped with a handwheel for manual movement and can also be controlled by power feed.

6. Tool Post

The tool post is a component of the carriage and holds the cutting tool. It allows for easy and quick replacement of the tool and provides stability during machining operations. The tool post can be adjusted to control the tool’s position and angle.

7. Tailstock

The tailstock is located opposite the headstock and provides support for long workpieces during turning operations. It consists of a quill that can be extended or retracted to hold the workpiece securely. The tailstock can also be used for drilling operations by holding the drill bit.

8. Turret

The turret is a rotating tool holder mounted on top of the carriage. It allows for the use of multiple cutting tools without the need for manual tool changes. The turret can hold various tool holders, which can be indexed to position the desired tool for machining operations.

9. Control Panel

The control panel is usually located at the front of the machine and contains various controls for operating the turret lathe. It may include buttons, switches, and dials for controlling spindle speed, feed rate, tool movement, and other machine functions.

10. Chip Conveyor

A chip conveyor is often integrated into the turret lathe to remove the chips and coolant generated during machining. It helps maintain a clean working environment and prevents the chips from interfering with the machining process.

These are the major components of a turret lathe that work together to provide high precision and efficiency in machining operations. Understanding the functions and capabilities of each component is essential for effectively operating a turret lathe.

Working Principle of Turret Lathe

A turret lathe is a type of lathe machine that is designed with a turret headstock. The turret headstock is a rotating toolholder that holds multiple cutting tools. This allows the lathe to perform multiple operations without the need to change tools manually. The working principle of a turret lathe involves the rotation of the turret headstock and the movement of the cutting tools.

Here is a step-by-step explanation of the working principle of a turret lathe:

- The workpiece is mounted on the lathe chuck or collet, which holds it securely in place.

- The turret headstock is rotated by the lathe motor, which is usually powered by an electric motor.

- The operator selects the desired cutting tool from the turret headstock.

- The cutting tool is brought into contact with the workpiece, and the cutting operation begins.

- As the turret headstock rotates, the cutting tool moves along the workpiece, removing material and shaping it according to the desired specifications.

- If multiple cutting operations are required, the operator can select a different cutting tool from the turret headstock without stopping the lathe.

- The turret headstock continues to rotate, and the cutting operations are repeated until the desired shape is achieved.

The working principle of a turret lathe allows for high efficiency and productivity in machining operations. With the ability to hold multiple cutting tools, the lathe can perform various operations such as turning, facing, drilling, boring, and threading without the need for manual tool changes. This saves time and reduces the chance of errors.

In addition, the turret headstock can be indexed to position specific cutting tools accurately, further enhancing the precision and repeatability of the lathe. This makes the turret lathe a versatile machine for mass production and high-precision machining.

Applications of Turret Lathe

1. Mass Production

Turret lathes are commonly used in mass production settings where large quantities of parts need to be manufactured quickly and efficiently. The turret lathe’s ability to perform multiple operations simultaneously allows for high production rates, making it ideal for industries such as automotive, aerospace, and appliance manufacturing.

2. Turning and Facing Operations

Turret lathes excel at performing turning and facing operations. These machines can quickly and accurately shape the outer diameter of a workpiece, as well as create flat surfaces on the ends of the part. Examples of products that often require turning and facing operations include shafts, bolts, and valves.

3. Screw Cutting

Turret lathes are frequently used for screw cutting applications. These machines are capable of cutting both external and internal threads with precision. Industries that commonly require screw cutting include plumbing, automotive, and electronics.

4. Drilling and Boring

Turret lathes can also perform drilling and boring operations. These machines can accurately create holes of various diameters and depths in workpieces. Industries that often require drilling and boring include oil and gas, construction, and metalworking.

5. Milling

Some turret lathes are equipped with milling capabilities, allowing for the creation of complex shapes and contours. This makes them suitable for industries that require intricate machining, such as aerospace, medical, and tool and die manufacturing.

6. Taper Turning

Turret lathes are capable of creating tapered surfaces on workpieces. This is useful in industries such as furniture manufacturing, where tapered legs or spindles are commonly used.

7. Knurling

Turret lathes can also perform knurling, a process that creates a textured pattern on the surface of a workpiece for better grip or decorative purposes. Industries that often require knurling include automotive, aerospace, and consumer goods manufacturing.

8. Bar Feeding

Turret lathes are often equipped with bar feeders, which allow for the automatic feeding of long bars of material into the machine. This makes them ideal for industries that require continuous machining of long workpieces, such as automotive, aerospace, and construction.

9. Prototyping

Turret lathes are also used in prototyping applications. Their versatility and ability to perform multiple operations make them valuable tools for quickly creating prototypes of parts and components across various industries.

