Best carbide wood lathe tools

Woodturning is an art that requires precision and skill, and having the right tools is essential for achieving the best results. Carbide wood lathe tools have become increasingly popular among woodturners for their durability, versatility, and ease of use. These tools are made with carbide inserts that can be easily rotated or replaced when worn out, saving time and money in the long run.

One of the advantages of carbide wood lathe tools is their exceptional sharpness and cutting ability. The carbide inserts are designed to stay sharp for a longer period, allowing woodturners to make clean cuts effortlessly. This is especially important when working with hardwoods or difficult-to-turn materials, as it reduces the risk of tear-out and provides a smoother finish.

Another benefit of carbide wood lathe tools is their versatility. These tools come in a variety of shapes and sizes, allowing woodturners to tackle different projects with ease. Whether it’s roughing, shaping, or finishing, there’s a carbide tool that can get the job done efficiently. Additionally, carbide inserts can be rotated to expose a fresh cutting edge, extending the tool’s lifespan and eliminating the need for constant sharpening.

What are Carbide Wood Lathe Tools?

Carbide wood lathe tools, often called carbide tipped woodturning tools or carbide inserts, are special cutting tools designed for use with a wood lathe. They consist of a hardened steel body with a replaceable carbide insert attached to the cutting edge. These tools are specifically designed to provide efficient and precise wood turning results, making them a popular choice among woodworkers and artisans.

Carbide wood lathe tools offer several advantages over traditional high-speed steel tools. Firstly, the carbide inserts are extremely durable and can maintain their sharpness for a longer period of time, reducing the need for frequent sharpening. This makes them ideal for extended woodturning sessions or heavy-duty projects. Additionally, carbide inserts are designed with multiple cutting edges, allowing for quick and easy rotation of the cutting edge when it becomes dull. This not only saves time but also provides a cost-effective solution for woodturners.

Carbide wood lathe tools come in a variety of shapes and sizes to accommodate different woodturning techniques. Some common types include roughing gouges, spindle gouges, bowl gouges, and parting tools. Each tool has a specific shape and function, allowing woodturners to create various shapes and designs in the wood. These tools are known for their stability and ease of use, making them suitable for both beginners and experienced woodturners.

Overall, carbide wood lathe tools offer versatility, durability, and efficiency for woodturners. They provide exceptional cutting performance and require less maintenance compared to traditional high-speed steel tools. Whether you are a professional woodworker or a hobbyist, using carbide wood lathe tools can enhance your woodturning experience and help you achieve precise and beautiful results.

Advantages of Carbide Wood Lathe Tools

Carbide wood lathe tools offer several advantages over traditional high-speed steel tools when it comes to woodworking. The unique properties of carbide allow for greater efficiency, durability, and accuracy in wood turning applications.

1. Longer Lifespan: Carbide wood lathe tools have a significantly longer lifespan compared to high-speed steel tools. This is due to the extreme hardness of the carbide material, which allows it to maintain a sharp edge for a longer period of time. This means less time spent on tool maintenance and more time spent on woodworking projects.

2. Greater Cutting Speed: Carbide wood lathe tools can be used at much higher cutting speeds than high-speed steel tools. The hardness of carbide allows for faster feed rates, resulting in smoother cuts and reduced chip loads. This is especially beneficial when working with dense or difficult-to-turn woods.

3. Reduced Vibration: Carbide wood lathe tools have a dampening effect on vibrations, leading to a smoother turning experience. The rigid structure of carbide helps to minimize chatter and vibration, resulting in cleaner cuts and improved surface finishes.

4. Versatility: Carbide wood lathe tools are available in a wide range of shapes and sizes to suit various cutting needs. From roughing gouges to detail spindle gouges, there is a carbide tool for every woodworking task. The replaceable carbide inserts also allow for easy and cost-effective tool maintenance.

5. Minimal Resharpening: Unlike traditional high-speed steel tools that require frequent resharpening, carbide wood lathe tools do not need to be sharpened as often. The sharp edges of the carbide inserts can simply be rotated or replaced when they become dull, saving time and effort in the workshop.

Overall, carbide wood lathe tools are a valuable investment for woodturners of all skill levels. They offer exceptional performance and longevity, making woodworking tasks more efficient and enjoyable.

Factors to Consider When Choosing Carbide Wood Lathe Tools

When it comes to choosing carbide wood lathe tools, there are several factors that you should consider to ensure you get the best tools for your needs. These factors will help you choose tools that are durable, efficient, and produce high-quality results.

1. Material Quality: One of the most important factors to consider is the quality of the carbide material used in the tools. High-quality carbide tools are made from a durable and long-lasting material that can withstand the harsh conditions of wood turning. Look for tools that are made from solid carbide or have a carbide tip, as these will provide better performance and longevity.

2. Cutting Geometry: The cutting geometry of the lathe tools can greatly affect the quality of the wood turning. Different tools have different cutting angles and profiles, which can impact the smoothness of the cuts and the ability to shape the wood. Consider the type of wood projects you plan to work on and choose tools with appropriate cutting geometries to achieve the desired results.

3. Tool Size and Shape: The size and shape of the tools are also important considerations. While larger tools may allow for faster stock removal, smaller tools can provide more control and precision. Additionally, the shape of the tools, such as straight edges or curved profiles, can determine the types of cuts and designs you can create. Assess your wood turning needs and select tools that are sized and shaped appropriately.

4. Ease of Use: Another factor to consider is the ease of use of the carbide wood lathe tools. Look for tools that have comfortable handles and ergonomic designs to reduce fatigue during long periods of use. Additionally, tools with replaceable carbide tips can be more convenient, as you can easily replace the worn-out tips without having to buy a whole new tool.

