Best cnc lathe shaft factories

When it comes to manufacturing high-quality CNC lathe shafts, it is important to find a reliable factory that can meet your specific needs. With the increasing demand for precision-engineered components, finding the best CNC lathe shaft factories has become crucial for many industries such as aerospace, automotive, and medical.

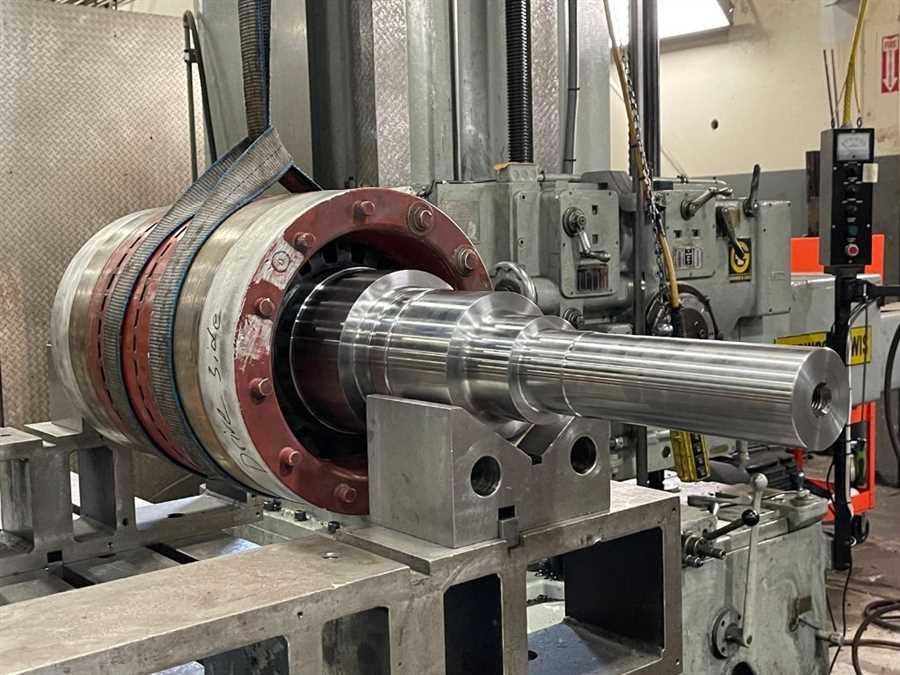

One of the key factors to consider when choosing a CNC lathe shaft factory is their ability to produce shafts with tight tolerances. These factories should have state-of-the-art CNC machinery and advanced measuring equipment to ensure accuracy and precision. Additionally, they should have a team of skilled engineers and technicians who have experience in creating complex and intricate lathe shaft designs.

Another important aspect to consider is the factory’s quality control processes. The best CNC lathe shaft factories have strict quality control measures in place to ensure that each shaft meets the required specifications. This could include thorough inspections at every stage of the manufacturing process, as well as proper documentation and traceability.

Lastly, it is essential to choose a CNC lathe shaft factory that has a strong reputation in the industry. Look for factories that have a track record of delivering high-quality products on time and have positive customer reviews. A reputable factory will also have a knowledgeable and responsive customer service team who can assist you throughout the manufacturing process.

Best CNC Lathe Shaft Factories: A Comprehensive Guide

In the field of manufacturing, CNC lathe shafts play a crucial role in various industries. When it comes to finding the best CNC lathe shaft factories, it can be a daunting task to filter through the numerous options available. To help you in your search, we have compiled a comprehensive guide that highlights some of the top CNC lathe shaft factories in the industry.

1. Precision Machining Co.: With years of experience and a reputation for delivering high-quality products, Precision Machining Co. is a leading CNC lathe shaft factory. They utilize advanced CNC machines and cutting-edge technology to manufacture precision-engineered shafts that meet the specific requirements of their clients. Their commitment to quality and customer satisfaction has made them a preferred choice among industries such as automotive, aerospace, and medical.

2. Advanced Manufacturing Ltd.: Known for their expertise in CNC machining, Advanced Manufacturing Ltd. is another top CNC lathe shaft factory. They have a team of skilled engineers and technicians who are adept at producing complex and customized shafts. Their state-of-the-art facility and strict quality control measures ensure that every shaft produced meets the highest standards of precision and durability.

3. Elite Shafts Inc.: With a focus on innovation and continuous improvement, Elite Shafts Inc. has gained a reputation for delivering top-notch CNC lathe shafts. They utilize advanced software and machinery to manufacture shafts with high dimensional accuracy and surface finish. Their commitment to research and development allows them to stay ahead of industry trends and provide their clients with cutting-edge solutions.

When selecting a CNC lathe shaft factory, it is essential to consider factors such as expertise, quality control measures, and the ability to meet specific requirements. The aforementioned factories have proven themselves in the industry and are known for their reliability and excellence in manufacturing CNC lathe shafts.

Exploring the Leading CNC Lathe Shaft Manufacturers in the Industry

When it comes to sourcing high-quality CNC lathe shafts, it is imperative to choose a reliable and reputable manufacturer. With the market flooded with numerous options, it can be challenging to determine which factories are the best. To help you make an informed decision, we have gathered information about some of the top CNC lathe shaft factories in the industry.

1. Specialized Shafts Co., Ltd: With years of experience and a strong focus on precision engineering, Specialized Shafts Co., Ltd has earned a reputation for producing top-notch CNC lathe shafts. Their state-of-the-art manufacturing facilities and skilled technicians ensure the highest quality standards are met. They offer a wide range of shaft options, including customizable designs, to cater to various industrial needs.

2. Precision Components Corporation: Known for their attention to detail and commitment to excellence, Precision Components Corporation is a leading manufacturer of CNC lathe shafts. They utilize advanced machinery and cutting-edge technologies to deliver shafts that exhibit superior performance and durability. Their stringent quality control measures guarantee consistency and reliability in every product.

3. Machined Components Inc: Machined Components Inc is a trusted name in the CNC lathe shaft manufacturing industry. They have a team of highly skilled engineers and technicians who leverage their expertise to produce shafts that adhere to strict tolerances and meet specific customer requirements. With a focus on continuous improvement and innovation, Machined Components Inc delivers reliable and high-quality shafts for various applications.

4. Precision Works Manufacturing: As the demand for CNC lathe shafts continues to grow, Precision Works Manufacturing has emerged as one of the prominent players in the market. They leverage their cutting-edge technology and advanced manufacturing processes to produce shafts with exceptional precision and accuracy. Their commitment to customer satisfaction and timely delivery makes them a preferred choice for many businesses.

5. Advanced Shafts Technologies: Advanced Shafts Technologies is renowned for its expertise in CNC lathe shaft manufacturing. They have a comprehensive range of shafts that are designed to meet the diverse needs of different industries. Their emphasis on quality, coupled with their extensive knowledge of machining, ensures that customers receive reliable and high-performance shafts.

When selecting a CNC lathe shaft factory, it is crucial to consider factors such as quality standards, customization options, delivery time, and customer support. By choosing one of the reputable factories mentioned above, you can ensure that you receive CNC lathe shafts of the highest quality and precision.

Factors to Consider when Choosing a CNC Lathe Shaft Factory

When looking for a CNC lathe shaft factory, there are several important factors to consider. These factors can help you ensure that you select a reliable and high-quality factory that meets your specific requirements. By taking these factors into account, you can make an informed decision and find a factory that will provide you with the best CNC lathe shafts for your needs.

One important factor to consider is the factory’s experience and expertise in producing CNC lathe shafts. A factory with years of experience in manufacturing these parts will likely have the knowledge and skills required to produce high-quality products. They will be familiar with the latest industry standards and have the ability to meet your specific requirements.

Another factor to consider is the factory’s production capacity. Depending on your needs, you may require a high volume of CNC lathe shafts within a specific timeframe. Therefore, it is important to choose a factory that can handle the production volume you require and deliver the products in a timely manner. This will help you avoid delays and ensure that your project proceeds smoothly.

Furthermore, it is essential to consider the factory’s quality control measures. A reputable CNC lathe shaft factory will have strict quality control processes in place to ensure that every product meets the highest standards. They should be able to provide documentation or certifications to prove that their products have undergone rigorous testing and inspection.

- Consider the factory’s experience and expertise in producing CNC lathe shafts.

- Evaluate the factory’s production capacity to ensure they can meet your volume requirements.

- Assess the factory’s quality control measures to ensure high-quality products.

By considering these factors, you can choose a CNC lathe shaft factory that will meet your requirements and provide you with reliable and durable products. Taking the time to research and evaluate different factories will ultimately lead to a successful partnership and the availability of high-quality CNC lathe shafts for your projects.

Quality Standards and Certifications for CNC Lathe Shafts

When it comes to CNC lathe shafts, ensuring high quality is crucial for their performance and reliability. The use of quality standards and certifications plays a significant role in reassuring customers about the quality of these products.

One of the commonly recognized quality standards for CNC lathe shafts is ISO 9001. This certification signifies that the manufacturer has implemented a comprehensive quality management system and meets the requirements for consistent quality. It covers aspects such as the design, development, production, installation, and servicing of CNC lathe shafts.

In addition to ISO 9001, manufacturers may also seek certifications specific to the industry or market they serve. For example, some CNC lathe shaft factories may possess certifications from industries like automotive, aerospace, or medical. These certifications demonstrate compliance with industry-specific quality standards, ensuring that the CNC lathe shafts meet the stringent requirements of these sectors.

To further enhance confidence in the quality of CNC lathe shafts, manufacturers may also undergo product testing and certification by independent organizations. These tests may evaluate factors such as material strength, dimensional accuracy, and performance under various operating conditions. Certifications from such organizations provide customers with an additional level of assurance about the quality and reliability of the CNC lathe shafts.

In conclusion, quality standards and certifications are essential for CNC lathe shafts as they establish the manufacturer’s commitment to producing high-quality products. ISO 9001 certification and industry-specific certifications ensure compliance with general and sector-specific quality requirements, while independent product testing adds an extra layer of confidence for customers. When choosing CNC lathe shafts, customers should consider products from factories that prioritize quality and possess appropriate certifications.

5 Best cnc lathe shaft factories

Features

| Part Number | Spacnanay3gibkwug1-13 |

| Model | Spacnanay3gibkwug1-13 |

| Size | SBHA 20-32 |

Features

| Part Number | 70MMKP2-3/4AU |

| Model | KP2-3/4 |

| Color | Argent |

Features

| Part Number | Walfrontd0z42a7n9v2955 |

Features

| Part Number | TP849515XWTRPAR10K0 |

| Model | TP849515XWTRPAR10K0 |

| Color | As Shown |

| Size | 300mm |

Question-answer:

What are quality standards for CNC lathe shafts?

Quality standards for CNC lathe shafts refer to the set of criteria and requirements that determine the level of quality and performance expected from these components. These standards ensure that the shafts meet specific dimensions, tolerances, surface finish, and other critical parameters.

What are some commonly used quality standards for CNC lathe shafts?

Some commonly used quality standards for CNC lathe shafts include ISO 9001:2015, ISO 14001:2015, AS9100D, ISO 13485:2016, and ISO/TS 16949:2016. These standards cover various aspects of quality management, environmental management, aerospace quality management, medical device quality management, and automotive quality management, respectively.

What is the purpose of certifications for CNC lathe shafts?

Certifications for CNC lathe shafts serve as official recognition that the shafts meet the required quality standards. These certifications provide assurance to customers and other stakeholders that the shafts have been tested and verified to meet the specified criteria, ensuring reliability, performance, and safety.

How can one obtain certifications for CNC lathe shafts?

To obtain certifications for CNC lathe shafts, manufacturers need to undergo a certification process conducted by accredited certification bodies. This process typically involves an assessment of the manufacturing processes, quality management systems, and product testing procedures to ensure compliance with the relevant standards. If all requirements are met, the certification body will issue the necessary certifications.

What are the benefits of complying with quality standards and obtaining certifications for CNC lathe shafts?

Complying with quality standards and obtaining certifications for CNC lathe shafts can provide several benefits. These include enhanced credibility and trust in the market, improved product quality and consistency, increased customer satisfaction, access to new markets and customers who require certified components, and compliance with regulatory requirements in certain industries.

What are quality standards for CNC lathe shafts?

There are several quality standards applicable to CNC lathe shafts. Some of the commonly used standards include ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018. These standards ensure that the manufacturing processes, materials used, and final products meet certain quality criteria.

Are there any certifications specific to CNC lathe shafts?

Yes, there are certifications that are specific to CNC lathe shafts. One example is the AS9100 certification, which is an aerospace industry standard that includes specific requirements for CNC machined components, including lathe shafts. This certification ensures that the products meet the quality requirements of the aerospace industry.

Conclusion

In conclusion, quality standards and certifications play a crucial role in ensuring the reliability and performance of CNC lathe shafts. The adoption of these standards can help manufacturers uphold consistent quality, meet customer expectations, and enhance the overall efficiency of their operations. Certifications such as ISO 9001 and ISO 14001 signify a company’s commitment to maintaining high quality, while standards like ISO 286-2 and ISO 230-2 provide detailed guidelines for the production and measurement of lathe shafts. By adhering to these standards and obtaining certifications, manufacturers can instill confidence in their customers and strengthen their position in the market. Overall, quality standards and certifications are essential in achieving excellence in CNC lathe shaft manufacturing.