Why do my drill bits keep breaking?

If you find yourself constantly replacing drill bits, you may be wondering why they keep breaking. There are several factors that can contribute to this frustrating problem. Understanding these factors can help you prevent future breakages and save you both time and money.

One of the main reasons drill bits break is due to excessive heat. When drilling into a hard material, such as metal or concrete, friction is created which generates heat. This heat can cause the drill bit to become brittle and eventually break. To avoid this, it is important to use the correct drill bit for the material you are drilling into and to keep the bit cool by using a lubricant or water to reduce heat buildup.

Another common cause of drill bit breakages is improper usage and technique. Applying too much pressure or drilling at the wrong angle can cause the bit to snap. It is important to follow the manufacturer’s instructions and guidelines for proper usage. Taking your time, using the correct drilling technique, and applying the right amount of pressure can help prevent breakages.

Furthermore, using a worn-out or damaged drill bit can also lead to breakages. Over time, the cutting edges of the drill bit can become dull or chipped, reducing its effectiveness and increasing the risk of breakage. Regular maintenance and sharpening of the drill bits can help prolong their lifespan and prevent breakages.

Common Issues with Drill Bits Breaking

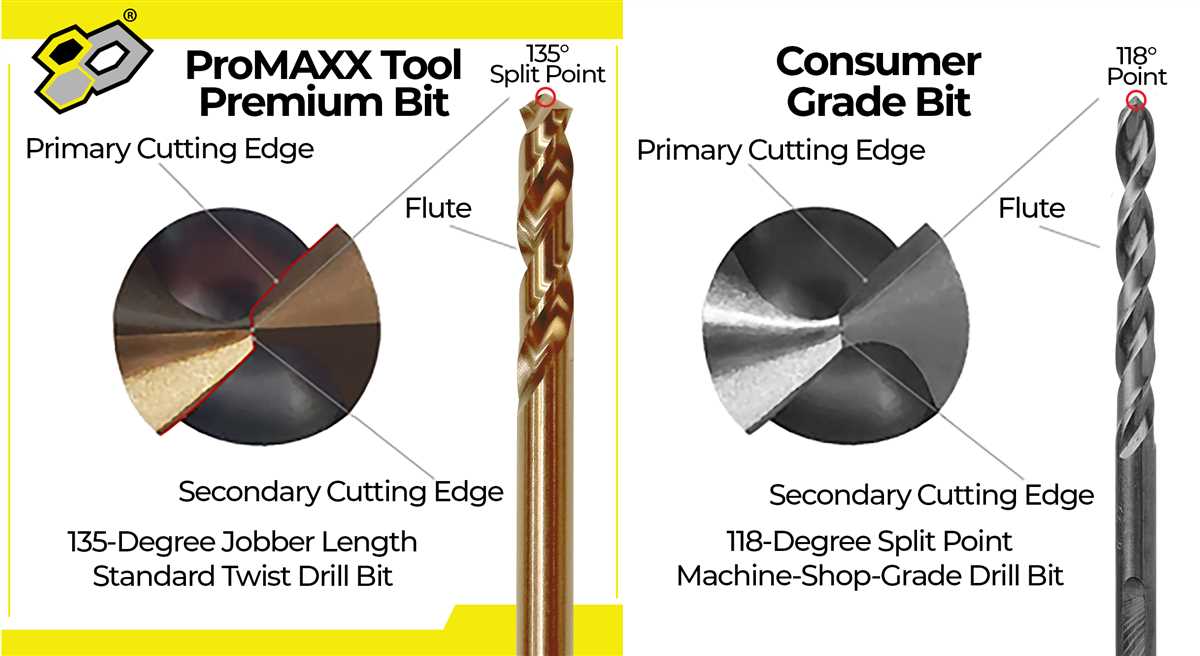

- Poor quality drill bits: One of the most common reasons why drill bits break is due to their low quality. Investing in high-quality drill bits can significantly reduce the risk of breakage. Quality drill bits are made from superior materials and have better heat treatment, which makes them more durable and less likely to break during use.

