What does a lathe machine do: A comprehensive guide on lathe operations

Lathe machines are an essential tool in the field of machining and manufacturing. They are used to shape and cut various materials such as wood, metal, and plastic. A lathe machine operates by rotating a workpiece on its axis while a cutting tool is applied to shape the material.

One of the main operations performed by a lathe machine is turning. Turning involves removing material from the workpiece to create a cylindrical shape. This can be done by using various cutting tools such as drills, chisels, and gouges. Turning is commonly used to create cylindrical objects such as shafts, rods, and spindles.

In addition to turning, lathe machines can also perform other operations such as facing, threading, and boring. Facing involves creating a flat surface on the end of the workpiece, while threading is used to create screw threads on the surface of the material. Boring is the process of enlarging an existing hole in the workpiece.

Lathe machines come in different sizes and configurations, ranging from small benchtop models to large industrial machines. The size of the machine determines the maximum diameter and length of the workpiece that can be accommodated. Additionally, lathe machines can be manual or computer-controlled, with the latter offering greater precision and automation.

Overall, a lathe machine is a versatile tool that can perform a wide range of operations on various materials. Whether you are a hobbyist or a professional machinist, understanding the capabilities of a lathe machine is essential for achieving accurate and high-quality results in your machining projects.

What is a lathe machine and its purpose

A lathe machine is a tool used in machining and metalworking processes to shape, cut, or drill a workpiece. It is one of the oldest and most widely used machine tools in the industry. The primary purpose of a lathe machine is to rotate a workpiece on its axis while various cutting tools, such as drills, cutting tools, or sanding tools, are applied to shape or finish the workpiece.

The lathe machine consists of a rotating spindle, which holds and drives the workpiece, and a cutting tool that is mounted on a tool post and can move along different axes to make various cuts. The workpiece is clamped securely on the spindle and can be rotated at different speeds to achieve the desired shape or finish.

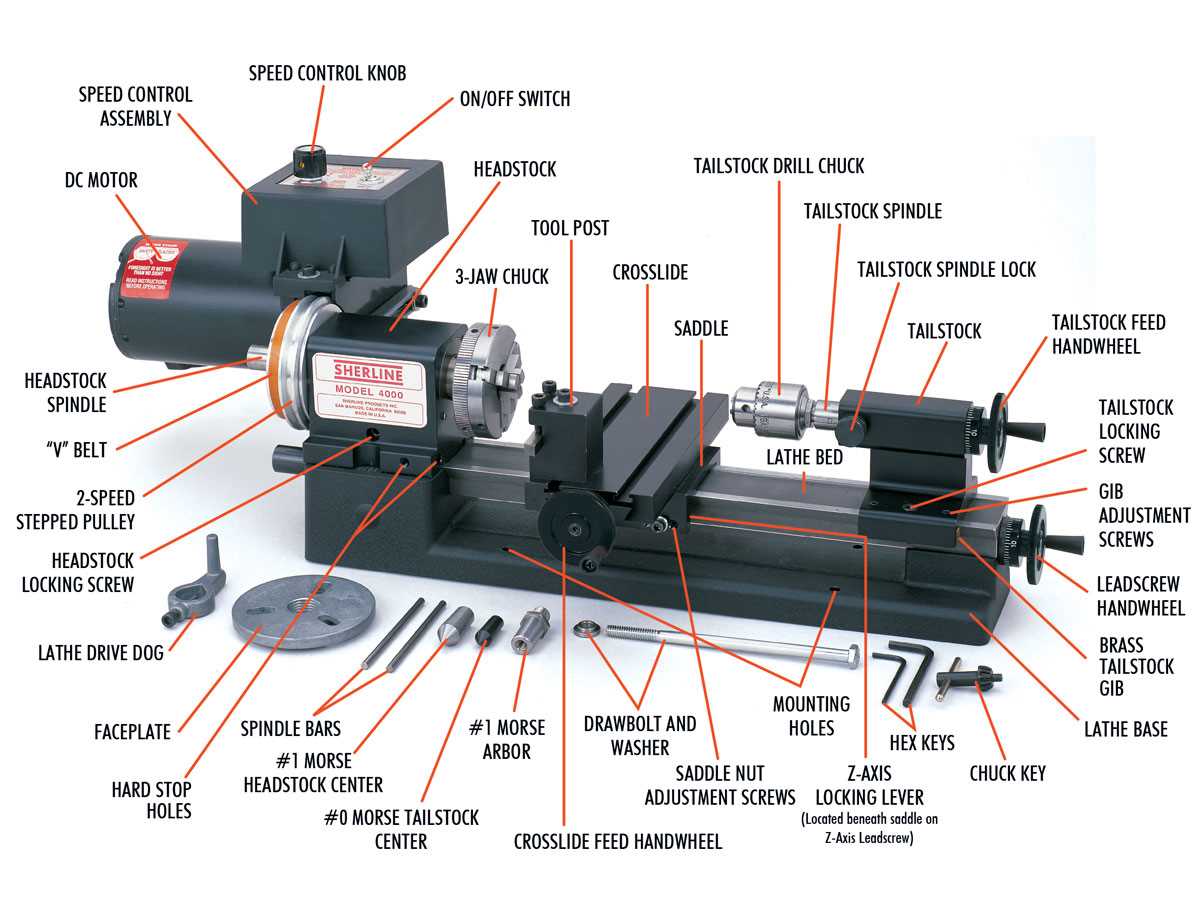

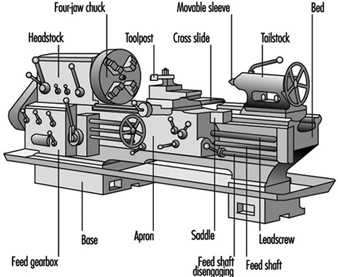

Key components of a lathe machine

- Bed: The bed is the base of the lathe machine and provides a foundation for other components. It is usually made of cast iron and has hardened and precision-ground ways to provide stability and accuracy.

- Headstock: The headstock is located at the left end of the lathe and contains the main spindle. It provides the rotational power to the workpiece and usually has multiple speed settings to control the rotation speed.

- Tailstock: The tailstock is located at the right end of the lathe and serves as a support for longer workpieces. It can be moved along the bed to accommodate different lengths of workpieces and can be clamped in position to provide stability during machining.

- Carriage: The carriage is mounted on the bed and holds the tool post, cutting tools, and other accessories. It can be moved along the bed and across the workpiece to make different cuts and perform various machining operations.

- Chuck: The chuck is a device attached to the spindle that holds and secures the workpiece during machining. It can be adjusted to accommodate different sizes and shapes of workpieces.

Purpose of a lathe machine

A lathe machine has several purposes and applications in industries and workshops. Some of the main purposes include:

- Machining: The primary purpose of a lathe machine is to machine or shape a workpiece to achieve the desired dimensions and finish. It can perform various machining operations such as turning, facing, boring, drilling, and threading.

- Prototyping: Lathe machines are often used in the prototyping process to create preliminary models or prototypes of objects. They can quickly and accurately shape different materials to test their functionality or appearance.

- Repair and Maintenance: Lathe machines are also used for repair and maintenance work. They can be used to repair or replace damaged or worn-out parts of machinery or equipment.

- Woodworking: Although lathe machines are primarily used in metalworking processes, they can also be used in woodworking. They can shape and finish wooden workpieces such as furniture legs, bowls, and decorative ornaments.

Overall, a lathe machine is a versatile tool that plays a crucial role in various industries and workshops. Its ability to shape and finish workpieces makes it essential for machining, prototyping, and repair work.

History and Evolution of Lathe Machines

Early Origins of Lathe Machines

The lathe machine can be traced back to ancient Egypt and ancient Mesopotamia, where early lathes were used to shape wood and other materials. These early lathes were operated manually and consisted of a rotating spindle and a tool that could be guided over the material. Over time, the design and capabilities of lathes evolved, leading to the development of the modern lathe machine we know today.

Rise of Mechanical Lathes

In the 19th century, significant advancements were made in the field of lathe machines. The Industrial Revolution brought about new manufacturing techniques and the need for more sophisticated machines. Mechanical lathes, powered by steam engines or belts and pulleys, were developed during this time. These machines allowed for greater precision and efficiency in shaping materials, leading to increased productivity in industries such as metalworking and woodworking.

Introduction of Electric Lathes

In the early 20th century, the introduction of electric power revolutionized the lathe machine industry. Electric motors replaced steam engines and belts, making the operation of lathes much easier and more convenient. Electric lathes also allowed for greater control and precision in machining operations. This marked a significant turning point in the evolution of lathe machines, as they became more accessible to a wider range of industries and users.

Computer Numerical Control (CNC) Lathes

In the late 20th century, computer technology revolutionized the manufacturing industry once again. Computer Numerical Control (CNC) lathes were introduced, which further enhanced the capabilities of lathe machines. CNC lathes are controlled by computer programs, allowing for highly precise and automated machining operations. These machines can perform complex tasks and produce intricate designs with ease, making them indispensable in industries such as aerospace, automotive, and electronics.

Modern Advancements

Today, lathe machines continue to evolve with the advancement of technology. Modern lathes often feature advanced features such as automatic tool changers, multi-axis capabilities, and real-time monitoring systems. These advancements have further improved the efficiency, accuracy, and productivity of lathe operations. With ongoing research and development efforts, it is likely that lathe machines will continue to evolve and play a vital role in the manufacturing industry.

Types of Lathe Machines

Lathe machines come in various types, each designed for specific purposes and applications. Here are some common types of lathe machines:

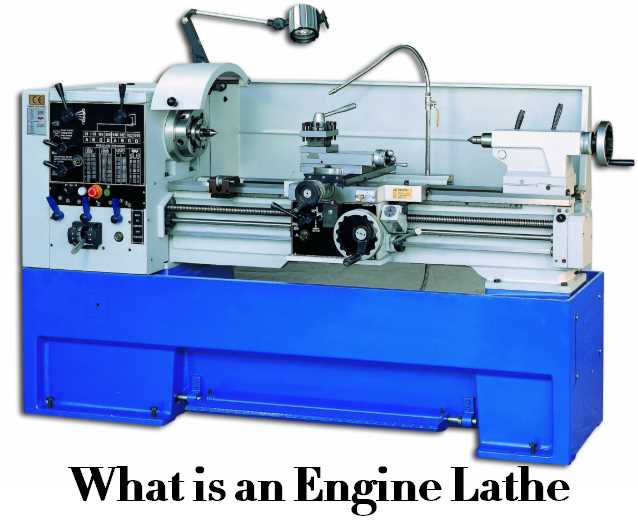

1. Engine Lathe

Engine lathes are the most common type of lathe machines. They are used for a wide range of applications, including turning, facing, threading, and drilling. Engine lathes are versatile machines that can handle both small and large workpieces.

2. Bench Lathe

Bench lathes are smaller and lightweight machines designed for small-scale projects. They are commonly used in workshops and laboratories for precision work. Bench lathes are compact and easy to operate, making them suitable for hobbyists and beginners.

3. CNC Lathe

CNC (Computer Numerical Control) lathes are automated machines that are controlled by computer programs. They offer high precision and efficiency, making them ideal for complex and repetitive tasks. CNC lathes can be programmed to perform various operations, such as turning, milling, and drilling.

4. Turret Lathe

Turret lathes are specialized machines that feature a revolving turret with multiple cutting tools. This allows for quick tool changes and reduces setup time. Turret lathes are commonly used for producing large quantities of identical parts.

5. Gap Bed Lathe

Gap bed lathes have a removable bed section that allows for machining longer workpieces. The bed can be removed to accommodate large diameter or extended length parts. Gap bed lathes are versatile machines used in various industries, including automotive and aerospace.

6. Speed Lathe

Speed lathes are small machines designed for light-duty operations. They are commonly used for tasks like polishing, grinding, and sanding. Speed lathes have a high-speed spindle and are often used by jewelers and watchmakers.

7. Automatic Lathe

Automatic lathes are fully automated machines that can perform multiple operations without manual intervention. They are commonly used in mass production settings to produce large quantities of identical parts. Automatic lathes can be programmed to perform various tasks, such as drilling, chamfering, and tapping.

8. Multi-Spindle Lathe

Multi-spindle lathes are specialized machines that have multiple spindles, allowing for simultaneous machining of multiple workpieces. They are used for high-volume production and offer increased productivity and efficiency. Multi-spindle lathes are commonly used in automotive and appliance manufacturing industries.

9. Pipe Lathe

Pipe lathes are designed specifically for machining pipes and cylindrical workpieces. They have features like a larger spindle hole, extended bed length, and specialized tooling to handle pipe and tube machining. Pipe lathes are commonly used in industries like oil and gas, plumbing, and construction.

10. Vertical Lathe

Vertical lathes, also known as vertical turning centers, have a vertical spindle orientation. This allows for the machining of large, heavy workpieces in a vertical position. Vertical lathes are commonly used in industries like aerospace, power generation, and manufacturing of large equipment.

| Machine Type | Features | Applications |

|---|---|---|

| Engine Lathe | Versatile, suitable for a wide range of operations | General machining, turning, facing, threading |

| Bench Lathe | Compact, suitable for small-scale projects | Precision work, hobbyist projects |

| CNC Lathe | Automated, high precision and efficiency | Complex and repetitive tasks |

| Turret Lathe | Revolving turret with multiple cutting tools | High-volume production of identical parts |

| Gap Bed Lathe | Removable bed section for machining longer workpieces | Automotive, aerospace, general machining |

| Speed Lathe | High-speed spindle, suitable for light-duty operations | Polishing, grinding, sanding |

| Automatic Lathe | Fully automated, multiple operations without manual intervention | Mass production of identical parts |

| Multi-Spindle Lathe | Multiple spindles for simultaneous machining | High-volume production, increased productivity |

| Pipe Lathe | Specialized for pipe and tube machining | Oil and gas, plumbing, construction |

| Vertical Lathe | Vertical spindle orientation, suitable for large, heavy workpieces | Aerospace, power generation, large equipment |

These are just some of the common types of lathe machines available. Each type has its own advantages and applications, so it’s important to choose the right machine for your specific needs and requirements.

Bench lathe machines

Bench lathe machines, also known as benchtop lathes, are compact and portable versions of standard lathe machines. They are designed to be used on a workbench or table, hence the name. Bench lathes are commonly used in small-scale workshops, home garages, and educational institutions for various machining operations.

Features of bench lathe machines

- Small Size: Bench lathes are smaller in size compared to regular lathe machines, making them ideal for limited workspace areas.

- Portability: These machines are relatively lightweight and portable, allowing them to be easily moved or stored when not in use.

- Variable Speed: Most bench lathes come with adjustable speed controls, allowing users to work at different spindle speeds for different materials.

- Tailstock and Headstock: Bench lathes typically have both a tailstock and headstock, allowing for various operations such as turning, facing, drilling, and threading.

- Chuck and Carriage: The chuck holds the workpiece in place, while the carriage moves the cutting tool along the workpiece.

Applications of bench lathe machines

Bench lathe machines are versatile tools that can be used for a wide range of machining operations. Some common applications include:

- Turning: Bench lathes are primarily used for turning operations, which involve rotating the workpiece against a cutting tool to create cylindrical shapes. Turning is commonly used for making shafts, rods, and other round components.

- Facing: Facing is the process of creating a flat surface on the end of a workpiece. Bench lathes can be used to face the end of a cylindrical workpiece to ensure it is perpendicular to the axis.

- Drilling: Bench lathes can be equipped with a drilling attachment, allowing users to drill holes in the workpiece.

- Threading: With the help of a lead screw and proper gears, bench lathes can be used for creating threaded surfaces on the workpiece.

Conclusion

Bench lathe machines are a compact and versatile solution for small-scale machining operations. They offer the convenience of portability and can be used for a variety of tasks such as turning, facing, drilling, and threading. Whether you are a hobbyist or a professional, bench lathes are a valuable addition to any workshop.

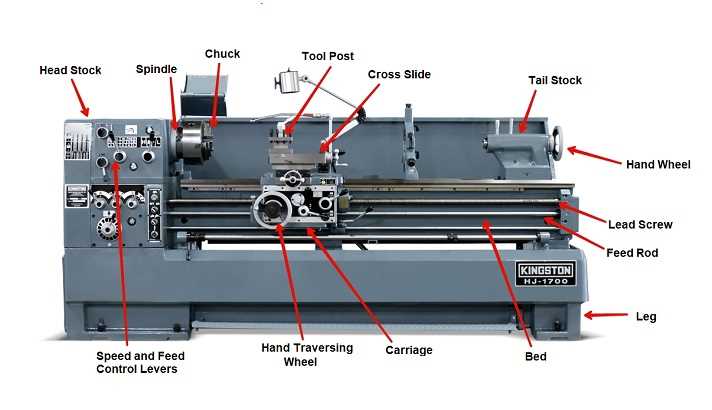

Engine lathe machines

Engine lathe machines, also known as center lathe machines, are one of the most common types of lathe machines used in metalworking and machining operations. They are general-purpose machines that can perform a wide range of turning operations with great precision and accuracy.

Some of the key features of engine lathe machines include:

- Bed: Engine lathes have a rigid bed on which the other components of the machine are mounted. The bed provides stability and support to the workpiece during machining.

- Headstock: The headstock of an engine lathe houses the main spindle, which holds the workpiece and provides rotational movement.

- Tailstock: The tailstock is located at the opposite end of the headstock and provides additional support to long workpieces. It may also include a quill that can be extended or retracted to accommodate different workpiece lengths.

- Carriage: The carriage is responsible for moving the cutting tool across the workpiece. It consists of a saddle and cross-slide that can be adjusted to control the depth and direction of the cuts.

- Toolpost: The toolpost is mounted on the carriage and holds the cutting tools. It allows for quick and easy tool changes during machining operations.

- Apron: The apron is located below the carriage and houses various mechanisms for controlling the movement of the carriage and engaging the feed mechanisms.

Engine lathe machines are versatile and can be used for a variety of turning operations, including facing, taper turning, thread cutting, and grooving. They can accommodate workpieces of different sizes and materials, making them suitable for both small-scale and large-scale production.

Engine lathe machines are commonly used in industries such as automotive, aerospace, and general manufacturing. They are essential tools in machine shops and workshops, providing the capability to create precise and complex components.

In conclusion, engine lathe machines are a fundamental tool in the world of machining, offering the versatility and precision needed to perform a wide range of turning operations. With their robust construction and various adjustable components, they are an indispensable machine for any metalworking operation.

Turret lathe machines

Turret lathe machines are a type of lathe machines that have a turret tooling system. A turret is a component of the machine that holds multiple tools and allows for quick and easy tool changes.

These machines are designed for high-volume production and are often used in manufacturing industries such as automotive, aerospace, and electronics.

The turret tooling system allows the operator to quickly switch between different cutting tools, resulting in increased productivity and efficiency. This is especially useful for jobs that require multiple tools or operations.

Turret lathe machines can perform a variety of operations, including turning, facing, drilling, boring, and threading. The turret can hold different types of tools, such as cutting tools, drills, and taps, allowing for a wide range of operations to be performed on the workpiece.

One of the main advantages of turret lathe machines is their versatility and flexibility. The turret can be loaded with different tools, allowing the machine to perform different operations without the need for manual tool changes. This saves time and reduces the risk of errors.

Another advantage of turret lathe machines is their high accuracy and precision. The turret tooling system ensures that the tools are positioned correctly, resulting in accurate and consistent machining. This is particularly important for parts that require tight tolerances.

In addition, turret lathe machines are known for their high production rates. The quick tool changes and efficient machining capabilities of these machines make them ideal for high-volume production environments.

Overall, turret lathe machines are a valuable tool in the manufacturing industry. Their ability to perform multiple operations and their high productivity make them an essential machine for many production processes.

Special purpose lathe machines

Special purpose lathe machines are designed for specific tasks or industries. These machines are equipped with additional features and capabilities that allow them to perform specialized operations.

1. Turret lathe:

A turret lathe is a type of lathe machine that has a turret, which holds multiple cutting tools. This allows the machine to perform multiple operations without the need to manually change the tool. The turret can be rotated to position the desired tool for the operation.

2. Copy lathe:

A copy lathe is used to reproduce complex shapes or patterns. It is equipped with a mechanical or electronic device that follows the contour of a template or model. The machine then cuts the workpiece to replicate the shape or pattern of the template.

3. CNC lathe:

CNC lathe machines are controlled by computer numerical control (CNC) systems. They can carry out complex operations with high precision and accuracy. The machine is programmed with the desired cutting path and speeds, and the CNC system controls the movement of the cutting tool to perform the operation.

4. Automatic lathe:

An automatic lathe is designed to perform operations automatically, without manual intervention. These machines are often used for high-volume production of small parts. They are equipped with automatic feeding mechanisms and tool changers to increase efficiency and productivity.

5. Vertical lathe:

A vertical lathe, also known as a vertical turning lathe (VTL), has a vertical orientation of the spindle. This allows for the machining of large, heavy workpieces that cannot be accommodated by traditional horizontal lathes. Vertical lathes are often used in industries such as aerospace and automotive for the production of large components.

These are just a few examples of special purpose lathe machines. There are many more variations and configurations available, each designed to meet the specific needs of different industries and applications.

Basic Lathe Operations

1. Turning

Turning is the most basic and common operation performed on a lathe machine. It involves rotating the workpiece while a cutting tool is pressed against it to remove material and create a cylindrical shape. The cutting tool can be fed either parallel or perpendicular to the axis of rotation to create different shapes and profiles.

2. Facing

Facing is the operation of machining the end of a workpiece to create a flat surface that is perpendicular to the axis of rotation. This is typically done to ensure that the end of the workpiece is square and properly finished.

3. Drilling

A lathe machine can be used to drill holes in a workpiece. This is done by rotating the workpiece and feeding the drilling tool into it to create a hole of the desired size and depth. The lathe machine provides the necessary rotational motion and the drilling tool provides the cutting action.

4. Boring

Boring is a similar operation to drilling, but it is used to enlarge an existing hole in a workpiece. The lathe machine is used to rotate the workpiece, while a boring tool is fed into the existing hole to remove material and increase the size of the hole.

5. Thread cutting

Thread cutting is the process of creating threads on a workpiece using a lathe machine. This is done by rotating the workpiece and feeding a threading tool into it to cut the threads. The lathe machine provides the rotational motion, and the threading tool creates the grooves that form the threads.

6. Knurling

Knurling is a process used to create a pattern of ridges on a workpiece for better gripping. It is commonly used on handles and knobs. Knurling can be done using a lathe machine by rotating the workpiece and pressing a knurling tool against it to create the desired pattern.

7. Parting

Parting is the process of cutting off a part of a workpiece to create separate pieces. This is typically done using a parting tool, which is fed radially into the workpiece to create a groove and separate the desired part. The lathe machine provides the necessary rotational motion and the parting tool provides the cutting action.

8. Taper turning

Taper turning is the process of creating a taper on a workpiece. This can be done using a lathe machine by offsetting the tailstock, adjusting the angle of the tool, and feeding the tool in a certain way to create the desired taper. Taper turning is often used in applications such as manufacturing conical shapes or creating Morse tapers.

9. Grooving

Grooving is the process of cutting a narrow groove or channel on a workpiece. This can be done using a lathe machine by feeding a grooving tool into the workpiece to create the desired groove. Grooving is often used to create internal or external threads, decorative patterns, or to provide clearance for other components.

These are just a few of the many operations that can be performed on a lathe machine. The versatility of the lathe machine makes it an essential tool in various industries, including metalworking and woodworking.

Turning and facing

Turning and facing are two common operations performed on a lathe machine. They involve the removal of material from the workpiece to create a desired shape or finish.

Turning

Turning is the process of removing material from the outside diameter of a workpiece. This operation is typically used to create cylindrical shapes, such as shafts or tubes. The workpiece is clamped in a chuck or a collet and rotated against a cutting tool called a tool bit. The tool bit is moved along the workpiece to remove the desired amount of material.

There are different types of turning operations, including rough turning, finishing turning, and grooving. Rough turning is used to remove a large amount of material quickly, while finishing turning is used to achieve a smooth surface finish. Grooving is used to create a groove or channel in the workpiece.