10. Precision Machining

Turret lathes are widely used in industries that require high precision machining, such as aerospace, medical, and optics. The ability of turret lathes to perform multiple operations with accuracy and repeatability makes them an excellent choice for producing parts with tight tolerances.

Advantages of Turret Lathe

- Increased Productivity: Turret lathes are designed for high-speed production, allowing for faster machining and increased productivity compared to manual lathes.

- Precision and Accuracy: Turret lathes are equipped with CNC technology, which ensures precise and accurate machining operations. This results in high-quality finished products.

- Versatility: Turret lathes can perform a wide range of operations, such as turning, drilling, milling, and threading. This versatility makes them suitable for various machining tasks, reducing the need for multiple machines.

- Automation: Turret lathes can be fully automated, reducing the need for manual intervention and increasing efficiency. This automation feature allows for unattended operation, freeing up operators to perform other tasks.

- Tooling Options: Turret lathes are equipped with a turret that holds multiple tools. This allows for quick tool changes, reducing downtime and increasing productivity.

- Cost Savings: Turret lathes can complete complex machining tasks in a single operation, eliminating the need for multiple setups. This reduces manufacturing time, labor costs, and material waste, resulting in overall cost savings.

- Consistency: Turret lathes are capable of producing multiple identical parts with consistent quality and precision. This is especially important for industries that require standardized products.

- Efficient Material Removal: Turret lathes are designed to remove material at a rapid rate, resulting in efficient machining and reduced cycle times.

- Reliability: Turret lathes are known for their reliability and durability. They are built to withstand heavy usage and maintain consistent performance over time.

Disadvantages of Turret Lathe

- Turret lathes are not suitable for large or heavy workpieces. Because of their limited size and capacity, turret lathes are unable to handle large or heavy workpieces. This can be a disadvantage for industries that deal with large-scale machining.

- Turret lathes are not as versatile as other types of lathes. While turret lathes are excellent for repetitive and high-volume production, they may not be the best choice for more complex machining operations. Other types of lathes, such as CNC lathes, offer greater flexibility and can handle a wider range of machining tasks.

- Turret lathes require skilled operators. Operating a turret lathe requires specialized knowledge and skills. The operator must be able to set up and program the machine, as well as monitor and adjust its performance. This can be a disadvantage for companies that have difficulty finding or training qualified personnel.

- Turret lathes can be expensive. Turret lathes are precision machines that require high-quality materials and precision manufacturing processes. This can result in higher costs compared to other types of lathes. Additionally, the initial investment and ongoing maintenance costs can be significant, making it a disadvantage for small or budget-conscious businesses.

- Turret lathes have limited tooling options. Turret lathes are designed to hold a specific number of tools in their turret. This limited tooling capability can be a disadvantage when working on projects that require a wide variety of cutting tools or tool changes. Other types of lathes, such as CNC lathes, offer greater flexibility in terms of tooling options.

FAQ

What is a turret lathe?

A turret lathe is a type of lathe machine that is equipped with a turret tooling system. It is used to perform various machining operations on a workpiece, such as turning, drilling, and milling.

How does a turret lathe work?

A turret lathe works by rotating the workpiece while a cutting tool, held in the turret, is used to remove material and shape the workpiece. The turret can hold multiple tools, allowing for quick tool changes and the ability to perform multiple operations without the need to manually change tools.

What are the advantages of using a turret lathe?

There are several advantages of using a turret lathe. Firstly, it allows for rapid tool changes, which increases productivity and reduces downtime. Secondly, the turret lathe can perform multiple operations without the need to manually change tools, saving time and effort. Additionally, the turret lathe can handle larger workpieces and performs accurate machining operations.

What are the different types of turret lathes?

There are two main types of turret lathes: vertical turret lathe (VTL) and horizontal turret lathe (HTL). VTLs have a vertical spindle and are used for large, heavy workpieces. HTLs have a horizontal spindle and are used for smaller, lighter workpieces.

What are some common applications of turret lathes?

Turret lathes are commonly used in various industries for a range of applications. Some common applications include turning and shaping cylindrical workpieces, drilling holes, milling flat surfaces, and producing threads.

What safety precautions should be taken when using a turret lathe?

When using a turret lathe, it is important to follow safety precautions to prevent accidents and injuries. Some safety precautions include wearing protective clothing and equipment, ensuring proper machine guarding, keeping the work area clean and organized, and undergoing proper training and supervision.

What factors should be considered when choosing a turret lathe?

When choosing a turret lathe, several factors should be considered. These include the size and weight of the workpiece, the required machining operations, the speed and power of the lathe, the level of precision needed, the available workspace, and the budget.