Simple Steps to Level a Lathe: Essential Guide for Beginners

Leveling a lathe is an important step in ensuring accuracy and precision in your machining work. If a lathe is not properly leveled, it can lead to uneven cuts, inaccuracies in measurements, and even damage to the lathe itself. Fortunately, leveling a lathe is a relatively simple process that can be done by beginners with the right tools and a little bit of patience.

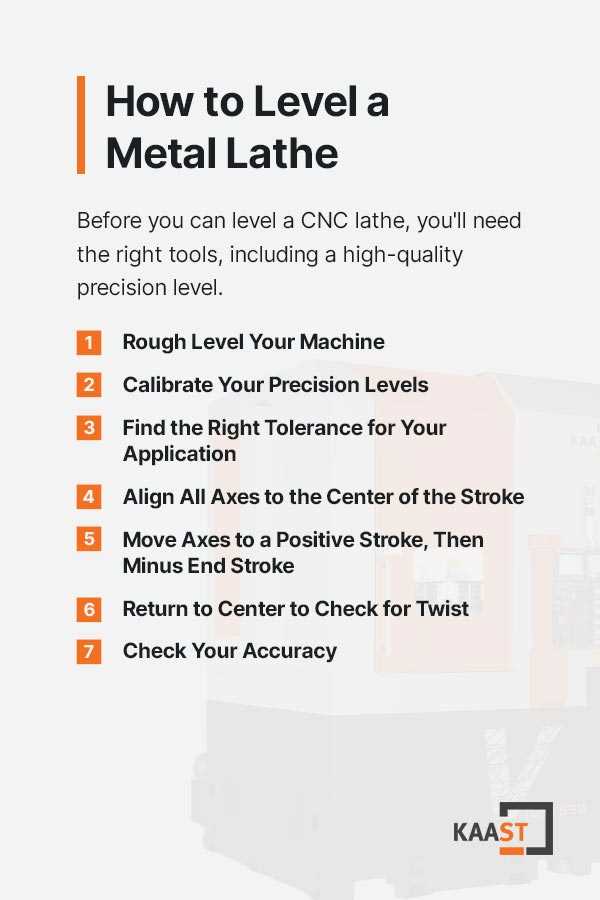

The first step in leveling a lathe is to make sure the lathe is placed on a sturdy and level surface. This can be a workbench or a dedicated lathe stand, as long as it is solid and stable. Once the lathe is in place, use a spirit level to check if it is level from front to back and side to side. Adjust the height of the lathe’s feet or use shims to level it if necessary.

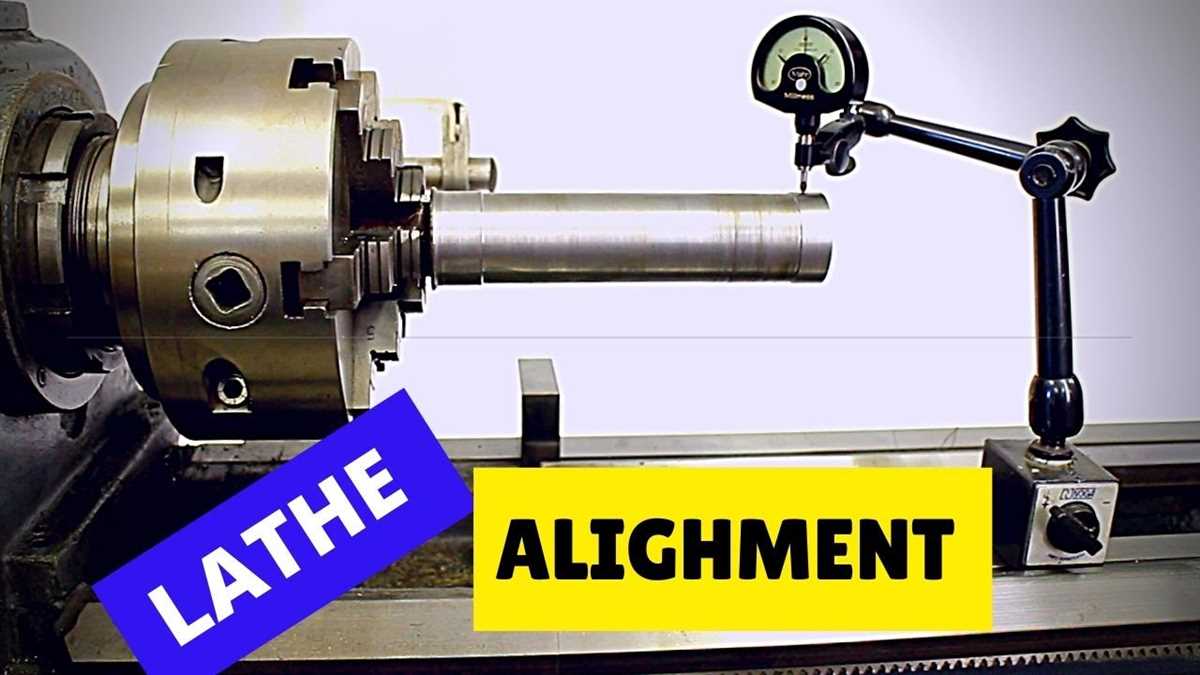

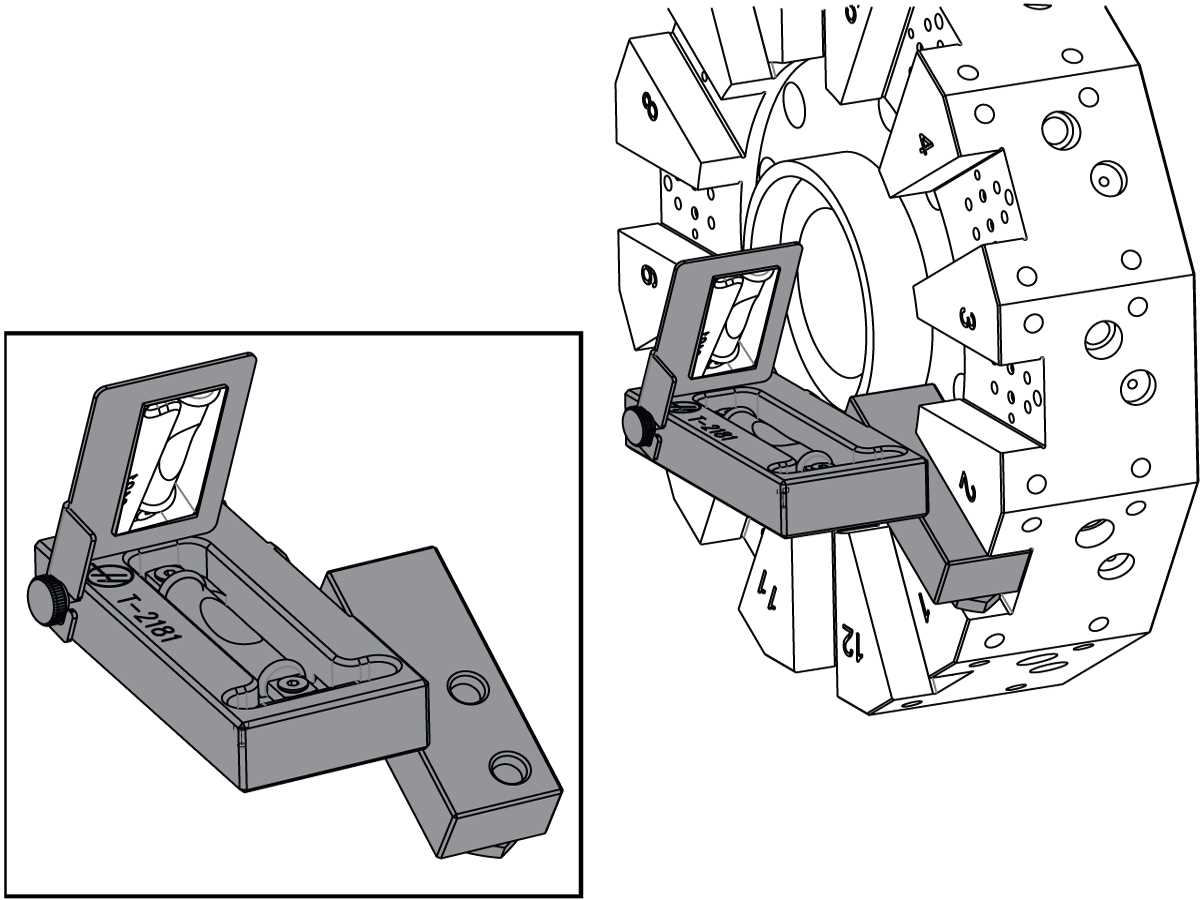

Next, you’ll want to check the level of the lathe bed. The lathe bed is the flat surface upon which the workpiece rests. It should be parallel to the ground to ensure even cuts. To check the level of the lathe bed, use a precision level or a dial indicator mounted on a magnetic base. Place the level or dial indicator on different points along the bed and adjust the feet or shims as needed to make it level.

Once the lathe bed is level, you can move on to leveling the tailstock. The tailstock should be aligned with the lathe bed to ensure precise drilling and turning operations. To do this, insert a precision bar or spindle into the headstock and tailstock, and bring the two ends together. If they do not align perfectly, adjust the tailstock by loosening the locking bolts and moving it until it is aligned with the lathe bed. Tighten the locking bolts to secure it in place.

Finally, you’ll want to check the level of the lathe’s headstock. The headstock is the motorized component of the lathe that holds the workpiece in place. Like the lathe bed, it should be parallel to the ground for accurate machining. Use a precision level or a dial indicator to check the level of the headstock and adjust the feet or shims as necessary.

By following these simple steps, you can level your lathe and ensure accurate and precise machining. Remember to recheck the level periodically, as it may change over time due to factors such as vibration or movement. With a level lathe, you can confidently tackle all your machining projects and achieve top-notch results.

Step 1: Gather the necessary tools

Before you begin leveling your lathe, make sure you have all the necessary tools. Having the right tools on hand will make the process much easier and more efficient. Here are the tools you will need:

