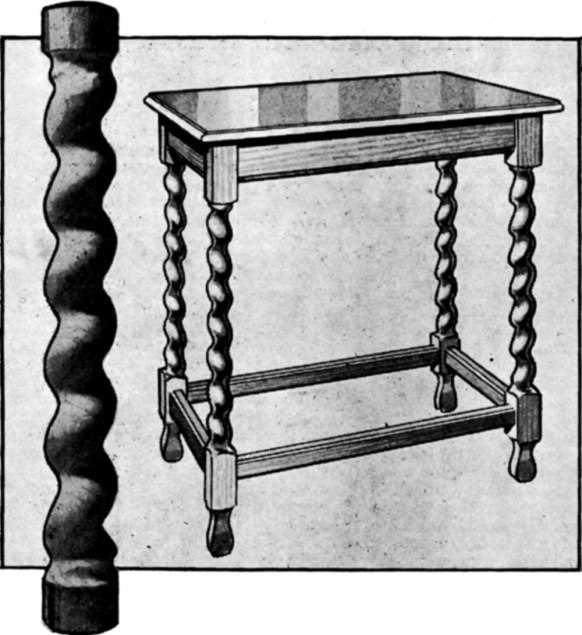

DIY: How to Make Round Table Legs Without a Lathe

Creating your own furniture can be a rewarding experience, allowing you to customize your home decor and showcase your craftsmanship. One common challenge when making furniture is creating round table legs, especially if you don’t have access to a lathe. However, with a few simple tools and techniques, you can achieve beautifully rounded legs for your table project.

One method to make round table legs without a lathe is by using a technique called “turning by hand.” This method involves shaping the legs manually using handheld tools such as rasps, files, sandpapers, and a lot of patience. While it might take a bit more time and effort, the end result can be just as impressive as lathe-turned legs.

Start by selecting the wood for your table legs. Hardwoods like oak, walnut, or maple are ideal as they are sturdy and durable. Mark the length and thickness you want for your legs and cut the wood to size using a saw. Next, use a square to mark a line down the center of each leg’s face.

Once you have your square line marked, begin shaping the legs by removing material gradually. This can be done by using a rasp or a coarse file to shape the initial curves. Then, switch to finer files and sandpaper to refine the shape further. Take your time and make sure to work symmetrically on all sides to maintain a uniform shape.

As you approach the desired shape, use a chisel or a carving knife to smooth out any rough spots and add small decorative details. Finally, finish the legs with a few coats of varnish or paint of your choice to protect the wood and enhance its appearance. With some practice and patience, you can create beautifully rounded table legs without a lathe.

Safety Precautions for DIY Projects

1. Wear Protective Gear

Before starting any DIY project, it is important to wear appropriate protective gear. This includes safety goggles, gloves, and a dust mask. Protective gear will help prevent injuries to your eyes, hands, and respiratory system.

2. Use Proper Tools and Equipment

Make sure to use the correct tools and equipment for the task at hand. Using the wrong tools can lead to accidents or damage to the project. If you are unsure about the tools needed, consult a professional or do research before starting.

3. Follow Instructions and Guidelines

Read and follow all instructions and guidelines provided by the manufacturer of the materials or tools you are using. This will ensure that you use them safely and properly. Skipping or incorrectly following instructions can lead to accidents or poor results.

4. Work in a Well-Ventilated Area

When working with chemicals, paints, or any materials that produce fumes or dust, be sure to work in a well-ventilated area. This will help prevent respiratory issues and ensure that you are not inhaling harmful substances.

5. Maintain a Clean and Organized Workspace

A cluttered and messy workspace can be hazardous. Keep your workspace clean and organized to reduce the risk of accidents and injuries. Store tools and materials properly when not in use, and clean up any spills or debris immediately.

6. Take Breaks and Rest When Needed

DIY projects can be physically demanding. Remember to take regular breaks and rest when needed. Pushing yourself too hard and not taking breaks can lead to fatigue, which can increase the risk of accidents.

7. Keep Children and Pets Away

Ensure that children and pets are kept away from the area where you are working. DIY projects often involve sharp tools, chemicals, and other hazards that can pose a danger to curious children or pets. Create a safe environment by restricting access to the project area.

8. Be Mindful of Electrical Safety

If your DIY project involves electrical work, take the necessary precautions to ensure electrical safety. Turn off the power to the area you are working on, use insulated tools, and always consult a professional if you are unsure about any electrical work.

9. Know Your Limits

It is important to know your limits and not take on projects that are beyond your skill level or knowledge. If a project requires expertise or specialized tools that you do not have, consider hiring a professional to ensure the task is completed safely.

10. Know What to Do in Case of an Emergency

Finally, familiarize yourself with basic first aid procedures and have an emergency plan in place. Accidents can happen, so knowing what to do in case of an emergency can make a difference in the outcome. Keep a first aid kit handy and know how to use its contents.

Conclusion

By following these safety precautions, you can minimize the risks associated with DIY projects and ensure a safe working environment. Remember, safety should always be a top priority when working on any DIY project.

Choosing the Right Wood for Round Table Legs

When it comes to making round table legs without a lathe, choosing the right wood is essential. The wood you select will determine the overall strength, appearance, and durability of your table legs. Here are a few factors to consider when choosing the right wood for your project:

1. Hardwood vs. Softwood

The first decision to make is whether you want to use hardwood or softwood for your table legs. Hardwoods, such as oak, maple, or cherry, are generally more durable and resistant to wear and tear. Softwoods, like pine or cedar, are often cheaper and easier to work with but may be less durable in the long run.

2. Grain Pattern

Consider the grain pattern of the wood you choose. Straight-grained woods, like maple, can provide a sleek and modern look, while woods with prominent grain patterns, such as oak or walnut, can add character and visual interest to your table legs.

3. Stability and Strength

It’s important to select a wood species that is stable and has sufficient strength to bear the weight of the table. If you plan on using the table for heavy objects or as a dining table, opt for a dense and strong wood species like oak or maple.

4. Availability and Price

Consider the availability and price of the wood species you are considering. Some hardwoods can be expensive and may not be readily available in your area. Softwoods like pine are often more affordable and easier to find.

5. Finishing Options

Think about the finishing options that are available for the wood species you choose. Some woods, like cherry or mahogany, have beautiful natural finishes and may only require a clear varnish to enhance their beauty. Other woods, like pine, may require staining or painting to achieve the desired look.

Conclusion

Choosing the right wood for your round table legs is crucial for the overall success of your DIY project. Consider the durability, grain pattern, stability, availability, price, and finishing options of different wood species to select the perfect wood for your specific needs and preferences. Remember, each wood species has its own unique characteristics and will affect the final look and feel of your table legs.

Measuring and Marking the Required Length

To start making round table legs without a lathe, you will need to measure and mark the desired length of your legs. Follow these steps:

- Measure the Current Leg Length: If you already have a table with legs, measure the length of one leg to determine how long the new legs should be. Make sure to measure from the top of the leg to the floor.

- Decide on the Desired Leg Length: Determine the desired height for your table legs. This will depend on personal preference and the overall height of your table. Consider the standard table heights for the type of tables you are making (e.g., dining table, coffee table, etc.).

- Calculate the Difference: Calculate the difference between the current leg length and the desired leg length. This will give you an idea of how much material you need to add to your existing legs or if you need to start from scratch.

- Transfer Measurements to New Legs: If you need to start from scratch, get the appropriate length of wood or other material and mark it with the desired leg length using a measuring tape and a pencil. Make sure to mark all four legs evenly.

- Double-check the Measurements: After marking the legs, double-check your measurements to ensure accuracy. This will help avoid any mistakes or inconsistencies in the final product.

By measuring and marking the required length, you will be ready to move on to the next step of the process: shaping the legs.

Shaping the Legs with a Hand Saw

Once you have marked the desired length of your table legs using a measuring tape and pencil, it’s time to shape them using a hand saw. While a power saw or a lathe would make the process easier, a hand saw can achieve similar results with a bit of patience and precision.

Here are the steps to shape the legs with a hand saw:

- Secure the leg: Place the leg in a sturdy workbench or clamp it securely to a stable surface. This will prevent any movement or wobbling while cutting.

- Start the cut: Begin by making a straight cut on one end of the leg. This will help create a flat surface for you to work with.

- Angle the cut: Once you have a flat surface, you need to angle the cut to shape the leg. Decide on the desired angle and tilt the hand saw accordingly. Make sure to keep the saw straight and aligned with the angle to achieve a clean and precise cut.

- Work slowly and steadily: Using long, smooth strokes, start cutting into the leg. Take your time and make sure to follow the marked lines accurately. Keep the saw blade aligned with the angle and maintain a steady pace to prevent any mistakes or inaccuracies.

- Check and adjust: Periodically stop cutting to check the leg’s shape and compare it to the other legs. Adjust your sawing technique if needed to ensure consistency among all the legs.

- Repeat for each leg: Once you have shaped one leg, repeat the process for the remaining legs. Remember to double-check your measurements and angles before cutting to ensure a symmetrical look.

By using a hand saw and following these steps carefully, you can shape your table legs without the need for a lathe. Patience and attention to detail are key to achieving professional-looking results.

Smoothing the Surface with Sandpaper

Once you have shaped the round table legs to your desired dimensions, it’s time to smooth the rough surface using sandpaper. This step is crucial to ensure a polished and professional finish.

Materials you will need:

- Coarse-grit sandpaper (around 80-100 grit)

- Medium-grit sandpaper (around 120-150 grit)

- Fine-grit sandpaper (around 220 grit)

- Sanding block or sanding sponge

- Dust mask

- Protective gloves

Steps to follow:

- Put on a dust mask and protective gloves to protect yourself from dust and debris.

- Start with a coarse-grit sandpaper (around 80-100 grit) to remove any noticeable bumps, rough edges, or imperfections on the leg’s surface. Rub the sandpaper along the entire length of the leg, applying firm pressure and sanding in the direction of the wood grain.

- Switch to a medium-grit sandpaper (around 120-150 grit) to further smooth the leg’s surface. Repeat the sanding process, making sure to remove all marks left by the coarse-grit sandpaper.

- Finally, use a fine-grit sandpaper (around 220 grit) to achieve a smooth and polished finish. Sand the leg’s surface lightly and evenly, following the direction of the wood grain.

- If necessary, use a sanding block or sanding sponge to reach tight spots or curves on the leg’s surface.

- After sanding, wipe away any dust or residue with a clean, damp cloth.

Remember to inspect the leg’s surface after each sanding step to ensure that it is becoming smoother. If there are still rough spots or imperfections, repeat the sanding process using the appropriate grit of sandpaper.

Once you have achieved a smooth surface on all the legs, you are ready to move on to the next step in the process of building your round table without a lathe.

Creating Decorative Details on the Legs

Once you have shaped the legs for your round table, you may want to add decorative details to enhance their appearance. Here are some ideas on how you can achieve that:

1. Carving

Carving can add a lot of character to your table legs. You can use a variety of carving tools to create intricate designs or simple patterns. Consider using a wood burning tool for a more rustic look.

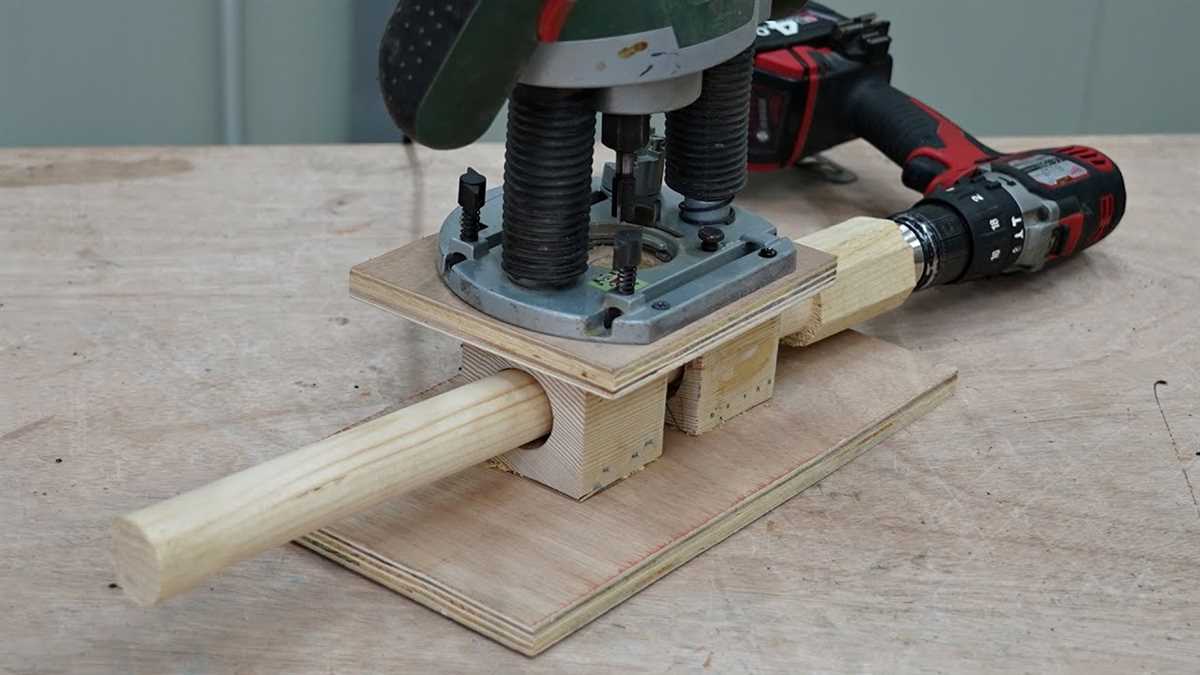

2. Routing

Routing is another technique you can use to add decorative details to your legs. With a router, you can create fluted or patterned designs. There are many different router bits available, so you can choose one that suits your desired style.

3. Inlay

Inlaying is a technique where you cut a groove into the wood and then fill it with a contrasting material like wood, metal, or resin. You can use this method to create geometric patterns or intricate designs.

4. Painting or Staining

If you prefer a simpler approach, you can paint or stain your table legs to add color and texture. Consider using multiple layers of paint or different shades of stain to create a distressed or weathered look.

5. Metal Accents

Adding metal accents, such as metal banding or decorative metal brackets, can give your table legs a unique and industrial touch. You can attach these accents with screws or adhesive.

Remember to plan and sketch out your design before starting any decorative work on your table legs. This will help you visualize the final result and make any necessary adjustments.

Whether you choose to carve, route, inlay, paint, or add metal accents, adding decorative details to your table legs can bring them to life and make your DIY round table truly one-of-a-kind.

Applying a Finish to the Legs

Once you have finished shaping and sanding your round table legs, it’s time to apply a finish to protect the wood and enhance its appearance. Here are the steps to follow:

1. Choose a Finish

There are various finishes available for wooden furniture legs, such as oil-based finishes, water-based finishes, and polyurethane finishes. Consider the look you want to achieve and the level of protection you need when choosing a finish.

2. Prepare the Legs

Before applying the finish, make sure the legs are clean and free of dust. Use a clean cloth or a soft brush to remove any sawdust or debris from the legs.

3. Apply the Finish

There are different methods to apply a finish to wooden legs, such as brushing, wiping, or spraying. Follow the instructions on the finish product for the best application method.

- If you are brushing the finish, use a clean brush and apply an even coat of finish to the legs. Brush in the direction of the wood grain for a smoother finish.

- If you are wiping the finish, apply a small amount of finish on a clean cloth and rub it onto the legs in a circular motion. Make sure to cover the entire surface of the legs.

- If you are spraying the finish, use a spray gun or a spray can to evenly coat the legs. Make sure to apply thin and even layers to avoid drips or uneven coverage.

4. Let it Dry

After applying the finish, let the legs dry according to the instructions provided by the finish manufacturer. It usually takes a few hours to several days for the finish to fully cure, so be patient and avoid touching the legs during this time.

5. Sand and Apply Additional Coats (Optional)

If you want a smoother and more durable finish, you can lightly sand the legs with a fine-grit sandpaper after the first coat has dried. Wipe off the dust and apply additional coats of finish following the same method you used initially. Allow each coat to dry before sanding and applying the next one.

6. Buff and Polish (Optional)

If you want to achieve a glossy or satin finish, you can buff and polish the legs after the final coat of finish has dried. Use a soft cloth or a buffing pad to gently rub the legs in a circular motion until you achieve the desired shine.

Following these steps will help you apply a beautiful finish to your DIY round table legs without the need for a lathe. Remember to work in a well-ventilated area and wear appropriate protective gear, such as gloves and a mask, when handling finish products. Enjoy your newly finished table legs!

Attaching the Legs to the Tabletop

Once you have completed making the round table legs without a lathe, it’s time to attach them to the tabletop. Follow these steps to ensure a secure and stable attachment:

- Clean the tabletop surface and the bottom of the legs to remove any dust or debris.

- Place the tabletop upside down on a stable work surface.

- Align one leg with the corner or edge of the tabletop where you want it to be attached.

- Using a measuring tape or ruler, ensure that the leg is positioned at the desired height. Make any adjustments if needed.

- Mark the attachment points on the tabletop where the leg will be secured.

- Drill pilot holes at the marked points on the tabletop using a drill and an appropriate-sized drill bit.

- Apply wood glue to the bottom of the leg that will be in contact with the tabletop surface.

- Place the leg onto the tabletop, aligning it with the pilot holes.

- Insert screws through the pilot holes and into the leg. Use a screwdriver or power drill to secure them, but be careful not to overtighten and damage the wood.

- Repeat steps 3 to 9 for the remaining legs, ensuring they are evenly spaced and aligned.

- Allow the wood glue to dry according to the manufacturer’s instructions. This usually takes several hours or overnight.

Once the wood glue has dried and the legs are securely attached, carefully flip the table upright. Test the stability of the table by applying gentle pressure and checking for any wobbling or movement. If necessary, adjust the screws or add additional support to ensure a sturdy and level tabletop.

FAQ

What are round table legs?

Round table legs are the vertical support structures that hold up the table top and provide stability and balance to the table.

Why would someone want to make round table legs without a lathe?

There are several reasons why someone would want to make round table legs without a lathe. One reason could be that they do not have access to a lathe or do not want to invest in one. Another reason could be that they prefer the challenge and satisfaction of making things by hand. Additionally, making round table legs without a lathe allows for more creativity and customization in terms of design.

What are some alternative methods for making round table legs without a lathe?

There are several alternative methods for making round table legs without a lathe. One method is using a hand plane and a chisel to shape the legs. Another method is using a router and a roundover bit to shape the legs. Additionally, a bandsaw and a spindle sander can be used to create the desired shape.

How difficult is it to make round table legs without a lathe?

Making round table legs without a lathe can be a challenging task, especially for those who are not experienced in woodworking. It requires precision, patience, and a good understanding of the tools and techniques involved. However, with proper planning and practice, it is definitely achievable for DIY enthusiasts.

What materials and tools are needed to make round table legs without a lathe?

The materials needed to make round table legs without a lathe include wooden stock or dowels, sandpaper, and wood glue. As for the tools, you will need a hand plane or a router with a roundover bit, chisels, a bandsaw or a jigsaw, a spindle sander or sanding drums, clamps, and a measuring tape.

Can the same techniques be used to make other types of furniture legs?

Yes, the techniques used to make round table legs without a lathe can be applied to make other types of furniture legs as well. Whether it’s for a coffee table, a chair, or a bench, the same principles of shaping and sanding can be employed to achieve the desired results.