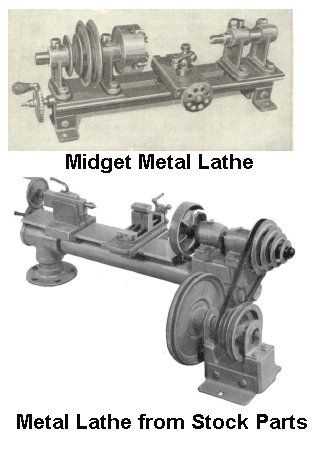

Learn How to Make a Metal Lathe from Scratch with this PDF Guide

If you have ever wanted to learn how to make a metal lathe from scratch, then this PDF guide is for you. Whether you are a DIY enthusiast or a professional machinist looking to expand your skills, this comprehensive guide will walk you through the process step by step.

Building your own metal lathe has many advantages. Not only does it save you money, but it also allows you to customize the lathe to suit your specific needs. From choosing the materials to assembling the components, this guide covers it all.

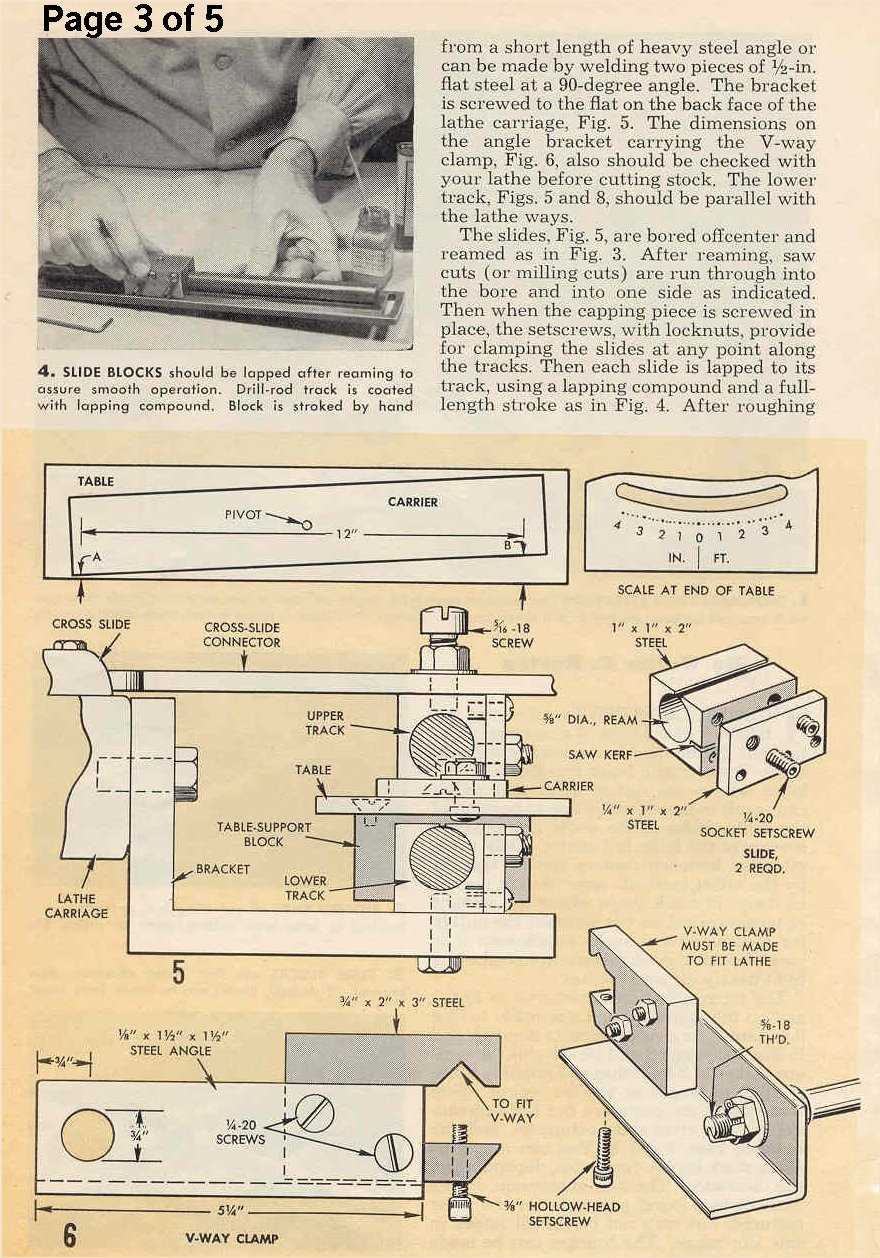

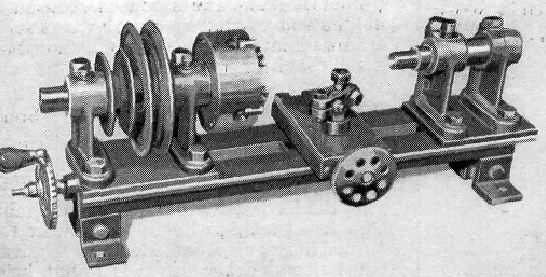

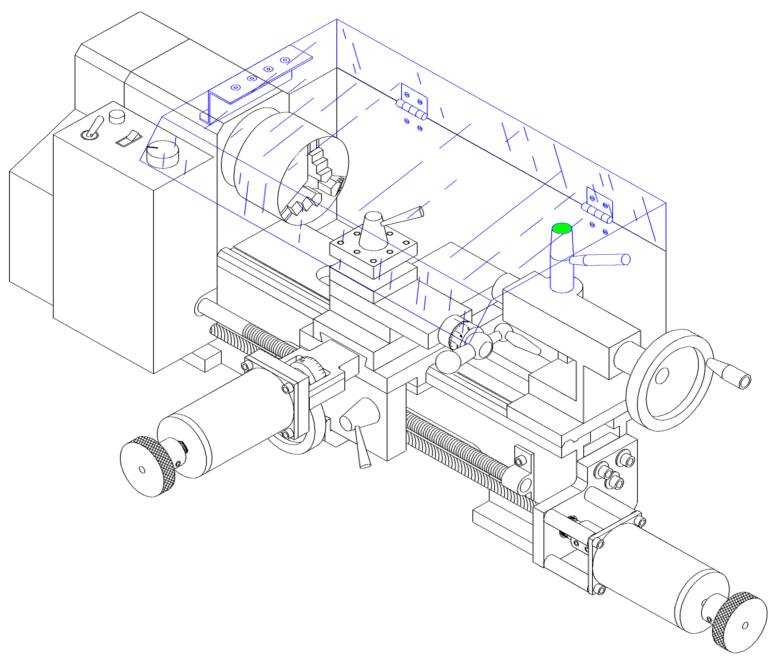

Inside the PDF, you will find detailed instructions, diagrams, and photographs that will help you visualize each step of the process. You will learn about the different types of lathes, the tools and materials needed, and the techniques required to make a functional and durable machine.

Whether you are a beginner or an experienced machinist, this guide will provide you with the knowledge and skills to build your own metal lathe. With patience and dedication, you can create a tool that will serve you for years to come.

So why wait? Start your journey to becoming a metal lathe maker today. Download this PDF guide and begin learning how to make a metal lathe from scratch. You’ll be amazed at what you can accomplish with your own two hands.

Step-by-Step Guide to Building a Metal Lathe from Scratch

1. Gather Materials and Tools

Before you start building your metal lathe, it is important to gather all the necessary materials and tools. Here is a list of the key items you will need:

- Steel bars of various sizes

- Bearings

- Gears and pulleys

- Threaded rods and nuts

- Motor

- Drill press and other machining tools

- Measuring tools (calipers, micrometers, etc.)

- Safety equipment (goggles, gloves, etc.)

2. Design and Planning

Before starting the construction process, it is essential to have a clear design and plan in place. This includes deciding on the dimensions, layout, and functionality of your metal lathe. Consider consulting online resources or books for reference designs.

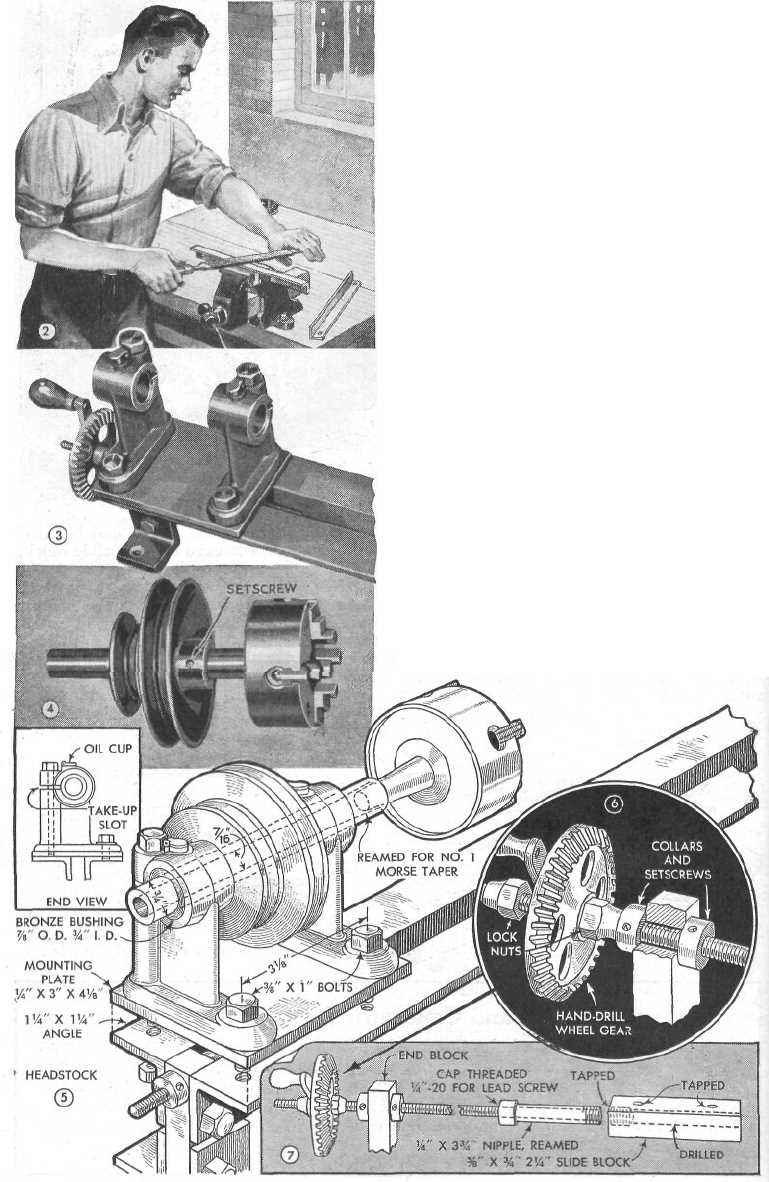

3. Frame Construction

Begin by constructing the frame of the metal lathe using the steel bars. Use precise measurements and ensure proper alignment to ensure stability and accuracy. Weld or bolt the bars together to create a solid and rigid frame.

4. Headstock Assembly

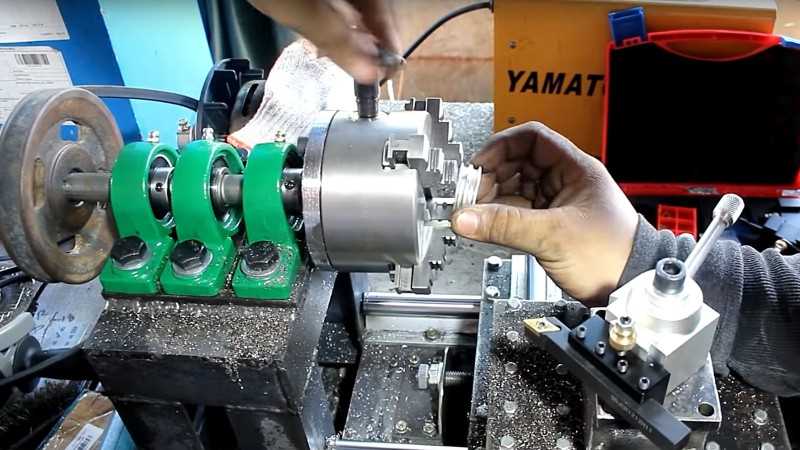

The headstock is a critical component of the metal lathe that houses the motor, gears, and spindle. Follow the design and instructions to assemble the headstock accurately. Pay attention to the alignment and proper fit of the components.

5. Tailstock Assembly

The tailstock is responsible for supporting the other end of the workpiece. Assemble the tailstock using the appropriate bearings and ensure smooth sliding motion along the lathe bed. Make any necessary adjustments to achieve precise alignment with the headstock.

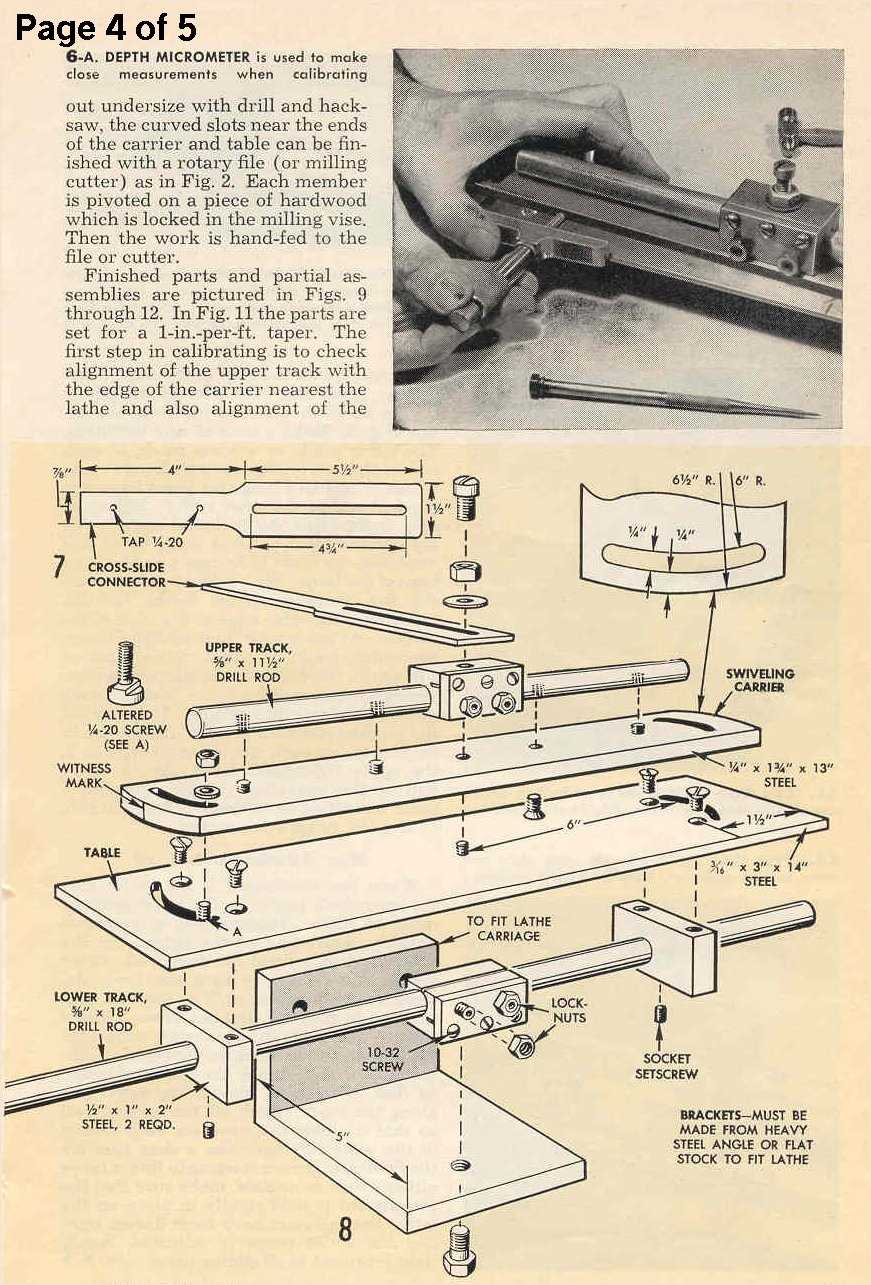

6. Tool Rest and Carriage Assembly

The tool rest and carriage are important for tool positioning and feed control. Construct and install the tool rest and carriage according to the design. Ensure smooth movement and proper alignment to facilitate precise metalworking operations.

7. Motor Installation

Mount the motor onto the lathe frame, ensuring proper alignment with the pulleys and gears. Connect the motor to the main spindle, ensuring smooth and efficient power transmission. Double-check the connections and secure them properly.

8. Testing and Calibration

Once the construction is complete, it is time to test the functionality and calibrate the metal lathe. Power on the lathe and check for smooth operation of the motor, spindle, and other moving components. Calibrate the lathe using measuring tools to ensure accurate machining operations.

9. Safety Precautions

Always prioritize safety when using or working on the metal lathe. Wear the necessary safety equipment, such as goggles and gloves, to protect yourself from flying debris or sharp edges. Follow all safety guidelines while operating the lathe to prevent accidents or injuries.

10. Practice and Skill Development

Building a metal lathe from scratch is an impressive feat, but it is equally important to develop the necessary skills and expertise to operate the lathe effectively. Practice using the lathe with simple projects and gradually move on to more complex metalworking tasks. Continuously improve your skills and seek guidance from experienced machinists to become proficient in using your homemade metal lathe.

By following these steps and putting in the necessary effort and dedication, you can successfully build a metal lathe from scratch and embark on a rewarding journey of metalworking.

Discover the Benefits of Building Your Own Lathe

Building your own lathe can be a rewarding and satisfying experience. It allows you to have complete control over the design and functionality of the machine, and provides numerous benefits that make it a worthwhile project to undertake. Below are some of the key benefits of building your own lathe:

1. Cost Savings

One of the main advantages of building your own lathe is the potential for cost savings. Purchasing a ready-made lathe can be expensive, especially if you are looking for a high-quality machine. By building your own lathe, you can save a significant amount of money by sourcing materials and components at a lower cost.

2. Customization

Building your own lathe gives you the freedom to customize the machine to your specific needs and preferences. You can select the size, features, and capabilities that are most important to you. Whether you require a larger or smaller lathe, or need specific attachments or accessories, building your own lathe allows you to tailor the machine to suit your projects.

3. Learning Experience

Building a lathe from scratch provides a valuable learning experience. It allows you to gain a deep understanding of the inner workings of a lathe and how it functions. You will learn about different components, machining principles, and the process of assembling and aligning the machine. This knowledge can be applied to future projects and can enhance your overall machining skills.

4. Sense of Achievement

Completing a project as complex as building your own lathe can give you a great sense of achievement. It is a challenging undertaking that requires planning, problem-solving, and perseverance. Seeing your lathe come together and successfully performing its intended tasks can be incredibly satisfying and boost your confidence in your DIY abilities.

5. Opportunity for Upgrades

When you build your own lathe, you have the flexibility to incorporate future upgrades and modifications as needed. As you gain more experience and identify areas for improvement, you can easily make adjustments to your lathe to enhance its performance. This provides you with a machine that can adapt and evolve alongside your skills and needs.

6. Community and Networking

Building your own lathe can connect you with a community of like-minded individuals who share your passion for DIY machining. You can join forums, attend workshops or events, and engage with other lathe builders to exchange ideas, tips, and knowledge. This creates opportunities for networking, learning from others, and fostering a sense of camaraderie.

Conclusion

The benefits of building your own lathe are numerous and wide-ranging. Not only does it offer cost savings and the opportunity for customization, but it also provides a valuable learning experience and a sense of achievement. Additionally, building your own lathe allows for future upgrades and enhances networking opportunities within the DIY machining community. So if you have the skills, tools, and determination, building your own lathe can be a highly rewarding endeavor.

Get Started with the Right Tools and Materials

If you want to create your own metal lathe from scratch, it’s important to have the right tools and materials on hand. Here are some essential items you’ll need to get started:

Tools:

- A drill press: A drill press is necessary for making accurate holes in metal and other materials. It allows for precise drilling and ensures that holes are aligned properly.

- A bench grinder: A bench grinder is useful for sharpening and shaping metal tools. It can be used to remove rust or imperfections from metal surfaces.

- A metal lathe tool set: A set of lathe tools is essential for cutting and shaping metal. These tools come in various sizes and shapes to accomplish different tasks.

- A welding machine: A welding machine is necessary for joining metal pieces together. It allows for strong and durable connections.

- Safety equipment: Safety goggles, gloves, and a welding helmet are all important for protecting yourself while working with metal and using power tools.

Materials:

- Steel: You’ll need steel in various sizes and shapes to construct the base, motor mount, and other components of the lathe.

- Screws and nuts: These are necessary for securing different parts of the lathe together.

- Bearings: Bearings ensure smooth rotation of the lathe’s components. You’ll need them for the spindle, tailstock, and other moving parts.

- A motor: A motor provides the power for the lathe. Choose one that is suitable for the size and weight of your lathe.

- Electrical wiring: You’ll need wires to connect the motor to a power source and control panel.

- Lubricants: Lubricants are necessary for reducing friction between moving parts. Use a high-quality lubricant to ensure smooth operation of the lathe.

Make sure you have all the necessary tools and materials before you begin building your metal lathe. Having everything on hand will ensure that you can work efficiently and avoid any unnecessary delays.

Learn the Fundamentals of Lathe Design and Mechanics

Understanding the design and mechanics of a metal lathe is essential for effectively using and maintaining the machine. Whether you are a beginner or an experienced machinist, having a solid grasp of the fundamentals will help you achieve better results and prolong the lifespan of the lathe.

Lathe Components

A lathe consists of several key components that work together to perform various operations. Some of the main components include:

- Bed: The bed is the main base of the lathe, providing stability and support.

- Headstock: The headstock houses the main spindle, which rotates and holds the workpiece.

- Tailstock: The tailstock is located on the opposite end of the lathe and provides additional support for long workpieces.

- Carriage: The carriage moves along the bed and holds the cutting tool, allowing it to move along the workpiece.

- Tool Post: The tool post holds the cutting tool in place and allows for precise adjustment.

Lathe Mechanics

The mechanics of a lathe involve the movement and interaction of its various components. Understanding these mechanics will help you perform operations and troubleshoot issues that may arise. Some key aspects of lathe mechanics include:

- Spindle Rotation: The rotation of the lathe spindle is controlled by the motor, allowing for the turning of the workpiece.

- Feed Rate: The feed rate determines how quickly the cutting tool moves along the workpiece. It can be adjusted to achieve different surface finishes.

- Cutting Tools: Various cutting tools, such as turning tools, boring tools, and threading tools, are used to shape and remove material from the workpiece.

- Tailstock Movement: The tailstock can be adjusted to accommodate different workpiece lengths and provide additional support during operations.

- Chuck and Collet: The chuck and collet are used to securely hold the workpiece in place, preventing it from rotating or moving during machining.

Importance of Understanding Lathe Design and Mechanics

Having a thorough understanding of lathe design and mechanics is vital for several reasons:

- Safe Operation: Understanding how the lathe components interact will help you operate the machine safely, minimizing the risk of accidents.

- Effective Tooling: By knowing the capabilities and limitations of the lathe, you can select and utilize the appropriate cutting tools for each operation, improving efficiency and precision.

- Troubleshooting: When issues arise, having a solid understanding of the lathe’s mechanics will enable you to troubleshoot problems, identify their causes, and implement solutions.

- Maintenance: Knowing how the lathe is designed and how its components function will help you properly maintain the machine, allowing for smoother operation and longer lifespan.

By learning the fundamentals of lathe design and mechanics, you will be well-equipped to make the most of your metal lathe and achieve high-quality machining results.

Master the Art of Machining and Assembly

Introduction

Machining and assembly are two critical skills in the world of metalworking. Whether you are a hobbyist or a professional machinist, having a deep understanding of these processes is essential for success. In this guide, we will delve into the art of machining and assembly, providing you with the knowledge and techniques needed to create precise and functional metal parts.

Basic Machining Techniques

Before diving into more complex machining operations, it is crucial to learn the basics. This includes understanding different cutting tools, such as lathe tools, end mills, and drills, and how they are used to shape the metal. You will also need to familiarize yourself with various machining operations, such as turning, drilling, and milling. Learning how to read and interpret technical drawings and measurements is another essential skill for a machinist.

Advanced Machining Techniques

Once you have mastered the basics, it’s time to move on to more advanced machining techniques. This includes learning how to work with more complex geometries, such as threads, gears, and splines. Moreover, you will explore the world of CNC machining, where computer-controlled machines are used to achieve high precision and intricate designs. Understanding CAM (Computer-Aided Manufacturing) software and G-code programming is crucial for this level of machining.

Assembly Techniques

Once you have completed machining your parts, the next step is assembly. This involves joining the different machined components together to create a functional assembly. There are various methods of assembly, including welding, brazing, bolting, and soldering. Each technique has its advantages and appropriate applications. In this guide, you will learn about the different assembly techniques and when to use them.

Troubleshooting and Problem Solving

As with any skilled trade, problems and challenges will inevitably arise during machining and assembly. Learning how to troubleshoot and solve issues is an essential part of mastering these arts. In this section, we will cover common problems you may encounter and provide practical solutions to overcome them. Whether it’s dealing with tool wear, dimensional inaccuracies, or assembly errors, you will learn how to diagnose and rectify these issues.

Conclusion

Machining and assembly are intricate arts that require practice, patience, and attention to detail. By mastering these skills, you will be able to create precise and functional metal parts that meet your specific requirements. Whether you are building a metal lathe from scratch or working on a complex machining project, the knowledge and techniques gained from this guide will serve as a solid foundation for your metalworking journey.

Gain Insight into Safety Precautions and Best Practices

Always Wear Proper Protective Equipment

When working with a metal lathe, it is crucial to wear the right protective equipment to ensure your safety. This includes safety goggles, a face shield, ear protection, and gloves. These items will protect you from flying metal chips, dust, and noise.

Secure Your Workspace

Before operating a metal lathe, it is essential to have a clean and organized workspace. Remove any clutter and ensure there are no loose objects near the lathe that could interfere with its operation. Make sure your lathe is securely anchored to the floor or workbench to prevent any movement while in use.

Inspect the Lathe Before Use

Before starting work, carefully inspect the lathe for any signs of damage or worn-out parts. Check the belts, gears, and chucks for any defects. Ensure that all controls are functioning correctly and lubricate the moving parts as needed.

Follow Proper Operating Procedures

One of the essential safety precautions is following the correct operating procedures for your metal lathe. Familiarize yourself with the manufacturer’s instructions and guidelines for safe operation. Be sure to adjust cutting tools and workpieces properly and avoid any sudden movements or excessive force.

Use Proper Cutting Techniques

When using a metal lathe, it is essential to use the proper cutting techniques to prevent accidents and ensure accuracy. Take your time when setting up the cutting tools and ensure they are properly sharpened. Avoid removing too much material at once and take frequent breaks to prevent overheating.

Always Turn off the Lathe When Not in Use

Never leave the lathe unattended while it is running. Always turn off the lathe and wait for it to come to a complete stop before leaving the machine. This will prevent any unintended movements or accidents while you are away.

Regularly Maintain and Clean Your Lathe

To ensure the safe and efficient operation of your metal lathe, it is crucial to regularly maintain and clean it. This includes regularly checking and replacing lubricants, cleaning the filter and cooling system, and removing any debris or metal chips from the machine and its surrounding area.

Seek Professional Assistance When Needed

If you are unsure about a specific operation or encounter any issues with your metal lathe, do not hesitate to seek professional assistance. Contact the manufacturer or an experienced machinist for guidance and support. It is better to ask for help rather than risking injury or damage to the machine.

Stay Informed About Safety Updates

Lastly, always stay informed about safety updates and best practices in operating a metal lathe. Make sure to keep up with any new safety guidelines or recommendations provided by the manufacturer and industry professionals. By staying informed, you can continuously improve your knowledge and ensure a safer working environment.

Explore Advanced Techniques and Customization Options

Once you have built a basic metal lathe using the instructions from the PDF guide, you will have a solid foundation to start exploring advanced techniques and customization options. With a metal lathe, you can create precise and intricate metal parts for various projects. Here are some techniques and options you can consider:

Metalworking Techniques

- Turning: With a metal lathe, you can perform turning operations, which involve rotating a workpiece against a cutting tool to remove excess material and create the desired shape. Experiment with different cutting tools and speeds to achieve the best results.

- Thread Cutting: Another useful technique is thread cutting. You can create external or internal threads on a workpiece using a lathe. This skill is particularly valuable for creating threaded holes or fasteners.

- Boring: Boring is a technique used to enlarge existing holes or create precise holes in metal workpieces. With a metal lathe, you can bore holes with accuracy and control, ensuring the perfect fit for screws, bolts, or other components.

Customization Options

In addition to exploring various metalworking techniques, you can also consider customizing your metal lathe to suit your specific needs and preferences. Here are some customization options you can explore:

- Tailstock Modification: The tailstock is an essential part of a metal lathe that provides support for long workpieces. You can modify the tailstock to add features like a built-in live center or a quick-release mechanism for easy adjustment.

- Cross-slide Improvement: The cross-slide allows for precise movement of the cutting tool in the horizontal direction. You can improve its functionality by adding a digital depth gauge or incorporating a ball bearing system for smoother movement.

- Motor Upgrade: Upgrading the motor of your metal lathe can improve its performance. Consider replacing the stock motor with a more powerful one or adding variable speed control for enhanced versatility.

By exploring advanced techniques and customization options, you can take your metal lathe to the next level and expand its capabilities. Whether you want to create intricate metal parts or tailor your lathe to meet specific requirements, there are endless possibilities for customization and improvement. So, don’t hesitate to experiment and push the boundaries of what your metal lathe can do.

Access a Free PDF Guide with Detailed Instructions

If you want to learn how to make a metal lathe from scratch, you’re in luck! We have put together a comprehensive PDF guide that provides you with detailed instructions on every step of the process. Whether you’re a beginner or an experienced hobbyist, this guide is designed to help you successfully build your own metal lathe.

The PDF guide covers everything from the tools and materials you’ll need to the step-by-step construction process. It includes clear and concise instructions, accompanied by detailed diagrams and photographs, to ensure that you understand each step and can easily follow along.

Here’s a quick overview of what you can expect to find in the guide:

- A list of tools and materials needed for the project

- Step-by-step construction instructions

- Guidance on safety precautions to take during construction

- Tips and tricks for troubleshooting common issues

- Useful resources for further learning and exploration

Whether you’re an aspiring machinist, a DIY enthusiast, or simply someone who enjoys learning new skills, this PDF guide is a valuable resource. It can help you develop the knowledge and confidence to create your own metal lathe and embark on new and exciting projects.

So, why wait? Access the free PDF guide today and start your journey towards building your own metal lathe.

Join a Community of DIY Metal Lathe Enthusiasts

If you are interested in learning how to make a metal lathe from scratch, you’re not alone. There is a vibrant community of DIY metal lathe enthusiasts who are eager to share their knowledge and experiences with others.

By joining this community, you will have the opportunity to connect with like-minded individuals who share your passion for metalworking. Whether you are a beginner just starting out or a seasoned DIYer, there is always something new to learn from others who have undertaken similar projects.

Benefits of Joining the DIY Metal Lathe Community

- Access to valuable resources: The DIY metal lathe community is a treasure trove of information. Members often share plans, schematics, and tutorials that can help you in your own metal lathe project. You can also find recommendations for tools, materials, and techniques.

- Ask questions and get advice: If you have a question or need advice, the community is there to help. Whether you’re facing a technical challenge or looking for suggestions to improve your lathe, you can count on the experience and knowledge of the community members to guide you.

- Inspiration and motivation: Seeing the projects of others can be a great source of inspiration. The DIY metal lathe community often shares their finished creations, which can spark new ideas and motivate you to keep pushing forward with your own lathe build.

- Building connections and sharing experiences: Being part of a community means you can connect with people who have similar interests. You can share your progress, ask for feedback, and celebrate successes together. It’s a great way to forge friendships and be part of a supportive network.

How to Join the DIY Metal Lathe Community

There are several ways to connect with the DIY metal lathe community:

- Online forums: Participate in online discussion forums dedicated to metalworking or specifically to DIY metal lathe projects. Some popular forums include MachinistWeb, Practical Machinist, and Home Model Engine Machinist. Introduce yourself, ask questions, and contribute to the conversations.

- Social media groups: Join metalworking or DIY communities on platforms like Facebook, Reddit, or Instagram. These groups often have members who are knowledgeable about metal lathes and can provide guidance or share their experiences.

- Local workshops or makerspaces: Check if there are any local workshops or makerspaces in your area that focus on metalworking. These spaces often host events, classes, or meetups where you can meet fellow DIYers and enthusiasts in person.

Remember to always be respectful and grateful for the help and knowledge that others in the community provide. Building a metal lathe from scratch is a challenging but rewarding journey, and being part of a community can make it even more enjoyable.

So, why wait? Join the DIY metal lathe community today and embark on an exciting adventure of building your own metal lathe!

FAQ

What is the purpose of a metal lathe?

A metal lathe is a machine tool that is used to shape or cut metal objects. It is commonly used in metalworking and machining operations.

Is it difficult to make a metal lathe from scratch?

Creating a metal lathe from scratch can be a challenging project, as it requires knowledge of mechanical engineering and access to tools and materials. However, with the right guidance and resources, it is possible for an experienced individual to construct their own metal lathe.

What are the advantages of making a metal lathe from scratch?

Building a metal lathe from scratch allows you to customize the machine according to your specific needs and preferences. Additionally, it can be a rewarding project that enhances your skills and knowledge in engineering and metalworking.

Do I need any special tools to build a metal lathe from scratch?

Yes, building a metal lathe from scratch requires various tools such as a lathe chuck, cutting tools, drill bits, tap and die sets, and measuring instruments. Additionally, welding or machining tools may be necessary for certain parts of the construction process.

Are there any safety considerations when building a metal lathe from scratch?

Yes, when constructing a metal lathe from scratch, it is important to prioritize safety. This includes wearing appropriate personal protective equipment, such as safety glasses and gloves, using tools and machinery correctly, and following safety protocols and guidelines throughout the construction process.