Best manual toolroom lathe

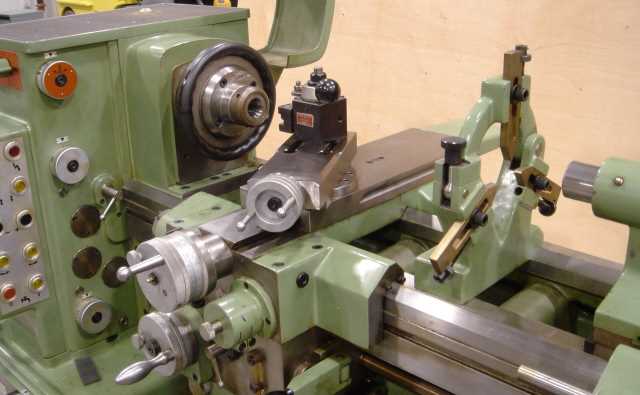

A manual toolroom lathe is an essential machine in any workshop or manufacturing facility. It is specifically designed for precision turning operations, allowing for the creation of high-quality parts and components. Toolroom lathes are known for their versatility, accuracy, and ease of use, making them a popular choice among machinists and engineers.

When it comes to selecting the best manual toolroom lathe, several factors need to be considered. Firstly, the lathe should have a solid construction and be made from high-quality materials to ensure durability and stability during operation. It should also have a robust spindle system that allows for smooth and precise turning.

In addition, a wide range of chuck sizes and options for tooling should be available to accommodate different workpieces and cutting requirements. The lathe should also have a powerful motor and variable speed control for increased flexibility and improved machining capabilities.

Furthermore, the best manual toolroom lathe should have advanced features and controls that enable operators to make precise adjustments and achieve the desired results. This includes features such as digital readouts, quick-change tooling systems, and automatic feed control.

Overall, the best manual toolroom lathe will offer exceptional performance, reliability, and versatility. It will provide machinists and engineers with the necessary tools to produce precise and high-quality parts efficiently. With the right lathe in the workshop, the possibilities for creating complex components are endless.

What is a manual toolroom lathe?

A manual toolroom lathe is a type of lathe machine that is used in a toolroom or workshop environment for precision machining and manufacturing processes. It is operated manually by skilled machinists and has the ability to perform various cutting and shaping operations on different types of materials.

Unlike automated or computer-controlled lathes, a manual toolroom lathe requires the operator to manually set up and adjust the machine for each specific task. This includes selecting the appropriate tools, securing the workpiece, and adjusting the feed and speed settings. The machinist must have a solid understanding of the machine’s capabilities and the machining process to achieve accurate and precise results.

A manual toolroom lathe typically has a horizontal bed and a rotating spindle that holds the workpiece. The operator can use various cutting tools, such as turning tools, boring tools, and threading tools, to shape the workpiece according to the desired specifications. The machine may also have additional features, such as a tailstock for supporting long workpieces and a cross-slide for more precise positioning.

Overall, a manual toolroom lathe is an essential tool in any toolroom or workshop setting, as it allows for precise and intricate machining operations on a wide range of materials. Its manual operation requires skilled machinists who can make adjustments and control the machine with precision to achieve the desired results.

Importance of manual toolroom lathes in machining

Manual toolroom lathes play a crucial role in the field of machining, providing operators with the ability to accurately and precisely shape and cut various materials. These lathes are essential tools in toolrooms and machine shops, allowing for intricate work and customization to meet specific requirements.

One key importance of manual toolroom lathes lies in their versatility. These lathes can work with a wide range of materials, including metal, wood, and plastics. This versatility allows for the production of various components, parts, and prototypes, making them highly valuable in industries such as automotive, aerospace, and manufacturing.

Manual toolroom lathes also provide operators with a high level of control and precision. Unlike their automated counterparts, manual lathes require hands-on operation, enabling operators to have direct control over the machining process. This level of control allows for meticulous adjustments and fine-tuning, resulting in accurate and flawless finished products.

Furthermore, manual toolroom lathes offer flexibility in terms of customization. Operators can easily adjust and modify the lathe’s settings, speed, and cutting tools to suit specific machining needs. This flexibility ensures that different materials and projects can be accommodated, enhancing efficiency and productivity in the machining process.

In conclusion, manual toolroom lathes play a vital role in the world of machining. Their versatility, precision, and flexibility make them indispensable tools in toolrooms and machine shops. By using manual lathes, operators can achieve exceptional results in shaping and cutting materials, enabling the production of high-quality components and parts.

Features to consider when choosing a manual toolroom lathe

When it comes to selecting a manual toolroom lathe, there are several important features to consider that can greatly impact its performance and suitability for your specific needs. These features include:

- Bed construction: The bed is the main frame of the lathe and should be made of high-quality, well-machined materials, such as cast iron. A rigid and stable bed is essential for accurate machining.

- Swing over bed: This refers to the maximum diameter of the workpiece that can be accommodated by the lathe. A larger swing over bed provides more versatility for different types of projects.

- Distance between centers: The distance between centers determines the maximum length of the workpiece that can be supported by the lathe. It is important to choose a lathe with a distance between centers that suits your specific needs.

- Spindle speed range: The spindle speed range determines the range of cutting speeds that can be achieved with the lathe. It is important to choose a lathe with a wide enough speed range to accommodate different materials and cutting operations.

- Tooling options: Consider the availability and compatibility of tooling options for the lathe. Look for a lathe that supports a wide range of tooling options to ensure maximum versatility.

- Accuracy and repeatability: Look for a lathe that provides high accuracy and repeatability in machining operations. This is essential for producing precise and consistent results.

By carefully considering these features when choosing a manual toolroom lathe, you can ensure that you are selecting a machine that meets your specific needs and provides excellent performance for your machining projects.

Precision and accuracy

Precision and accuracy are crucial factors to consider when selecting the best manual toolroom lathe. These lathes are designed to provide extremely accurate and precise results, making them ideal for intricate and delicate machining operations.

One key aspect that contributes to precision and accuracy is the robust construction of the lathe. The lathe should be made from high-quality materials and have a sturdy design to minimize vibrations and ensure stability during operation. This helps to prevent any deviation in measurements and ensures consistent and accurate machining results.

Additionally, the toolroom lathe should have advanced features such as precise spindle control, adjustable feed rates, and accurate depth of cut adjustment mechanisms. These features allow for fine-tuning and precise control over the machining process, resulting in accurate and repeatable cuts.

Furthermore, the lathe should have a reliable and precise measuring system, such as a high-resolution digital readout. This enables the machinist to monitor the dimensions and make accurate adjustments during the machining process. The lathe should also have a rigid and precise tool post system that securely holds the cutting tools in place, allowing for precise and consistent cuts.

In conclusion, precision and accuracy are vital considerations when choosing the best manual toolroom lathe. The lathe should have a robust construction, advanced features for precise control, and a reliable measuring system to ensure accurate and repeatable machining operations.

Versatility and flexibility

A manual toolroom lathe is a versatile and flexible machine that offers a wide range of functionalities. It allows for various types of machining operations, such as turning, facing, drilling, and threading, making it suitable for a wide range of applications. Whether you need to create intricate designs or produce simple parts, a manual toolroom lathe can handle it all.

One of the key advantages of a manual toolroom lathe is its flexibility. It can accommodate different materials, sizes, and shapes, allowing you to work with various workpieces. Whether you’re dealing with metals, plastics, or even wood, a manual toolroom lathe can handle the task. Its adjustable settings and interchangeable tooling options make it easy to adapt to different machining requirements.

Furthermore, a manual toolroom lathe offers the flexibility to make precise adjustments and fine-tune your machining process. You have complete control over the speed, feed rate, and depth of cut, allowing for precise and accurate results. This level of control is especially valuable when working on complex parts that require high precision.

In conclusion, the versatility and flexibility of a manual toolroom lathe make it an essential machine for any workshop. Its ability to handle various machining operations and accommodate different materials and shapes make it a reliable choice for a wide range of applications. Whether you’re a professional machinist or a hobbyist, a manual toolroom lathe can help you achieve your machining goals with precision and ease.

5 Best manual toolroom lathe

Features

| Part Number | Fafeicy8xk1zidugh2384 |

Features

| Part Number | TOPINCNnz4guki7o8 |

| Energy Efficiency Class | perfect |

Features

| Part Number | WYUK-063 |

Features

| Part Number | KYI9199280797950HW |

Q&A:

What is versatility?

Versatility refers to the ability to adapt or be adapted to many different functions or activities. It means being flexible and adaptable in various situations.

Why is versatility important?

Versatility is important because it allows individuals or things to be useful in different situations. It provides more opportunities and options, and can enhance problem-solving abilities.

What is flexibility?

Flexibility is the quality of being adaptable or easily bent without breaking. It can refer to physical flexibility in the body or the ability to be open-minded and adapt to change in one’s thinking or plans.

How can I improve my versatility and flexibility?

To improve versatility and flexibility, you can try new things and step out of your comfort zone. It’s important to be open to change and willing to learn new skills. Physical exercises like yoga or stretching can also help improve physical flexibility.

Conclusion

In conclusion, versatility and flexibility are two essential qualities that can greatly benefit individuals in various aspects of life. Whether it is in personal relationships, career choices, or day-to-day tasks, being adaptable and open-minded can lead to success and personal growth. By embracing new challenges and embracing change, individuals can become more resilient and better equipped to handle the uncertain nature of the world. With a versatile and flexible mindset, one can navigate through obstacles and seize opportunities with ease. Ultimately, versatility and flexibility are key traits that can enhance the quality of life and open doors to new possibilities.