Sharpening Carbide Lathe Tools: A Comprehensive Guide

Sharpening carbide lathe tools plays a crucial role in achieving precise and clean cuts in various woodworking and metalworking projects. Carbide tools are known for their long-lasting sharpness and durability, but they need regular sharpening to maintain their optimal performance. This comprehensive guide will provide you with detailed instructions and tips on how to sharpen your carbide lathe tools effectively.

One of the most important steps in sharpening carbide lathe tools is selecting the right grinding wheel. The wheel should be specifically designed for sharpening carbide and have a medium grit size to provide a good balance between material removal and surface finish. It is also crucial to ensure that the wheel is properly aligned and balanced to achieve accurate and consistent sharpening results.

To sharpen carbide lathe tools, it is recommended to use a bench grinder with a diamond wheel or a dedicated carbide tool grinder. The process involves carefully grinding the edge of the tool at the correct angle, typically around 60-75 degrees, while maintaining a steady hand and applying light pressure. It is essential to avoid overheating the tool during the sharpening process to prevent damage to the carbide tip.

After grinding, honing the tool’s edge is necessary to remove any burrs and refine the sharpness. This can be done using a honing guide and a series of sharpening stones with progressively finer grits. The honing process helps to achieve a razor-sharp edge that is essential for achieving precise cuts and smooth finishes in your lathe projects.

Remember to always wear appropriate safety gear, such as safety glasses and gloves, when sharpening carbide lathe tools. Take your time and practice the sharpening technique to ensure consistent and accurate results. With proper sharpening and maintenance, your carbide lathe tools will serve you well for many projects to come.

The Importance of Sharpening Carbide Lathe Tools

1. Enhanced Cutting Performance

Sharpening carbide lathe tools is crucial for achieving enhanced cutting performance. Over time, carbide tools can become dull and lose their sharpness, resulting in poor cutting performance. Sharpening the tools allows you to restore their sharp cutting edges, ensuring smooth and precise cuts.

2. Extended Tool Life

Regular sharpening of carbide lathe tools helps extend their tool life. Dull tools can wear out quickly, leading to frequent replacements and increased costs. By keeping your carbide tools sharp, you can maximize their lifespan, saving both time and money in the long run.

3. Improved Surface Finish

Sharp carbide tools are essential for achieving a high-quality surface finish. Dull tools can leave behind rough surfaces, requiring additional finishing work. By sharpening your carbide lathe tools, you can ensure smooth cuts and achieve a professional and polished surface finish.

4. Minimized Chattering and Vibration

When carbide tools become dull, they can cause chattering and vibration during operation. This not only affects the quality of the cut but can also lead to tool breakage and damage to the workpiece. Sharpening the tools helps eliminate chattering and vibration, resulting in improved stability during cutting.

5. Increased Efficiency

Sharp carbide lathe tools require less force and pressure to cut through the material compared to dull tools. This increased efficiency allows for faster and more efficient machining, reducing overall production time and increasing productivity.

6. Precision and Accuracy

Sharpened carbide tools offer better precision and accuracy in cut depths and dimensions. Dull tools can lead to inaccuracies and inconsistencies, resulting in flawed workpieces. By regularly sharpening your carbide lathe tools, you can ensure precise cuts and maintain the desired dimensions for your projects.

7. Safe Operation

Dull carbide tools can be dangerous to work with as they require excessive force and can easily slip or break. Sharpening the tools reduces the risk of accidents, providing a safer working environment for both the operator and others in the vicinity.

In conclusion, sharpening carbide lathe tools is crucial for achieving enhanced cutting performance, prolonging tool life, improving surface finish, reducing chattering and vibration, increasing efficiency, ensuring precision and accuracy, and promoting safe operation. Regular sharpening maintenance is essential to maximize the potential of carbide lathe tools and optimize your machining operations.

Understanding the Basics of Carbide Lathe Tools

Carbide lathe tools are a popular choice among woodturners and metalworkers due to their durability and ability to maintain a sharp cutting edge for extended periods of time. Understanding the basics of carbide lathe tools is essential for maximizing their effectiveness and longevity.

Carbide Inserts

Carbide lathe tools consist of a holder or shank that holds a replaceable carbide insert. The carbide insert is the cutting portion of the tool and is available in various shapes and sizes, depending on the desired cutting action.