- Incorrect usage: Using the wrong drill bit for the material or task at hand can cause them to break. Different drill bits are designed for specific materials such as wood, metal, concrete, or tile. Using the wrong type of bit can lead to excessive heat generation and result in breakage. It is important to select the appropriate drill bit for the job to avoid unnecessary breakage.

- Excessive heat and friction: High heat and friction can weaken drill bits, making them more prone to breaking. This can occur when the drill bit gets too hot during use, usually due to too much pressure, improper lubrication, or incorrect drilling speed. To prevent excessive heat and friction, it is important to ensure proper lubrication, use the correct drilling speed, and not apply excessive force during drilling.

- Dull or worn-out drill bits: Over time, drill bits can become dull or worn-out, which affects their ability to cut effectively. Dull drill bits may require more pressure and force to function, leading to an increased risk of breakage. Regularly inspecting and replacing dull or worn-out drill bits can help prevent breakage and ensure optimal performance.

- Poor drilling technique: Incorrect drilling technique, such as using excessive lateral pressure or not maintaining a straight drilling angle, can cause drill bits to break. It is important to use the proper technique when drilling, applying even pressure and maintaining a consistent angle to reduce the risk of breakage.

- Overloading the drill bit: Overloading the drill bit by drilling into excessively hard or dense materials can lead to breakage. It is important to know the limitations of the drill bit and avoid pushing it beyond its capabilities. If the material is too hard or dense, it may be necessary to use a different drill bit or pre-drill to reduce the load on the bit.

By understanding these common issues with drill bits breaking, you can take the necessary precautions to prevent breakage and prolong the lifespan of your drill bits.

Inadequate Drill Bit Quality

Another possible reason why your drill bits keep breaking is due to their inadequate quality. Cheap or low-quality drill bits are more likely to break or dull quickly compared to high-quality ones.

When purchasing drill bits, it’s essential to consider the material they are made of. High-quality drill bits are typically made of hardened steel or carbide, which makes them more durable and resistant to breaking. On the other hand, low-quality drill bits may be made of softer materials that cannot withstand the force and pressure applied during drilling.

In addition to material, the design and construction of the drill bits can also affect their quality. Drill bits with poor craftsmanship or inconsistent manufacturing may have weak points or uneven edges, making them prone to breaking. It’s important to choose drill bits from reputable brands known for their quality and reliability.

Using inadequate drill bits can lead to frustration and wasted time, as you will constantly have to replace broken bits. Investing in high-quality drill bits may initially cost more, but it will save you money in the long run as they will last longer and provide better performance.

Incorrect Drill Bit Type

One common reason why drill bits may keep breaking is because the incorrect drill bit type is being used for the material being drilled. Different materials, such as wood, metal, or concrete, require different types of drill bits that are specifically designed to effectively penetrate and drill through them.

Using the wrong drill bit type can put excessive stress on the bit, leading to breakage. For example, if a wood drill bit is used on metal, it may not be able to handle the hardness of the material and can break or become dull quickly. Similarly, using a masonry drill bit on wood might cause the bit to break due to the difference in drilling requirements.

To avoid this issue, it is important to select the appropriate drill bit for the material being drilled. There are various types of drill bits available, including twist drill bits, spade bits, masonry bits, and hole saws, among others. It is important to choose the right type of bit based on the specific drilling needs.

Additionally, using a low-quality drill bit or one that is worn out can also contribute to breakage. It is important to invest in high-quality drill bits that are specifically designed for the intended material. These drill bits are often made from hardened steel or other durable materials that can withstand the drilling forces without breaking.

Using the correct drill bit type not only ensures that the drilling process is efficient, but it also helps to prevent breakage and prolong the lifespan of the drill bits. By following the manufacturer’s recommendations and guidelines regarding drill bit selection, users can avoid the frustration and expense of dealing with repeated drill bit breakage.

Excessive Heat Generation

- Using the wrong speed or feed rate for the material being drilled can lead to excessive heat generation. Different materials require different drilling speeds and feed rates, so it’s important to refer to the manufacturer’s recommendations.

- Using a dull or worn-out drill bit can cause excessive heat generation. When a drill bit is dull, it has to work harder to cut through the material, which creates friction and generates heat. It’s important to regularly sharpen or replace drill bits to ensure they are in optimal condition.

- Applying too much pressure while drilling can also lead to excessive heat generation. If you push too hard on the drill, it can cause the bit to heat up quickly. It’s important to let the drill bit do the work and apply a consistent, steady pressure without forcing it.

- Poor lubrication can contribute to excessive heat generation. Lubricating the drill bit and the material being drilled helps reduce friction and heat. Using an appropriate lubricant, such as cutting oil or coolant, can help prolong the life of the drill bit and prevent excessive heat buildup.

- Drilling at a high speed for an extended period of time without giving the drill bit a chance to cool down can result in excessive heat generation. It’s important to take regular breaks during drilling to allow the drill bit to cool down and reduce the risk of overheating.

- Using a drill press or other drilling equipment that is not properly calibrated can lead to excessive heat generation. If the equipment is not set up correctly, it can cause the drill bit to wobble or vibrate, which increases friction and generates heat. It’s important to ensure that the equipment is properly calibrated and in good working order.

- Drilling into hard or dense materials without using the appropriate drill bit can cause excessive heat generation. Using a drill bit that is not designed for the specific material can result in overheating and premature wear. It’s important to use the correct drill bit for the material being drilled.

By avoiding these common mistakes and following best practices, you can minimize the risk of excessive heat generation and extend the life of your drill bits.

Improper Drill Bit Size

Inadequate or improper drill bit size can also be a common reason for drill bit breakage. When using a drill, it’s essential to use the correct size of drill bit for the task at hand. Using a drill bit that is too small or too large can lead to excessive stress on the bit, resulting in breakage.

Using a smaller drill bit than necessary can put excessive pressure on the bit, causing it to bend or snap under the load. This can happen when drilling into hard materials, such as metal or concrete, where a larger bit size is required to handle the drilling force.

Conversely, using a larger drill bit than needed can cause the bit to become unstable and wobble during drilling. This instability can lead to the bit chattering or bouncing around, increasing the risk of it breaking.

To avoid these issues, it’s crucial to select the correct size of drill bit for the specific drilling task. Consult the manufacturer’s recommendations or a drill bit size chart to ensure using the appropriate size for the material and the desired hole diameter.

Additionally, it’s important to use the proper technique when drilling. Applying consistent and even pressure, using the correct drilling speed, and lubricating the bit can help reduce the risk of breakage due to improper bit size.

If unsure about the appropriate drill bit size, it’s advisable to start with a smaller bit and gradually increase the size until the desired hole diameter is achieved. This approach allows for more control and reduces the risk of excessive stress on the bit.

Dull or Damaged Drill Bits

One of the most common reasons why drill bits keep breaking is because they are dull or damaged. Over time, drill bits can become worn down and lose their sharpness, making it difficult to drill through tough materials.

When a drill bit becomes dull, it can cause excessive heat and friction, which can lead to the bit breaking or shattering. Additionally, a dull drill bit may cause the drill to become unstable, resulting in inaccurate holes and potential damage to the workpiece.

To prevent drill bits from becoming dull or damaged, it is important to use the correct type of bit for the material you are drilling. Different materials require different types of drill bits, such as wood, metal, concrete, or masonry. Using the wrong type of bit can cause excessive wear and tear, leading to breakage.

Regular maintenance and sharpening of drill bits can also help prevent them from becoming dull. It is recommended to inspect your drill bits before each use and replace any that show signs of damage or wear.

Proper drilling techniques can also help minimize the risk of breaking drill bits. Applying too much pressure while drilling or using excessive speed can cause the bit to overheat and become damaged. It is important to use a steady and controlled drilling motion, allowing the bit to do the work without forcing it.

