When Was the First Drill Invented?

Drills have become an essential tool in our modern world, used for a wide range of purposes, from woodworking to construction to dentistry. But have you ever wondered when the first drill was invented?

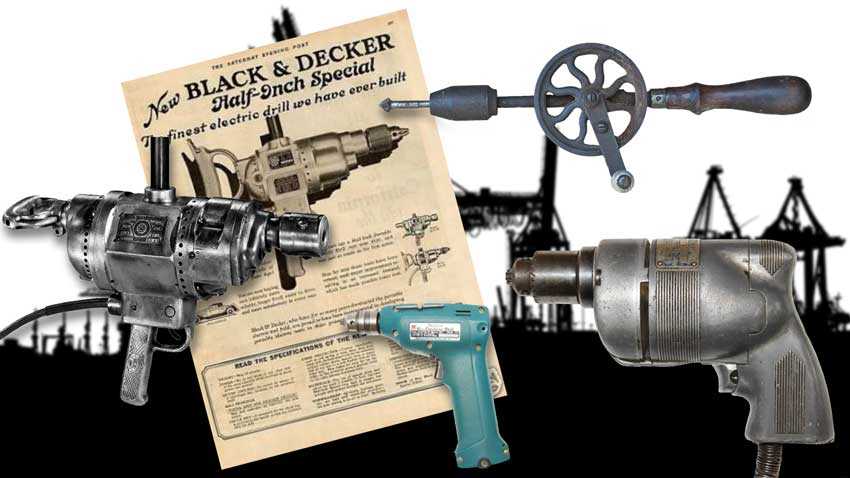

The origins of the drill can be traced back to ancient times, with evidence of early drilling tools dating back to the Roman Empire. These early drills were powered by hand and consisted of a simple pointed object, usually made of stone or bone, that was rotated manually to create a hole.

However, it wasn’t until the Middle Ages that the true precursor to the modern drill was developed. This early version, known as the bow drill, consisted of a wooden shaft with a cord tied to both ends. By twisting the cord, the wooden shaft would spin rapidly, allowing the user to exert more force and create larger holes.

Over the centuries, the drill continued to evolve, with improvements in materials and design. In the 19th century, the invention of steam power and later electricity revolutionized drilling, allowing for greater precision and efficiency.

The Early Origins of Drilling

The concept of drilling dates back thousands of years, with its origins rooted in ancient civilizations. Humans have long recognized the usefulness of creating holes in various materials for practical purposes.

Prehistoric Drilling Methods

Prehistoric humans used primitive drilling methods to create holes in wood, bone, and other materials. These early drills were typically made from pointed stones or animal bones. By rotating these tools manually, ancient people were able to bore holes for purposes such as making jewelry or creating tools.

One of the earliest known examples of prehistoric drilling is the ancient Egyptian practice of drilling holes in stones such as limestone and granite. The Egyptians used wooden drills with copper or bronze bits to create holes for construction projects, such as building temples and pyramids.

Ancient Drilling Tools

As civilizations progressed, so did the drilling techniques and tools. Ancient Mesopotamians, for example, developed the hand-powered auger, a tool that featured a spiral-shaped blade attached to a wooden handle. This allowed them to dig deep holes for various applications, including agriculture and construction.

The Ancient Greeks further refined drilling technology by inventing the gimlet, a small hand tool used for making small holes in wood. By rotating the gimlet manually, the Greeks were able to perforate wood with greater precision.

Industrial Revolution and Modern Drilling

The Industrial Revolution marked a significant milestone in the development of drilling technology. With the invention of the steam engine, powered drills became more prevalent. These machines enabled faster and more efficient drilling, revolutionizing various industries such as mining, oil extraction, and construction.

With advancements in technology, modern drilling techniques have further evolved. Today, various types of drills are used, including electric drills, pneumatic drills, and hydraulic drills. These tools are capable of drilling through a wide range of materials, from wood and metal to concrete and rock, with speed and precision.

| Year | Development |

|---|---|

| 30,000 BC | Prehistoric humans create holes using primitive drill tools |

| 2600 BC | Ancient Egyptians use wooden drills with copper or bronze bits |

| 1000 BC | Ancient Mesopotamians develop hand-powered auger |

| 4th century BC | Ancient Greeks invent the gimlet |

| 18th century AD | Industrial Revolution introduces steam-powered drills |

| 19th-20th century AD | Advancements in technology lead to the development of various modern drilling tools |

From the early days of primitive stone drills to modern electric and hydraulic drills, drilling has come a long way. Its evolution has played a crucial role in shaping the world we live in today, enabling us to create and modify the environment to meet our needs.

