Who Invented the Electric Drill?

When it comes to power tools, one of the most essential and versatile ones is the electric drill. This tool allows us to effortlessly bore holes into various materials such as wood, metal, or concrete. But have you ever wondered who is responsible for inventing such a useful device?

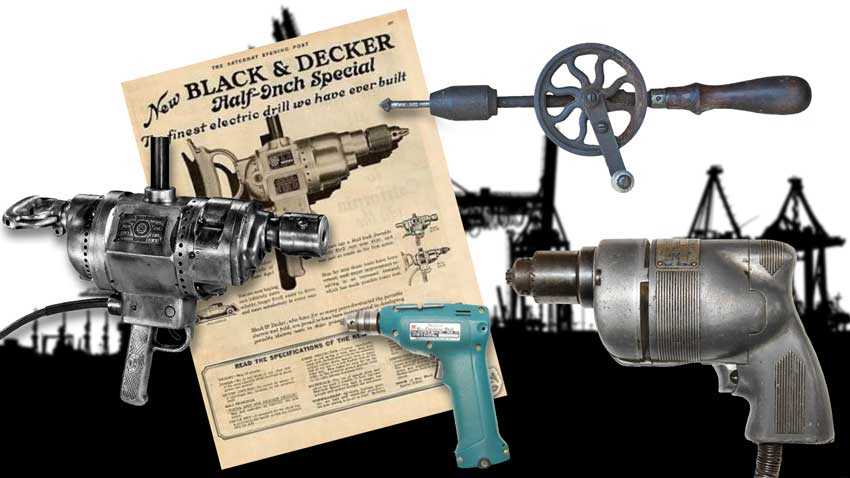

While the exact identity of the person who invented the electric drill is a topic of debate, there are a few key figures who played a significant role in its development. One name that often comes up in discussions is Arthur James Arnot, an English engineer who is credited with patenting the electric drill in 1889. Arnot’s design included a pistol-grip handle and a trigger mechanism, making it easier to operate.

However, it is worth mentioning that Arnot’s design was not the first attempt at creating an electric drill. In fact, there were earlier iterations of the tool that were commonly used in dental procedures. These early electric drills were powered by foot pedals and primarily used in dentistry to remove decay from teeth. They laid the groundwork for future advancements in electric drill technology.

Early Handheld Drilling Devices

Before the invention of the electric drill, handheld drilling devices were used for various tasks, such as drilling holes in wood, metal, and other materials.

Bow Drill

The bow drill is one of the oldest known handheld drilling devices, dating back to ancient times. It consists of a spindle and a bow-like device that is used to rotate the spindle. The spindle is pressed against the material to be drilled, and the bow is moved back and forth rapidly to create rotational motion, allowing the drill bit to penetrate the material.

Brace and Bit

The brace and bit, also known as a hand drill, was a popular handheld drilling device during the 19th and early 20th centuries. It consists of a U-shaped handle called a brace, which holds a bit. The handle is turned manually, causing the bit to rotate and drill into the material. The brace and bit were commonly used in woodworking and metalworking.

Eggbeater Drill

The eggbeater drill, also known as a hand drill or push drill, was another type of handheld drilling device that gained popularity in the late 19th century. It consisted of a cylindrical body with gears and a crank handle. When the handle was turned, the gears inside the body would rotate the drill bit, allowing it to penetrate the material. The eggbeater drill was often used for lighter drilling tasks.

Auger

An auger is a handheld drilling device used primarily for drilling holes in wood. It consists of a long cylindrical body with a spiral or helical-shaped bit at the end. The auger is rotated manually by using a handle, causing the spiral-shaped bit to dig into the wood and create a hole. Augers were commonly used in woodworking and carpentry.

These early handheld drilling devices laid the foundation for the development of the electric drill, which revolutionized drilling technology and made drilling faster and more efficient.

Archimedes’ Screw Drill

The Archimedes’ screw drill is often credited as one of the earliest examples of a mechanical drill. It is believed to have been invented by the Ancient Greek mathematician and engineer, Archimedes, in the 3rd century BCE.

The design of the Archimedes’ screw drill revolves around a cylindrical tube with an auger-like screw inside. The screw is attached to a handle that is rotated manually, allowing the drill bit at the end of the screw to bore into materials, such as wood or stone. The rotating motion of the screw applies pressure, enabling the drill bit to create a hole.

This ancient drill had several advantages. It allowed for precision drilling and was effective in both soft and hard materials. The Archimedes’ screw drill was versatile and could be used for various purposes, including construction, woodworking, and even dentistry.

One of the notable features of this drill was its simplicity. The design consisted of only a few components, making it relatively easy to manufacture and operate. This simplicity also made the Archimedes’ screw drill durable and reliable, allowing it to withstand the test of time.

Although no physical examples of the Archimedes’ screw drill have been found, references to its existence can be found in ancient texts, including those by the Roman engineer Vitruvius. These written accounts provide valuable insights into the design and function of this ancient drill.

In conclusion, Archimedes’ screw drill is considered one of the earliest known mechanical drills and a testament to the ingenuity of ancient engineers. Its design and simplicity laid the foundation for the development of more complex drilling tools in later centuries.

Hand Crank Drills

A hand crank drill is a manual tool used for drilling holes in various materials. Before the invention of the electric drill, hand crank drills were the primary drilling tools used by professionals and DIY enthusiasts.

Design and Operation

A hand crank drill consists of a cylindrical body with a handle attached to one end and a chuck at the other end. The chuck is used to hold the drill bit in place. The handle is rotated manually to turn the drill bit and create a hole in the material being drilled.

Most hand crank drills have a gear mechanism that allows for increased torque and easier drilling. The gears inside the drill convert the rotational motion of the handle into a higher rotational speed for the drill bit.

Advantages

- Portability – Hand crank drills are lightweight and compact, making them easy to transport and use in various locations.

- Reliability – As manual tools, hand crank drills do not depend on electricity or batteries, making them reliable in situations where power supply is not available.

- Precision – Hand crank drills allow for precise control over drilling speed and pressure, making them suitable for delicate and accurate drilling tasks.

- Low Maintenance – Hand crank drills do not have motors or complex electrical components, reducing the need for maintenance and repairs.

Limitations

- Limited Power – Hand crank drills rely on human strength, so they have limited power compared to electric drills. They may not be suitable for drilling through hard materials or large holes.

- Slower Operation – Hand crank drills require more time and effort to create holes compared to electric drills.

- Fatigue – Extended use of hand crank drills can lead to fatigue and strain on the user’s arm and wrist.

Conclusion

Hand crank drills were widely used before the invention of the electric drill. Although they have limitations in power and speed, these manual tools offer portability, reliability, and precision for a variety of drilling tasks. They continue to be used today for specific applications and by enthusiasts who appreciate their simplicity and functionality.

Bow Drills

A bow drill is a simple hand-held tool that has been used for thousands of years to create friction and generate heat for various purposes, including starting fires and drilling holes. It consists of a wooden bow-shaped handle, a spindle, a fireboard or wood block, and a cord or string.

To use a bow drill, the spindle is placed into a hole in the fireboard with a small amount of pressure applied. The bow is then used to rotate the spindle rapidly, creating friction between the spindle and the fireboard. This friction generates heat, which can be used to start a fire or create a hole in a material.

Bow drills have been used by many ancient cultures around the world, including the Egyptians, Greeks, Romans, and Native Americans. They were often used for tasks such as making fire, creating holes in wood or stone, and making tools and weapons.

The bow drill is believed to have been invented thousands of years ago by early humans. Its invention marked a significant milestone in human history, as it provided a portable and efficient way to create fire and bore holes in various materials without the need for more complex tools.

Despite its ancient origins, the bow drill is still used today in certain traditional and survivalist communities. It is valued for its simplicity, reliability, and versatility, making it a valuable tool for various outdoor activities and emergency situations.

In modern times, the bow drill has also been adapted and modified into various powered drilling tools, including electric drills. These tools are powered by electricity and use a rotating bit to create holes in materials. While the principles of the bow drill are still present in electric drills, the introduction of electricity has greatly increased their speed and efficiency.

Pump Drills

A pump drill is a manual hand-powered drilling tool that has been used for centuries. It is a simple tool consisting of a long rod with a drill bit attached to one end and a handle attached to the other end. The handle is moved up and down in a pumping motion to create rotation, which in turn drives the drill bit into the material being drilled.

Pump drills were commonly used in ancient civilizations, such as the Egyptians and the Romans. They were used primarily for drilling holes in soft materials like wood and bone.

One of the advantages of pump drills is their simplicity. They do not require any external power source or complex mechanisms. This makes them easy to use and maintain.

Components of a Pump Drill

A typical pump drill consists of the following components:

- Drill Bit: The drill bit is the cutting tool that is attached to the end of the rod. It is designed to create holes in the material being drilled.

- Rod: The rod is a long, straight piece of metal or wood that connects the drill bit to the handle. It allows for the transfer of motion from the handle to the drill bit.

- Handle: The handle is the part of the pump drill that is held by the user. It is used to generate the pumping motion that creates rotation and drives the drill bit into the material.

Usage of Pump Drills

Pump drills were widely used for various purposes, including:

- Creating holes in wood for joinery and carpentry.

- Drilling holes in bone or antler for the production of tools and ornaments.

- Preparing materials for weaving by drilling holes in beads and other decorative elements.

- Creating holes in soft stones for crafting jewelry and decorative items.

Advancements and Modern Alternatives

While pump drills have been replaced by electric drills in many modern applications, they are still used in certain areas where manual drilling is preferred or necessary. They are also valued by hobbyists and enthusiasts who enjoy traditional craftsmanship techniques.

Modern alternatives to pump drills include electric drills powered by batteries or electricity. These drills provide greater speed and convenience, making them suitable for a wide range of drilling applications.

Despite the advancements in power drills, the simple and elegant design of pump drills continues to fascinate and inspire engineers and enthusiasts alike.

The Electric Drill is Invented

The invention of the electric drill marked a major milestone in the history of power tools. This innovative tool revolutionized various industries, from construction to woodworking.

Although several individuals contributed to the development of the electric drill, it was Arthur James Arnot who can be credited with the invention. Arnot, an Australian electrical engineer, patented his design for an electric drill in the late 19th century.

Arnot’s electric drill consisted of an electric motor, a chuck, and a rotating drill bit. The motor provided the power to rotate the drill bit, allowing it to penetrate different materials with ease.

The electric drill quickly gained popularity due to its efficiency and convenience. It eliminated the need for manual labor and made drilling holes faster and more precise than ever before.

Advancements in Electric Drill Technology

Over the years, the electric drill has undergone significant advancements in terms of design and functionality. Manufacturers introduced cordless drills, which eliminated the hassle of cords and allowed for greater portability.

In addition, modern electric drills incorporate adjustable speeds, enabling users to control the drilling speed based on the material they are working with.

The development of different types of drill bits, such as spade bits and hole saws, further expanded the capabilities of the electric drill. These specialized bits allowed users to drill larger holes and perform various tasks with greater precision.

Impact on Industries

The invention of the electric drill had a profound impact on numerous industries. In construction, electric drills made it easier and faster to install fixtures, assemble structures, and perform other tasks that require drilling.

In woodworking, electric drills became an essential tool for carpenters and furniture makers. They allowed for precise drilling and the creation of intricate designs.

Furthermore, the electric drill found applications in the automotive industry, where it was used for tasks such as drilling holes for screws and bolts during assembly and repair work.

Conclusion

The invention of the electric drill by Arthur James Arnot revolutionized the way tasks requiring drilling were performed. It introduced efficiency, precision, and convenience, making it an indispensable tool in various industries.

With ongoing advancements in electric drill technology, this essential tool continues to evolve and improve, providing professionals and DIY enthusiasts with new possibilities and capabilities.

William Brainard’s Drill

In the mid-19th century, William Brainard made significant contributions to the development of the electric drill. His drill design incorporated many innovative features that revolutionized the way drilling was done.

Key Features

- Electric Power: Brainard’s drill was powered by electricity, eliminating the need for manual labor.

- Portable: The drill was designed to be lightweight and compact, making it easy to transport and use in various locations.

- Variable Speed: Brainard’s drill allowed users to adjust the drilling speed according to the requirements of the task.

- Chuck Mechanism: The drill featured a chuck mechanism that made it easy to change drill bits quickly.

Inventions Inspired by Brainard’s Drill

Brainard’s drill design paved the way for numerous advancements in drilling technology. It served as a foundation for the development of more powerful and efficient electric drills in the future.

- Cordless Drills: Brainard’s portable drill inspired the creation of cordless drills that are widely used today.

- Industrial Drills: The invention of Brainard’s drill led to the development of powerful industrial drills that can handle heavy-duty drilling tasks.

- Precision Drills: Brainard’s drill design influenced the creation of precision drills used in delicate operations such as dentistry and electronics.

Legacy

William Brainard’s drill played a crucial role in the advancement of drilling technology. His innovative design and features set the stage for the development of modern electric drills, which continue to be an essential tool in various industries.

Today, the electric drill remains one of the most ubiquitous and indispensable tools, thanks in part to the contributions of William Brainard.

Wilhelm Fein’s Drill

Wilhelm Fein, a German inventor and engineer, played a crucial role in the development of the electric drill. In 1895, together with his brother Carl Fein, he founded the company C. & E. Fein GmbH, which focused on the production of electrical equipment for medical purposes.

However, Wilhelm Fein soon realized the potential of electric motors for other applications and began to experiment with using them in drilling machines. In 1901, Fein patented his first electric drill, which was the first of its kind to be produced in large quantities.

The Fein drill featured a powerful electric motor that was connected to a rotating chuck. This allowed for precise and effortless drilling, eliminating the need for manual labor. The drill was also equipped with a switch that allowed users to control the speed of the rotation.

Fein’s electric drill quickly gained popularity in various industries, including construction and manufacturing. Its efficiency and versatility made it an essential tool for many professionals.

Over the years, Fein’s company continued to innovate and improve the design of their drills. They introduced features such as keyless chucks, adjustable handles, and variable speed controls, further enhancing the usability and functionality of their drills.

Today, Wilhelm Fein’s legacy lives on in the Fein Power Tools company, which is still a leading manufacturer of power tools, including electric drills. The advancements made by Fein in the field of drilling technology have paved the way for the development of modern, high-performance drills that are used worldwide.

FAQ:

Who is credited with inventing the first electric drill?

The first electric drill was invented by Arthur Arnot and William Blanch Brainard in 1889.

What was the inspiration behind the invention of the electric drill?

The electric drill was inspired by the need for a power tool that could easily and efficiently drill holes in various materials.

How did the invention of the electric drill impact the construction industry?

The invention of the electric drill revolutionized the construction industry by making drilling holes faster, easier, and more precise. This allowed for increased efficiency and productivity in various construction projects.

What advancements have been made to the electric drill since its invention?

Since its invention, the electric drill has undergone numerous advancements in terms of power, speed, size, and features. Today, there are cordless drills, drill drivers, hammer drills, and impact drivers, among others.

How does an electric drill work?

An electric drill works by converting electrical energy into rotational motion. When the drill is turned on, electricity powers an electric motor, which then turns a drive shaft. The rotational motion of the drive shaft is transferred to the drill bit, allowing it to drill into materials.

Can you provide examples of situations where an electric drill is commonly used?

An electric drill is commonly used in various situations, such as drilling holes in walls for hanging shelves or pictures, assembling furniture, DIY projects, woodworking, and construction tasks.

Video: