How hot melt glue gun works

A hot melt glue gun is a versatile tool that is commonly used for crafts, DIY projects, and small repairs. It works by heating a solid adhesive, often in the form of a cylindrical stick, until it reaches a liquid state. The heated glue is then dispensed through a nozzle at the end of the gun.

The glue inside the gun is typically made from materials such as polymers, resins, and wax. When heated, these materials melt and become viscous, allowing the glue to flow easily through the nozzle. The gun is designed with a heating element that rapidly raises the temperature of the glue, quickly transforming it into a liquid state.

Once the liquid glue is dispensed onto a surface, it cools and solidifies, forming a strong bond. The cooling process happens rapidly, causing the glue to harden within a matter of seconds. This allows users to quickly apply the glue and continue with their project without having to wait for the adhesive to dry.

The hot melt glue gun is powered by electricity and is typically equipped with a trigger mechanism that controls the flow of glue. When the trigger is squeezed, the heated glue is forced out through the nozzle. Some guns also have adjustable temperature settings, allowing users to control the viscosity of the glue and its bonding strength.

In conclusion, a hot melt glue gun works by heating a solid adhesive until it becomes a liquid and then dispensing it through a nozzle. The glue quickly cools and solidifies upon contact with a surface, creating a strong bond. This tool is widely used for various applications due to its ease of use and fast drying time.

What is a hot melt glue gun?

A hot melt glue gun is a device that is used to melt and dispense hot melt adhesive. It consists of a trigger mechanism, a heating element, and a nozzle for dispensing the adhesive. The glue gun is powered by electricity and is typically used in crafts, arts, and DIY projects.

Hot melt glue guns are available in various sizes and designs, ranging from small handheld models to larger industrial-grade guns. The size and design of the glue gun will depend on the specific application and the amount of adhesive that needs to be dispensed.

Hot melt glue guns work by heating a solid adhesive stick or pellet inside the gun. When the adhesive is heated, it melts and becomes a liquid. The user then squeezes the trigger to dispense the melted adhesive through the nozzle onto the desired surface.

The adhesive quickly cools and hardens upon contact with the surface, creating a strong bond. Hot melt adhesive is versatile and can bond a wide range of materials, including wood, metal, fabric, and plastic.

Hot melt glue guns offer several advantages over other types of adhesive applications. They are quick and easy to use, as the adhesive heats up and melts in a matter of minutes. The glue guns also offer precise control over the amount of adhesive being dispensed, allowing for accurate application.

Hot melt glue guns are commonly used in a variety of industries, including construction, packaging, and manufacturing. They are also popular for home use, as they are a convenient tool for a wide range of projects and repairs.

In conclusion, a hot melt glue gun is a versatile tool that uses heat to melt and dispense adhesive. It is a popular choice for crafts, arts, and DIY projects, as well as various industrial applications. Whether you are a professional or a hobbyist, a hot melt glue gun can be a handy addition to your toolkit.

Working mechanism of hot melt glue guns

Hot melt glue guns work by utilizing a simple yet effective mechanism to melt and dispense hot adhesive glue. These versatile tools are commonly used in various industries and DIY projects due to their fast and efficient operation.

Heating the glue

The main component of a hot melt glue gun is the heating element, which is usually located inside the gun near the nozzle. This heating element is connected to a power source, and when activated, it starts to heat up.

The glue sticks, which are cylindrical rods of solid adhesive, are inserted into the back of the glue gun. As the heating element reaches the desired temperature, it begins to melt the glue sticks, turning them into a liquid or semi-liquid state.

Dispensing the glue

Once the glue sticks have melted, the user can squeeze the trigger or apply pressure to a manual mechanism to release the molten glue. By squeezing the trigger, the user activates a mechanism that pushes the molten glue towards the nozzle of the gun.

The glue is forced out of the nozzle in a controlled manner, allowing the user to apply it precisely to the desired surface. As the glue exits the gun, it quickly starts to cool down and solidify, forming a strong bond between the materials being glued together.

Hot melt glue guns also have a built-in thermostat to regulate the temperature and prevent overheating. This ensures that the glue stays at the optimal temperature for efficient melting and dispensing.

Overall, the working mechanism of hot melt glue guns involves heating the glue sticks until they turn into a liquid state, and then dispensing the molten glue through the nozzle onto the desired surface. This simple yet effective process allows hot melt glue guns to provide a fast and reliable bonding solution for various applications.

Applications of hot melt glue guns

Hot melt glue guns are versatile tools that can be used in a wide range of applications. Here are some common uses for hot melt glue guns:

- Arts and crafts: Hot melt glue guns are commonly used in arts and crafts projects to bond materials such as paper, fabric, cardboard, and wood. They provide a quick and easy way to adhere these materials together.

- DIY repairs: Hot melt glue guns are handy tools for DIY repairs around the house. They can be used to fix broken furniture, repair loose edges, and seal cracked surfaces. The glue provides a strong and durable bond that can withstand everyday wear and tear.

- Model making: Hot melt glue guns are widely used in model making as they provide a secure and fast way to assemble small parts. From building model cars to creating architectural models, hot melt glue guns are an essential tool for many hobbyists and professionals.

- Floral arrangements: Hot melt glue guns are often employed in floral arrangements to hold flowers and decorations in place. The glue dries clear and does not damage delicate petals, making it ideal for flower arrangement projects.

- Package sealing: Hot melt glue guns are commonly used in the packaging industry to seal boxes and secure packages. The glue quickly bonds to various surfaces and provides a secure seal that can withstand the rigors of transportation.

- Product assembly: Hot melt glue guns are utilized in product assembly to bond components together. They can be used in various industries, including electronics, woodworking, and automotive, to quickly and securely join different parts.

These are just a few examples of the many applications of hot melt glue guns. The versatility and ease of use make them a popular choice among hobbyists, DIY enthusiasts, and professionals alike.

Tips for using a hot melt glue gun

A hot melt glue gun is a versatile tool that can be used for various projects and repairs. Whether you are a beginner or an experienced user, here are some tips to help you get the most out of your hot melt glue gun:

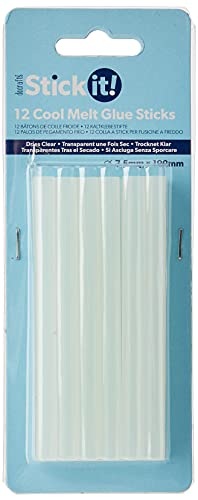

1. Choose the right glue sticks

Before using a hot melt glue gun, make sure to select the appropriate glue sticks for your project. Glue sticks come in different sizes and formulations, such as low-temperature or high-temperature glue sticks. Read the packaging or consult the manual to determine which type of glue stick is best suited for your specific needs.

2. Preheat the glue gun

Preheating your glue gun is essential to ensure proper melting and application of the glue. Most hot melt glue guns have an indicator light that turns off when the gun is ready to use. Allow the glue gun to heat up fully before starting your project, as using it while it’s still warming up may result in uneven glue distribution.

3. Use caution when handling the gun

Hot melt glue guns can reach high temperatures, so it’s crucial to handle them with care. Always grip the gun by the handle and avoid touching the heated nozzle. It’s also a good idea to wear protective gloves to avoid burns or accidents.

4. Work in a well-ventilated area

When using a hot melt glue gun, it’s important to work in a well-ventilated area. The glue can produce fumes as it melts, which may be harmful if inhaled in large quantities. Open a window or use a fan to improve air circulation and minimize exposure to the fumes.

5. Start with small amounts of glue

When applying glue, start with small amounts and build up as needed. It’s easier to add more glue than to remove excess glue once it has hardened. Apply the glue in a smooth, continuous motion for better adhesion and aesthetics.

6. Clean the nozzle after each use

To keep your glue gun in good condition, it’s important to clean the nozzle after each use. Use a damp cloth or paper towel to remove any excess glue residue. This will prevent clogs and ensure that the glue gun functions properly during your next use.

By following these tips, you can use your hot melt glue gun more effectively and achieve better results in your projects. Remember to always use caution and prioritize safety when working with hot glue.

FAQ

What is a hot melt glue gun and how does it work?

A hot melt glue gun is a tool that is used to dispense hot melt adhesive. The gun consists of a heating element that melts the glue stick, a trigger to control the flow of the melted glue, and a nozzle that the glue is dispensed through. When the glue stick is inserted into the gun and the trigger is squeezed, the heating element melts the glue, which is then forced out through the nozzle.

Can you explain the process of melting the glue in a hot melt glue gun in more detail?

When a glue stick is inserted into a hot melt glue gun, it comes into contact with a heating element, usually located towards the back of the gun. This heating element is typically made of metal and is heated to a specific temperature, usually between 200 and 400 degrees Fahrenheit. The heat from the heating element causes the glue stick to melt, turning it into a liquid form. Once the glue is melted, it is forced forward through the gun by a piston or screw mechanism, and then out through the nozzle.