Ancient Hand Drills and Boring Tools

Ancient civilizations developed a variety of tools and techniques for drilling and boring holes in materials such as wood, stone, and bone. These early hand drills played a crucial role in shaping the world as we know it today. Let’s explore some of the fascinating ancient hand drills and boring tools that were used throughout history.

1. Bow Drill

The bow drill is one of the oldest known drilling tools, with evidence of its use dating back to the Paleolithic era. It consists of a simple wooden bow and a drill bit. The operator would use a cord to rotate the drill bit rapidly, creating enough friction to bore a hole in the material. The bow drill was commonly used for woodworking and creating fire.

2. Pump Drill

The pump drill is another ancient drilling tool that was used in various cultures, including ancient Egypt and Greece. It features a hollow wooden handle with a spindle on top and a weighted flywheel at the base. By repeatedly moving the handle up and down, the flywheel would rotate the drill bit, allowing for efficient drilling. The pump drill was often used for creating holes in hard materials like stone and bone.

3. Hand Brace

The hand brace, also known as the brace and bit, was a major advancement in drilling technology during the Middle Ages. It consisted of a metal frame with a crank handle and a chuck that held interchangeable drill bits. The operator would turn the crank handle, causing the drill bit to rotate and penetrate the material. The hand brace was widely used for drilling holes in wood and metal.

4. Auger

The auger is a tool that has been used since ancient times for drilling holes in wood and other soft materials. It features a helical screw blade attached to a long cylindrical shaft. By rotating the shaft, the screw blade would cut into the material, creating a hole. This type of drilling tool was particularly useful for creating deep holes, such as those needed for well construction.

5. Gimlet

The gimlet is a small hand tool that has been used for drilling holes in wood for centuries. It consists of a tapered metal shaft with a handle at one end and a screw-like tip at the other. By twisting the gimlet into the wood, it would bore a small hole. Gimlets were often used for tasks such as installing screws and creating pilot holes for larger drill bits.

| Tool | Origin | Main Use |

|---|---|---|

| Bow Drill | Paleolithic era | Woodworking, fire making |

| Pump Drill | Ancient Egypt, Greece | Stone and bone drilling |

| Hand Brace | Middle Ages | Wood and metal drilling |

| Auger | Ancient times | Wood and soft material drilling |

| Gimlet | Centuries ago | Wood drilling, pilot holes |

These ancient hand drills and boring tools were essential in various aspects of human life, from crafting tools and weapons to constructing buildings. They laid the foundation for the advanced drilling technology that we have today, showcasing the ingenuity and resourcefulness of our ancestors.

The Emergence of Mechanical Drills

The invention of the mechanical drill revolutionized the way tasks were performed that required making holes in various materials. Before the creation of the mechanical drill, humans relied on manual methods like chisels, awls, and augers.

The first incarnation of the mechanical drill appeared in ancient Egypt around 2500 BCE. These early drills were handheld and operated by a simple bow mechanism. The drill bit, made of copper or bronze, was attached to a spindle that would rotate when the bow was moved back and forth. This allowed craftsmen to drill precise holes in wood, bone, and other materials.

The advent of iron and steel during the Industrial Revolution enabled the production of more robust and efficient mechanical drills. The first hand-cranked drill was invented in the 15th century in Europe. It consisted of a gear mechanism operated by a handle, which provided a more reliable and controlled drilling motion.

Over time, mechanical drills evolved to include various improvements and adaptations. In the 19th century, the introduction of steam power and the industrialization of production techniques led to the development of larger and more powerful drill presses. These machines featured a rotating spindle driven by a belt system.

Today, mechanical drills come in a wide range of types and sizes, including cordless drills, impact drills, and hammer drills. They have become an essential tool in various industries, such as construction, woodworking, and metalworking.

| Date | Development |

|---|---|

| 2500 BCE | Ancient Egyptian bow drills |

| 15th century | First hand-cranked drills in Europe |

| 19th century | Introduction of steam-powered drill presses |

| 20th century | Invention of cordless drills and other specialized drill types |

The Industrial Revolution and Drill Advances

Introduction

The Industrial Revolution, which occurred in the late 18th century and early 19th century, brought about significant advances in various industries, including the development of new and improved tools. One such tool that underwent significant advancements during this period was the drill.

Advancements in Drill Technology

During the Industrial Revolution, the basic design of the drill remained similar to its earlier counterparts. However, the advancements in metallurgy and manufacturing techniques allowed for the production of stronger and more durable drill bits. This resulted in drills that were capable of drilling through harder materials, such as metals and rocks.

Additionally, the Industrial Revolution saw the introduction of steam-powered and later electric-powered drills. These drills provided a significant boost in drilling efficiency and allowed for the automation of drilling processes in various industries.

Impact on Industries

The advancements in drill technology during the Industrial Revolution had a profound impact on several industries. In the mining industry, for example, the improved drills allowed for more efficient extraction of minerals and ores from deep within the Earth. This led to increased productivity and the expansion of mining operations.

In the construction industry, the use of more powerful drills enabled the drilling of deeper and stronger foundations for buildings and bridges. This contributed to the construction of larger and more stable structures.

Conclusion

The Industrial Revolution played a crucial role in the advancement of drill technology. Through the development of stronger drill bits and the introduction of steam-powered and electric-powered drills, the Industrial Revolution revolutionized the drilling processes in various industries. Today, drills continue to evolve and improve, with new technologies such as cordless drills and drill press machines further enhancing their capabilities.

The Invention of the Electric Drill

The electric drill, a widely used power tool today, was invented in the late 19th century. It was an important development that revolutionized the drilling industry and made many tasks easier and more efficient.

Invention of the Electric Drill:

In 1889, Wilhelm Fein, a German inventor, invented the first portable electric drill. This drill was initially designed for dentists, as they needed a more efficient and precise tool for drilling teeth. The electric drill allowed dentists to drill at high speeds with less effort and improved accuracy, making dental procedures quicker and less painful for patients.

Commercial Success:

The electric drill quickly gained popularity not only in the dentistry field but also in other industries. The improved efficiency and convenience provided by electric drills made them valuable tools for construction, woodworking, metalworking, and various other applications.

Advancements and Modifications:

The early electric drills were powered by hand-cranked motors and operated at relatively low speeds. However, over time, advancements in technology led to the development of more powerful electric motors and higher-speed drills.

Modern Electric Drills:

Today, electric drills come in various sizes, shapes, and power ratings to suit different tasks. They are equipped with accessories such as drill bits, screwdriver bits, and sanding attachments, making them versatile tools for many applications.

Conclusion:

The invention of the electric drill was a significant milestone in the history of drilling tools. It not only revolutionized the dental industry but also made drilling tasks easier and more efficient in various fields. From its humble beginnings as a tool for dentists, the electric drill has evolved into a widely used power tool that continues to be improved upon and adapted for different applications.

Drilling Techniques in the Modern Era

With advancements in technology and engineering, drilling techniques have evolved significantly in the modern era. These techniques are designed to improve efficiency, accuracy, and safety in various drilling applications.

1. Rotary Drilling

One of the most commonly used drilling techniques in the modern era is rotary drilling. This method involves the use of a rotating drill bit that cuts through the earth’s surface to create a hole. Rotary drilling is commonly used in oil and gas exploration, mining, and construction projects.

During rotary drilling, a drill string carries the drill bit to the desired depth. As the drill bit rotates, it creates a hole by grinding and breaking the rock formations. The drill cuttings are then brought to the surface using drilling fluids or compressed air.

2. Percussion Drilling

Percussion drilling is another commonly used technique in modern drilling operations. This method involves repeatedly lifting and dropping a heavy drill bit into the ground to break through hard rock formations.

During percussion drilling, the drill bit is attached to a string of drill rods that are raised and dropped by a heavy drilling machine. This continuous pounding action allows the drill bit to chip away at the rock, creating a hole.

3. Directional Drilling

Directional drilling, also known as slant drilling or deviated drilling, is a technique used to drill non-vertical wells. It allows drillers to reach targets that are not directly beneath the drilling location.

This technique involves the use of specialized drill bits and equipment, such as mud motors and rotary steerable systems, to control the direction and angle of the wellbore. Directional drilling is commonly used in oil and gas exploration, underground mine workings, and geothermal drilling.

4. Hydraulic Fracturing

Hydraulic fracturing, also known as fracking, is a drilling technique used to extract oil and gas from shale formations deep underground. This method involves injecting a mixture of water, sand, and chemicals into the wellbore at high pressure to fracture the rock and release the trapped hydrocarbons.

Hydraulic fracturing has revolutionized the oil and gas industry by allowing access to previously inaccessible reserves. However, it has also raised concerns regarding water contamination and seismic activities.

Conclusion

The modern era has seen significant advancements in drilling techniques, leading to increased efficiency, accuracy, and safety. From rotary drilling to hydraulic fracturing, these techniques have revolutionized industries such as oil and gas, mining, and construction, allowing for the extraction of valuable resources and the completion of challenging projects.

Innovations in Drill Design and Functionality

Cordless Drills

One of the biggest innovations in drill design was the introduction of cordless drills. Before cordless drills were developed, drills were powered by electricity and required a cord to be plugged into an outlet. Cordless drills, on the other hand, are powered by rechargeable batteries, giving users the freedom to move around without being limited by the length of a cord.

These drills are lightweight, portable, and versatile, making them ideal for both professional and DIY use. They come in various sizes and power ranges, allowing users to choose the right drill for their needs.

Hammer Drills

Hammer drills are another innovative addition to drill design. These drills are specifically designed for drilling into hard materials such as concrete or masonry.

They feature a forward and backward hammering motion that helps break up the material as the drill bit rotates, making it much easier to drill into tough surfaces. This hammering action, coupled with the rotating motion, allows hammer drills to quickly and efficiently drill into even the toughest materials.

Impact Drills

Impact drills are similar to hammer drills in that they provide an extra force to help drill through hard materials. However, impact drills use a different mechanism to achieve this.

Instead of a hammering motion, impact drills use a rotating mechanism that generates a high amount of torque. This torque is then used to deliver quick, powerful bursts of force that help the drill bit penetrate the material more easily.

Impact drills are particularly useful for tasks such as driving screws into tough materials or loosening stubborn bolts.

Automatic Clutches

Traditionally, drills did not have a clutch mechanism, which meant that users had to be careful not to apply too much force when drilling. This could lead to the drill bit getting stuck or damaging the material being drilled.

Automatic clutches were introduced to address this issue. These clutches disengage the drill’s motor when a certain level of resistance is detected, preventing the drill bit from getting stuck or causing any damage. This feature not only makes drilling safer but also prolongs the life of the drill bit and reduces the risk of injury.

Compact and Lightweight Design

In recent years, drill manufacturers have made significant advances in reducing the size and weight of drills without compromising on power or functionality. This has made drills more ergonomic and comfortable to use, especially for longer periods of time.

Compact and lightweight design features have also made it easier for users to work in tight spaces or overhead, where maneuverability can be challenging.

Variable Speed Control

Variable speed control is a feature that allows users to adjust the speed of the drill bit rotation based on the task at hand. This feature is particularly useful when working with different materials or when performing delicate tasks that require more precision.

By being able to adjust the speed, users can prevent damage to the material being drilled and achieve better results.

Drilling in Various Industries Today

The invention of the drill has revolutionized many industries, allowing for the extraction of resources and the construction of structures with greater ease and efficiency. Today, drilling is used in a wide range of industries, including:

Oil and Gas Industry

Drilling plays a vital role in the exploration, extraction, and production of oil and gas. It is used to create boreholes in the earth’s surface, allowing access to underground reservoirs of oil and gas. Different drilling techniques, such as rotary drilling and directional drilling, are employed to reach these resources.

Mining Industry

In the mining industry, drilling is used to extract valuable minerals and ores from the earth. It is used to create blastholes for explosives, as well as for exploration and survey purposes. Drilling rigs equipped with specialized drilling tools are deployed to penetrate various rock formations and extract the desired materials.

Construction Industry

Drilling is an integral part of the construction industry, used in various applications. It is used to create foundation piles, anchor bolts, and tunnels. Drilling is also used for soil investigation and environmental sampling. Different drilling techniques, such as auger drilling and percussion drilling, are employed in construction projects.