In some cases, drill bits may break due to manufacturing defects or poor quality materials. It is essential to purchase drill bits from reputable manufacturers and suppliers to ensure their durability and performance.

In summary, some possible reasons why drill bits keep breaking include:

- Using dull or damaged drill bits

- Using the wrong type of bit for the material

- Not properly maintaining or sharpening drill bits

- Using excessive pressure or speed while drilling

- Purchasing drill bits of poor quality or with manufacturing defects

By understanding and addressing these issues, you can help prevent drill bits from breaking and ensure a smooth and efficient drilling experience.

Misalignment or Incorrect Drilling Technique

Misalignment and incorrect drilling technique can be significant factors in the frequent breaking of drill bits. When a drill bit is not aligned properly with the material being drilled, it can cause excessive stress and strain on the bit, leading to its failure.

Common causes of misalignment and incorrect drilling technique can include:

- Improper positioning: When drilling, it’s crucial to position the drill bit in the correct location before starting. Failing to do so can result in the bit hitting a hard spot or other obstacles, causing it to break.

- Excessive pressure: Applying too much pressure while drilling can cause the bit to become misaligned or bend. This can weaken the structure of the bit and make it more prone to breaking.

- Inadequate lubrication: Using a lubricant while drilling can help reduce friction and heat buildup, which can contribute to bit failure. Without proper lubrication, the bit can overheat and become more susceptible to breaking.

- Incorrect drilling speed: Different materials require different drilling speeds. Using the wrong speed can cause the bit to become overloaded and break. It’s essential to adjust the drilling speed based on the material being drilled.

Tips to prevent misalignment and improve drilling technique:

- Always mark the drill spot accurately using a pencil or other marking tool.

- Start drilling at a slow speed and gradually increase it as needed.

- Apply steady and even pressure while drilling, avoiding excessive force.

- Use a lubricant appropriate for the material being drilled.

- Keep the drill bit and drilling area clean to prevent debris from interfering with the drilling process.

- Consider using a guide or template to ensure accurate positioning.

By practicing proper alignment techniques and employing correct drilling methods, you can significantly reduce the chances of your drill bits breaking prematurely.

High Drilling Speed

Using a high drilling speed can be one reason why your drill bits keep breaking. While it may seem efficient to drill at a high speed, it can actually put excessive strain on the drill bit and cause it to snap or bend.

When drilling at high speeds, the friction between the drill bit and the material being drilled increases significantly. This can lead to overheating, which weakens the drill bit and makes it more prone to breaking. Additionally, the high speed can cause the drill bit to lose its grip on the material, resulting in less control and a higher risk of breakage.

It’s important to find the right drilling speed for the material you are working with. Different materials require different drilling speeds to ensure a successful and safe drilling process. Consult the manufacturer’s recommendations or do some research to determine the optimal drilling speed for your specific project.

It’s also important to use the appropriate drilling technique when working with high speeds. Applying too much pressure or angling the drill incorrectly can lead to increased stress on the drill bit and increase the likelihood of breakage. Make sure to use a steady and consistent pressure while drilling, and keep the drill bit aligned with the desired drilling path.

Consider using lubrication or cooling agents when drilling at high speeds. These can help reduce friction and heat buildup, providing better lubrication and cooling to the drill bit. This can extend the life of the drill bit and reduce the chances of it breaking.

Remember, drilling at a high speed may seem like a time-saving technique, but it can actually result in more harm than good. Take the time to find the right drilling speed for your project and use proper drilling techniques to ensure the longevity of your drill bits.

Using the Wrong Drill Bit for the Material

One of the most common reasons why drill bits keep breaking is because people often use the wrong drill bit for the material they are working on. Different materials require different types of drill bits in order to achieve the best results. Here are some examples of how using the wrong drill bit for the material can lead to breakage:

1. Hard Materials

When working with hard materials such as metal or concrete, it is important to use drill bits that are specifically designed for these materials. These drill bits are usually made of carbide or cobalt, which are much more durable and able to withstand the hardness of these materials. Using a regular drill bit on hard materials can cause it to overheat and break easily.

