How to Safely Move a Lathe: Step-by-Step Guide

Moving a lathe can be a daunting task, as it is a heavy and delicate piece of machinery. However, with proper planning and equipment, you can safely relocate your lathe without causing any damage. In this step-by-step guide, we will walk you through the process of moving a lathe, from preparing the machine to transporting it to its new location.

Step 1: Prep your lathe

Before you start moving your lathe, it’s important to prepare it for the journey. Start by cleaning the machine thoroughly and removing any loose or detachable parts. Make sure to disconnect any power cords and remove any fluids or oil that may be present.

Step 2: Gather the necessary equipment

To safely move your lathe, you will need several pieces of equipment. This includes a heavy-duty dolly or pallet jack, straps or ropes to secure the lathe, packing materials such as moving blankets or bubble wrap, and a truck or trailer for transportation.

Step 3: Secure the lathe to the dolly or pallet jack

Once you have all the necessary equipment, carefully lift the lathe onto the dolly or pallet jack. Use straps or ropes to secure the lathe to the equipment, making sure it is stable and immobile. This will prevent the lathe from shifting or falling during transportation.

Step 4: Protect the lathe with packing materials

To prevent any damage to your lathe during transportation, cover it with moving blankets or bubble wrap. This will provide an extra layer of protection against bumps and vibrations. Make sure to secure the packing materials tightly around the lathe to keep them in place.

Step 5: Transport the lathe to its new location

With your lathe properly secured and protected, carefully load it onto a truck or trailer. Make sure the lathe is positioned vertically and is well balanced to avoid any tipping or tilting. During transportation, drive cautiously and avoid any sudden stops or turns that may cause the lathe to shift.

By following these steps, you can safely move your lathe to its new location without causing any damage. Remember to take your time, use proper equipment, and seek assistance if needed. Keeping your lathe safe during the moving process will ensure its longevity and performance in the years to come.

Preparation for Lathe Moving: Tools and Equipment

1. Safety Gear

Before you start moving a lathe, it is crucial to ensure that you have the necessary safety gear to protect yourself and prevent any accidents. The following safety gear is recommended:

- Protective gloves

- Protective eyewear

- Steel-toed boots

- Ear protection

2. Moving Straps or Ratchet Straps

Moving straps or ratchet straps are essential tools for securing the lathe during the moving process. These straps can be used to hold the lathe in place and prevent it from shifting or falling during transportation. Make sure to choose straps that are durable and have a high weight capacity.

3. Dollies or Hand Trucks

Dollies or hand trucks are indispensable equipment when it comes to moving heavy machinery like a lathe. These devices are designed to provide stability and ease of movement. Choose dollies or hand trucks with sturdy construction and strong wheels that can handle the weight of the lathe.

4. Moving Blankets or Padding Material

Moving blankets or padding material is important for protecting the lathe from scratches, dents, and other damages during transit. Wrap the lathe with moving blankets or use padding material to provide cushioning and prevent any impact or vibration that could potentially harm the lathe.

5. Straps or Chains for Secure Fastening

In addition to moving straps or ratchet straps, it is advisable to have additional straps or chains to ensure secure fastening of the lathe during transportation. These straps or chains can be used to secure the lathe to the dollies or hand trucks and to prevent any movement or displacement.

6. Tools for Unmounting the Lathe

Depending on the configuration and design of your lathe, you may need specific tools to unmount certain parts or components before moving it. Some common tools that may be required include wrenches, screwdrivers, and socket sets. Consult the lathe’s user manual or manufacturer’s guidelines to determine the necessary tools.

7. Protective Coverings

If you are moving the lathe outdoors or in unfavorable weather conditions, it is essential to have protective coverings such as tarps or plastic sheets. These coverings will shield the lathe from moisture, dust, and other elements that could potentially damage the machine.

8. Personal Lifting Equipment

If the lathe is too heavy to be moved manually, you may need personal lifting equipment such as a forklift or a crane. Make sure to have the appropriate lifting equipment available and ensure that the operators are properly trained to use them safely.

9. Trolley Jack or Lifting Bars

In some cases, you may need a trolley jack or lifting bars to elevate the lathe slightly off the ground for easier maneuvering or to fit it onto the dollies or hand trucks. These tools can provide the necessary leverage and support during the lifting process.

10. Cleaning Supplies

Before moving the lathe, it is advisable to clean it thoroughly to remove any debris or dirt that could potentially interfere with its functionality or cause damage during transportation. Prepare cleaning supplies such as rags, brushes, and appropriate cleaning solutions to ensure a clean and smooth moving process.

11. Labels and Identification Tags

To keep track of the various parts and components of the lathe during the moving process, it is helpful to use labels and identification tags. These labels can be placed on the lathe, its parts, and the packaging materials to ensure proper identification and avoid any confusion or loss of parts.

12. Operator’s Manual

Always keep the operator’s manual of the lathe handy during the moving process. The manual can provide essential instructions, guidelines, and safety precautions specific to your lathe model. Make sure to consult the manual whenever necessary.

By using the appropriate tools and equipment listed above, you can ensure a safe and successful move for your lathe.

Measuring and Assessing the Lathe

Before you begin the process of moving a lathe, it’s important to measure and assess the machine to ensure that it can be safely relocated. Taking these steps will help prevent damage to the lathe and ensure a smooth moving process.

1. Gather the necessary tools

Before you start measuring the lathe, gather the following tools:

- Tape measure

- Level

- Notebook and pen

2. Measure the dimensions

Using a tape measure, measure the dimensions of the lathe. This includes the length, width, and height of the machine. Write down these measurements in your notebook.

3. Assess the weight

Determine the weight of the lathe by consulting the manufacturer’s documentation or by using a weight scale. Knowing the weight will help you determine the appropriate equipment needed for lifting and transporting the lathe.

4. Check for any special considerations

Inspect the lathe for any special considerations that may affect the moving process. This may include fragile components, sensitive wiring, or any other specific instructions provided by the manufacturer or previous movers.

5. Evaluate the accessibility

Assess the path and location where the lathe needs to be moved. Take note of any obstacles, narrow doorways, or staircases that may require additional planning or equipment to navigate.

6. Consider the environment

Take into account the environment where the lathe is currently located and where it will be moved to. This includes factors such as temperature, humidity, and potential vibrations or impact during transportation.

7. Consult a professional if necessary

If you have any doubts or concerns about moving the lathe safely, consider consulting a professional rigging or machinery moving service. They will have the expertise and equipment needed to handle the task properly.

By measuring and assessing the lathe before moving it, you can ensure that the relocation process goes smoothly and minimize the risk of damage to the machine. This step-by-step guide will help you prioritize safety and efficiency when moving a lathe.

Safety Precautions

Before moving a lathe, it is important to take several safety precautions to ensure the safety of yourself and others. Here are some important safety measures to follow:

1. Wear Personal Protective Equipment (PPE)

Always wear appropriate personal protective equipment, such as safety goggles, gloves, and steel-toed boots, when handling heavy machinery like a lathe. This will protect you from potential injuries caused by flying debris, sharp edges, or heavy objects.

2. Disconnect Power Source

Prior to moving the lathe, make sure to disconnect its power source and unplug it. This will prevent any accidental starting of the machine during the moving process, which could be dangerous.

3. Secure Loose Parts

Before moving the lathe, secure any loose parts or accessories, such as chuck keys or tailstock centers. Loose parts can become a hazard if they fall off during transportation or shift unexpectedly.

4. Use Proper Lifting Techniques

When lifting the lathe, use proper lifting techniques to avoid straining your back or causing other injuries. Lift with your legs and not your back, and use appropriate lifting equipment, such as a forklift or crane, if necessary.

5. Clear the Pathway

Ensure that the pathway is clear from any obstructions or tripping hazards. Clear away any clutter, debris, or cables that could cause accidents or make it difficult to move the lathe safely.