Geothermal Energy Industry

Drilling is essential in the geothermal energy industry, which harnesses heat from the earth’s interior for power generation. Geothermal wells are drilled to access hot water and steam reservoirs, which are then used to produce electricity. Deep drilling techniques are typically employed to reach the necessary depths for geothermal energy extraction.

Environmental and Groundwater Industries

Drilling is used in environmental and groundwater industries for the installation of monitoring wells and extraction of groundwater samples. It is also used for investigating soil and groundwater contamination. Drilling techniques, such as direct push drilling and sonic drilling, are utilized in these industries.

Scientific Research

Drilling is employed in scientific research to study the composition of the Earth’s crust and gather geological data. It allows scientists to extract rock samples for analysis, explore subglacial environments, and access ancient sediment layers. Drilling, in combination with other scientific techniques, helps researchers understand the Earth’s history and processes.

Conclusion

From the extraction of oil and gas to the exploration of scientific mysteries, drilling plays a crucial role in various industries. The continuous advancements in drilling technology have enabled these industries to operate more efficiently and bring about significant advancements in their respective fields.

The Future of Drilling Technology

1. Advances in Automation

The future of drilling technology holds great promise with the advancement of automation. Drilling processes are becoming increasingly automated, reducing the need for manual labor and improving both safety and efficiency. With the use of artificial intelligence and machine learning algorithms, drills can be programmed to make real-time adjustments based on data collected during the drilling process. This automation allows for faster and more accurate drilling, reducing the risk of human error.

2. Integration of Robotics

The integration of robotics into drilling technology is another exciting development for the future. Robots can be employed to carry out drilling activities in challenging environments where human access is limited or dangerous. These robots are equipped with advanced sensors and cameras, allowing them to navigate and operate autonomously. They can also be remotely controlled by human operators, providing a safe and efficient drilling solution.

3. Enhanced Drilling Techniques

Advancements in drilling techniques are continuously being made to improve the efficiency and effectiveness of drilling operations. One such technique is directional drilling, which allows for the drilling of wells at angles or curves, reaching previously inaccessible oil or gas reserves. Furthermore, the development of micro-drilling techniques will enable the extraction of resources from smaller and harder-to-reach deposits.

4. Environmentally Friendly Drilling

With increasing concerns over the environmental impact of drilling, the future of drilling technology will focus on developing more environmentally friendly drilling methods. This includes the reduction of carbon emissions, minimizing water consumption, and finding alternative drilling fluids that are less harmful to the environment. Additionally, efforts are being made to improve waste management and recycling practices in drilling operations.

5. Integration of Data Analytics

The future of drilling technology will heavily rely on data analytics to optimize drilling operations. By collecting and analyzing vast amounts of data, drilling companies can make data-driven decisions to improve drilling efficiency, reduce costs, and increase overall productivity. Data analytics can also be used to predict and prevent drilling failures, ensuring safer and more reliable drilling operations.

| Improved Safety | Higher Efficiency | Reduced Environmental Impact |

|---|---|---|

| Automation reduces the risk of human error and improves worker safety. | Advanced drilling techniques and automation lead to faster and more accurate drilling, saving time and resources. | Environmentally friendly drilling methods minimize the impact on ecosystems and reduce carbon emissions. |

| Integration of robotics allows for drilling in dangerous or hard-to-reach locations without risking human lives. | Data analytics optimize drilling operations and help identify areas for improvement. | Improved waste management and recycling practices reduce environmental pollution. |

FAQ:

Who invented the first drill and when?

The first drill was invented by the ancient Egyptians around 4,000 years ago. They made drills by attaching a wooden handle to a copper tube, and then inserting a sharp wooden or metal point into the tube.

How did the ancient Egyptians use their drills?

The ancient Egyptians used their drills for various purposes such as woodworking, making holes in jewelry, and even for medical procedures. They were skilled at using their drills to create precise holes in different materials.

What materials were used for the first drill?

The first drills were made using copper tubes with sharp wooden or metal points. The handles were typically made of wood. These materials allowed the ancient Egyptians to create functional and effective drilling tools.

Did the design of drills change over time?

Yes, the design and functionality of drills have changed significantly over time. After the ancient Egyptians, other civilizations such as the Greeks and Romans developed more advanced drilling tools. In modern times, drills have become much more powerful and efficient, utilizing electricity or battery power.

Video: