Learn how to sharpen lathe tools without a grinder – Step-by-step guide

Do you enjoy woodworking but find that your lathe tools are becoming dull? Are you frustrated with the cost and hassle of using a grinder to sharpen them? Look no further – we have a step-by-step guide that will teach you how to sharpen your lathe tools without a grinder.

Sharpening lathe tools is essential for maintaining their effectiveness and longevity. Dull tools can lead to rough and uneven cuts, making it difficult to create precise and smooth finishes on your projects. While using a grinder is the traditional method for sharpening lathe tools, it requires expensive equipment and can be intimidating for beginners.

Fortunately, there are alternative methods that are both affordable and accessible to anyone, regardless of their skill level. In this step-by-step guide, we will walk you through the process of sharpening your lathe tools using simple hand tools and techniques. You’ll learn how to achieve razor-sharp edges that will enhance your woodworking experience and improve the quality of your finished projects.

Whether you are a seasoned woodworker looking for a new approach to sharpening your lathe tools or a beginner who wants to learn this essential skill, our guide will provide you with the knowledge and confidence to sharpen your lathe tools without a grinder. So, let’s dive in and unlock the secrets to keeping your lathe tools sharp and ready for your next woodworking project!

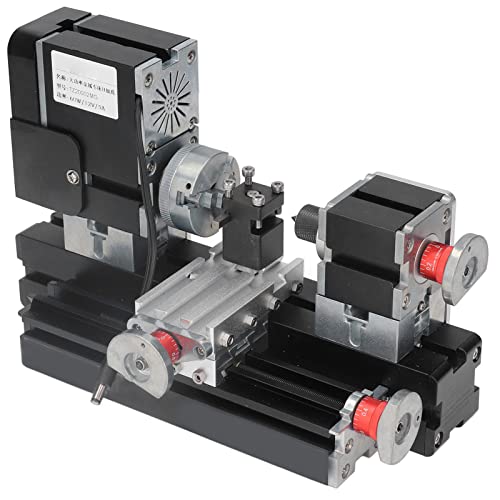

What are lathe tools and why do they need sharpening?

Lathe tools are cutting tools used in a lathe machine, which is a machining tool used for shaping and creating cylindrical objects. These tools are essential for the lathe machine to perform various operations such as turning, facing, drilling, knurling, parting, and threading.

Lathe tools are typically made from high-speed steel (HSS) or carbide materials. They have specific shapes and angles that allow them to cut through materials with precision and efficiency. However, over time and with continual use, lathe tools can become dull and lose their cutting edge.

Sharpening lathe tools is crucial for maintaining their cutting efficiency and performance. Dull tools not only result in poor-quality work but also require more effort and time to complete machining operations. By sharpening lathe tools, you can ensure smooth cutting, improved surface finish, and reduced machining time.

Regularly checking and sharpening lathe tools is essential to ensure the best results in machining operations. It is also cost-effective as it prolongs the tool’s lifespan and avoids the need for frequent tool replacement.

When sharpening lathe tools, it’s important to consider the material being machined and the desired outcome. Different materials and machining operations require specific tool geometry and angles. Therefore, understanding the proper techniques and angles for sharpening lathe tools is crucial.

The importance of sharpening lathe tools

Sharpening lathe tools is an essential skill for any woodturner. Dull tools not only make it difficult to achieve clean and accurate cuts, but they can also be dangerous to use.

Here are some reasons why sharpening your lathe tools is important:

- Improved performance: When your lathe tools are sharp, you can achieve smoother cuts and better finishes on your turned pieces. Sharp tools allow you to work more efficiently and produce higher-quality work.

- Enhanced safety: Dull tools require more force to cut through the wood, which can lead to slipping or catches. This increases the risk of accidents, such as the wood piece being thrown off the lathe or the tool being jerked out of your hands. Keeping your tools sharp reduces the likelihood of these incidents.

- Cost-effective: Sharpening your tools regularly can actually save you money in the long run. Instead of replacing dull tools, you can simply sharpen them, extending their lifespan and avoiding unnecessary expenses.

- Consistency: Sharp tools allow you to reproduce the same cuts and shapes consistently. This is especially important for projects that require precision and symmetry, such as bowls or spindles.

By regularly sharpening your lathe tools, you can ensure that your woodturning experience is more enjoyable, efficient, and safe. It’s a skill worth mastering for any woodturning enthusiast.