The carbide inserts are made from a hard and wear-resistant material called cemented carbide. This material is a combination of tungsten carbide particles and a metal binder, typically cobalt.

The Advantages of Carbide Lathe Tools

There are several advantages to using carbide lathe tools:

- Durability: Carbide lathe tools are extremely durable and can withstand high speeds and heavy cutting forces without chipping or dulling.

- Sharpness: The carbide inserts maintain a sharp cutting edge for a longer time compared to traditional high-speed steel tools.

- Versatility: Carbide inserts are available in various shapes and sizes, allowing for a wide range of cutting actions and applications.

- Efficiency: Carbide lathe tools often require less frequent sharpening, saving time and effort in the long run.

Sharpening Carbide Inserts

Although carbide inserts can maintain their sharpness for a longer time compared to other tools, they will eventually dull and require sharpening. Proper sharpening techniques should be followed to ensure the longevity and effectiveness of the inserts.

Sharpening carbide inserts typically involves using a diamond grinding wheel or sharpening stone specifically designed for carbide materials. The process involves carefully removing the dulled edge of the insert and restoring a sharp cutting edge.

Conclusion

Understanding the basics of carbide lathe tools is essential for any woodturner or metalworker. By knowing how these tools work, their advantages, and proper sharpening techniques, you can maximize their effectiveness and longevity in your projects.

Choosing the Right Sharpening Equipment

When it comes to sharpening carbide lathe tools, choosing the right equipment is crucial. There are several options available, each with its own advantages and disadvantages. Here are some factors to consider when selecting the right sharpening equipment for your needs:

1. Bench Grinder

A bench grinder is a popular choice for sharpening carbide lathe tools due to its affordability and ease of use. It consists of a motor that spins grinding wheels at high speeds. Bench grinders come with different grit sizes, allowing you to choose the level of coarseness for your sharpening needs.

2. Belt Sander

A belt sander is another option for sharpening carbide lathe tools. It has a continuous loop of sandpaper that rotates on two wheels, providing a large contact area for sharpening. Belt sanders are often used by professionals due to their versatility and ability to quickly remove material.

3. Tormek-style Sharpening System

A Tormek-style sharpening system is a popular choice among woodturners for carbide lathe tool sharpening. It features a slow-speed water-cooled grinding wheel and a leather honing wheel. This system provides precise and controlled sharpening, ensuring optimal results.

4. Diamond Wheels

Diamond wheels are known for their durability and ability to sharpen carbide tools effectively. They use industrial diamonds embedded on the surface to grind away the material. Diamond wheels can be used with bench grinders or Tormek-style sharpening systems.

5. Sharpening Jigs

Sharpening jigs are accessories that can be used with bench grinders or Tormek-style systems to ensure consistent and accurate sharpening. They hold the tool in a fixed position, allowing you to maintain the correct bevel angle and avoid mistakes.

6. Honing Guides

Honing guides are another useful accessory for sharpening carbide lathe tools. They help in maintaining a consistent angle while honing the cutting edge. Honing guides can be used in conjunction with bench grinders or Tormek-style systems.

When choosing the right sharpening equipment, it is essential to consider your budget, sharpening needs, and personal preference. It is recommended to start with a basic setup and gradually invest in more advanced equipment as you gain experience and fine-tune your sharpening techniques.

Step-by-Step Guide to Sharpening Carbide Lathe Tools

1. Gather your materials

Before you begin sharpening your carbide lathe tools, make sure you have all the necessary materials:

- Diamond wheel dresser

- Bench grinder

- Sharpening jig

- Gloves

- Safety goggles

2. Prepare the grinder

Attach a diamond wheel dresser to your bench grinder and turn it on. Use the dresser to true the wheel and remove any glazing or debris from the surface.

3. Set up the sharpening jig

Mount your carbide lathe tool in the sharpening jig. The jig will hold the tool at the correct angle for sharpening.

4. Start sharpening

Gently rest the tool against the grinding wheel, making sure it is positioned at the correct angle. Move the tool back and forth across the wheel, applying light pressure. Be careful not to overheat the tool.

Continue sharpening until you have achieved the desired edge. Check the tool frequently to ensure it remains cool and does not become damaged.

5. Dress the wheel as needed

Periodically dress the grinding wheel with the diamond wheel dresser to maintain its effectiveness. This will help ensure a smooth and consistent sharpening process.

6. Test the edge

After sharpening, carefully touch the edge of the carbide lathe tool to ensure it is sharp. If necessary, make any final adjustments using the sharpening jig and grinder.

7. Clean up

Once you have finished sharpening your carbide lathe tools, clean up any debris and store your equipment properly. Remember to always prioritize safety when working with power tools.

Sharpening carbide lathe tools can be a delicate process, but with the right tools and techniques, you can achieve a sharp and durable edge. Follow this step-by-step guide for successful sharpening and maintain the performance of your lathe tools.

Common Mistakes to Avoid While Sharpening Carbide Lathe Tools

Sharpening carbide lathe tools can be a challenging task, but avoiding common mistakes can help you achieve better results and extend the life of your tools. Here are some common mistakes to avoid:

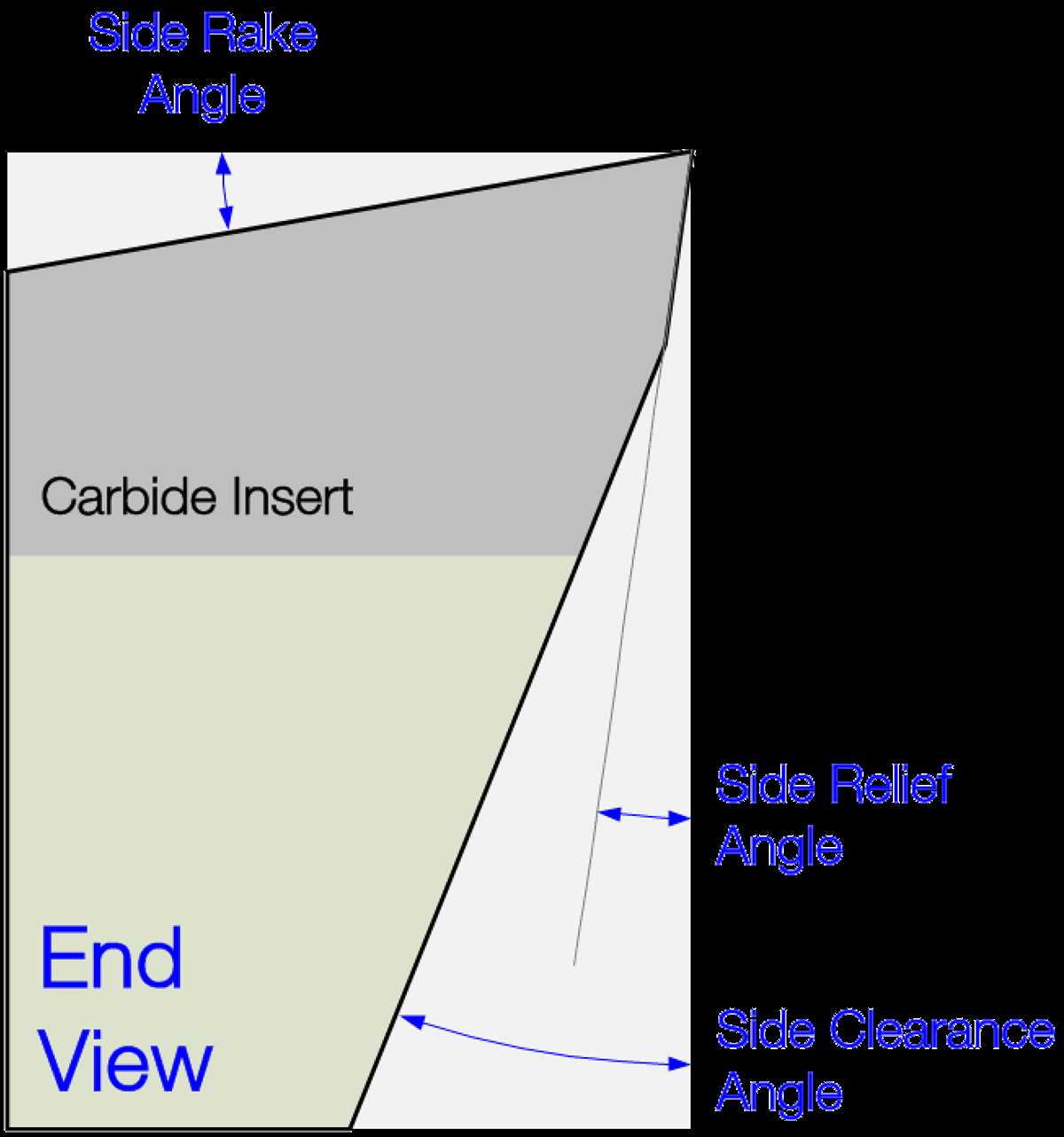

- Using incorrect grinding angles: One of the most common mistakes is using incorrect grinding angles. Each carbide lathe tool has a specific geometry and grinding angle that should be followed. Using incorrect angles can result in a dull edge or excessive tool wear.

- Applying too much pressure: Another common mistake is applying too much pressure while sharpening. Carbide is a hard material, but it is also brittle. Applying excessive pressure can cause the tool to chip or break. It is important to use light, even pressure to avoid damaging the tool.

- Neglecting to use coolant: Carbide lathe tools generate a significant amount of heat during sharpening. Neglecting to use coolant can result in excessive heat buildup, which can damage the tool and degrade its cutting performance. It is important to use coolant to keep the tool cool and prevent overheating.

- Skipping grits: When sharpening carbide lathe tools, it is important to start with a coarse grit to remove any nicks or damage and then progress to finer grits. Skipping grits can result in an uneven or ineffective sharpening process. It is recommended to follow the proper grit sequence to achieve the best results.

- Using worn or damaged grinding wheels: Grinding wheels wear over time and can become uneven or damaged. Using worn or damaged grinding wheels can result in poor sharpening results and can even damage the carbide lathe tool. It is important to regularly inspect and replace grinding wheels when necessary.

