What can you make with a metal lathe: Exploring the possibilities

If you have ever seen a metal lathe in action, you may have marveled at the precision and skill it takes to create intricate metal parts. But what exactly can you make with a metal lathe? The possibilities are truly endless. From simple components like screws and bolts to complex machinery parts, a metal lathe can be used to create a wide range of objects.

One of the most common uses for a metal lathe is in the manufacturing industry. Many industries rely on the production of metal parts to create their products, and a lathe is an essential tool in this process. With a metal lathe, manufacturers can create precise and accurate parts that meet their specific requirements. Whether it is a gear or a piston, a lathe can shape metal into the desired shape and size.

But the capabilities of a metal lathe go beyond just manufacturing. Artists and hobbyists also use lathes to create unique and intricate metal designs. From ornate jewelry to custom knife handles, a lathe can bring a variety of artistic visions to life. The ability to shape metal with such precision allows artists to create truly one-of-a-kind pieces.

In addition to manufacturing and art, metal lathes also have applications in the automotive and aerospace industries. These industries rely on highly complex machinery and parts, and a lathe is crucial in their production process. From engine components to airplane parts, metal lathes play a vital role in ensuring the safety and functionality of vehicles and aircraft.

Overall, the possibilities are endless when it comes to what you can make with a metal lathe. From simple nuts and bolts to intricate works of art, a lathe is a versatile tool that can be used in a variety of industries and applications. Whether you are a manufacturer, artist, or hobbyist, exploring the possibilities of a metal lathe can open up a world of creativity and innovation.

Understanding the Basics of Metal Lathe

What is a metal lathe?

A metal lathe is a machine tool used in the metalworking industry to shape, cut, or drill metal objects. It operates by rotating a workpiece against a stationary cutting tool, allowing for precision machining and creating various shapes and forms.

Parts of a metal lathe

A metal lathe consists of several essential parts that work together to perform various operations:

- Bed: The bed provides a rigid base for the lathe and supports the various components. It is usually made of cast iron.

- Headstock: The headstock houses the main spindle, which holds the workpiece and provides rotational motion.

- Tailstock: The tailstock is located opposite the headstock and can be moved along the bed. It provides support for long workpieces and can be used to hold drilling or cutting tools.

- Carriage: The carriage holds the cutting tool and can be moved along the bed horizontally. It consists of the saddle, cross-slide, and toolpost.

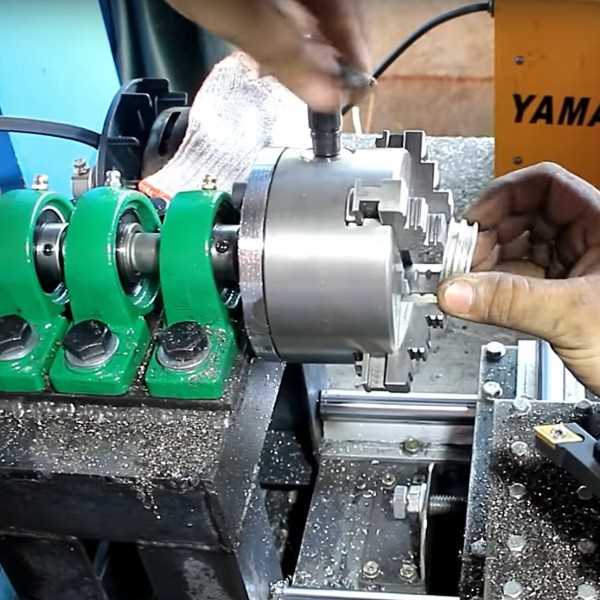

- Chuck: The chuck is a device attached to the spindle and used to secure the workpiece during turning operations.

- Toolpost: The toolpost holds the cutting tool in place and allows for easy adjustment and positioning.

Basic operations

There are several fundamental operations that can be performed on a metal lathe:

- Turning: In turning, the workpiece is rotated against a stationary cutting tool to remove material and create a cylindrical shape.