6. Assess the Weight Capacity of the Equipment

Before proceeding with the move, make sure that the equipment being used to transport the lathe, such as a pallet jack or dolly, can safely handle the weight of the lathe. Overloading the equipment can lead to accidents and damage to the machine.

7. Teamwork

When moving a lathe, it is important to have a team of trained individuals working together to ensure the safe and successful relocation. Having multiple people helps distribute the weight and allows for better coordination during the move.

8. Follow Manufacturer’s Guidelines

Always consult the lathe manufacturer’s guidelines or user manual for specific instructions on how to safely move the lathe. Different lathes may have unique requirements or considerations that need to be followed.

Disconnecting and Securing the Lathe

Before moving a lathe, it is important to disconnect and secure it properly to prevent any damage or accidents during transportation. Follow these steps to disconnect and secure your lathe:

- Turn off the lathe and unplug it from the power source to ensure your safety during the disconnection process.

- Inspect the lathe thoroughly to identify any loose parts, tools, or accessories that may need to be removed or secured separately.

- Remove any attached accessories or tooling, such as chucks or tool holders, according to the manufacturer’s instructions.

- Secure all loose or detachable parts, such as tailstocks or steady rests, using appropriate padding and straps to prevent them from moving or getting damaged during transportation.

- Lower the lathe’s tool rest and tailstock to their lowest positions and lock them securely in place using the locking mechanisms provided.

- If your lathe has a motor, disconnect it from the lathe and secure it separately. This will help distribute the weight more evenly and reduce the risk of damage to the lathe or motor.

- Use a dolly or lifting equipment to carefully lift the lathe onto a sturdy wooden pallet or a platform with wheels that can support its weight.

- Once the lathe is securely positioned on the pallet or platform, use straps or ropes to fasten it in place. Make sure to tighten the straps firmly but not excessively, as this could cause damage.

- If the lathe has any loose cables or hoses, secure them to the lathe or bundle them together using zip ties or straps to prevent them from tangling or getting damaged.

- Attach a clear and visible “Do Not Tilt” sign to the lathe to alert anyone handling it during the moving process.

- Double-check all the connections, straps, and fastenings to ensure that the lathe is securely and safely positioned for transportation.

By following these steps, you can disconnect and secure your lathe properly, reducing the risk of damage and ensuring a smoother and safer moving process.

