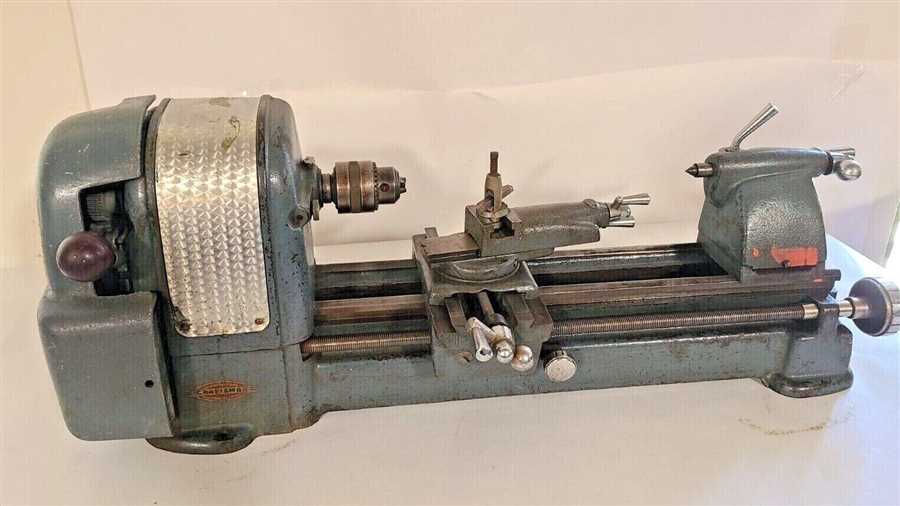

Best old metal lathe

When it comes to working with metal, having a reliable and sturdy lathe is essential. While newer models offer advanced features and cutting-edge technology, many craftsmen and machinists still prefer the old metal lathes for their durability and precision. In this article, we will explore some of the best old metal lathes available on the market.

The South Bend Heavy 10 Lathe: Known for its superior quality and exceptional performance, the South Bend Heavy 10 Lathe is a classic choice for metalworkers. Built with a cast-iron construction, this lathe offers stability and vibration resistance, ensuring precise and smooth machining operations.

The Atlas Craftsman 12×36 Lathe: Another popular choice among machinists is the Atlas Craftsman 12×36 Lathe. This old metal lathe is praised for its versatility and durability. With its robust construction and solid steel bed, this lathe can handle a wide range of metalworking projects with ease.

The Logan 820 Lathe: The Logan 820 Lathe is a well-known name in the metalworking industry. This vintage lathe is cherished for its rigid and hefty build, making it capable of handling heavy-duty tasks. Equipped with a powerful motor and precision components, the Logan 820 Lathe delivers high accuracy and reliability.

The Monarch 10EE Lathe: If precision is your top priority, the Monarch 10EE Lathe is the perfect choice. Widely regarded as one of the best metal lathes ever made, this machine offers unparalleled accuracy and exceptional craftsmanship. Its intricate design and high-quality materials make it a favorite among professional machinists.

While newer metal lathes may boast advanced features, there is something special about the classic charm and reliability of an old metal lathe. Whether you are a professional machinist or a hobbyist, investing in a high-quality old metal lathe can significantly enhance your metalworking capabilities.

The Evolution of Metal Lathes: A Brief Overview

Metal lathes have been an essential tool in machining for centuries, and their evolution over time has significantly contributed to the advancements in manufacturing and engineering. These sturdy machines have undergone numerous innovations and improvements, allowing for increased precision, efficiency, and versatility in turning metal workpieces.

Early metal lathes, dating back to ancient times, were simple in design and operated manually. They consisted of a spindle that rotated the workpiece while a cutting tool was manually guided to shape the metal. As technology progressed, powered lathes were introduced, employing mechanisms such as waterwheels or steam engines to drive the spindle rotation. These early powered lathes greatly increased productivity and reduced the operator’s physical efforts.

With the advent of the Industrial Revolution in the 18th century, metal lathes underwent significant advancements. The use of steam power to drive lathes became more widespread, leading to the creation of more complex and sophisticated lathe designs. The introduction of sliding gears, quick-change toolposts, and feedscrew systems allowed for enhanced precision and efficiency in metal turning. These innovations paved the way for the mass production of metal components, transforming industries and fueling technological progress.

In the 20th century, electronic and computer-controlled lathes emerged, revolutionizing the manufacturing industry. CNC (Computer Numerical Control) machines enabled automated machining processes with precise control over cutting speeds, positions, and tool movements. These advanced lathes expanded the capabilities of machining, making it possible to produce intricate and complex parts with high accuracy and repeatability.

Today, metal lathes continue to evolve, incorporating modern technologies such as advanced control systems, high-speed cutting tools, and integrated sensors. These advancements allow for even greater efficiency, accuracy, and flexibility in metalworking. From the ancient manual lathes to the high-tech CNC machines of today, the evolution of metal lathes exemplifies the relentless pursuit of perfection in machining and the never-ending drive to push the boundaries of what is possible.

Metal Lathes Through the Ages

The history of metal lathes is a fascinating one, as these machines have played a vital role in shaping the course of human civilization. From ancient civilizations to modern factories, metal lathes have been used for centuries to create various tools, parts, and components.

One of the earliest examples of a metal lathe dates back to ancient Egypt, where wooden lathes were used to turn objects made of soft metals such as copper and bronze. These early lathes were operated by hand and required skilled craftsmen to create intricate designs. Over time, advancements in technology led to the development of more sophisticated metal lathes, such as the screw-cutting lathe invented by Henry Maudslay in the early 19th century.

During the Industrial Revolution, metal lathes became indispensable in factories, allowing for mass production of precision parts. The invention of the steam engine and the development of steam-powered lathes further revolutionized the manufacturing industry. Metal lathes played a crucial role in the construction of railways, steam engines, and other innovations that shaped the modern world.

In the 20th century, the advent of electricity and computer technology gave rise to even more advanced metal lathes. Computer Numerical Control (CNC) lathes, which are programmable and capable of complex operations, have become the standard in modern machining. These machines can create intricate and precise parts with minimal human intervention, significantly increasing productivity and accuracy.

From ancient Egypt to the modern era, metal lathes have continuously evolved and improved, reflecting advancements in technology and the needs of an ever-changing world. These machines have played a vital role in shaping our modern society, facilitating innovation, and driving economic growth.

Exploring Old Metal Lathes: Key Features and Benefits

Old metal lathes offer a unique set of features and benefits that make them attractive to both hobbyists and professionals in the machining industry. These lathes, despite their age, continue to be sought after for their durability, precision, and versatility.

One key feature of old metal lathes is their solid construction. Made from sturdy materials such as cast iron, these lathes are built to withstand heavy use and can provide years of reliable performance. Their robust construction also contributes to their stability, eliminating vibrations and ensuring smooth operation.

Another notable feature is the accuracy and precision that old metal lathes offer. Equipped with precision gears and slides, these machines allow for precise control over the machining process. This level of accuracy is crucial in producing high-quality components with tight tolerances.

In addition to their durability and precision, old metal lathes are known for their versatility. These machines can handle a wide range of materials, including various metals and alloys, allowing machinists to tackle different projects without the need for multiple machines.

Furthermore, some old metal lathes come with additional attachments and accessories that further enhance their capabilities. These may include tool holders, chucks, and steady rests, which expand the range of operations that can be performed on the lathe.

Despite being considered “old,” these metal lathes continue to be valuable assets in the machining world. Their solid construction, precision, and versatility make them well-suited for a variety of applications, from small-scale hobby projects to large-scale industrial production. So, if you’re in the market for a reliable and versatile lathe, don’t overlook the benefits that old metal lathes can offer.

Durability for Decades: Why Old Metal Lathes Still Stand Out

In today’s fast-paced world of technology, it’s easy to disregard older machines as outdated and obsolete. However, when it comes to metal lathes, age often brings with it a level of durability and reliability that is hard to match. Despite lacking the modern features and technology found in newer models, older metal lathes continue to stand out for their longevity and ability to withstand years of heavy use.

One of the primary reasons why old metal lathes are still highly regarded is their rugged construction. These machines were built to last, with solid cast iron frames and heavy-duty components that can handle the toughest machining tasks. Unlike some of the lighter, more portable models available today, older metal lathes are built to be stable and sturdy, ensuring precise and accurate results. This durability allows them to withstand years of heavy use without compromising their performance.

Moreover, older metal lathes often have simpler designs and fewer electronic components, making them easier to maintain and repair. While their modern counterparts may require specialized knowledge and expensive replacements, older machines can often be serviced with basic tools and readily available parts. This not only makes them more cost-effective in the long run, but also ensures that they can be kept in optimal working condition for decades, providing reliable performance year after year.

Additionally, older metal lathes have stood the test of time in terms of their performance capabilities. Despite lacking the latest technological advancements, these machines can still achieve high levels of precision and accuracy. Their robust construction and well-calibrated components allow them to produce smooth and consistent results, making them ideal for a wide range of metalworking projects. Whether you are a hobbyist or a professional machinist, an old metal lathe can often meet your machining needs with ease.

In conclusion, while newer models may offer advanced features and cutting-edge technology, it’s important not to overlook the durability and reliability that older metal lathes bring to the table. Their solid construction, simplicity of design, and ability to maintain high levels of performance make them stand out in a crowded market. Whether you’re looking for a machine to handle light projects or heavy-duty tasks, an old metal lathe may just be the reliable workhorse you need to get the job done for decades to come.

5 Best old metal lathe

Features

| Part Number | Fafeicy8xk1zidugh2384 |

Features

| Part Number | VSW8522820982477LQ |

Features

- HIGH PRECISION: Driven by a ¾ HP motor, this miniature metal lathe is designed for high quality precision craftsmanship with spindle accuracy to within 0.0004" (0.01mm). Also, the digital screen can clearly show the speed and ensure precise and smooth operation.

- PROFESSIONAL CROSS SLIDE: Designed with abrasive resistance, moving blades freely with feed rod. 16 TPI reversible leadscrew and V-slide rails with 350mm (14") center to ensure this lathe is durable, turns more accurate and professional.

- 3-JAW CHUCK: 3-jaw self-centering chuck ensures perfect placement without excessive trimming. By changing the angle of the tool column, the positions of inward cutting, end face cutting and bevel cutting can be realized.

- VARILABLE SPEED: The 18 x 35 cm (7 x 14 in) lathe still delivers 550 watts which is suitable for small or medium projects. This metal lathe can be operated manually or automatically with a spindle speed range of 50-2250 Rpm. The feed rate can be adjusted according to the requirements of different workpieces.

- WIDE APPLICATION: Our mini benchtop metal lathe can be used for small part machining, sample machining and modeling work. It's the perfect addition to your workbench!

Q&A:

What is the durability of old metal lathes?

Old metal lathes are known for their exceptional durability, often lasting for decades. These machines were built with high-quality materials and robust construction techniques, making them highly reliable and long-lasting.

Why do old metal lathes still stand out?

Old metal lathes continue to stand out due to their unmatched performance and reliability. Despite being older models, these machines were built with precision and attention to detail, allowing them to produce high-quality results and withstand heavy use in industrial settings.

What are the advantages of using old metal lathes?

Using old metal lathes comes with several advantages. Firstly, their durability ensures that they can handle demanding projects without breaking down or requiring frequent repairs. Secondly, their robust construction and solid design contribute to their stability, precision, and ability to withstand heavy workloads. Lastly, these machines often come with a range of customizable features and accessories, providing versatility and flexibility in various machining tasks.

Are there any drawbacks to using old metal lathes?

While old metal lathes are generally reliable and durable, there are a few drawbacks to consider. Firstly, older models may lack some of the latest technological advancements and innovations found in newer machines, limiting their capabilities in certain areas. Additionally, sourcing replacement parts for older models may be more challenging compared to readily available parts for newer machines. However, many enthusiasts and professionals still prefer old metal lathes due to their proven track record and classic craftsmanship.

Conclusion

In conclusion, old metal lathes continue to stand out due to their durability that can last for decades. While modern technology and advancements have introduced new and improved manufacturing techniques, old metal lathes have proven their reliability and endurance in the machining industry. These machines have stood the test of time and continue to be cherished by craftsmen and manufacturers around the world. Their robust construction and ability to withstand heavy-duty work make them a reliable choice for various machining tasks. Additionally, their simplicity and easy maintenance make them accessible to users of all skill levels. Despite the availability of newer models, the enduring appeal and effectiveness of old metal lathes ensure that they will continue to hold their place in the machining world for years to come.