- Facing: Facing is the process of creating a flat surface at the end of a workpiece.

- Drilling: Drilling involves creating holes in the workpiece using a rotating cutting tool.

- Boring: Boring is similar to drilling but involves enlarging an existing hole.

- Thread cutting: Thread cutting is the process of creating threads on a workpiece.

Safety precautions

When working with a metal lathe, it is important to follow safety precautions to prevent accidents and injuries:

- Wear protective gear: Use safety goggles, gloves, and other protective gear to protect yourself from flying chips and debris.

- Secure the workpiece: Always ensure that the workpiece is securely fastened in the chuck or collet to prevent it from coming loose during operation.

- Use the machine guards: Keep the chuck guard and other machine guards in place to protect against accidental contact with moving parts.

- Keep the work area clean: Remove any clutter, chips, or oil spills from the work area to prevent slips, trips, and falls.

- Be familiar with the machine: Read the manual and receive proper training on how to operate the lathe before using it.

Conclusion

Understanding the basics of a metal lathe is essential for anyone working in the metalworking industry. By knowing the various parts, operations, and safety precautions, you can safely and effectively operate a metal lathe to create a wide range of shapes and forms.

Turning Raw Materials into Functional Objects

Lathes are powerful machines that allow craftsmen to transform raw materials into functional, customized objects. With a metal lathe, the possibilities are endless as it can shape and cut various types of metal including aluminum, brass, and steel. Whether you are a hobbyist or a professional, a metal lathe can be a valuable tool in your workshop.

Creating Customized Parts

One of the key benefits of a metal lathe is its ability to create customized parts with precision and accuracy. By using different tools and techniques, craftsmen can turn a block of metal into various components such as gears, screws, and shafts. These parts can be used in a wide range of applications, from automotive to industrial machinery.

Precision Machining

When it comes to precision machining, a metal lathe excels at creating intricate and detailed designs. Craftsmen can use their skills and creativity to turn a simple piece of metal into a work of art. With the lathe’s ability to cut threads, bore holes, and shape metal, the possibilities for creating unique and functional objects are limitless.

Restoring Antique Objects

Another exciting application of a metal lathe is the restoration of antique objects. Craftsmen can use the lathe to recreate missing or damaged parts of antique machinery, furniture, or other objects. With careful craftsmanship and attention to detail, a metal lathe can bring new life to cherished antiques.

Prototyping and Small-Scale Production

For inventors and entrepreneurs, a metal lathe can be an invaluable tool for prototyping and small-scale production. With the ability to create customized parts and objects, craftsmen can quickly and efficiently produce prototypes for testing and refinement. This allows for faster product development and a shorter time to market.

Conclusion

A metal lathe is a versatile tool that can turn raw materials into functional objects. With its ability to shape, cut, and create intricate designs, the possibilities are endless. Whether you are a hobbyist, a professional craftsman, or an entrepreneur, a metal lathe can help bring your ideas to life and create unique and customized objects.

Creating Intricate Metal Designs

With a metal lathe, you have the ability to create intricate and detailed metal designs that can be used for various purposes. Whether you are a hobbyist or a professional, the possibilities are endless.

Jewelry

One of the most popular uses for a metal lathe is in the creation of jewelry. The precision and accuracy of a metal lathe allow you to create intricate patterns and designs that will enhance the beauty of any piece of jewelry. You can turn simple pieces of metal into stunning rings, pendants, earrings, and bracelets.

Artwork

A metal lathe can also be used to create beautiful metal artwork. From sculptures to decorative panels, the lathe allows you to shape and carve metal into intricate designs that can be used to decorate homes, offices, and public spaces. The ability to create intricate patterns and textures opens up a world of possibilities for artists looking to work with metal.

Instrument Making

If you have a passion for music, a metal lathe can be used to create high-quality, custom-made instruments. From guitar necks to trumpet mouthpieces, the lathe allows you to shape metal to create the perfect sound and playability for any instrument. The precision and accuracy of the lathe ensure that the instrument will have excellent tonal quality and playability.

Toolmaking

A metal lathe is an essential tool for anyone involved in toolmaking. With a lathe, you can create precision tools that are tailored to your specific needs. From drill bits to cutting tools, the lathe allows you to shape and sharpen metal to create tools that will provide superior performance and durability.

Custom Parts

For engineers and inventors, a metal lathe is a valuable tool for creating custom parts. Whether you need a specific component for a machine or a unique piece for a project, the lathe allows you to shape metal to meet your exact specifications. The ability to create custom parts ensures that you can bring your ideas to life and solve problems in a practical and efficient manner.

Conclusion

The metal lathe opens up a world of possibilities for creating intricate and detailed metal designs. From jewelry to artwork, instrument making to toolmaking, and custom parts to prototypes, a lathe provides the precision and accuracy needed to bring your ideas to life. Whether you are a hobbyist or a professional, a metal lathe is a versatile tool that will help you unleash your creativity and turn simple pieces of metal into works of art.

Building Custom Tools and Components

Create Unique Tools for Specific Projects

A metal lathe allows you to create custom tools that are specifically tailored to your unique projects. By using raw materials like steel or aluminum, you can turn and shape them into specialized tools to make your work easier and more efficient.

For example, if you need a special-sized wrench for a particular job, you can use a metal lathe to create the perfect fit. Instead of spending time looking for a pre-made tool that might not exist, you can simply make it yourself.

Repair or Replace Existing Components

In addition to creating custom tools, a metal lathe also allows you to repair or replace existing components. Whether it’s a broken gear, a worn-out part, or a missing piece, you can use the lathe to manufacture exact replicas or improve upon the originals.

By having the ability to repair or replace components, you can save time and money. Rather than purchasing a new machine or equipment, you can repair the existing one and extend its lifespan.

Customize Designs for Aesthetic Appeal

With a metal lathe, you can also customize the design of various components for aesthetic appeal. Whether you want to add decorative patterns, engravings, or unique shapes, the lathe allows you to turn a simple piece of metal into a work of art.

By customizing the design of components, you can elevate the visual appeal of your projects. This is particularly useful for craftspeople, artists, or anyone who wants to add a personal touch to their work.

Create Functional Prototypes

Using a metal lathe, you can also create functional prototypes for your projects. Whether you’re designing a new tool or developing a machine part, the lathe allows you to quickly produce prototypes for testing and evaluation.

By having the ability to create functional prototypes, you can refine and perfect your designs before mass production. This can save you time and money in the long run by ensuring that your final product meets all the necessary requirements.

Conclusion

A metal lathe opens up a world of possibilities for building custom tools and components. From creating unique tools for specific projects to customizing designs for aesthetic appeal, the lathe offers versatility and precision. With its capabilities, you can unleash your creativity and bring your projects to life.

Restoring and Replicating Antique Parts

One of the most valuable applications of a metal lathe is the ability to restore and replicate antique parts. Whether you are a collector of antique machinery or own an old piece that requires repair, a metal lathe can be a powerful tool in bringing these parts back to life.

Restoration

Restoring antique parts can be a challenging task, as many of these pieces may be rusted, damaged, or missing certain components. However, with a metal lathe, you can turn back the hands of time and restore these parts to their former glory.

Rusted parts: Antique parts that have been exposed to the elements for many years often develop rust. With a metal lathe, you can remove the rust by gently turning and shaping the part until the rust is completely eradicated. This process may require careful measurement and precise cutting, but the end result will be a clean and functional part.

Damaged parts: If an antique part has been damaged, a metal lathe can be used to repair or recreate the damaged section. By carefully measuring the existing part and using the lathe to shape a new piece, you can seamlessly integrate the repaired or replicated section with the rest of the antique part.

Replication

In some cases, antique parts may be missing or irreparably damaged. In these situations, a metal lathe can come to the rescue by allowing you to replicate the missing part.

Missing components: If an antique machine or device is missing a specific part, you can use a metal lathe to replicate it. By studying existing parts or referencing historical documentation, you can create an accurate replica that fits seamlessly into the overall antique piece.

Irreparable damage: Sometimes, an antique part may be so damaged that it cannot be repaired. In these cases, a metal lathe can be used to create a brand new part that matches the original design and specifications. This allows you to maintain the integrity and authenticity of the antique piece, even with a replacement part.

Conclusion

A metal lathe is an invaluable tool for restoring and replicating antique parts. Whether you are preserving a piece of history or repairing a cherished antique, the precision and versatility of a metal lathe can help bring these pieces back to their former glory.

Prototyping Different Mechanical Structures

A metal lathe is a versatile machine tool that can be used to create a wide variety of mechanical structures. One of the main benefits of using a metal lathe for prototyping is its ability to accurately shape and form metal components. This makes it ideal for creating complex mechanical structures that require precision and durability.

Benefits of prototyping with a metal lathe

- Ability to work with different types of metals, such as steel, aluminum, and brass.

- Precision and accuracy in creating intricate parts and components.

- Flexibility to create custom designs and modifications.

- Durability and strength in the final product.

- Cost-effectiveness for small-scale production.

Examples of mechanical structures that can be prototyped

A metal lathe can be used to prototype various mechanical structures, including:

- Gears and gearboxes: Metal lathes are capable of producing precise gear teeth and gear ratios for a wide range of applications, such as automotive transmissions and industrial machinery.

- Shafts and axles: Metal lathes can create shafts and axles with accurate dimensions, ensuring a proper fit and performance in rotating systems.

- Valves and valve components: The ability to create intricate designs and precise measurements makes metal lathes suitable for prototyping valves and their components, such as valve stems and seats.

- Pulleys and belts: Metal lathes can shape pulleys and belt grooves to exact specifications, ensuring efficient power transmission in various mechanical systems.

- Structural frames: Metal lathes can be used to prototype structural frames for machines and equipment, providing the necessary strength and stability.

Conclusion

The metal lathe is a valuable tool for prototyping different mechanical structures. Its versatility, precision, and durability make it an ideal choice for creating complex parts and components. Whether it’s gears, shafts, valves, pulleys, or structural frames, a metal lathe can help bring your mechanical designs to life.

Exploring the Artistic Side of Metalworking

Metalworking is often associated with practical, functional applications such as machining parts or fabricating tools. However, the possibilities offered by a metal lathe extend well beyond these utilitarian purposes. With a bit of imagination and creativity, a metal lathe can be used to create stunning works of art that showcase the artistic side of this versatile tool.

Sculptures

One of the most exciting ways to explore the artistic potential of a metal lathe is by creating sculptures. The ability to shape metal allows artists to bring their ideas to life in three-dimensional form. From intricate figurines to abstract forms, the options are only limited by the artist’s imagination.

Using a metal lathe, artists can turn a solid piece of metal into a sculpture by carefully removing material to create the desired shape and texture. The high precision and control of the lathe make it possible to achieve intricate details and smooth finishes, resulting in stunning sculptures that capture the attention of viewers.

Decorative Artwork

In addition to sculptures, a metal lathe can be used to create various forms of decorative artwork. By combining different materials, such as metal and wood, artists can produce unique pieces that blend functionality with aesthetics.

For example, artists can use a metal lathe to craft ornamental finials, candle holders, or even decorative bowls. By incorporating intricate patterns or engraving, these pieces can become the focal point of any room and contribute to the overall ambiance and style of the space.

Jewelry

Another exciting avenue for artistic exploration with a metal lathe is jewelry making. The precision and control offered by the lathe make it an ideal tool for creating intricate details and precise shapes required for jewelry pieces.

Artists can use a metal lathe to turn solid metal rods into rings, pendants, or earrings. By combining different metals or adding gemstones, these pieces can be transformed into unique and one-of-a-kind jewelry items that make a statement.

