How does hot melt glue gun work

A hot melt glue gun is a tool that uses a thermoplastic adhesive to join materials together. It is commonly used in crafts, woodworking, and other DIY projects. The glue gun heats up the adhesive to a liquid state, allowing it to be applied easily and quickly.

Inside the glue gun, there is a heating element that heats up the adhesive. When the gun is plugged in and turned on, the heating element starts to heat up, melting the adhesive and turning it into a liquid. The glue gun is designed to reach a specific temperature, usually between 200 to 400 degrees Fahrenheit, depending on the type of adhesive being used.

Once the adhesive has reached the desired temperature, it is ready to be applied. The glue gun has a trigger mechanism that allows the user to control the flow of the adhesive. By pulling the trigger, the liquid adhesive is pushed forward through a nozzle. The adhesive then cools down and solidifies, bonding the materials together.

The hot melt glue gun is a versatile tool that can be used with various types of adhesives, including standard glue sticks, specialty glue sticks, and even colored glue sticks. It offers a quick and efficient way to bond materials together, making it a staple tool in many DIY enthusiasts’ toolbox.

What is a hot melt glue gun

A hot melt glue gun is a handheld tool that uses a heating element to melt solid adhesive glue sticks. The melted glue is then dispensed through a nozzle, allowing users to apply it to various surfaces for bonding purposes.

The main components of a hot melt glue gun include the heating element, trigger mechanism, nozzle, and a glue stick chamber. The heating element is responsible for melting the glue stick, which is inserted into the chamber. The trigger mechanism controls the flow of the melted glue, allowing users to apply it precisely.

Hot melt glue guns are commonly used in crafting, woodworking, and other applications where a strong and quick bond is required. They are versatile tools that can be used on a variety of materials, including paper, fabric, plastic, and wood.

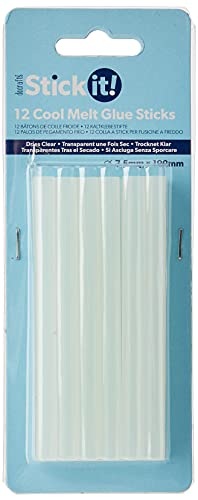

The glue sticks used in hot melt glue guns are available in different sizes and formulations, catering to various bonding requirements. Some glue sticks dry clear, while others may have a colored or translucent finish. They also differ in terms of strength, flexibility, and temperature resistance.

Using a hot melt glue gun is relatively simple. Once the gun is plugged in and heated up, a glue stick is inserted into the chamber. The trigger is then squeezed to start the flow of melted glue. It is important to exercise caution when using a hot melt glue gun, as the glue can be extremely hot and may cause burns if not handled properly. It is advisable to wear protective gloves and work in a well-ventilated area.

How does a hot melt glue gun heat up

A hot melt glue gun is a versatile tool that uses heat to melt a solid adhesive and apply it in liquid form. The heating process is essential for the glue gun to work effectively and efficiently.

Here is a step-by-step explanation of how a hot melt glue gun heats up:

1. Heating element

The glue gun contains a heating element, usually made of ceramic or metal, located near the tip of the gun. This element is responsible for generating the necessary heat.

2. Electrical power

When the hot melt glue gun is plugged into a power source, electricity flows through the heating element. The heating element has a high electrical resistance, which causes it to heat up quickly.

3. Thermoplastic adhesive sticks

The user inserts a thermoplastic adhesive stick into the back of the glue gun. These adhesive sticks are made of solid thermoplastic materials, such as EVA (ethylene vinyl acetate) or polyamide.

4. Melting process

As the heating element heats up, the thermoplastic adhesive stick placed in the gun begins to soften and eventually melt. The glue gun reaches a temperature high enough to melt the adhesive, typically between 250 to 400 degrees Fahrenheit (120 to 204 degrees Celsius).

5. Flow control

Inside the glue gun, there is a trigger mechanism that controls the flow of the melted adhesive. When the user pulls the trigger, the melted glue is forced through the nozzle or applicator tip of the gun.

6. Solidification

Once the melted adhesive is dispensed onto the desired surface, it begins to cool down and solidify. As it solidifies, the glue forms a strong bond between the materials it is applied to.