Step 1: Gather the necessary tools

Before you can begin sharpening your lathe tools without a grinder, you’ll need to gather the necessary tools and materials. Here is a list of items you’ll need:

- Honing guide: A honing guide will help you maintain the correct angle while sharpening your tools.

- Diamond file: A diamond file is a coarse file that can be used to reshape the bevel of your lathe tools.

- Sharpening stone: You’ll need a sharpening stone with different grits to achieve a polished edge on your tools.

- Paper towels or rags: These will be used to wipe down your tools and keep them clean throughout the sharpening process.

- Container of water: You’ll need water to lubricate the sharpening stone and to keep the tools cool during the sharpening process.

- Angle gauge: An angle gauge will help you determine the correct angle for sharpening your lathe tools.

Make sure you have all of these tools and materials on hand before proceeding to the next steps of the sharpening process. Having everything ready and within reach will make the process much smoother and easier.

What tools do you need to sharpen lathe tools without a grinder?

Sharpening lathe tools without a grinder requires a few essential tools to ensure proper sharpening. While a bench grinder is typically used for this task, it is possible to achieve good results by using other tools. The following list includes the necessary tools:

- Bench Vise: A bench vise is used to hold the lathe tool securely during the sharpening process. It provides stability and prevents any movement while working.

- Diamond Files: Diamond files are a crucial tool for sharpening lathe tools without a grinder. They come in various shapes and grits, allowing you to work on various types of lathe tools.

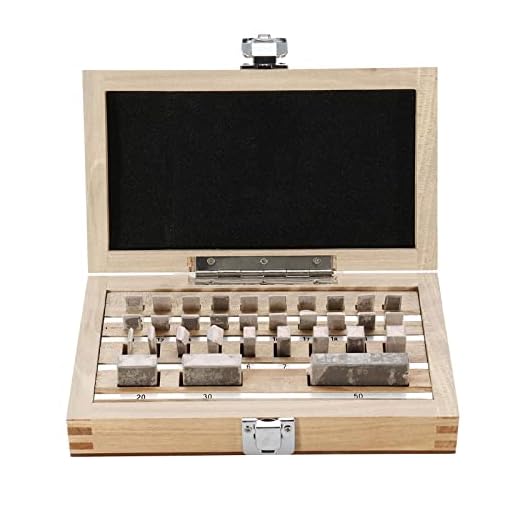

- Sharpening Stones: Sharpening stones are used for honing and refining the edges of the lathe tools. They come in different grits and can be made of various materials, such as oil stones or water stones.

- Honing Guide: A honing guide helps maintain a consistent angle while sharpening the lathe tools. It ensures that the tool edges are properly aligned and evenly sharpened.

- Oil or Water: Depending on the type of sharpening stone used, you may need oil or water for lubrication during the sharpening process. This lubrication helps to keep the tool cool and prevents the build-up of metal shavings.

- Ruler or Protractor: A ruler or protractor can be useful for measuring and maintaining the correct angles while sharpening the lathe tools. This ensures that the edges are sharpened at the desired angles.

- Cleaning Supplies: After sharpening the lathe tools, it is essential to clean them properly. You may need some cleaning supplies, such as a brush or cloth, to remove any metal shavings and debris.

By having these tools readily available, you will be equipped to sharpen your lathe tools without the need for a grinder. With practice and patience, you will be able to achieve sharp and effective lathe tools, allowing for precise and high-quality woodturning projects.

Step 2: Inspect the lathe tools

Before you begin sharpening your lathe tools, it’s important to inspect them for any damage or wear. This will help you determine the best course of action and ensure that you are working with tools that are in good condition.

Here are a few things you should look for during the inspection:

- Check for any chips or cracks: Carefully examine the cutting edge of each tool for any visible chips or cracks. These can affect the performance and longevity of the tool.

- Inspect the tool rest: Take a close look at the tool rest to ensure it is properly aligned and securely fastened. If it is loose or damaged, it may cause issues when sharpening.

- Examine the handles: Inspect the handles of your lathe tools for any signs of wear or damage. It’s important to have a good grip on the tools, so if the handles are cracked or slippery, consider replacing them.

- Check the overall condition: Take a step back and assess the general condition of your lathe tools. Look for any rust, pitting, or excessive wear. While some signs of use are expected, excessive damage may require more than just sharpening.

By thoroughly inspecting your lathe tools before sharpening, you can identify any potential issues and address them accordingly. This will help ensure that your tools are in optimal condition for sharpening and using them on the lathe.

How to identify if the lathe tools need sharpening?

Sharpening lathe tools is a crucial part of maintaining optimal cutting performance. Without sharp tools, the quality of your work can suffer, and you may experience difficulties in achieving accurate results. Here are some signs to help you identify if your lathe tools need sharpening:

- Poor cutting performance: If you notice that your lathe tools are not cutting as smoothly or efficiently as before, it may be a sign that they have become dull and need sharpening. Dull tools tend to produce rough finishes, tear-out, and require more force to make cuts.

- Burn marks on the wood: When a lathe tool is dull, it can cause friction and generate excessive heat, resulting in burn marks on the wood. If you notice burn marks during your turning process, it is an indication that your tools need sharpening.

- Increased effort needed: Dull tools require more effort to make cuts compared to sharp ones. If you find yourself applying more pressure or struggling to turn the wood smoothly, it may be a sign that your tools are in need of sharpening.

- Chattering or vibration: A dull tool can cause chattering or vibration during turning, making it challenging to create clean, smooth cuts. If you experience excessive vibration or chattering, it is likely that your lathe tools are dull and need sharpening.

- Difficulty in achieving desired shapes and details: When your tools are dull, it becomes difficult to achieve precise shapes and details in your turned pieces. Dull tools may not be able to remove wood efficiently or create clean curves, resulting in less control over the final outcome.

It is essential to regularly inspect your lathe tools for signs of dullness and sharpen them accordingly. By maintaining sharp tools, you can ensure the best cutting performance and achieve high-quality results in your woodturning projects.

Common problems with dull lathe tools

Dull lathe tools can cause a variety of problems in the woodworking process. Here are some common issues that can arise when your lathe tools are not properly sharpened:

- Poor cutting performance: Dull tools will struggle to cut cleanly through the wood, resulting in rough, uneven cuts.

- Tearing and splintering: As the tool loses its sharpness, it may start tearing and splintering the wood fibers instead of cleanly cutting through them. This can lead to a rough surface finish.

- Increased effort: When the cutting edge is dull, you will need to apply more force and pressure to make the tool cut. This can be tiring and can also increase the risk of accidents if the tool slips or jerks unexpectedly.

- Wandering and inaccurate cuts: Dull tools are more likely to wander off course, especially when turning long or intricate shapes. This can result in inaccurate cuts and ruin the intended design of your workpiece.

- Inconsistent results: A dull tool may produce inconsistent results, making it difficult to achieve the desired precision and symmetry in your turned pieces.

- Reduced tool life: If you continue to use dull tools, they will wear down faster and may become irreparably damaged. Sharpening your tools regularly helps extend their lifespan and maintain their cutting performance.

It is important to regularly check and sharpen your lathe tools to prevent these problems and ensure optimal performance in your woodworking projects.

Step 3: Choose the right sharpening method

When it comes to sharpening lathe tools without a grinder, there are several methods you can choose from. The method you choose will depend on your preferences, the tools you have available, and your skill level. Here are a few common methods to consider:

- Hand filing: This is the most basic and traditional method of sharpening lathe tools. It involves using a file to manually shape and sharpen the cutting edge of the tool. While it may take more time and effort, hand filing allows for greater control and precision.

- Honing with a sharpening stone: Honing involves using a sharpening stone to refine and polish the cutting edge of the tool. This method is best suited for maintaining the sharpness of the tool rather than reshaping it. It requires some practice and skill to achieve the desired results.

- Scraping with a burnisher: Scraping is a technique used to create a smooth finishing cut on wood. It involves using a burnisher to create a hook or burr on the cutting edge of the tool. This method is ideal for projects that require a highly polished finish.

- Using a jig or guide: Jigs and guides can be used to help maintain consistent angles while sharpening lathe tools. These tools provide support and guidance, making it easier to achieve a precise and uniform edge. Some jigs also offer the flexibility to sharpen different types of lathe tools.

It’s important to experiment with different sharpening methods and find the one that works best for you. Remember to take your time and practice regularly to improve your sharpening skills. It’s also a good idea to consult with experienced woodworkers or attend workshops to learn more about the different sharpening methods and techniques.

Popular methods for sharpening lathe tools without a grinder

While using a grinder is the most common way to sharpen lathe tools, there are other methods that can be used if you do not have access to one. Here are some popular methods for sharpening lathe tools without a grinder:

- Sharpening with a honing guide: One method is to use a honing guide to maintain the correct angle while sharpening the lathe tool. The honing guide holds the tool at the desired angle and allows you to run it along a sharpening stone or sandpaper to remove any burrs and achieve a sharp edge.

- Using a diamond card file: Another method involves using a diamond card file to sharpen lathe tools. The card file has a diamond-coated surface that can be used to sharpen the tool by rubbing it back and forth across the edge. This method is suitable for touch-ups and minor sharpening tasks.

- Using sandpaper: Sandpaper can also be used to sharpen lathe tools. You can wrap a piece of sandpaper around a dowel or other cylindrical object and use it to sharpen the tool by moving it in a circular motion. Start with coarse-grit sandpaper and gradually move to finer grits to achieve a polished edge.

- Sharpening with a file: If you have a file, you can use it to sharpen the lathe tool. Hold the file at the correct angle and push it along the edge of the tool in one direction. This method may require more effort and time compared to using a grinder, but it can still produce effective results.

It is important to note that these methods may not provide the same level of precision and speed as sharpening with a grinder. However, they can still be used to maintain the sharpness of lathe tools and ensure efficient turning on the lathe.

Pros and cons of each method

Using a grinder

- Pros:

- Fast and efficient sharpening process.

- Creates a professional and precise cutting edge.

- Allows for easy and accurate angle adjustments.

- Suitable for sharpening a wide range of lathe tools.

- Cons:

- Requires a specific tool – a grinder.

- Can be expensive to purchase and maintain.

- May require additional safety precautions due to high-speed grinding.

- Not accessible for those without a grinder or workshop.

Using sandpaper or a sharpening stone

- Pros:

- Minimal equipment required – sandpaper or sharpening stone.

- Lower cost compared to a grinder.

- Can achieve a sharp cutting edge with practice and patience.

- Portable and can be done anywhere.

- Cons:

- Slower and more time-consuming process compared to using a grinder.

- Difficult to maintain consistent angles without proper guidance.

- May not achieve the same precision as a grinder.

- Not suitable for sharpening certain types of lathe tools.

Using a honing guide

- Pros:

- Provides precise guidance for angle adjustment.

- Can be used with different sharpening techniques.

- Ensures consistent and accurate results.

- Improves the longevity of lathe tools by maintaining their correct shape.

- Cons:

- Requires the additional purchase of a honing guide.

- May take some time and practice to become comfortable with using the guide.

- Not suitable for all types of lathe tools.

- Requires incorporating additional sharpening steps into the process.

FAQ

Can I sharpen lathe tools without using a grinder?

Yes, you can sharpen lathe tools without using a grinder. In fact, there are several methods that you can use to achieve a sharp edge on your lathe tools, including using a honing guide, sandpaper, or a diamond file.

What is a honing guide and how does it work?

A honing guide is a tool that helps you maintain a consistent angle while sharpening your lathe tools. It typically consists of a guide that holds the tool at the desired angle and a mechanism that allows you to move the tool back and forth over the sharpening surface.

Can I use sandpaper to sharpen my lathe tools?

Yes, you can use sandpaper to sharpen your lathe tools. By wrapping sandpaper around a block of wood or a dowel, you can create a surface that will allow you to sharpen your tools. Start with a coarse grit and gradually work your way up to a finer grit for a polished edge.

What is a diamond file and how can I use it to sharpen my lathe tools?

A diamond file is a tool that is coated with industrial diamonds, making it extremely effective for sharpening. To use a diamond file, you simply rub it back and forth along the cutting edge of your lathe tool until it becomes sharp. It is a quick and efficient method for achieving a sharp edge.

Do I need any special tools or equipment to sharpen my lathe tools without a grinder?

No, you don’t necessarily need any special tools or equipment to sharpen your lathe tools without a grinder. The methods mentioned earlier, such as using a honing guide, sandpaper, or a diamond file, can all be done with basic household items or tools that you may already have on hand.

Is it difficult to sharpen lathe tools without a grinder?

Sharpening lathe tools without a grinder can be a bit more time-consuming and requires some practice, but it is not necessarily difficult. With the right technique and tools, you can achieve a sharp edge on your lathe tools and maintain the quality of your work.