The Intersection of Art and Technology

Exploring the artistic side of metalworking with a lathe allows artists to combine their creativity with the precision and capabilities offered by this modern tool. The intersection of art and technology opens up endless possibilities for creating captivating and evocative works that push the boundaries of what is traditionally associated with metalworking.

Whether it’s sculpting, decorative artwork, or jewelry making, a metal lathe provides artists with the means to express their artistic vision in a durable and tangible form. With a metal lathe, the world of metalworking becomes a canvas for artistic expression.

Expanding the Possibilities with CNC Metal Lathes

Traditional metal lathes have long been used to shape and cut metal materials to create various parts and components. However, with the introduction of computer numerical control (CNC) technology, the capabilities of metal lathes have expanded even further, opening up a world of possibilities for manufacturers and craftsmen.

Increased Precision

CNC metal lathes offer unparalleled precision in metalworking. The use of computer-controlled movements and automated cutting ensures that every detail of the final product is executed with the utmost accuracy. This level of precision allows for the creation of intricate designs, delicate parts, and tight tolerances that may not be achievable by traditional methods.

Complex Shapes and Designs

With CNC metal lathes, complex shapes and designs can be effortlessly achieved. The ability to program the lathe to follow specific patterns and paths enables the creation of intricate curves, contours, and profiles. This opens up a wide range of possibilities for custom-made parts and unique designs that may not be feasible or cost-effective using traditional machining methods.

Efficiency and Time Savings

CNC metal lathes significantly improve efficiency and save valuable time. Once the desired design is programmed, the machine can operate autonomously, executing the instructions with speed and consistency. This eliminates the need for manual intervention and reduces the chances of human error, resulting in faster production times and increased productivity.

Automation and Repetitive Tasks

CNC metal lathes excel at automating repetitive tasks. By storing and recalling programs, operators can effortlessly reproduce parts with consistent quality and without the need for meticulous manual adjustments. This allows for mass production of identical components, streamlining manufacturing processes, and reducing labor costs.

Expanded Materials Compatibility

CNC metal lathes are capable of working with a wide range of materials. From various grades of steel and aluminum to brass, bronze, and even exotic alloys, the versatility of CNC lathes allows for the creation of parts and components from diverse materials, expanding the possibilities for manufacturers and craftsmen alike.

Conclusion

With CNC metal lathes, the possibilities for metalworking have vastly expanded. The combination of precision, versatility, automation, and efficiency makes CNC metal lathes an essential tool for manufacturers and craftsmen looking to push the boundaries of what can be achieved with metal materials. As technology continues to advance, so too will the possibilities offered by CNC metal lathes, revolutionizing the way we create and shape metal objects.

FAQ

What are some common projects that can be made with a metal lathe?

Some common projects that can be made with a metal lathe include turning metal rods and tubes, making bolts and screws, creating intricate metal designs, and shaping metal parts for machinery.

Is it possible to make custom jewelry with a metal lathe?

Yes, it is possible to make custom jewelry with a metal lathe. You can turn metal rods into different shapes and sizes to create unique pieces of jewelry like rings, earrings, and pendants.

Can a metal lathe be used to make tools?

Yes, a metal lathe can be used to make various types of tools. With a metal lathe, you can create custom cutting tools, drill bits, taps, and dies, among other tools.

What are the benefits of using a metal lathe for woodworking projects?

One of the benefits of using a metal lathe for woodworking projects is the ability to create precise and intricate designs on wooden objects. Additionally, a metal lathe allows for easy shaping and smoothing of wood, resulting in a professional-looking finish.

Can a metal lathe be used for 3D printing?

No, a metal lathe cannot be used for 3D printing. A metal lathe is a machining tool used for shaping metal objects, while 3D printing involves creating objects layer by layer using a different technology.

Video

![Insecure in Love: How Anxious Attachment Can Make You Feel Jealous, Needy, and Worried and What You Can Do About It [large print edition]](https://m.media-amazon.com/images/I/31t2fLisqYL._SL160_.jpg)