What size pilot hole should I drill?

When it comes to drilling holes for screws or bolts, using a pilot hole can make a big difference in the success and longevity of your project. A pilot hole is a small-diameter hole drilled into the material before the larger screw or bolt is inserted.

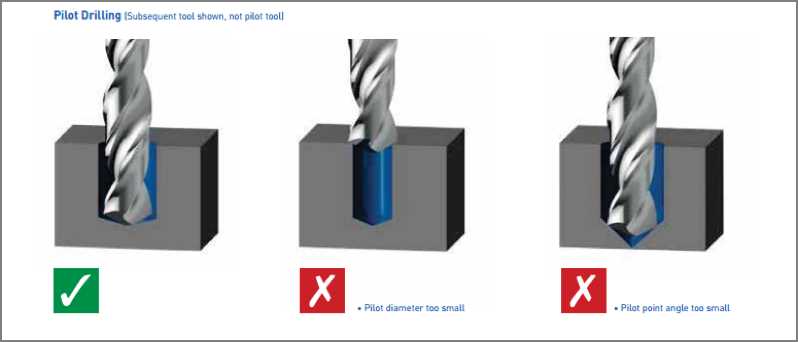

The size of the pilot hole needed depends on several factors, including the type of material being drilled into and the size of the screw or bolt. If the pilot hole is too small, it can cause the material to split or the screw to break. On the other hand, if the pilot hole is too large, the screw or bolt may not have enough material to grip onto, resulting in a weaker connection.

One general rule of thumb is to use a pilot hole that is slightly smaller than the diameter of the screw or bolt. This will allow the screw or bolt to grip the material securely without splitting it. However, it’s important to consider the specific requirements of your project, as some materials may require a larger or smaller pilot hole.

For softer materials such as wood or plastic, a pilot hole that is approximately 70-80% of the diameter of the screw or bolt can be used. This will provide enough room for the screw to bite into the material without causing it to split. Harder materials such as metal may require a smaller pilot hole, closer to 50-60% of the screw or bolt diameter.

It’s also worth noting that different types of screws and bolts may have different requirements for pilot hole size. For example, self-tapping screws may not require a pilot hole at all, while others may require a specific size depending on the design of the screw or bolt.

In summary, choosing the right size pilot hole is crucial for the success of your project. Taking into account the type of material and the size of the screw or bolt will help ensure a secure and long-lasting connection. When in doubt, it’s always best to start with a smaller pilot hole and gradually increase the size if needed.

Guide to Choosing the Right Pilot Hole Size for Drilling

When it comes to drilling holes, one important step is to choose the right size pilot hole. A pilot hole is a small hole drilled into a material before the main hole is drilled. It helps to guide the drill bit and prevent the material from splitting or splintering. The size of the pilot hole you need to drill depends on various factors, including the type of material, the size of the screw or nail you plan to use, and the type of drill bit you will be using.

Factors to consider when choosing the pilot hole size:

- Material: Different materials require different pilot hole sizes. Softer materials, such as wood or plastic, generally require smaller pilot holes, while harder materials, such as metal or concrete, may require larger pilot holes. It’s important to choose the right size pilot hole to ensure a secure and safe installation.

- Screw or nail size: The size of the screw or nail you plan to use also affects the pilot hole size. Generally, the diameter of the pilot hole should be slightly smaller than the diameter of the screw or nail. This allows the screw or nail to grip the material securely while still being able to penetrate it easily.

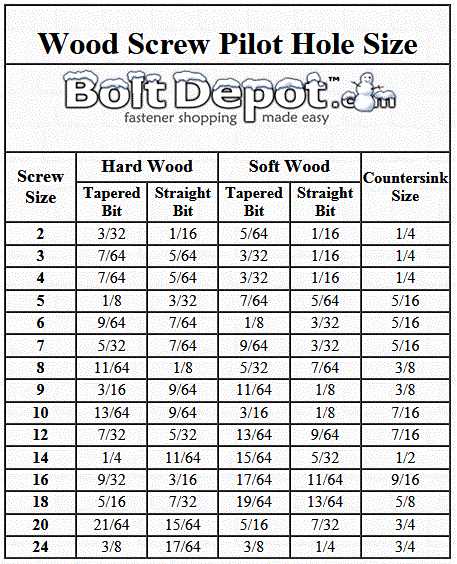

- Drill bit type: The type of drill bit you use can also influence the size of the pilot hole. For example, a brad-point bit has a sharp point and is ideal for drilling pilot holes in wood, while a masonry bit is designed for drilling pilot holes in concrete or masonry surfaces. Make sure to choose the right type of drill bit for your specific application.