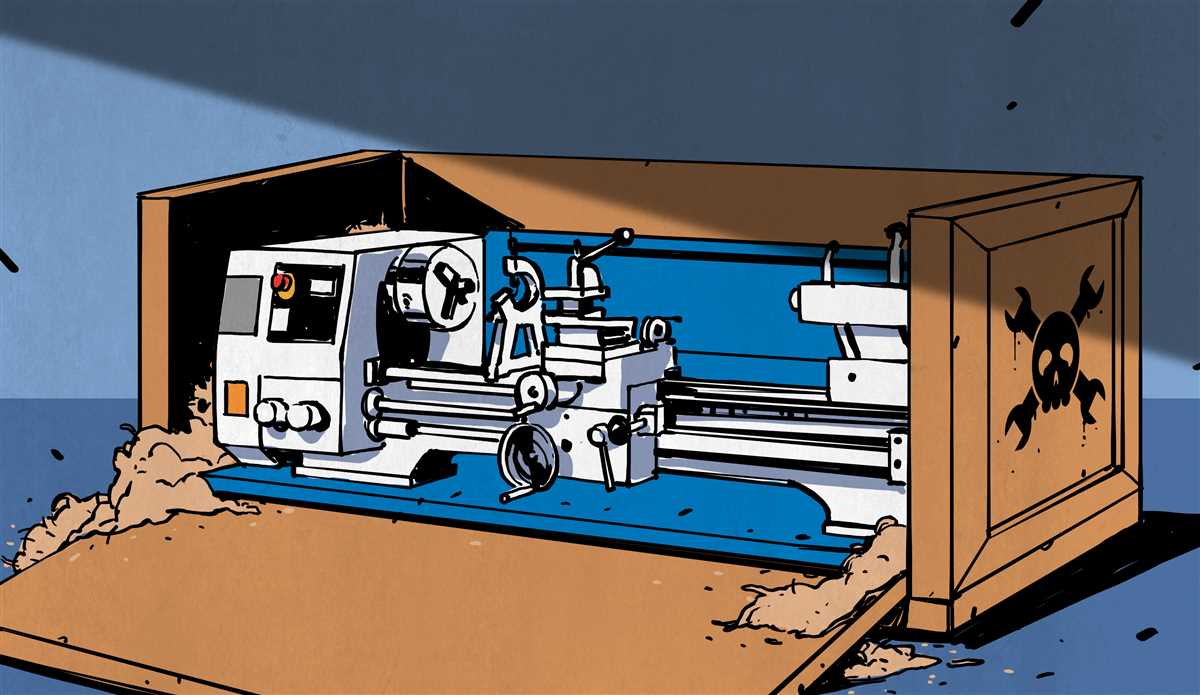

Disassembling the Lathe if Necessary

If your lathe is too large or heavy to move in one piece, you may need to disassemble it before moving it. Here are the steps to follow:

1. Consult the User Manual

Before you begin disassembling the lathe, consult the user manual for specific instructions. The manual will provide guidance on which parts can be safely removed and how to disconnect any electrical or mechanical components.

2. Gather the Necessary Tools

Make sure you have all the necessary tools on hand before you start disassembling the lathe. This may include wrenches, screwdrivers, pliers, and other basic hand tools. Additionally, you may need specialized tools based on the specific make and model of your lathe.

3. Disconnect the Power

Prior to disassembling the lathe, it is essential to disconnect the power supply. This will help prevent any electrical accidents or damage to the lathe during the disassembly process. Unplug the lathe from the wall outlet and remove any batteries if applicable.

4. Remove Accessories and Attachments

Begin by removing any accessories or attachments that are detachable from the lathe, such as chucks, tool rests, or tailstocks. These parts are typically secured using screws or bolts, so use the appropriate tools to loosen and remove them.

5. Remove the Tailstock

If your lathe has a tailstock, you will need to remove it next. Loosen the locking mechanism and slide the tailstock away from the bed of the lathe. Place it in a secure location to prevent damage during the move.

6. Disassemble the Bed and Headstock

The bed and headstock are typically the heaviest parts of the lathe. To disassemble them, start by loosening any bolts or screws that hold them together. Depending on the design of your lathe, you may need to remove the motor or other components before separating the bed from the headstock.

7. Secure and Label Small Parts

As you remove smaller parts from the lathe, such as gears, pulleys, or handles, make sure to secure them in separate containers or bags. Additionally, label each container or bag with the corresponding part name and make sure to keep them organized for easier reassembly later.

8. Store and Transport the Disassembled Parts

Maintain the safety of the disassembled parts by securely packaging them for transport. Use padding, packing materials, or specialized cases to protect fragile or sensitive components. Additionally, make sure to load the parts into a suitable vehicle for transport to their new location.

Note: If you are unsure about the disassembly process or lack the necessary skills and tools, it is recommended to hire a professional machinery mover or consult with a qualified technician.

Preparing the Transport Vehicle

Before moving your lathe, it’s crucial to properly prepare the transport vehicle to ensure a secure and safe relocation. Follow these steps to prepare the transport vehicle:

1. Assess the size and weight of your lathe

Measure the dimensions and weight of your lathe to determine the appropriate size and capacity of the transport vehicle. Consider factors such as the length, width, height, and weight of the lathe to ensure that the vehicle can accommodate it.

2. Select a suitable transport vehicle

Choose a transport vehicle that can comfortably accommodate the size and weight of your lathe. Options may include a flatbed truck, a box truck, or a trailer. Ensure that the vehicle has a hydraulic lift or loading ramp for easy loading and unloading.

3. Secure the lathe on the transport vehicle

Use straps, chains, or ropes to secure the lathe firmly to the transport vehicle. Ensure that the lathe is centered and balanced on the vehicle to prevent any shifting or tilting during transportation. Use padding or cushioning materials to protect the lathe from scratches or bumps.

4. Test the stability of the lathe

Once the lathe is secured on the transport vehicle, check its stability by gently rocking or shaking the vehicle. If the lathe remains stable and does not shift or move, it is properly secured. Make any necessary adjustments to the straps or supports if needed.

5. Clear the transport vehicle’s path

Ensure that the path and surroundings of the transport vehicle are clear and free from obstacles. This includes removing any debris, rocks, or other objects that may cause issues during transportation.

6. Plan the route

Before starting the journey, plan the route from the current location to the desired destination. Consider factors such as road conditions, clearance heights, weight limits, and any potential obstacles that may be encountered along the way.

By properly preparing the transport vehicle, you can ensure a smooth and secure relocation of your lathe. Follow these steps to minimize the risk of damage or accidents during transportation.

Loading and Securing the Lathe

Once you have prepared the lathe for transport and have a safe location to load it onto, it’s time to carefully load and secure the lathe. Follow these steps to ensure a secure and safe loading process:

1. Gather the necessary equipment

Before you begin, gather the following equipment:

- Heavy-duty moving straps or ropes

- Furniture dollies or a pallet jack

- Plywood sheets or sturdy wooden boards

- Bungee cords or ratchet straps

- Moving blankets or padding

- Packing tape

2. Position the loading area

Choose a flat and stable surface for loading the lathe. It should be able to support the weight of the lathe and allow for easy maneuvering.

3. Place the plywood sheets or wooden boards

Position the plywood sheets or boards on the ground to create a stable base for the lathe. Ensure they are secured tightly together and large enough to accommodate the size of the lathe.

4. Position the furniture dollies or pallet jack

If using furniture dollies, place them near the plywood sheets or boards. Make sure they are sturdy and have a weight capacity that can support the lathe. Attach the lathe securely to the dollies using straps or ropes.

If using a pallet jack, position it near the plywood sheets or boards. Place the lathe on the pallet jack and secure it with straps or ropes.

5. Load the lathe onto the dollies or pallet jack

With the help of another person, carefully lift the lathe and place it onto the dollies or pallet jack. Make sure it is centered and secure on the equipment.

6. Secure the lathe with straps or ropes

Using heavy-duty moving straps or ropes, secure the lathe to the dollies or pallet jack. Make sure the straps or ropes are tight and fasten them securely to prevent any movement during transport.

7. Protect the lathe with blankets or padding

Wrap the lathe with moving blankets or padding to protect it from any bumps or scratches during transit. Secure the blankets or padding with packing tape.

8. Inspect and test the securement

Before moving the lathe, thoroughly inspect the straps, ropes, and blankets to ensure they are securely fastened and will not come loose during transport. Give the lathe a gentle shake to check for any movement.

9. Enlist professional help if necessary

If the lathe is exceptionally heavy or you are unsure about the loading process, it is recommended to enlist the help of professional movers or machinery transport services. They have the experience and equipment necessary to ensure a safe and secure move.

By following these steps, you can safely load and secure your lathe for transportation to its new location. Remember to drive cautiously and avoid any sudden movements or sharp turns that may cause the lathe to shift or become unstable.

Unloading and Reassembling the Lathe

1. Position the Equipment

When unloading the lathe from the truck or trailer, carefully position it in the area where you plan to reassemble it. Make sure the space is large enough to accommodate the lathe and provides enough room for you to work around it.

2. Gather the Necessary Tools

Before beginning the reassembly process, gather all the necessary tools you will need. This may include wrenches, screwdrivers, a level, and any other tools specific to your lathe model. Having all the tools on hand will save time and ensure you have everything you need to complete the task.

3. Carefully Remove Packaging

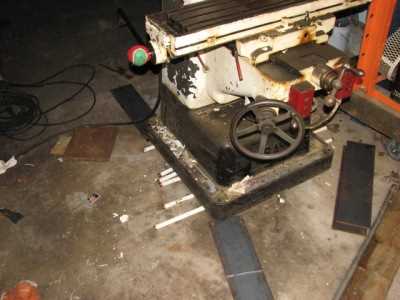

Remove any packaging or protective materials from the lathe, taking care not to damage any components in the process. Use a utility knife or scissors to carefully cut away any plastic or cardboard that may be covering the machine.

4. Inspect the Lathe

Once the packaging is removed, inspect the lathe for any signs of damage or loose parts. Look for any obvious signs of mishandling during transit. If you notice any damage, document it and contact the shipping company as soon as possible.

5. Clean and Lubricate

Before reassembling the lathe, take the time to clean and lubricate any parts that may have collected dust or debris during transport. Use a mild cleaning solution and a soft cloth to gently remove any dirt or grime. Apply a light coat of lubricant to moving parts to ensure smooth operation.

6. Reassemble the Lathe

Follow the manufacturer’s instructions or refer to the lathe’s user manual to reassemble the machine. Start with the base and work your way up, attaching each component securely. Use the tools you gathered earlier to tighten screws and bolts, ensuring everything is properly aligned.

7. Level the Lathe

Once the lathe is fully reassembled, use a level to ensure it is sitting flat and level on the floor. Adjust the leveling feet as necessary to achieve a stable and balanced position. A level lathe will perform better and minimize the risk of vibrations during operation.

8. Test the Lathe

After reassembling and leveling the lathe, test its functionality to ensure everything is working properly. Turn on the machine and check for any unusual noises, vibrations, or issues with the controls. Make any necessary adjustments before proceeding with any future use of the lathe.

9. Dispose of Packaging

Dispose of the packaging materials properly, recycling or discarding them according to your local regulations. Keeping a clean and organized workspace will make future use of the lathe more efficient and safer.

FAQ

What tools and materials do I need to move a lathe?

To safely move a lathe, you will need several tools and materials, including heavy-duty straps or ropes, a dolly or hand truck, wooden blocks, a moving blanket or bubble wrap, and possibly a lifting device or hoist if the lathe is particularly heavy.

How should I prepare my lathe for transportation?

Before moving your lathe, it is important to properly prepare it for transportation. Start by cleaning the lathe and removing any accessories or attachments. Secure all loose parts and covers to prevent them from being damaged during the move. It is also advisable to disconnect and secure any electrical or pneumatic cables.

Can I move the lathe by myself, or do I need help?

The answer to this question depends on the size and weight of your lathe. If it is a small, lightweight lathe, you may be able to move it by yourself with the help of a dolly or hand truck. However, if the lathe is large and heavy, it is highly recommended to have at least one or two people to assist you in the process. This will help ensure the safety of both you and the lathe.

How should I lift the lathe onto a dolly or hand truck?

Lifting a lathe onto a dolly or hand truck requires caution and proper technique to avoid injury. It is best to use a lifting device or hoist if possible, especially for heavy lathes. Place wooden blocks under the lathe to elevate it slightly and create clearance for the dolly or hand truck. Carefully lift one end of the lathe at a time, using straps or ropes to secure it to the dolly. Take small, deliberate steps while lifting to maintain control and prevent accidents.

How should I secure the lathe during transportation?

Securing the lathe during transportation is crucial to prevent damage. Start by placing a moving blanket or bubble wrap around the lathe to provide a layer of protection. Use heavy-duty straps or ropes to secure the lathe to the dolly or hand truck. Make sure the lathe is securely fastened and does not wobble or move during transportation. If needed, use additional straps or ropes to secure the lathe in the moving vehicle to prevent shifting.

What precautions should I take while moving a lathe?

When moving a lathe, it is important to take several precautions to ensure safety and prevent damage. Always wear protective gloves and footwear to protect yourself from potential injuries. Use proper lifting techniques and avoid overexerting yourself. Take your time and move slowly to maintain control and prevent accidents. Finally, follow all manufacturer guidelines and recommendations for moving the specific lathe model.

Video