Is a cool melt glue gun too hot for plastic

When it comes to crafting and DIY projects, a glue gun is a handy tool to have. But if you’re working with delicate materials like plastic, you might be wondering if a cool melt glue gun is a safe option. After all, no one wants their plastic items to melt or warp during the gluing process.

The good news is that cool melt glue guns are specifically designed for low-temperature applications, making them ideal for working with materials like plastic. Unlike traditional hot glue guns, which operate at higher temperatures, cool melt glue guns have a lower heat output, reducing the risk of damage to sensitive materials.

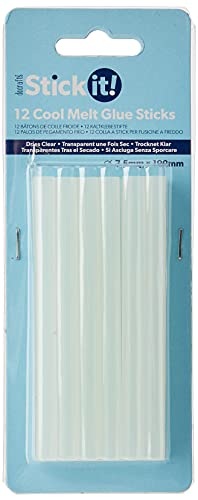

However, it’s still important to exercise caution when using a cool melt glue gun with plastic. While the lower temperature can help minimize the risk of melting, it’s essential to choose the right type of glue stick for the job. Opt for a glue stick that is specifically labeled as safe for use with plastic, as these are formulated to have a lower melting point.

Additionally, it’s crucial to apply the glue judiciously and avoid using excessive amounts. Too much glue can increase the heat transfer and potentially damage the plastic. Remember to let the glue gun fully heat up before use, and always test a small, inconspicuous area before applying glue to the entire piece.

Overview

When it comes to working with plastic, using a glue gun can be a convenient and efficient option. However, it’s important to ensure that the glue gun you choose is not too hot for the type of plastic you are using. If the temperature is too high, the plastic may melt, warp, or become damaged.

One popular type of glue gun is the cool melt glue gun. As the name suggests, this type of glue gun operates at a lower temperature compared to some other models. The cool melt glue gun typically reaches a temperature of around 250°F (120°C).

While a cool melt glue gun may seem less powerful compared to a high-temperature glue gun, it can still effectively bond various types of plastic materials. It is suitable for use with lightweight and thin plastics, such as craft foam, thin PVC sheets, and certain types of plastic containers.

However, for thicker or heavier plastics, such as ABS or polycarbonate, a higher temperature may be required for a stronger bond. In these cases, it is recommended to use a glue gun with a higher temperature range.

Advantages of Cool Melt Glue Guns

Cool melt glue guns offer several advantages when working with plastic materials:

- Gentle on the material: The lower temperature of the glue gun helps to prevent damage or distortion to the plastic.

- Quick drying time: Cool melt glue typically dries faster than its hot melt counterparts, allowing for more efficient work.

- Safer to use: With a lower temperature, there is reduced risk of burns or accidents when using a cool melt glue gun.

Tips for Using a Cool Melt Glue Gun with Plastic

Here are some tips to keep in mind when using a cool melt glue gun with plastic:

- Choose the right glue sticks: Use glue sticks that are specifically designed for use with cool melt glue guns and plastic materials.

- Test on a small area: Before applying the glue to the entire surface, test it on a small, inconspicuous area of the plastic to ensure it adheres properly without causing any damage.

- Apply even pressure: When gluing plastic, apply even pressure to ensure a strong bond between the adhesive and the plastic surface.

- Avoid excessive glue: Using too much glue can result in unsightly messiness or dripping. Use a controlled amount to achieve a neat and clean bond.

By following these guidelines, you can safely and effectively use a cool melt glue gun with plastic materials, ensuring secure and long-lasting bonds without causing damage to the plastic surfaces.

Effects of Temperature on Plastic

Plastics are widely used materials due to their versatility and durability. However, they can be sensitive to temperature changes, which can have various effects on their properties and performance. Understanding these effects is essential for ensuring the proper use and longevity of plastic products.

Melting Point

Each type of plastic has a specific melting point, which is the temperature at which it transitions from a solid to a liquid state. Exposing plastic to temperatures higher than its melting point can cause it to melt, deform, or even burn. Therefore, it is crucial to avoid subjecting plastic to temperatures beyond its maximum limit to prevent damage.

Thermal Expansion and Contraction

Plastic materials expand and contract with changes in temperature, just like most other materials. When exposed to high temperatures, plastics tend to expand, and when cooled, they contract. This thermal expansion and contraction can lead to dimensional changes in plastic products, which may affect their fit, function, or structural integrity.

Brittleness

Extreme cold temperatures can cause certain plastics to become brittle. When plastic materials lose their flexibility, they become more prone to cracking, breaking, or shattering upon impact. This is why it is essential to consider the intended application and temperature range when selecting a plastic material for a specific use.

Thermal Degradation

Prolonged exposure to high temperatures can cause thermal degradation of plastic materials. This degradation involves chemical changes in the structure of the plastic, leading to a loss of strength, stiffness, and other mechanical properties. It can also result in discoloration, warping, or the release of toxic fumes.

To ensure the longevity of plastic products, it is important to avoid exposing them to temperatures beyond their recommended operating range. Manufacturers often specify the recommended temperature limits for their plastic materials, and it is crucial to adhere to these guidelines to prevent any adverse effects on the plastic’s performance.

Cool Melt Glue Guns: What are They?

Cool melt glue guns are a type of glue gun that operate at lower temperatures compared to traditional hot glue guns. They are designed for use with materials that may be sensitive to high heat, such as plastic.

Unlike hot glue guns that typically use glue sticks with a melting point between 375°F and 450°F (190°C and 232°C), cool melt glue guns have lower temperature settings ranging from 250°F to 350°F (121°C to 177°C). This makes them ideal for crafts and projects that involve delicate materials.

Cool melt glue guns work by heating the adhesive stick to a lower temperature, which allows them to be used on plastic, foam, and other heat-sensitive materials without causing damage. The glue sticks used with cool melt glue guns are specially formulated to have a lower melting point, but still provide a strong bond.

These glue guns are also convenient to use as they heat up quickly, usually within a few minutes, and have a comfortable grip. They come with a trigger mechanism that allows for precise control of the glue flow, reducing the chance of accidental spills or excessive glue application.

In addition to their lower operating temperature, cool melt glue guns often have additional safety features such as automatic shut-off after a period of inactivity or a built-in stand to prevent the heated tip from touching surfaces.

Whether you’re a DIY enthusiast or a professional crafter, a cool melt glue gun can be a useful tool for your creative projects. Its lower temperature makes it versatile and safe to use on a variety of materials, including plastic, without the risk of damage or deformation.

So, if you’re looking for a glue gun that’s gentle on plastic and other delicate materials, consider investing in a cool melt glue gun.

Advantages of Using a Cool Melt Glue Gun

A cool melt glue gun is a versatile tool that offers several advantages over traditional hot melt glue guns. From its lower temperature to the ease of use, here are some benefits of using a cool melt glue gun:

1. Low Temperature

One of the main advantages of a cool melt glue gun is that it operates at a lower temperature compared to hot melt glue guns. This makes it suitable for use on delicate materials such as plastic. The lower temperature reduces the risk of damage, melting, or warping of the plastic surfaces.

2. Safer to Use

With a cool melt glue gun, there is a decreased risk of burns or injuries compared to hot melt glue guns. The lower temperature reduces the likelihood of accidental contact with the heated glue and minimizes the risk of skin burns. This makes it a safer option, especially when working with children or in a busy environment.

3. Quick Bonding

Cool melt glue guns also offer quick bonding capabilities. The glue solidifies rapidly after application, allowing for faster project completion. This is especially beneficial when working on time-sensitive or small-scale projects where waiting for the glue to cool down can be time-consuming.

In summary, a cool melt glue gun provides several advantages over traditional hot melt glue guns. Its lower temperature makes it suitable for working on plastic and other delicate materials, and it offers a safer user experience. Additionally, the quick bonding capabilities of a cool melt glue gun allow for efficient project completion.

FAQ

Does a cool melt glue gun generate enough heat to melt plastic?

Yes, a cool melt glue gun generates enough heat to melt plastic. However, it operates at a lower temperature compared to a regular hot glue gun, making it safer to use on delicate materials.

Can I use a cool melt glue gun on plastic without damaging it?

Yes, you can safely use a cool melt glue gun on plastic without damaging it. Since it operates at a lower temperature, it reduces the risk of melting or warping the plastic.

Is a cool melt glue gun suitable for bonding plastic crafts?

Yes, a cool melt glue gun is suitable for bonding plastic crafts. It provides a secure bond while minimizing the risk of damaging the plastic due to excessive heat.

What are the advantages of using a cool melt glue gun on plastic?

Using a cool melt glue gun on plastic offers several advantages. First, it reduces the risk of melting or warping the plastic. Second, it provides a secure bond without the need for high temperatures. Finally, it allows for precise and controlled application of glue.

Are there any disadvantages of using a cool melt glue gun on plastic?

While using a cool melt glue gun on plastic has its advantages, there are also a few disadvantages to consider. The lower temperature may result in a slightly weaker bond compared to a hot glue gun. Additionally, it may take longer for the glue to set and fully cure, depending on the specific adhesive being used.