Overall, the hot melt glue gun’s heating mechanism allows for quick and precise application of adhesive, making it a popular choice for various crafts, DIY projects, and industrial applications.

Heating mechanism of a hot melt glue gun

A hot melt glue gun is powered by electricity and relies on a heating mechanism to melt solid glue sticks and turn them into a liquid adhesive. The heating mechanism consists of several key components:

- Heating element: The heating element is typically made of a resistive wire, such as nichrome, which has a high resistance to electric current. When the glue gun is turned on, the electric current flows through the heating element, causing it to heat up.

- Trigger or switch: The trigger or switch on the glue gun controls the flow of electric current to the heating element. When the trigger is pressed or the switch is turned on, the electric current is allowed to pass through the heating element, initiating the heating process.

- Thermistor: A thermistor is a temperature-sensitive resistor that monitors the temperature of the heating element. It is connected to a control circuit, which helps regulate the temperature of the glue gun. If the temperature exceeds a certain threshold, the control circuit can reduce the current flowing through the heating element to prevent overheating.

- Glue chamber: The glue chamber is where the solid glue sticks are inserted. It is usually located at the rear of the glue gun and can be accessed by removing a protective cover. Inside the glue chamber, the glue sticks are positioned in such a way that they come into direct contact with the heating element.

- Metal nozzle: The metal nozzle is attached to the front of the glue gun and acts as an outlet for the melted adhesive. It is designed to be narrow and precise, allowing for controlled application of the glue.

When the glue gun is turned on, the heating element starts to heat up, gradually melting the solid glue sticks. As the glue sticks melt, the liquid adhesive flows down through the glue chamber and towards the metal nozzle. When the trigger is pressed, the melted glue is forced out of the nozzle, ready for application. The glue gun continues to heat the glue chamber to maintain a constant supply of liquid adhesive as needed.

Overall, the heating mechanism of a hot melt glue gun plays a vital role in transforming solid glue sticks into a liquid adhesive, allowing for easy and precise application of glue in various projects and applications.

How does a hot melt glue gun dispense glue

A hot melt glue gun is a handy tool that uses heat to melt solid glue sticks, allowing the melted adhesive to be dispensed through a nozzle. The process of dispensing the glue is relatively simple and straightforward.

Heating Mechanism

The hot melt glue gun consists of an internal heating mechanism that heats the glued stick to a high temperature, typically between 250°F and 400°F (121°C and 204°C). This heating mechanism can be powered by electricity or butane gas, depending on the type of glue gun.

Glue Stick Feeding

To dispense glue, the user inserts a solid glue stick into the rear of the glue gun. The glue stick is held in place with a spring-loaded mechanism that pushes the stick forward as it melts. The glue stick is typically made of a thermoplastic material such as ethylene-vinyl acetate (EVA), which melts at high temperatures.

The heating mechanism inside the glue gun applies heat to the back end of the glue stick, causing it to melt gradually. As the glue stick melts, it moves forward due to the pressure exerted by the spring-loaded mechanism, feeding a continuous supply of molten glue to the dispensing nozzle.

Glue Dispensing

At the front end of the glue gun, there is a nozzle attached to a trigger mechanism. When the user squeezes the trigger, it pushes the molten glue through the nozzle’s opening. The nozzle typically has a narrow aperture, allowing for precise application of the glue.

The glue is dispensed in a molten state and quickly solidifies upon contact with surfaces, creating a strong bond. The user can control the amount of glue dispensed by adjusting the pressure applied to the trigger.

Overall, the hot melt glue gun efficiently dispenses adhesive by melting solid glue sticks and allowing the molten glue to be pushed through a nozzle with the help of a spring-loaded feeding mechanism. This simple yet effective process makes the hot melt glue gun a popular choice for various applications, including crafting, DIY projects, and industrial purposes.

Dispensing mechanism of a hot melt glue gun

A hot melt glue gun operates by using a dispensing mechanism to melt and apply the adhesive. The main components of the dispensing mechanism include:

1. Heating element

The heating element in the hot melt glue gun is responsible for melting the solid glue sticks into a liquid state. It is typically made of a high-resistance metallic wire that heats up when an electric current passes through it.