Facing

Facing is the process of removing material from the end or face of a workpiece. This operation is typically used to create a flat surface, such as the end of a shaft or the face of a disc. The workpiece is clamped in a chuck or a collet and rotated against a facing tool. The facing tool is moved along the end of the workpiece to remove the desired amount of material.

Facing can also be combined with other operations, such as turning or boring, to create complex shapes or features. For example, a workpiece may be turned to a specific diameter and then faced to create a flat surface perpendicular to the axis of rotation.

Both turning and facing operations can be performed manually or using computer numerical control (CNC) machines. CNC machines allow for precise control and automation of the cutting process, resulting in higher accuracy and efficiency.

In conclusion, turning and facing are important operations performed on a lathe machine to shape and finish workpieces. These operations involve the removal of material from the workpiece using cutting tools, resulting in the creation of cylindrical shapes or flat surfaces. Whether performed manually or using CNC machines, turning and facing are essential processes in various industries and applications.

Drilling and boring

Drilling and boring are two common operations performed on a lathe machine. These operations involve creating holes in the workpiece or enlarging existing holes with a precision tool called a drill bit or boring tool. Drilling is the process of creating holes by removing material along the axis of rotation, while boring is the process of enlarging existing holes with a specialized tool.

Drilling

Drilling is one of the fundamental operations performed on a lathe machine. It is used to create holes of various sizes and depths in the workpiece. The process involves mounting a rotating drill bit onto the lathe machine and moving it into the workpiece to remove material and form a hole.

Here are the steps involved in drilling on a lathe machine:

- Secure the workpiece in the lathe chuck or between centers.

- Select an appropriate drill bit size and mount it onto the lathe machine’s spindle.

- Position the drill bit at the desired location on the workpiece.

- Start the lathe machine and slowly feed the drill bit into the workpiece.

- Continue feeding the drill bit into the workpiece until the desired depth is reached.

- Withdraw the drill bit from the workpiece.

- Remove the workpiece from the lathe machine.

Drilling on a lathe machine allows for precise hole placement and depth control. It is commonly used in various industries, such as metalworking, woodworking, and plastics fabrication.

Boring

Boring is another operation performed on a lathe machine, which involves enlarging existing holes with a boring tool. This process is often used to achieve a high degree of accuracy and surface finish in hole machining.

Here are the steps involved in boring on a lathe machine:

- Secure the workpiece in the lathe chuck or between centers.

- Mount a boring tool onto the lathe machine’s toolpost.

- Position the boring tool into the existing hole.

- Start the lathe machine and slowly feed the boring tool into the hole.

- Rotate the boring tool to remove material and enlarge the hole to the desired size.

- Withdraw the boring tool from the hole.

- Remove the workpiece from the lathe machine.

Boring on a lathe machine allows for precise hole enlargement and can be used to achieve tight tolerances and smooth surface finishes. It is commonly used in industries that require high precision, such as automotive, aerospace, and medical device manufacturing.

FAQ

What is a lathe machine?

A lathe machine is a tool that rotates a workpiece on its axis to perform various operations such as cutting, drilling, sanding, facing, and turning.

What are the main parts of a lathe machine?

The main parts of a lathe machine include the bed, headstock, tailstock, carriage, chuck, and toolpost.

What are the different types of lathe machines?

There are several types of lathe machines, including engine lathes, bench lathes, toolroom lathes, turret lathes, and special purpose lathes.

What are the operations that can be performed on a lathe machine?

A lathe machine can perform operations such as facing, turning, drilling, boring, knurling, threading, and taper turning.

How does a lathe machine work?

A lathe machine works by rotating the workpiece on its axis while a cutting tool is fed into the workpiece to perform various operations.

What are the benefits of using a lathe machine?

Some benefits of using a lathe machine include the ability to perform multiple operations on a single machine, high precision and accuracy, and the ability to work with different types of materials.

Are there any safety precautions that should be followed when using a lathe machine?

Yes, some safety precautions that should be followed when using a lathe machine include wearing appropriate protective gear, ensuring the workpiece is securely mounted, and keeping hands clear of the rotating parts.