Best carbide metal lathe tools

When it comes to working with metal on a lathe, having the right tools is essential. One type of tool that is highly recommended for this task is carbide metal lathe tools. Carbide tools are known for their durability, wear resistance, and ability to cut through various types of metal with ease.

Carbide metal lathe tools are made from a combination of carbide and cobalt, which gives them their unique characteristics. The carbide inserts on these tools are extremely hard and can withstand heat and high speeds without dulling or chipping. This makes them ideal for precision cutting and shaping metal on a lathe.

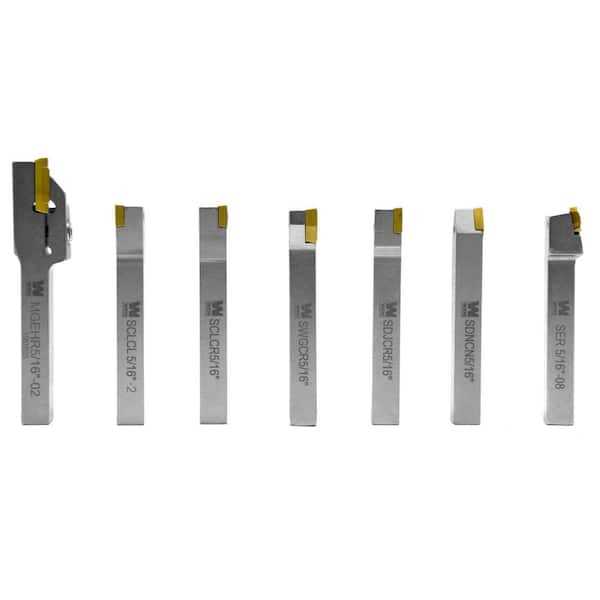

There are various types of carbide metal lathe tools available, each designed for specific tasks. Some of the most popular ones include carbide turning tools, carbide boring bars, and carbide threading tools. These tools come in different shapes and sizes to accommodate different lathe machines and metalworking projects.

When choosing the best carbide metal lathe tools, it is important to consider factors such as the type of metal you will be working with, the size of your lathe machine, and the specific task you need to perform. Additionally, it is worth investing in high-quality carbide tools from reputable brands to ensure longevity and optimal performance.

What are carbide metal lathe tools?

Carbide metal lathe tools are cutting tools specifically designed for use on metal lathes, also known as engine lathes. These tools are commonly used in machining operations to shape and cut metal workpieces with precision and efficiency. Unlike traditional high-speed steel (HSS) tools, carbide lathe tools are made of a much harder material called carbide, which allows them to withstand higher cutting speeds and last longer.

Carbide metal lathe tools consist of a carbide cutting insert that is mounted on a tool holder. The carbide insert is the actual cutting edge of the tool, and it is usually replaceable, allowing for easy and cost-effective tool maintenance. The tool holder, on the other hand, holds the cutting insert securely in place and provides the necessary stability and rigidity during cutting operations.

One of the key advantages of carbide metal lathe tools is their ability to maintain a sharp cutting edge for an extended period of time. This is due to the high hardness and wear resistance of carbide, which allows the tools to cut through metal materials without dulling or chipping easily. Additionally, carbide lathe tools are capable of withstanding high temperatures generated during cutting, making them suitable for a wide range of metalworking applications.

Carbide metal lathe tools come in various shapes and sizes, each designed for specific cutting operations and metal materials. Common types of carbide lathe tools include turning tools, facing tools, parting tools, and boring tools. These tools can be used on different types of metal lathes, from small benchtop lathes to large industrial lathes, and are widely used in industries such as aerospace, automotive, and manufacturing.

The Importance of Using Carbide Metal Lathe Tools

The use of carbide metal lathe tools is of utmost importance when it comes to achieving precise and efficient machining operations. Carbide tools are made from a combination of tungsten carbide and cobalt, which makes them extremely durable and resistant to wear and tear. This, in turn, results in a longer tool life, reduced downtime for tool changes, and ultimately, increased productivity.

One of the key advantages of carbide metal lathe tools is their ability to withstand high cutting speeds and feeds. Unlike traditional high-speed steel tools, carbide tools can handle intense heat and pressures without losing their cutting edge. This enables machinists to work at faster speeds, saving valuable time and increasing output. Additionally, carbide tools have excellent chip control, which helps prevent chip buildup and promotes efficient chip evacuation, further enhancing the overall machining process.

Utilizing carbide metal lathe tools also offers superior surface finish and accuracy. Due to their extreme hardness, carbide tools can maintain a sharp cutting edge even when machining tough materials such as stainless steel and hardened steel. This results in smoother and more precise cuts, minimizing the need for secondary finishing operations. The ability of carbide tools to hold tight tolerances ensures that the final product meets the required specifications, enhancing the overall quality and reliability of the machined parts.

Furthermore, the use of carbide metal lathe tools can result in cost savings in the long run. While carbide tools may have a higher initial cost compared to other tooling options, their extended tool life and increased performance more than compensate for the initial investment. With carbide tools, machinists can experience fewer tool replacements, reduced material waste, and improved overall efficiency, leading to a significant reduction in production costs over time.

In conclusion, the use of carbide metal lathe tools offers numerous advantages, including increased tool life, enhanced productivity, superior surface finish, and cost savings. By investing in high-quality carbide tools, machinists can optimize their machining operations and ensure outstanding results.

Features to consider when choosing carbide metal lathe tools

When it comes to selecting carbide metal lathe tools, there are several important features to consider. These tools are designed to cut through tough materials with precision and efficiency, so choosing the right features is essential for achieving optimal results.

Durability:

One of the key features to consider when choosing carbide metal lathe tools is their durability. Carbide cutting tips are known for their strength and ability to withstand high temperatures and wear. Look for tools with a solid carbide composition that can resist chipping, cracking, and other common issues that can occur during machining processes.

Design:

The design of the carbide metal lathe tools is another important aspect to consider. Look for tools with a well-designed geometry that allows for smooth chip evacuation and efficient material removal. The angle and shape of the cutting edge should be optimized for the specific application, whether it’s roughing, finishing, or threading. Consider tools with multiple cutting edges or inserts that can be rotated or replaced as needed.

Cutting Speed and Feed Rate:

Consider the recommended cutting speed and feed rate for the carbide metal lathe tools before making a purchase. These values can vary depending on the material being machined and the desired surface finish. Tools with lower cutting speeds and higher feed rates are generally more efficient, but it’s important to find the right balance to avoid tool wear or damage.

Compatibility:

Lastly, ensure that the carbide metal lathe tools you choose are compatible with your lathe machine. Check the tool holder or insert style required, as well as the dimensions and specifications of the tools. It’s always a good idea to consult the lathe manufacturer’s recommendations or seek professional advice to ensure compatibility and avoid any compatibility issues.

By considering these features, you can select the right carbide metal lathe tools for your specific machining needs, resulting in efficient and high-quality results.

Material Composition of Carbide Metal Lathe Tools

Carbide metal lathe tools are known for their durability and ability to handle high-speed cutting operations. One of the key factors contributing to their performance is the material composition used in their construction.

Typically, carbide metal lathe tools are made from a combination of tungsten carbide and cobalt. Tungsten carbide is an extremely hard and wear-resistant material, making it ideal for cutting through tough metals. Cobalt is added to the mix to improve the toughness and strength of the tools, enhancing their ability to withstand high loads and extreme cutting conditions.

Additionally, carbide metal lathe tools may also contain trace elements such as titanium, tantalum, or niobium. These elements can further enhance the performance of the tools by improving their heat resistance, hardness, and overall toughness. The specific composition of the carbide tools may vary depending on the manufacturer and the intended application.

Overall, the material composition of carbide metal lathe tools plays a crucial role in determining their performance and longevity. The combination of tungsten carbide and cobalt, along with other trace elements, ensures that these tools can withstand the demands of high-speed cutting operations and provide excellent results for various metalworking applications.

Cutting edge design and geometry

When it comes to carbide metal lathe tools, the cutting edge design and geometry play a crucial role in ensuring optimal performance and durability. The design of these tools focuses on maximizing their cutting efficiency and longevity, allowing for precise and efficient metalworking operations.

The cutting edge design involves the shape, size, and angle of the tool’s insert or blade. The geometry of the cutting edge is carefully engineered to provide the ideal combination of strength, sharpness, and chip evacuation. This ensures that the tool can withstand the high temperatures and forces involved in metal cutting while effectively removing material.

Sharper cutting edges are achieved through precise grinding and finishing processes, resulting in a tool that can create clean and accurate cuts. The shape and size of the cutting edge are optimized to reduce the cutting forces and minimize vibrations, resulting in improved surface finishes and reduced tool wear.

Chip evacuation is also an important consideration in the design of carbide metal lathe tools. The geometry of the cutting edge ensures that chips are efficiently removed from the cutting zone, preventing chip crowding and reducing the risk of workpiece damage or tool breakage.

In conclusion, the cutting edge design and geometry of carbide metal lathe tools are essential factors in their performance and longevity. By focusing on sharpness, optimal shape, and efficient chip evacuation, these tools can provide precision and efficiency in metalworking applications.

5 Best carbide metal lathe tools

Features

| Part Number | VSW8522820982477LQ |

Features

| Is Adult Product | |

| Release Date | 2021-10-25T00:00:01Z |

| Language | English |

| Number Of Pages | 113 |

| Publication Date | 2021-10-25T00:00:01Z |

Features

| Part Number | 9YOVAR6V417QWRQ1913NE4PW |

| Color | Blue |

| Size | 6.4X0.4cm |

Features

| Part Number | Walfrontkyq123f5xp |

| Model | Walfrontkyq123f5xp |

Q&A:

What is cutting edge design and geometry?

Cutting edge design and geometry refers to the latest and most innovative techniques and concepts in the field of design and geometry. It often involves using advanced technologies and materials to create unique and visually appealing designs.

How can cutting edge design and geometry benefit different industries?

Cutting edge design and geometry can benefit different industries by offering new ways to solve problems, improve efficiency, and enhance user experiences. It can also help businesses differentiate themselves and stay ahead of the competition.

What are some examples of cutting edge design and geometry in architecture?

Some examples of cutting edge design and geometry in architecture include buildings with complex and unconventional shapes, innovative use of materials, and sustainable design features.

How does cutting edge design and geometry impact product design?

Cutting edge design and geometry can have a significant impact on product design by allowing for more advanced and efficient manufacturing processes, improved functionality, and enhanced aesthetics. It can also open up new possibilities for customization and personalization.

What skills are required to work in cutting edge design and geometry?

Working in cutting edge design and geometry often requires a combination of technical skills, such as proficiency in CAD software and knowledge of advanced manufacturing techniques, as well as creativity, problem-solving abilities, and a strong understanding of aesthetics and user needs.

What is cutting edge design?

Cutting edge design is a term used to describe innovative and revolutionary designs that push the boundaries of traditional design principles. It involves incorporating new materials, technologies, and aesthetics to create visually appealing and functional products or spaces.

What is cutting edge geometry?

Cutting edge geometry refers to the use of advanced mathematical principles and techniques in the design and creation of three-dimensional shapes and structures. It involves the application of complex algorithms, computer-aided design tools, and fabrication methods to create unique and intricate geometries that were previously not possible.

Conclusion

In conclusion, cutting edge design and geometry are vital in today’s fast-paced and competitive world. They allow businesses and individuals to stand out from the crowd and make a lasting impression. With cutting edge design, products and services can be visually captivating and engaging. Geometry, on the other hand, allows for precision and efficiency in various fields such as architecture, engineering, and manufacturing. By combining the two, innovative and groundbreaking solutions can be achieved. As technology continues to evolve, it is crucial for designers, engineers, and creators to stay up to date with the latest design trends and geometry principles. This will ensure that they remain at the forefront of their respective industries and continue to push boundaries. Ultimately, cutting edge design and geometry have the power to shape the world we live in and shape the future of innovation.