- Leveling tool: This could be a precision level or a bubble level, whichever you prefer to use.

- Wrenches: You will need wrenches to loosen and tighten bolts and screws.

- Measuring tape: A measuring tape will be useful for measuring the distance between the lathe bed and the floor.

- Shims: Shims are thin pieces of material used to fill in gaps and help level the lathe. You may need shims of different thicknesses.

- Hammer: A hammer may be needed to gently tap the lathe into the correct position.

- Safety equipment: Always prioritize safety. Wear safety glasses, gloves, and any other protective gear necessary.

Once you have gathered all the necessary tools, you will be ready to move on to the next step in leveling your lathe.

Step 2: Place the lathe on a flat surface

Once you have chosen the location for your lathe, it’s important to ensure that the surface it will be placed on is completely flat. This is essential for the lathe to operate properly and to prevent any unnecessary vibrations or movements while you are using it. Follow the steps below to properly place your lathe on a flat surface.

- Clear the area: Remove any debris, tools, or objects from the surface where you will be placing the lathe. This will help to create a clean and clutter-free workspace.

- Level the surface: Use a level tool to check if the surface is already level. If it is not, you may need to make some adjustments. This can be done by placing shims or small pieces of wood under the legs of the lathe to level it. Alternatively, if the surface is uneven, you may need to use a plane or sander to flatten it.

- Check for stability: Ensure that the surface is stable and does not wobble. If it does, you may need to reinforce it by adding additional support or securing it to the floor.

Note: It is recommended to place a rubber mat or some sort of cushioning material under the lathe to reduce vibrations and protect the surface it is placed on.

By placing your lathe on a flat surface, you will create a stable and secure work environment that will enhance your woodworking experience. Remember to regularly check the level of the surface and make any necessary adjustments to ensure optimal performance.

Step 3: Use a spirit level to check the lathe’s level

After leveling the lathe bed and mounting it securely, it is important to check if the lathe is properly level. This will ensure accurate and precise turning operations.

Materials Needed:

- Spirit level

Instructions:

- Place the spirit level on the lathe bed, parallel to the lathe’s longitudinal axis.

- Adjust the level until the bubble is centered between the lines.

- Rotate the spirit level 90 degrees and place it across the bed, perpendicular to the lathe’s longitudinal axis.

- Again, adjust the level until the bubble is centered between the lines.

- Check the level in multiple spots along the lathe bed to ensure overall levelness.

Note: Some lathes have built-in leveling mechanisms that can be used instead of a spirit level. Follow the manufacturer’s instructions in such cases.

If the lathe is not level, adjust the leveling feet or shims until the lathe is perfectly level. A level lathe will provide more accurate and precise turning results.

Step 4: Adjust the leveling feet

After leveling the lathe bed and headstock, the next step is to adjust the leveling feet to ensure the lathe is stable and secure. The leveling feet are located at the base of the lathe and are used to adjust the height and stability of the machine.

Here are the steps to adjust the leveling feet of the lathe:

- Locate the leveling feet on the base of the lathe. They are usually four in number and positioned at the corners of the machine.

- Using a wrench or a suitable tool, loosen the locking nut on each leveling foot.

- Gently turn the leveling feet clockwise or counterclockwise to raise or lower them as needed. The goal is to make the lathe stable and level with the ground.

- Check the levelness of the lathe using a spirit level. Place the level on the lathe bed and check if the bubble is centered. If not, continue adjusting the leveling feet until the lathe is level.

- Tighten the locking nut on each leveling foot once the lathe is level and stable.

It is important to ensure that the lathe is properly leveled to prevent any vibrations or inaccuracies during operation. A stable and level lathe will result in better performance and more precise work.

Note: It is recommended to periodically check and readjust the leveling feet as needed, as the lathe may require re-leveling over time.

Step 5: Verify the lathe’s level

Once you have completed the previous steps to level your lathe, it’s important to verify that the lathe is indeed level. This step is crucial to ensure accurate and precise turning.

Here’s how you can verify the level of your lathe:

- Use a bubble level: Place a bubble level on the bed of the lathe. Make sure it is positioned lengthwise or across the bed, depending on your lathe’s design. The bubble should be centered within the level’s indicator lines. This will indicate that the lathe is perfectly level from side to side.

- Check the headstock alignment: Use a straight edge or a precision machinist level to check the alignment of the headstock. Place the straight edge horizontally across the bed and against the front face of the headstock. If the straight edge rests evenly against the headstock and the bed, it means that the headstock is aligned and parallel to the bed.

- Inspect the tailstock: The tailstock should also be checked for proper alignment. Slide the tailstock along the bed and observe if it moves smoothly and evenly. Also, check if it aligns properly with the headstock. If everything is in proper alignment, it means that the tailstock is correctly set up.

- Perform a test cut: To further verify the level of your lathe, you can perform a test cut. Use a piece of scrap wood or metal and turn it while observing the tool and the workpiece. If the tool moves smoothly and the cut is uniform across the entire turning, it confirms that the lathe is level and ready for use.

It’s important to note that regular maintenance and periodic checks are necessary to keep your lathe in optimal condition. If you notice any issues with the level or alignment, it’s recommended to address them promptly to ensure the best possible turning results.

Step 6: Test the lathe’s level by turning on the machine

Perform a test run

Once you have leveled your lathe using the previous steps, it’s time to put it to the test. Carefully turn on the machine and observe its performance.

Check for vibrations

As the lathe starts running, pay close attention to any vibrations that may occur. Excessive vibrations can indicate that the lathe is not properly leveled. If you notice any vibrations, it may be necessary to go back and repeat the leveling process.

Inspect the turning process

While the lathe is running, take a moment to observe the turning process. Make note of any irregularities or issues that may arise. This can include uneven cuts, wobbling, or other issues that could affect the quality of your work.

Check alignment

During the test run, check the alignment of the lathe bed and the tool rest. They should remain parallel and at the same height throughout the turning process. If you notice any misalignment, you may need to readjust the level of your lathe.

Make necessary adjustments

If you encounter any issues or irregularities during the test run, make the necessary adjustments to your lathe. This may involve further leveling, checking the alignment of the tool rest, or other corrective measures. Don’t rush this process, as achieving a properly leveled lathe is crucial for accurate and high-quality turning.

Repeat the test if necessary

After making any adjustments, repeat the test run to ensure that the lathe is now properly leveled. If you are satisfied with the results and there are no further issues, you can proceed to use your lathe for your turning projects with confidence.

Step 7: Make final adjustments if necessary

After going through the previous steps to level your lathe, it’s important to check for any final adjustments that may be necessary. Follow these steps to ensure your lathe is properly leveled:

- Check the lathe bed: Examine the lathe bed carefully for any signs of unevenness. If you notice any high or low spots, use shims or other leveling tools to make the necessary adjustments.

- Verify the headstock alignment: Check the alignment of the headstock by using a straight edge or precision level across the bed. Make any necessary adjustments to align the headstock with the bed.

- Inspect the tailstock: Check the alignment of the tailstock with the lathe bed. Make sure it is parallel to the headstock and adjust if necessary.

- Check for vibrations: Turn on the lathe and verify if there are any vibrations. If vibrations are present, check if they are caused by loose bolts, misaligned parts, or other factors. Make the necessary adjustments to reduce or eliminate vibrations.

- Test with a workpiece: Once you have made all the initial adjustments, test the lathe with a workpiece. Pay attention to the finish, accuracy, and smoothness of the cuts. If any issues are detected, revisit the previous steps and make further adjustments if necessary.

Remember, leveling a lathe is an ongoing process, and it may require periodic adjustments to maintain its accuracy. By following these steps and paying attention to detail, you can ensure your lathe’s performance remains at its best.

FAQ

What are some simple steps to level a lathe?

Leveling a lathe involves several simple steps. First, use a level to check the lathe bed for any discrepancies. Adjust the feet of the lathe until it is level. Then, check the headstock and tailstock alignment and make any necessary adjustments. Finally, make sure the lathe is securely mounted to a sturdy workbench or stand.

Why is it important to level a lathe?

Leveling a lathe is important to ensure accurate and precise turning operations. If a lathe is not level, it can cause the workpiece to be cut unevenly and can lead to inaccuracies in the finished product. Additionally, an unlevel lathe can put unnecessary stress on the machine, causing it to wear down faster.

Can I level a lathe on my own as a beginner?

Yes, leveling a lathe can be done by beginners. It does not require advanced technical knowledge or skills. By following the simple steps outlined in the guide, beginners can successfully level their lathe and improve the accuracy of their turning operations.

What tools do I need to level a lathe?

To level a lathe, you will need a level (preferably a precision machinist level), a wrench or adjustable wrench to adjust the feet, and a straight edge to check the alignment of the headstock and tailstock. Additionally, a sturdy workbench or stand is necessary to mount the lathe securely.

How often should I level my lathe?

The frequency of leveling a lathe depends on the usage and conditions. It is recommended to check the levelness of the lathe periodically, especially if it is being moved or if you notice any inconsistencies or inaccuracies in your turning operations. As a general guideline, you may want to level your lathe at least a couple of times a year.

What other maintenance tasks should I perform on my lathe?

In addition to leveling the lathe, there are several other maintenance tasks that should be performed on a regular basis. These include cleaning and lubricating the lathe, checking and adjusting the tension of the drive belt, inspecting and replacing worn or damaged parts, and regularly cleaning the chip tray and removing any debris.