Best tooling types for sub spindle lathes

A sub spindle lathe is a type of lathe machine that is equipped with two spindles, allowing for simultaneous machining on both sides of a workpiece. This type of lathe is commonly used in industries such as automotive, aerospace, and medical manufacturing. To maximize the efficiency and productivity of a sub spindle lathe, it is essential to use the best tooling types.

One of the most common and effective tooling types for sub spindle lathes is the live tooling. Live tooling refers to the use of tools that are driven by the machine’s spindle, allowing for multitasking operations such as drilling, milling, and tapping. Live tooling eliminates the need for additional tool changes and setup, resulting in significant time savings and increased productivity.

Another tooling type that works well with sub spindle lathes is the boring bar. Boring bars are used for enlarging or aligning existing holes in a workpiece. With a sub spindle lathe, boring bars can be used on both spindles simultaneously, further improving efficiency. Boring bars come in various sizes and shapes to accommodate different hole sizes and shapes.

Additionally, toolholders with quick-change systems are highly recommended for sub spindle lathes. Quick-change toolholders allow for rapid tool changes without the need for additional setup or calibration. This feature is particularly useful in high-volume production settings where minimizing downtime is essential. Quick-change toolholders can also help reduce tool change errors, resulting in improved accuracy and part quality.

In conclusion, choosing the right tooling types for a sub spindle lathe is crucial for maximizing efficiency and productivity. Live tooling, boring bars, and quick-change toolholders are among the best options to consider. By using these tooling types, manufacturers can optimize their sub spindle lathe operations and achieve higher quality parts in less time.

Understanding sub spindle lathes

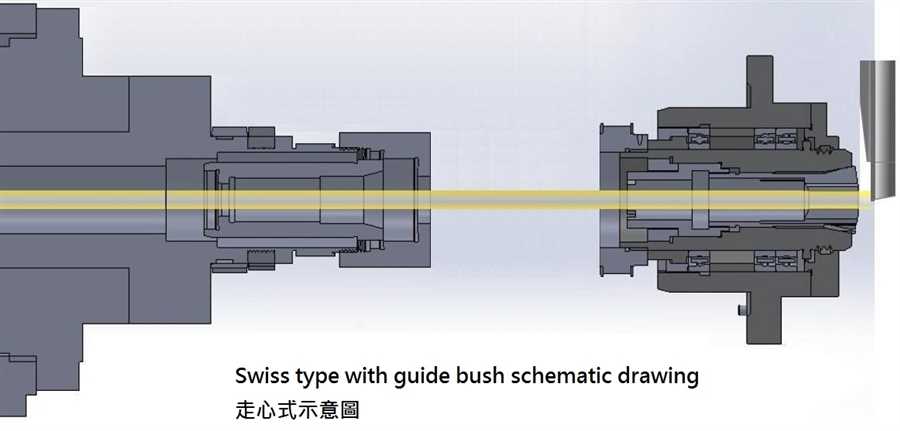

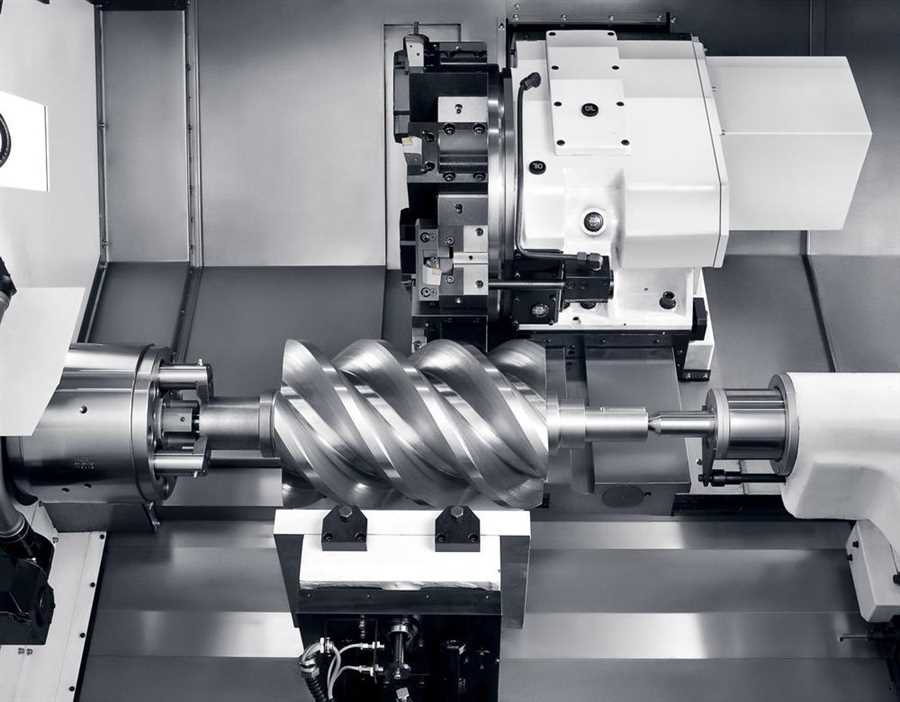

A sub spindle lathe is a type of lathe machine that has an additional spindle, known as the sub spindle, which operates in conjunction with the main spindle. This type of lathe is commonly used for complex machining operations that require multiple machining operations to be performed on a single workpiece.

The sub spindle lathe allows for improved efficiency and productivity, as it can perform simultaneous machining operations, reducing the need for manual intervention and setup time. Additionally, the sub spindle lathe enables the machining of complex parts with different features on both ends, as the sub spindle can hold the workpiece while the main spindle performs machining operations.

One key advantage of sub spindle lathes is their ability to perform secondary operations, such as drilling, milling, and tapping, on the workpiece. This eliminates the need for transferring the workpiece to a separate machine and ensures accuracy and consistency in the machining process.

Sub spindle lathes are commonly used in industries such as automotive, aerospace, and medical, where precision and efficiency are crucial. They can handle a wide range of materials, including metals, plastics, and composites, making them versatile machines for various manufacturing applications.

- Benefits of sub spindle lathes:

- Increased productivity and efficiency

- Ability to perform simultaneous machining operations

- Capability for secondary operations

- Precision and accuracy

- Versatility in machining various materials

The Importance of Tooling in Sub Spindle Lathes

Tooling plays a crucial role in sub spindle lathes, which are machines used for precision turning operations. Effective tooling can significantly impact the efficiency, accuracy, and quality of the machining process. It is important to use the right tools and tool holders to ensure optimal performance and achieve desired results.

One key aspect of tooling in sub spindle lathes is selecting the appropriate cutting tools. These tools must be capable of withstanding the high speeds and forces involved in machining operations. They should also have the necessary geometry and coatings to ensure efficient chip evacuation and reduce tool wear. Choosing the right cutting tool material and geometry is essential for achieving precise and consistent results.

Another important factor in sub spindle lathe tooling is the selection of tool holders. The tool holder is responsible for securely holding the cutting tool in place and transferring the necessary forces during the machining process. It should provide stability and rigidity to minimize vibrations and ensure accurate and repeatable cuts. The tool holder design should also allow for easy tool changes and adjustments.

Additionally, the use of tool presetting systems can greatly enhance the efficiency of sub spindle lathes. These systems allow for the pre-measurement and storage of tool geometry data, which can be quickly loaded into the machine when changing tools. This saves valuable setup time and ensures consistent and accurate tool positioning.

In conclusion, tooling is a critical aspect of sub spindle lathes. The selection of cutting tools, tool holders, and the use of tool presetting systems can have a significant impact on the performance and outcomes of machining operations. By investing in high-quality tooling and ensuring proper maintenance and calibration, manufacturers can optimize their sub spindle lathe processes and achieve superior results.

Turning Tool Holders for Sub Spindle Lathes

When it comes to sub spindle lathes, having the right turning tool holders is essential for achieving optimal machining performance. These tool holders play a crucial role in securely holding and positioning the cutting tools during the turning process.

One type of turning tool holder commonly used for sub spindle lathes is the boring bar holder. This tool holder is designed to hold boring bars that are used for enlarging existing holes or creating internal features, such as grooves or threads. Boring bar holders are typically adjustable, allowing for precise positioning and alignment of the boring bar within the workpiece.

Another type of tool holder commonly used for sub spindle lathes is the turning tool holder. This tool holder is used to hold external turning tools, which are used for removing material from the workpiece. Turning tool holders are available in various configurations, such as square, round, or diamond-shaped, to accommodate different types of turning inserts. They also provide adjustability for precise tool positioning and cutting depth.

Overall, choosing the right turning tool holders for sub spindle lathes is crucial for achieving accurate and efficient machining results. Whether using a boring bar holder or a turning tool holder, it is important to consider factors such as tool compatibility, adjustability, and rigidity to ensure optimal tool performance and longevity.

Boring Bars for Sub Spindle Lathes

Boring bars are an essential tool for sub spindle lathes, allowing for accurate drilling and enlarging of holes in workpieces. These bars are designed to fit into the toolholder and extend into the workpiece to create the desired bore. They come in a variety of sizes and geometries, allowing for versatility in different applications.

One type of boring bar commonly used for sub spindle lathes is the indexable boring bar. This type of bar features inserts that can be rotated or indexed to present a fresh cutting edge when one becomes dull. This allows for extended tool life and reduces the need for frequent tool changes. Indexable boring bars are available in different lengths and diameters, making them suitable for various hole depths and sizes.

- Another type of boring bar that works well for sub spindle lathes is the solid carbide boring bar. Made from high-quality carbide material, these bars offer excellent rigidity and vibration damping properties. This results in improved surface finishes and higher productivity. Solid carbide boring bars are often used for precision applications that require tight tolerances.

- For applications that require internal threading, carbide threading boring bars are commonly used on sub spindle lathes. These bars feature a modified geometry and special threading inserts to create accurate and reliable threaded holes. They are available in various thread sizes and pitch options, allowing for flexibility in different threading requirements.

Choosing the right boring bar for a sub spindle lathe depends on factors such as the material being machined, hole dimensions, and desired surface finish. It is essential to select the appropriate bar geometry, insert type, and cutting parameters to achieve optimal results. Additionally, regular maintenance and inspection of the boring bars are crucial to ensure their performance and longevity.

Threading Tools for Sub Spindle Lathes

When it comes to sub spindle lathes, threading tools play a crucial role in achieving precise and accurate threads. These tools are specifically designed to create threads on the workpiece with high precision and efficiency. They are an essential component for machining operations that require threaded parts.

Threading tools for sub spindle lathes come in various types, each designed for specific threading applications. One common type is the external threading tool, which is used to create external threads on the workpiece. This tool is typically made of high-speed steel or carbide and features a cutting edge that is shaped to match the desired thread profile.

Another type of threading tool is the internal threading tool, which is used to create internal threads. Similar to the external threading tool, the internal threading tool is made of high-speed steel or carbide and has a cutting edge designed for creating the desired thread profile. It is specifically designed to fit inside the workpiece and create threaded holes.

Threading tools for sub spindle lathes are also available in different sizes to accommodate various thread sizes. They can be single-point tools, which have a single cutting edge, or multi-point tools, which have multiple cutting edges. The choice of threading tool depends on the specific application and the required thread specifications.

- External threading tools

- Internal threading tools

- Various sizes and configurations

- Single-point and multi-point options

In conclusion, threading tools are essential for sub spindle lathes to create precise threads on workpieces. They come in different types, sizes, and configurations to accommodate various threading applications. Whether it’s external threads or internal threads, these tools ensure the accuracy and efficiency of the machining process.

5 Best tooling types for sub spindle lathes

Features

| Part Number | 14105100 |

| Model | 14105100 |

| Color | Black |

| Release Date | 2022-05-02T00:00:01Z |

| Size | T10S |

Features

| Part Number | GY-9781596471160 |

| Model | GY-9781596471160 |

| Release Date | 2006-08-20T00:00:01Z |

| Edition | 2 |

| Language | English |

| Number Of Pages | 108 |

| Publication Date | 2006-08-20T00:00:01Z |

Features

| Part Number | 1030102570 |

| Model | 1030102570 |

Q&A:

What are threading tools for sub spindle lathes?

Threading tools for sub spindle lathes are cutting tools specifically designed to create threads on workpieces in sub spindle lathes. They are used for producing external or internal threads with precise dimensions and thread profiles.

What are the types of threading tools for sub spindle lathes?

There are various types of threading tools for sub spindle lathes, including single-point threading tools, multi-point threading tools, thread mills, and threading inserts. Each type is designed for specific threading operations and materials.

What are the advantages of using threading tools for sub spindle lathes?

Using threading tools for sub spindle lathes provides several advantages. They allow for accurate and precise thread cutting, reducing the need for manual threading operations. They also enable faster production rates and improved thread quality.

How do threading tools for sub spindle lathes work?

Threading tools for sub spindle lathes are inserted into the lathe’s tool holder or turret and are positioned to cut the desired thread profile. As the lathe rotates the workpiece, the threading tool engages with the material, cutting or forming the thread as it moves along the workpiece.

What factors should be considered when selecting threading tools for sub spindle lathes?

When selecting threading tools for sub spindle lathes, factors such as the thread pitch, thread diameter, material being threaded, and desired thread quality must be considered. Different threading tools are designed for specific thread profiles and materials, so careful selection is essential to achieve the desired results.

What are threading tools for sub spindle lathes used for?

Threading tools for sub spindle lathes are used for cutting threads on workpieces that are being machined on a lathe with a sub spindle. The sub spindle allows for the workpiece to be transferred to the sub spindle for additional machining operations, including threading.

Conclusion

In conclusion, threading tools are crucial for sub spindle lathes as they play a vital role in creating accurate and efficient threaded parts. The use of high-quality threading tools allows for precise threading operations, resulting in the production of accurately threaded parts with consistent thread quality. The advancements in threading tool technology, such as the development of carbide threading inserts and coatings, have greatly improved the performance and durability of these tools. Moreover, the introduction of threading toolholders with internal coolant supply has enhanced chip removal and tool life, further increasing the efficiency of threading operations on sub spindle lathes. Overall, investing in high-quality threading tools is essential for sub spindle lathe users to achieve optimal performance and productivity in their threading processes.