2. Soft Materials

Conversely, using a drill bit designed for hard materials on softer materials such as wood or plastic can also lead to breakage. Drill bits for soft materials are usually made of high-speed steel and have a sharper point. Using a drill bit intended for hard materials on soft materials can cause it to dig too aggressively, resulting in chips or cracks.

3. Incorrect Size

Using a drill bit that is too small or too large for the intended hole can also cause breakage. If the drill bit is too small, the drill may have to work harder to create the hole, causing it to break. On the other hand, if the drill bit is too large, it may not fit properly in the hole and can easily break due to excessive pressure.

4. Worn or Dull Drill Bits

Another important factor to consider is the condition of the drill bit itself. Using worn or dull drill bits can increase the risk of breakage as they are not as effective in cutting through the material. It is important to regularly inspect and replace drill bits that show signs of wear and tear.

To avoid drill bit breakage, it is crucial to use the appropriate drill bit for the specific material being worked on. This will help ensure that the drill bit remains effective and can withstand the demands of the material.

FAQ:

Why do my drill bits keep breaking?

There could be several reasons why your drill bits keep breaking. One possible reason is that you are using the wrong type of drill bit for the material you are drilling into. Another reason could be that you are using too much pressure or force while drilling, which can cause the bit to overheat and eventually break. It is also possible that your drill is not properly aligned, causing the bit to break. Lastly, the quality of the drill bit itself might be poor, resulting in frequent breakage.

What can I do to prevent my drill bits from breaking?

There are a few steps you can take to prevent your drill bits from breaking. First, make sure you are using the correct type of drill bit for the material you are drilling into. Different materials require different types of bits, such as wood, metal, or concrete bits. Secondly, use steady and consistent pressure while drilling, avoiding excessive force. This will help prevent overheating and reduce the risk of breakage. Thirdly, ensure that your drill is properly aligned before drilling. Lastly, invest in high-quality drill bits, as they are less likely to break compared to cheaper ones.

Are there any signs that my drill bits are about to break?

There are a few signs that your drill bits may be about to break. One sign is visible wear and tear on the tip of the bit, such as dullness or chipping. If the bit appears damaged or worn, it is best to replace it before it breaks. Another sign is if the drill bit starts to vibrate excessively while drilling, which may indicate that it is about to break. Finally, if you notice that the drill bit is not cutting as efficiently or taking longer to drill through materials, it could be a sign of impending breakage.

How can I choose the right drill bit for the material I am drilling into?

Choosing the right drill bit for the material you are drilling into is essential to prevent breakage. One way to determine the correct bit type is to consult the manufacturer’s guidelines or recommendations for the specific material you are working with. Additionally, you can consider the hardness and density of the material. For example, a masonry bit is suitable for drilling into concrete or brick, while a wood bit is designed for drilling into wood. It is also helpful to consider the size of the hole you need to make, as different drill bits come in various sizes.

Should I invest in high-quality drill bits?

Investing in high-quality drill bits is generally recommended. While they may be more expensive upfront, they tend to be more durable and less likely to break compared to cheaper alternatives. High-quality drill bits are usually made from stronger materials and are designed to withstand the rigors of drilling into different materials. They also often feature better cutting edges and are less prone to dulling. In the long run, investing in high-quality drill bits can save you money by reducing the frequency of replacements.

Can a misaligned drill cause my drill bits to break?

Yes, a misaligned drill can cause your drill bits to break. When the drill is not properly aligned, it puts uneven pressure on the bit, causing it to strain and eventually break. Misalignment can also lead to the bit wandering off course while drilling, increasing the risk of breakage. Therefore, it is important to check and adjust the alignment of your drill before each use. If your drill consistently causes bits to break even when aligned correctly, there might be an issue with the drill itself that requires professional inspection or repair.

Video: