Discovering the Versatility: What Does a Wood Lathe Do and How Does It Work?

Have you ever wondered how wooden furniture, bowls, and decorative items are made with such precision and intricacy? The answer lies in a remarkable tool known as a wood lathe. A wood lathe is a versatile machine that enables craftsmen to shape and carve wood into a variety of shapes and forms.

At its core, a wood lathe consists of a motorized spinning spindle that holds the piece of wood in place. As the wood spins, the craftsman uses various cutting tools to shape and remove material from the spinning wood. This allows for the creation of symmetrical and intricate designs that would be difficult to achieve by hand.

The versatility of a wood lathe is truly impressive. With the right skills and tools, craftsmen can use a wood lathe to turn simple blocks of wood into beautiful vases, candlesticks, table legs, and even intricate ornaments. The possibilities are endless, limited only by the imagination and skill of the artist.

Wood lathes are commonly used in woodworking shops, but they are also becoming popular among hobbyists and DIY enthusiasts. Whether you are a seasoned woodworker or just starting out, learning to use a wood lathe can open up a whole new world of possibilities for creating unique and beautiful wooden objects.

Discovering the Versatility of Wood Lathe: What It Does and How It Works

Introduction

A wood lathe is a versatile tool used in woodworking for shaping wood into various forms. It is commonly used by woodworkers, artisans, and hobbyists to create a wide range of wooden items such as bowls, spindles, furniture legs, and decorative pieces.

Functionality

The primary function of a wood lathe is to rotate a piece of wood on an axis while a cutting tool, known as a chisel or gouge, shapes the wood. This rotation allows the woodworker to remove material in a controlled manner, creating symmetrical and intricate designs.

Wood lathes come in various sizes and configurations to accommodate different woodworking projects. Some lathes are small and portable, suitable for small-scale projects, while others are large and sturdy, capable of handling heavy-duty work.

Working Process

Wood lathe operations typically involve the following steps:

- Mounting the Wood: The wood to be shaped is mounted securely between the headstock, which holds the wood at one end, and the tailstock, which supports the other end.

- Tool Selection: The woodworker selects the appropriate cutting tool based on the desired shape and design. Different tools have different profiles and cutting edges to achieve specific results.

- Cutting and Shaping: The woodworker starts the lathe, and as the wood rotates, they carefully maneuver the cutting tool against the spinning wood to remove material and shape it according to their desired design.

- Sanding and Finishing: Once the desired shape is achieved, the woodworker sands the surface of the piece to smoothen any rough edges or imperfections. Finally, they apply a finish, such as varnish or wax, to enhance the appearance and protect the wood.

Versatility

Wood lathes offer a wide range of creative possibilities. Here are some of the many applications and projects that can be achieved with a wood lathe:

- Bowls and Plates: Woodturning on a lathe allows for the creation of intricately designed wooden bowls and plates.

- Spindles and Chair Components: Wood lathes are commonly used to produce spindles and various components for chairs, tables, and other furniture.

- Pens and Writing Instruments: With the use of small-scale lathes, woodworkers can create unique and personalized pens and other writing instruments.

- Decorative Items: Woodturning enables the creation of decorative items such as vases, candle holders, and ornaments.

Conclusion

A wood lathe is a versatile tool that allows woodworkers to unleash their creativity and transform raw wood into functional and beautiful pieces. With its ability to shape wood in various forms, a wood lathe opens up a world of possibilities for woodworking projects.

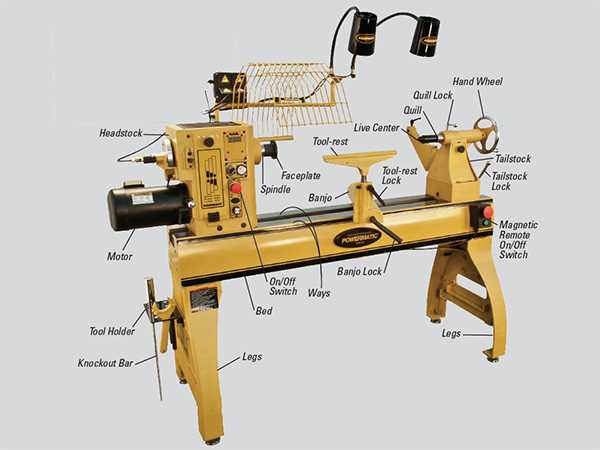

Understanding the basics of a wood lathe

A wood lathe is a versatile machine used in woodworking for shaping, cutting, and drilling wood. It consists of several key components that work together to create different shapes and designs on a piece of wood.

1. Bed

The bed is the base of the wood lathe and provides a sturdy and stable platform for the other components. It is typically made of cast iron or steel and is designed to support the weight of the workpiece and the cutting tools.

2. Headstock

The headstock is located at one end of the bed and houses the motor and the spindle. It is responsible for rotating the workpiece and driving the cutting tools. The headstock can typically be adjusted to accommodate different sizes and lengths of wood.

3. Tailstock

The tailstock is located at the opposite end of the bed and provides additional support for the workpiece. It can be moved along the bed to adjust the distance between the headstock and the tailstock, allowing for different lengths of wood to be turned.

4. Tool Rest

The tool rest is a horizontal beam that attaches to the bed and provides a stable platform for the cutting tools. It can be adjusted in height and distance from the workpiece to accommodate different cutting techniques and shapes.

5. Spindle

The spindle is a rotating shaft that is driven by the motor in the headstock. It is used to hold the workpiece in place and rotate it while the cutting tools shape the wood. The spindle can have different sizes and attachment options to accommodate various types of work.

6. Cutting Tools

The cutting tools are used to shape and cut the wood as it rotates on the lathe. There are various types of cutting tools, including gouges, chisels, and scrapers, each designed for specific cutting techniques and shapes.

Using a wood lathe involves securing the workpiece between the headstock and tailstock, adjusting the tool rest, selecting the appropriate cutting tool, and turning on the machine. The operator then moves the cutting tool along the rotating wood to create different shapes and designs.

Wood lathes are commonly used in woodworking shops and are suitable for turning bowls, spindles, furniture legs, and other decorative or functional items made of wood. They offer a range of possibilities for woodworkers to express their creativity and create unique pieces.

The components of a wood lathe

Wood lathes are versatile and essential tools for woodworkers. They consist of various components that work together to shape wood into different forms. Understanding these components is crucial for operating a wood lathe effectively.

1. Bed

The bed is the base of the wood lathe, providing stability and support for the other components. It is usually made of cast iron or steel and provides a flat surface where the other parts are mounted.

2. Headstock

The headstock is located on one end of the lathe’s bed. It houses the motor and provides the rotational force needed for turning the wood. It also holds the spindle, which connects to the accessories and holds the workpiece in place.

3. Tailstock

Located on the opposite end of the bed from the headstock, the tailstock provides additional support for the workpiece. It can be adjusted to accommodate different lengths of wood and is essential for holding the wood securely in place during turning.

4. Tool Rest

The tool rest is a metal bar that extends horizontally from the lathe’s bed. It provides support for the woodturning tools and allows for smooth and controlled movement while shaping the wood. The tool rest can be adjusted both vertically and horizontally to accommodate different projects and techniques.

5. Spindle

The spindle is a cylindrical rod that extends from the headstock and holds the accessories used for shaping the wood. These accessories, such as the drive center or faceplate, attach to the spindle and connect to the workpiece.

6. Controls

Wood lathes have various controls that enable the woodworker to adjust the speed and direction of the lathe’s rotation. These controls typically include a power switch, speed dial, and direction switch, allowing for precise control over the turning process.

7. Safety Features

Wood lathes are equipped with several safety features to protect the user. These may include a switch that prevents the lathe from starting accidentally, a emergency stop button, and a clear safety shield to protect the user from wood chips and debris.

Understanding the components of a wood lathe is essential for safely and effectively using this versatile tool. Each component plays a crucial role in shaping wood and allows for a wide variety of woodworking projects.

Exploring the different types of wood lathes

Wood lathes come in various types, each designed for specific purposes and projects. Here are some of the most common types of wood lathes:

1. Benchtop wood lathe

A benchtop wood lathe is a compact and portable option that can be easily fit onto a workbench or table. It is suitable for small to medium-sized woodworking projects and is often used by hobbyists and beginners. Despite its smaller size, it can still handle most turning tasks effectively.

2. Floor-standing wood lathe

As the name suggests, a floor-standing wood lathe is a larger and more robust machine that stands on the floor. It is suitable for heavier-duty projects and can accommodate larger workpieces. Floor-standing lathes often have more horsepower and can handle more demanding turning tasks.

3. Mini wood lathe

A mini wood lathe is a smaller version of a benchtop lathe. It is designed for delicate and intricate turning projects, such as pen turning and small spindle work. Mini lathes are often favored by woodturners who work with small-scale projects or have limited workspace.

4. Copy wood lathe

A copy wood lathe is a specialized type of lathe that allows precise duplication of existing woodturnings. It features a mechanism that allows the user to trace the shape of a template or model, which is then replicated by the lathe. Copy lathes are commonly used in woodworking shops that need to produce multiple identical turned objects.

5. CNC wood lathe

A CNC (Computer Numerical Control) wood lathe is a modern type of lathe that is controlled by computer software. It can automatically execute complex turning tasks based on a digital design. CNC lathes offer high precision and are often used in industrial settings where mass production and intricate designs are required.

Conclusion

Understanding the different types of wood lathes can help you choose the right one for your woodworking projects. Whether you are a beginner, a hobbyist, or a professional woodturner, there is a wood lathe available to suit your needs and preferences.

Mastering the techniques for using a wood lathe

Understanding the basics

In order to master the techniques of using a wood lathe, it is important to understand the basic components of the machine. A wood lathe consists of a motor, a headstock, a tailstock, a tool rest, and a live center. The motor powers the rotation of the wood, while the headstock holds the spindle and serves as the driving force. The tailstock, on the other hand, provides support and stability to the workpiece. The tool rest acts as a platform for the cutting tools, and the live center helps ensure smooth rotation.

Preparing the wood

Before using a wood lathe, it is essential to properly prepare the wood. Start by securing the wood blank onto the lathe using a chuck or faceplate. Ensure that the wood is securely fastened to avoid any accidents while turning. It is also important to inspect the wood for any cracks, knots, or defects that may affect the turning process.

Choosing the right tools

Next, it is important to select the right tools for the turning project. Wood lathes require specific cutting tools, such as gouges, skews, and parting tools. Each tool has a different shape and purpose, so it is important to choose the right tool for the desired cut. Additionally, keeping the tools sharp is crucial for achieving clean cuts and reducing the risk of accidents.

Mastering the cutting techniques

When using a wood lathe, there are various cutting techniques that can be employed to create different shapes and designs. Some common techniques include roughing, which involves removing excess material to shape the wood, and shearing, which produces smooth cuts. It is important for woodturners to practice and refine these techniques to achieve desired results.

Finishing touches

After completing the shaping process, it is time to add the finishing touches to the turned object. This may include sanding the wood to achieve a smooth finish, applying a protective coating or sealant, or adding decorative elements. The finishing process is crucial in enhancing the beauty, durability, and functionality of the turned object.

Practicing safety precautions

When using a wood lathe, it is important to prioritize safety. Always wear safety goggles, a face shield, and protective clothing to protect yourself from flying wood chips or dust. Keep long hair and loose clothing secured to prevent entanglement with the rotating wood. Additionally, always follow the manufacturer’s instructions and guidelines for safe operation of the wood lathe.

By mastering these techniques and practicing safety precautions, woodturners can unlock the full potential of a wood lathe and create beautiful and intricate wood turned objects.

Creating intricate designs with a wood lathe

A wood lathe is a versatile tool that allows craftsmen to create intricate and detailed designs in wood. With the right techniques and skill, a wood lathe can transform a plain piece of wood into a beautifully carved work of art.

Woodturning

Woodturning is the process of manipulating a piece of wood on a lathe to create various shapes and designs. The wood is mounted on the lathe and rotated at high speeds while the craftsman uses different tools to shape and carve the wood.

One of the main advantages of using a wood lathe for creating designs is the ability to work in three dimensions. Unlike other woodworking tools, such as chisels or saws, a wood lathe allows craftsmen to shape the wood in a radial direction, creating curves, contours, and intricate details.

Tools and Techniques

A wood lathe is equipped with a variety of tools that can be used to create different types of designs. These include gouges, chisels, scrapers, and skew chisels.

Gouges are used for rough shaping and removing larger amounts of wood, while chisels and skew chisels are used for finer details and smoothing the wood surface. Scrapers, on the other hand, are used to achieve a smooth finish and remove any imperfections or tool marks.

When working with a wood lathe, craftsmen employ various techniques to create intricate designs. These techniques include spindle turning, bowl turning, and faceplate turning.

Spindle Turning

Spindle turning is the process of shaping a piece of wood that is mounted between the headstock and tailstock of the lathe. This technique is commonly used to create items such as table legs, chair spindles, and candlesticks.

Bowl Turning

Bowl turning involves shaping a piece of wood that is mounted on a faceplate or held in a chuck on the lathe. This technique is used to create bowls, vases, and other hollow objects. It requires careful control of the lathe speed and tool positioning to achieve desired shapes and smooth surfaces.

Faceplate Turning

Faceplate turning is a technique used for turning larger, irregularly shaped objects such as platters or shallow bowls. The wood is attached to the faceplate using screws or other fasteners, and the lathe is used to shape the wood from the front.

Conclusion

A wood lathe is an essential tool for any woodworker who wants to create intricate and detailed designs. With the right tools and techniques, craftsmen can transform a piece of wood into a work of art, showcasing their creativity and skill.

Safety precautions when using a wood lathe

When working with a wood lathe, it is important to prioritize safety to avoid accidents and injuries. Here are some key safety precautions to keep in mind:

1. Wear appropriate protective gear

Always wear safety glasses or goggles to protect your eyes from flying wood chips and debris. Additionally, wearing a face shield can provide additional protection for your face and neck. It is also important to wear hearing protection, as wood lathes can be quite loud, especially when using larger pieces of wood.

2. Familiarize yourself with the lathe and its components

Before operating a wood lathe, take the time to thoroughly read and understand the manufacturer’s instructions and guidelines. Familiarize yourself with the lathe’s various components, such as the headstock, tailstock, tool rest, and cutting tools. This will allow you to operate the lathe safely and efficiently.

3. Secure the workpiece properly

Ensure that the workpiece is securely clamped onto the lathe before starting the machine. This will help prevent the workpiece from moving or spinning out of control while you are working on it. Use appropriate clamps or chucks to securely hold the wood in place.

4. Always use sharp cutting tools

Using dull or damaged cutting tools can increase the risk of accidents. Make sure your cutting tools are sharp and properly sharpened before using them on the lathe. Dull tools can cause the wood to catch and kick back, potentially causing injuries to your hands and fingers.

5. Start with slow speeds

When turning on the wood lathe, always start at a slow speed. This will allow you to better control the workpiece and make any necessary adjustments before increasing the speed. Starting at a high speed can cause the wood to vibrate or move unpredictably, leading to potential accidents.

6. Maintain a safe working distance

Always maintain a safe distance between your hands and the spinning workpiece. Never reach across the lathe while it is in motion. Use the tool rest to support your cutting tools and maintain a safe working position. Keep your fingers and hands away from the rotating wood to avoid accidents.

7. Take breaks and stay focused

Working with a wood lathe can be physically demanding and requires concentration. Take regular breaks to rest and relax your muscles. It is important to stay focused and avoid distractions while operating the lathe, as a momentary lapse in concentration can lead to accidents.

By following these safety precautions, you can enjoy using a wood lathe while minimizing the risk of injuries or accidents. Remember to prioritize safety and take the necessary steps to protect yourself while working with this versatile tool.

Finding the right wood lathe for your needs

Consider your turning needs

Before purchasing a wood lathe, it is important to consider your turning needs. Think about the types of projects you plan on completing and the size of the wood pieces you will be working with. Different wood lathes have varying capacities and capabilities, so it is important to choose one that can handle the size and complexity of your projects.

Decide on a budget

Wood lathes come in a wide range of prices, so it is important to decide on a budget before making your purchase. Consider how much you are willing to spend and what features are important to you. Keep in mind that more expensive lathes often have better quality and additional features, but you can still find a reliable wood lathe within your budget.

Research different brands and models

Once you have determined your turning needs and budget, it is time to research different wood lathe brands and models. Look for reputable brands that have good customer reviews and a history of producing high-quality lathes. Consider the features and specifications of each model to ensure it meets your requirements.

Visit a woodworking store

If possible, visit a local woodworking store to see different wood lathes in person. This will allow you to get a feel for the machine and see how it operates. You can also talk to the store staff for recommendations and ask any questions you may have about the different models available.

Read online reviews

Before making a final decision, read online reviews from other woodworkers who have purchased the lathe you are considering. This can provide valuable insight into the machine’s performance, reliability, and ease of use. Pay attention to any common issues or concerns mentioned in the reviews.

Consider additional accessories

In addition to the wood lathe itself, consider any additional accessories you may need. This could include chisels, faceplates, centers, and other turning tools. Some wood lathes may come with a variety of accessories included, while others may require separate purchases. Factor in the cost of these accessories when determining your overall budget.

Compare prices and warranties

Once you have narrowed down your options, compare prices from different retailers to ensure you are getting the best deal. Take into account any warranties or guarantees offered by the manufacturer or retailer. A good warranty can provide peace of mind in case of any defects or issues with the lathe.

Make your decision

After considering all of these factors, make your decision and purchase the wood lathe that best fits your needs and budget. Remember to follow the manufacturer’s instructions for setup and operation, and always prioritize safety when using a wood lathe.

Exciting projects you can tackle with a wood lathe

Wood lathes are versatile tools that can be used to create a wide range of projects. Whether you are a beginner or an experienced woodworker, there are plenty of exciting projects you can tackle with a wood lathe. Here are some ideas to get you started:

Bowls and Hollow Forms

- One of the most popular projects for wood lathes is turning bowls. You can create beautiful, functional bowls in various shapes and sizes. By using different types of wood and experimenting with different patterns and finishes, you can create unique, one-of-a-kind bowls.

- In addition to bowls, a wood lathe can also be used to create hollow forms such as vases, goblets, and boxes. These projects require more advanced skills and techniques, but the result is a stunning piece of art.

Pens and Writing Instruments

- If you enjoy woodworking and writing, turning pens and other writing instruments can be a great project for you. With a wood lathe, you can create custom pens using various woods and finishes. This is a popular project among woodworkers and can make great gifts for friends and family.

Spindles and Legs

- A wood lathe is also perfect for making spindles and legs for furniture. Whether you are repairing an old piece or building something from scratch, a wood lathe allows you to create perfectly shaped spindles and legs with ease.

Handles and Knobs

- Another exciting project you can tackle with a wood lathe is making handles and knobs. You can create custom handles and knobs for cabinets, drawers, and doors, adding a personal touch to your furniture.

Wooden Toys

- If you enjoy making wooden toys, a wood lathe can take your projects to the next level. You can turn wooden tops, spinning tops, yo-yos, and other toys that will delight both children and adults.

These are just a few examples of the exciting projects you can tackle with a wood lathe. The possibilities are endless, and with practice and creativity, you can create unique and beautiful pieces of art.

FAQ

What is a wood lathe?

A wood lathe is a machine that is used to shape and turn wooden objects. It works by rotating the wood while a cutting tool is used to shape and sculpt the wood into the desired form.

What can I make with a wood lathe?

A wood lathe can be used to make a variety of wooden objects such as bowls, vases, candlesticks, furniture legs, and even intricate woodturning designs. The possibilities are endless!

How does a wood lathe work?

A wood lathe works by spinning the wooden workpiece on its axis while a cutting tool is held against it. The rotation of the workpiece allows the cutting tool to remove material and shape the wood into the desired form.

Can a wood lathe be used by beginners?

Yes, a wood lathe can be used by beginners. However, it is important for beginners to start with simple projects and practice basic techniques before moving on to more complex projects. It is also recommended to take proper safety precautions and receive proper training before using a wood lathe.

Is a wood lathe expensive?

The cost of a wood lathe can vary depending on the brand, size, and features. Entry-level wood lathes can range from $200 to $500, while more advanced and professional-grade lathes can cost several thousand dollars. It’s important to consider your budget and intended use when purchasing a wood lathe.

What are the safety precautions to take when using a wood lathe?

When using a wood lathe, it is important to wear appropriate safety gear such as safety glasses, a face shield, and ear protection. It is also important to secure the wood properly on the lathe and ensure that the cutting tools are sharp and in good condition. Additionally, it is important to be mindful of the rotating workpiece and keep hands and clothing away from the moving parts to avoid accidents.

Video