2. Glue stick chamber

The glue stick chamber is where the solid glue sticks are inserted into the glue gun. The chamber is located at the rear end of the gun and is designed to hold the glue stick securely in place.

3. Trigger

The trigger serves as the control mechanism for dispensing the melted glue. When the trigger is pulled, it depresses a lever or mechanism that pushes the glue stick forward towards the heating element.

4. Melting chamber

As the glue stick is pushed forward, it enters the melting chamber, which is located just before the heating element. The melting chamber is designed to accommodate the glue stick and expose it to the intense heat of the heating element, causing the glue to melt and become a liquid.

5. Nozzle

Once the glue stick has melted, the liquid adhesive is forced through the nozzle of the hot melt glue gun. The nozzle is typically made of heat-resistant materials such as metal or plastic, and it determines the shape and size of the glue bead or stream that is dispensed.

Overall, the dispensing mechanism of a hot melt glue gun works by melting solid glue sticks using a heating element, pushing the melted glue towards the nozzle through a trigger-controlled mechanism, and finally dispensing the adhesive in its liquid form. This mechanism allows for precise, controlled application of hot melt glue for various bonding applications.

What are the applications of hot melt glue guns

Hot melt glue guns are versatile tools that can be used in various applications. Here are some of the common applications of hot melt glue guns:

1. Arts and crafts: Hot melt glue guns are widely used in arts and crafts projects. They are great for bonding different materials such as paper, fabric, wood, and plastic. Whether you are working on scrapbooking, card making, or DIY projects, a hot melt glue gun can provide a strong and durable bond.

2. Home repairs: Hot melt glue guns can be handy for quick and temporary fixes around the house. They can be used to repair broken furniture, fix loose tiles, mend broken toys, or patch up small holes in walls or other surfaces. The adhesive provided by hot melt glue guns sets quickly, making it ideal for small repairs that require immediate attention.

3. Product assembly: Hot melt glue guns are commonly used in product assembly and manufacturing processes. They can be used to bond various components together, such as attaching labels, securing packaging, or affixing ornaments. The fast-setting nature of the glue ensures that the assembly process is efficient and reliable.

4. Packaging industry: Hot melt glue guns are heavily used in the packaging industry. They are used to seal boxes, attach inserts or labels, and assemble packaging materials. The strong bond provided by the hot melt glue ensures that the packaging remains intact and secure throughout transportation and storage.

5. Floral arrangements: Hot melt glue guns are also popular for creating beautiful floral arrangements. They can be used to attach flowers, leaves, and other decorative elements to different surfaces, such as foam bases or wreaths. The hot melt glue provides a strong hold that keeps the arrangement intact.

6. DIY projects: Hot melt glue guns are great companions for DIY enthusiasts. They can be used to bond materials together, such as attaching trims, beads, or other embellishments to clothing or accessories. Hot melt glue guns provide a fast and efficient way to bring your creative ideas to life.

7. Woodworking: Hot melt glue guns are often used in woodworking projects. They can be used to bond wood pieces together, fill cracks or gaps, or secure small components. The adhesive provided by the hot melt glue is strong and durable, making it suitable for various woodworking applications.

In conclusion, hot melt glue guns have a wide range of applications, from arts and crafts to home repairs, product assembly, packaging, floral arrangements, DIY projects, and woodworking. These versatile tools provide a strong and efficient bonding solution, making them a valuable asset for both professionals and hobbyists.

Various uses of hot melt glue guns

Hot melt glue guns have a wide range of applications and are commonly used in various industries including crafting, woodworking, packaging, and more. Here are some of the common uses of hot melt glue guns:

1. Crafts: Hot melt glue guns are commonly used in crafting projects such as creating handmade cards, scrapbooking, and designing floral arrangements. The glue, when dried, provides a strong bond that securely holds different types of materials together.

2. Woodworking: Hot melt glue guns are also popular in woodworking for bonding wood pieces together. They can be used to assemble furniture, repair broken wooden objects, or to create intricate woodwork designs.

3. Packaging: Hot melt glue guns are extensively used in the packaging industry for sealing boxes, cartons, and envelopes. The glue provides a secure and durable bond, ensuring that the packaged items are safe during transportation.

4. DIY home repairs: Hot melt glue guns are handy tools for DIY enthusiasts for quick home repairs. They can be used to fix broken household items like ceramics, plastic, or metal objects, providing a strong and long-lasting bond.

5. Upholstery: Hot melt glue guns are commonly used in upholstery work for bonding fabric, foam, and other materials. They are particularly useful for securing the edges and corners of upholstery fabrics to give a neat and professional finish.

6. Electronics: Hot melt glue guns are used in electronics for cable management, securing loose wires, and providing insulation. The glue creates a protective barrier around the wires, preventing them from getting damaged or tangled.

7. Floral arrangements: Hot melt glue guns are commonly used in flower arranging, allowing flowers and foliage to be securely attached to various surfaces. The glue provides a strong bond while being invisible, ensuring that it does not detract from the overall aesthetic of the arrangement.

8. Model making: Hot melt glue guns are often used in model making for bonding different components together. Whether it’s a scale model of a building or a miniature vehicle, the glue provides a strong and reliable bond that holds the pieces securely in place.

9. School projects: Hot melt glue guns are commonly used by students for various school projects. They can be used to create three-dimensional models, build prototypes, or for general crafting purposes.

10. Floral preservation: Hot melt glue guns are used in floral preservation to create art and crafts with dried flowers. The glue helps to attach the preserved flowers to different surfaces, allowing them to be displayed and enjoyed for a longer period of time.

Overall, hot melt glue guns are versatile tools that find a wide range of uses in various industries and everyday projects. Their ability to provide a strong and reliable bond makes them an essential tool for professionals and DIY enthusiasts alike.

Tips for using a hot melt glue gun

1. Choose the right glue stick: Before using a hot melt glue gun, make sure you have the correct type of glue stick for your project. Different glue sticks have different melting points and adhesion strengths, so choose one that is suitable for the materials you will be bonding.

2. Preheat the glue gun: It is important to preheat your hot melt glue gun before using it. Follow the manufacturer’s instructions for preheating time, usually around 5 minutes. This ensures that the glue melts properly and is ready for use.

3. Use proper safety precautions: Hot glue can cause burns, so always use caution when handling a hot melt glue gun. Wear protective gloves and avoid touching the heated nozzle. Keep the gun away from children and flammable materials.

4. Work in a well-ventilated area: Hot melt glue guns can release fumes while in use. To avoid inhaling these fumes, make sure you are working in a well-ventilated area. Open windows or use a fan to circulate the air.

5. Apply glue in a controlled manner: When using a hot melt glue gun, it is important to apply the glue in a controlled and precise manner. Start by applying a small amount of glue and gradually increase as needed. This will help prevent the glue from dripping or oozing out uncontrollably.

6. Work quickly: Hot melt glue tends to harden quickly, so it is important to work efficiently and quickly once the glue is applied. Align the materials you are bonding and press them together firmly before the glue sets.

7. Clean the glue gun: After you have finished using the hot melt glue gun, clean any excess glue from the nozzle and remove any remaining glue sticks. This will help keep the gun in good working condition and prevent clogs.

By following these tips, you can ensure that you get the best results when using a hot melt glue gun for your projects. Remember to always read and follow the manufacturer’s instructions for your specific glue gun model.

FAQ

What is a hot melt glue gun?

A hot melt glue gun is a handheld tool that melts and dispenses thermoplastic adhesive, commonly referred to as hot glue. It is typically used for bonding various materials together.

How does a hot melt glue gun work?

A hot melt glue gun works by applying heat to a solid glue stick, causing it to melt. The molten glue is then pushed through the gun’s nozzle using a trigger or a mechanical mechanism. Once applied to a surface, the glue quickly cools and solidifies, creating a strong bond.

What are the components of a hot melt glue gun?

A hot melt glue gun consists of a heating element, a trigger or mechanical mechanism for glue dispensing, a nozzle for directing the glue, and a glue stick chamber. Some models may also have additional features such as temperature control settings and an LED indicator.