- Not maintaining the correct tool geometry: Carbide lathe tools have specific geometries that should be maintained during sharpening. Neglecting to maintain the correct tool geometry can result in poor cutting performance and increased tool wear. It is important to carefully follow the manufacturer’s recommendations for tool geometry.

Avoiding these common mistakes and following proper sharpening techniques can help you achieve better results and prolong the life of your carbide lathe tools. Remember to always take your time, use the correct angles and grits, and regularly inspect and maintain your tools to ensure optimal performance.

Tips and Techniques for Maintaining Sharpened Carbide Lathe Tools

1. Avoid Excessive Heat

Excessive heat can dull or damage the cutting edge of your carbide lathe tools. To prevent this, avoid using excessive pressure or speed when cutting. Additionally, make sure to keep the tool cool by using lubricants or coolants. This will help to prolong the sharpness of the tool and prevent premature wear.

2. Clean and Store Properly

After using your carbide lathe tools, it’s important to clean them thoroughly to remove any debris or buildup. This can be done using a brush or compressed air. Once clean, make sure to store the tools in a dry and secure location, away from any potential damage or contact with other tools.

3. Regularly Inspect and Sharpen

To maintain the sharpness of your carbide lathe tools, it’s crucial to regularly inspect them for any signs of wear or damage. Look for chips, cracks, or any dullness in the cutting edge. If any issues are detected, it’s important to sharpen or replace the tool as needed. Regular maintenance will ensure that your tools are always in optimal condition for use.

4. Use the Correct Cutting Speed and Feed Rate

When using carbide lathe tools, it’s essential to use the correct cutting speed and feed rate for the material being worked on. Using the wrong speed or feed rate can cause excessive wear and dulling of the tool. Consult the manufacturer’s guidelines or industry standards to determine the appropriate settings for your specific application.

5. Be Mindful of the Cutting Angle

The cutting angle plays a significant role in the performance of carbide lathe tools. It’s important to ensure that the tool is sharpened to the correct angle for the specific material being cut. Using the wrong angle can result in poor cutting performance and increased risk of tool damage. Regularly check and adjust the cutting angle as needed.

6. Proper Handling and Usage

When using carbide lathe tools, it’s crucial to handle them with care and use them correctly. Avoid dropping or mishandling the tools, as this can cause damage to the cutting edge. Additionally, follow proper lathe tool techniques and guidelines to prevent excessive wear or misuse of the tool.

7. Keep Spare Tools on Hand

It’s always a good idea to have spare carbide lathe tools on hand. This allows for quick replacement in case of tool damage or wear. It’s recommended to have a variety of tool sizes and shapes available to accommodate different turning operations. Regularly rotate and replace tools to ensure consistent performance.

8. Seek Professional Assistance if Needed

If you are unsure about how to properly maintain or sharpen your carbide lathe tools, it’s best to seek professional assistance. A professional can provide guidance and expertise to ensure that your tools are in optimal condition and perform at their best. They can also recommend specialized sharpening equipment or techniques if necessary.

By following these tips and techniques, you can effectively maintain the sharpness and performance of your carbide lathe tools. Proper maintenance will not only extend the lifespan of your tools but also ensure accurate and efficient turning operations.

Troubleshooting Common Issues with Sharpening Carbide Lathe Tools

1. Chipped or Dull Cutting Edges

One of the most common issues when sharpening carbide lathe tools is ending up with chipped or dull cutting edges. This can result in poor performance and a rough finish on the workpiece.

Possible causes:

- Dull or worn grinding wheel

- Incorrect grinding angle

- Excessive pressure during sharpening

Solutions:

- Replace the grinding wheel with a new one or dress the wheel to remove any dull spots.

- Ensure the correct grinding angle is maintained by using a tool rest or jig.

- Apply light pressure and let the grinding wheel do the work. Avoid excessive pressure, which can cause chipping.

2. Uneven Cutting Edges

Another common issue is ending up with uneven cutting edges after sharpening carbide lathe tools. This can lead to uneven cuts and an inconsistent finish on the workpiece.

Possible causes:

- Uneven grinding wheel wear

- Unequal pressure applied during sharpening

Solutions:

- Regularly dress the grinding wheel to ensure even wear and a uniform cutting edge.

- Apply equal pressure to both sides of the tool during sharpening to maintain symmetry.

3. Excessive Heat Build-up

Excessive heat build-up during the sharpening process can be problematic when sharpening carbide lathe tools. This can cause the carbide to become brittle and lead to premature tool failure.

Possible causes:

- Using a grinding wheel with a coarse grit

- Applying excessive pressure while sharpening

Solutions:

- Use a fine-grit grinding wheel or a diamond wheel to reduce heat build-up.

- Avoid applying excessive pressure and allow the tool to cool periodically during sharpening.

4. Inconsistent Cutting Performance

Inconsistent cutting performance can be frustrating when using carbide lathe tools. Tools that are not properly sharpened may result in uneven cuts, tool chatter, or difficulty in achieving the desired finish.

Possible causes:

- Inconsistent sharpening technique

- Incorrect cutting angles

Solutions:

- Develop a consistent sharpening technique to ensure uniform cutting edges.

- Use a tool rest or jig to maintain the correct cutting angles while sharpening.

5. Premature Tool Wear

Premature tool wear can occur when sharpening carbide lathe tools incorrectly. This can lead to reduced tool life and increased costs for tool replacement.

Possible causes:

- Excessive grinding that removes too much material

- Improper use of coolant or lubrication

Solutions:

- Use light pressure and take care not to remove more material than necessary during sharpening.

- Ensure the appropriate coolant or lubrication is used during sharpening to reduce heat and friction.

Conclusion

By troubleshooting common issues with sharpening carbide lathe tools, you can improve the performance and longevity of your tools. Pay attention to cutting edge quality, grinding wheel condition, sharpening technique, and cutting angles to achieve optimal results.

Frequently Asked Questions about Sharpening Carbide Lathe Tools

1. Why should I sharpen carbide lathe tools?

Sharpening carbide lathe tools is essential to maintain their cutting performance. Over time, the carbide tips of the tools can become dull, reducing their effectiveness and causing poor-quality cuts. By sharpening the tools, you can restore their sharpness and improve their cutting ability.

2. Can I sharpen carbide lathe tools myself?

Yes, you can sharpen carbide lathe tools yourself with the right tools and technique. However, it requires some knowledge and experience to sharpen them correctly. If you are unsure about sharpening carbide tools, it is recommended to seek guidance from a professional or attend a training course to learn the proper techniques.

3. What tools do I need to sharpen carbide lathe tools?

To sharpen carbide lathe tools, you will need the following tools:

- Diamond grinding wheel

- Bench grinder or lathe tool grinder

- Tool rest

- Proper safety equipment (safety glasses, gloves, etc.)

4. How often should I sharpen carbide lathe tools?

The frequency of sharpening carbide lathe tools depends on how often you use them and the type of material you are cutting. Generally, it is recommended to sharpen the tools when you notice a decrease in cutting performance or when the tips become visibly dull. Regular maintenance and inspections can help you identify when sharpening is necessary.

5. What are the benefits of sharpening carbide lathe tools?

Sharpening carbide lathe tools offers several benefits, including:

- Improved cutting performance and precision

- Reduced cutting forces and vibrations

- Extended tool life

- Cost savings by avoiding the need for frequent tool replacements

6. Can I use the same sharpening technique for all types of carbide lathe tools?

No, different carbide lathe tools may require different sharpening techniques. Each type of tool, such as inserts, drills, or turning tools, may have specific angles and shapes that need to be maintained during sharpening. It is important to refer to the manufacturer’s guidelines or consult an expert for the correct sharpening technique for each type of carbide lathe tool.

7. Are there any safety precautions I should take when sharpening carbide lathe tools?

Yes, sharpening carbide lathe tools involves working with sharp materials and rotating machinery, so it is important to take the following safety precautions:

- Wear safety glasses to protect your eyes from sparks and debris

- Wear gloves to protect your hands from sharp edges

- Secure the workpiece properly to prevent accidents

- Ensure the grinder or lathe tool grinder is stable and properly set up

FAQ

Why should I sharpen carbide lathe tools?

Sharpening carbide lathe tools is important to maintain their cutting performance. As carbide is a hard and durable material, it can retain its sharpness for a long time, but eventually it will dull and need sharpening for optimal cutting results.

What tools do I need to sharpen carbide lathe tools?

To sharpen carbide lathe tools, you will need a diamond grinding wheel, a bench grinder, a tool rest, and safety equipment such as goggles and gloves. You may also need a dressing tool to maintain the shape of the grinding wheel.

How do I know when my carbide lathe tools need sharpening?

There are several signs that indicate a carbide lathe tool needs sharpening. These include reduced cutting performance, increased effort required to make cuts, burning of the material being cut, and the appearance of dull or chipped edges on the tool. Inspecting the tool regularly and noticing these signs will help you determine when it’s time for sharpening.

Can I sharpen carbide lathe tools myself, or should I take them to a professional?

Sharpening carbide lathe tools can be done by both professionals and DIY enthusiasts. If you have the necessary tools and are comfortable with the process, you can sharpen them yourself. However, if you are unsure or inexperienced, it is recommended to seek the help of a professional to ensure the highest quality sharpening and to avoid damaging the tools.

What is the procedure for sharpening carbide lathe tools?

The procedure for sharpening carbide lathe tools involves grinding the edges of the tool on a diamond grinding wheel. The tool should be held securely in a tool rest and brought into contact with the grinding wheel at the correct angle. The grinding should be done evenly on both sides of the tool to maintain balance. After grinding, the tool should be honed to remove any burrs and achieve a sharp cutting edge.

Are there any safety precautions I need to take while sharpening carbide lathe tools?

Yes, there are several safety precautions that should be followed when sharpening carbide lathe tools. These include wearing safety goggles and gloves to protect your eyes and hands from sparks and abrasive particles. It is also important to ensure the stability of the tool and to avoid excessive pressure on the grinding wheel to prevent accidents. Additionally, sharpening should be done in a well-ventilated area to avoid inhaling harmful dust particles.

How often do carbide lathe tools need to be sharpened?

The frequency of sharpening carbide lathe tools depends on factors such as the type of material being cut, the cutting conditions, and the quality of the tool. In general, these tools can retain their sharpness for a long time, but it is recommended to inspect them regularly and sharpen as needed. Some professionals suggest sharpening after every few hours of use to maintain optimal cutting performance.

Video