5. Price: Lastly, consider your budget when choosing carbide wood lathe tools. While high-quality tools may come at a higher price, they often offer better performance and durability. However, there are also affordable options available that can still provide satisfactory results. Compare prices and consider the long-term value of the tools before making a decision.

By considering these factors, you can make an informed decision when choosing carbide wood lathe tools that meet your specific needs and help you achieve the best results in your woodworking projects.

Type of Cutting Edge

The type of cutting edge on a carbide wood lathe tool plays a crucial role in its performance and versatility. There are several different types of cutting edges that can be found on these tools, each designed to excel in specific applications.

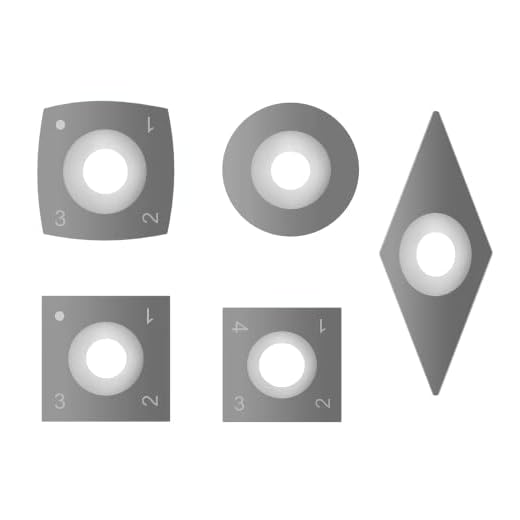

One common type of cutting edge is the straight edge, which is ideal for making straight cuts and shaping the wood’s surface. The straight edge allows for precise control and accuracy, making it a popular choice for detailed work and delicate projects. Another type of cutting edge is the round edge, which is used for creating curves and contours. The rounded shape allows for smooth and fluid movements, making it perfect for shaping bowls, vases, and other rounded objects.

There are also cutting edges with pointed tips, known as diamond or pointed tips, which are commonly used for creating fine details and intricate designs. These cutting edges are excellent for creating ornamental work and adding texture to the wood’s surface. Another type of cutting edge is the radius edge, which has a rounded tip that is slightly thicker than the round edge. This type of cutting edge is perfect for roughing out the initial shape of the wood, as well as for making large cuts and removing material quickly.

In addition to these basic cutting edges, there are also various combinations and variations available, such as the square edge, the negative rake angle, and the chipbreaker edge. Each of these cutting edges has its own unique characteristics and advantages, allowing woodturners to choose the best tool for their specific needs and preferences. By understanding the different types of cutting edges, woodturners can select the right tool for each project and achieve the desired results efficiently and effectively.

Handle Material

The handle material of a carbide wood lathe tool is an important aspect to consider when choosing the best tool for your woodworking needs. The handle is where you grip the tool and provide the control and maneuverability required for precise wood turning. It is essential that the handle is comfortable to hold, offers a good grip, and is durable enough to withstand the demands of wood turning.

There are several types of handle materials commonly used in carbide wood lathe tools. One popular option is hardwood, which provides a natural and classic look. Hardwood handles are known for their durability and strength, making them ideal for withstanding the forces applied during wood turning. They also offer a comfortable grip and can absorb vibrations, resulting in a smoother wood turning experience. Some common types of hardwood used for handles include oak, ash, and beech.

- Advantages of Hardwood Handles:

- – Durable and strong

- – Comfortable grip

- – Absorbs vibrations

Another handle material often used in carbide wood lathe tools is composite material. This is a combination of different materials, such as fiberglass and epoxy resin, which are molded together to form a handle. Composite handles are lightweight, yet strong and durable. They offer a comfortable grip and are resistant to moisture, making them suitable for both indoor and outdoor wood turning projects. Additionally, composite handles are less likely to crack or split, providing a longer lifespan for the tool.

- Advantages of Composite Handles:

- – Lightweight and strong

- – Comfortable grip

- – Resistant to moisture

5 Best carbide wood lathe tools

Features

| Part Number | 302222 |

| Color | Silver |

Features

| Part Number | DJMY-BIXCY190 |

| Model | DJMY-BIXCY190 |

Features

| Size | Check size picture |

Features

| Part Number | MB047 |

| Model | MB047 |

Questions and answers:

What is handle material?

Handle material refers to the substance or material used to make the handle of a tool, knife, or other objects. It can be made of various materials like wood, plastic, metal, or composite materials.

What are the different types of handle materials?

Some common types of handle materials include wood (such as walnut, ebony, or rosewood), plastic (such as G-10, PVC, or nylon), metal (such as stainless steel or aluminum), and composite materials (such as carbon fiber or fiberglass).

What factors should I consider when choosing handle materials?

When choosing handle materials, consider factors such as durability, grip, weight, and aesthetics. Each material has its own advantages and disadvantages, so it depends on your personal preferences and the intended use of the tool or object.

Are there any popular handle materials for specific purposes?

Yes, for example, wood handles are commonly used for traditional and decorative knives, while G-10 or other plastic handles are popular for tactical or outdoor knives due to their durability and non-slip properties. It ultimately depends on the intended use and the user’s preferences.

Conclusion

In conclusion, the choice of handle material is an important consideration when selecting tools, appliances, or other items. Different handle materials offer varying levels of durability, comfort, and aesthetic appeal. Each material has its own unique qualities that should be taken into account depending on the intended use and personal preferences. Whether it be the classic elegance of wood, the sleekness of metal, the versatility of plastic, or the reliability of rubber, it is essential to choose a handle material that is both functional and visually pleasing. By understanding the advantages and disadvantages of different handle materials, individuals can make informed decisions that will enhance their overall experience and satisfaction with the products they use. So next time you are in the market for a new tool or appliance, consider the handle material as a key factor in your decision-making process.