General guidelines for choosing pilot hole sizes:

While the exact pilot hole size will vary depending on the factors mentioned above, here are some general guidelines to help you choose the right size:

| Material | Screw or Nail Size | Pilot Hole Size |

|---|---|---|

| Wood | Up to #4 | 1/16″ |

| Wood | #5 to #8 | 3/32″ |

| Wood | #9 to #12 | 1/8″ |

| Wood | #14 or larger | 9/64″ |

| Metal | Up to #4 | 1/16″ |

| Metal | #5 to #8 | 3/32″ |

| Metal | #9 to #14 | 1/8″ |

| Metal | #14 or larger | 5/32″ |

| Concrete or Masonry | Any size | 1/4″ or larger |

Remember, these guidelines are general recommendations, and it’s important to consider the specifics of your project and the materials you are working with. If in doubt, it’s always a good idea to consult the manufacturer’s guidelines or seek professional advice.

By following these guidelines and choosing the right pilot hole size for drilling, you can ensure a successful and secure installation, whether you are working with wood, metal, or concrete.

Why Pilot Hole Size Matters

When it comes to drilling holes, the size of the pilot hole you create can have a significant impact on the success of your project. A pilot hole is a small hole that is drilled before the main hole. It helps guide and prepare the way for a larger drill bit and prevents the wood from splitting or splintering.

Choosing the correct size for your pilot hole is essential. If the hole is too small, it can cause the drill bit to bind or break. On the other hand, if the hole is too large, it may not provide enough support, causing the screw or nail to loosen over time.

So, how do you determine the right size for your pilot hole? It depends on the type of material you are working with and the size of the fastener you plan to use.

Wood:

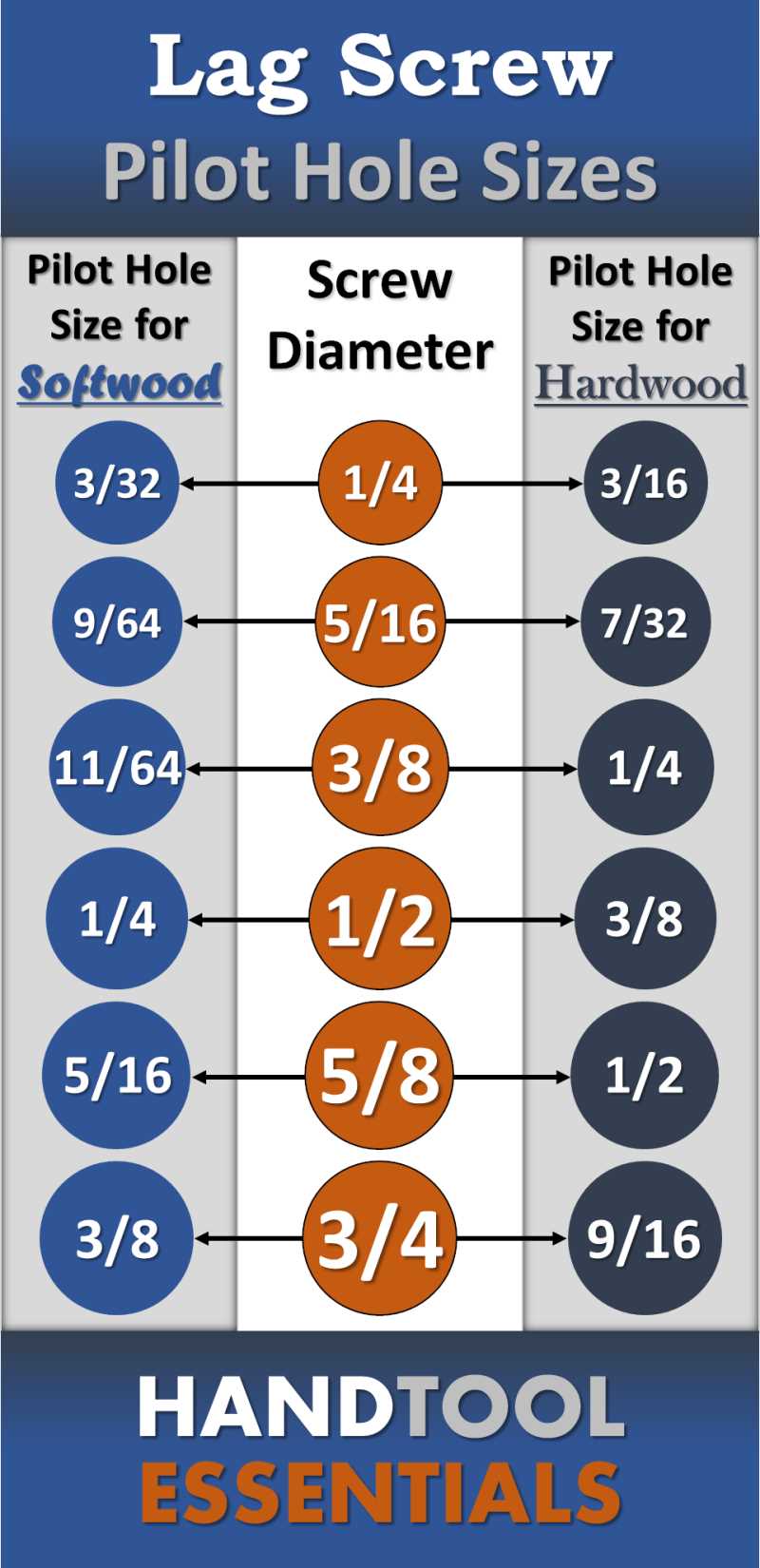

When drilling into wood, the general rule of thumb is to choose a pilot hole size that is slightly smaller in diameter than the fastener. For example, if you are using a 1/4-inch screw, you would typically use a 3/16-inch pilot hole.

To ensure a snug fit, you can use a drill bit set that includes a range of sizes. Start with a smaller bit and gradually increase the size until you find the perfect fit.

Metal:

Metal requires a different approach when it comes to pilot hole size. Since metal is a harder material than wood, you will typically need a larger pilot hole to accommodate the fastener.

When working with metal, it is best to refer to a drill bit size chart. This chart will provide you with the recommended pilot hole sizes based on the diameter of the screw or bolt you are using and the thickness of the metal.

Composite Material:

Composite materials, such as plastic or composite decking boards, also have specific requirements for pilot hole size.

Similar to wood, it is recommended to choose a pilot hole that is slightly smaller than the diameter of the fastener. However, due to the nature of composite materials, it is essential to use a slow drill speed and apply light pressure to avoid damaging the material.

Overall, selecting the correct pilot hole size is crucial for a successful drilling project. It ensures proper support, prevents splitting or breakage, and increases the longevity of the fasteners.

Remember, when in doubt, it is always better to start with a smaller pilot hole and gradually increase the size until you find the right fit. Taking the time to create the perfect pilot hole will save you time, effort, and frustration in the long run.

Factors Affecting Pilot Hole Size

1. Material Type:

Different materials require different pilot hole sizes. Softwoods like pine or cedar may require a smaller pilot hole compared to hardwoods like oak or maple. Similarly, drilling into metals like aluminum or steel may require a larger pilot hole compared to drilling into plastic or rubber materials.

2. Screw Size:

The size and type of screw you are using will also affect the size of the pilot hole. Larger screws generally require larger pilot holes, while smaller screws may only require a small pilot hole or no pilot hole at all.

3. Screw Material:

The material of the screw can also impact the size of the pilot hole. Screws made of softer materials like brass or plastic may require smaller pilot holes compared to screws made of harder materials like stainless steel or hardened steel.

4. Desired Holding Power:

If you want your screw to have maximum holding power, a larger pilot hole may be necessary. A larger hole allows for more threads of the screw to engage with the material, providing a stronger grip.

5. Material Density:

Denser materials may require larger pilot holes to reduce the risk of splitting or cracking. This is especially important when drilling into hardwoods or dense metals.

6. Screw Length:

If you are using a long screw, it is often recommended to drill a slightly deeper pilot hole to ensure the screw can penetrate the material fully without bottoming out.

7. Environmental Conditions:

Environmental factors such as temperature and humidity can affect the size of the pilot hole needed. For example, in high humidity conditions, wood may swell, requiring a larger pilot hole to accommodate the expanded material.

8. Personal Preference:

Some individuals may have personal preferences for pilot hole sizes based on their own experiences and the specific application they are working on.

9. Manufacturer Recommendations:

Always consult the manufacturer’s recommendations for pilot hole sizes. They may provide specific guidelines or tables based on the screw and material being used.

Remember, it is always better to start with a smaller pilot hole and gradually increase its size if necessary, rather than starting with a larger hole and risking weak or loose screw connections.

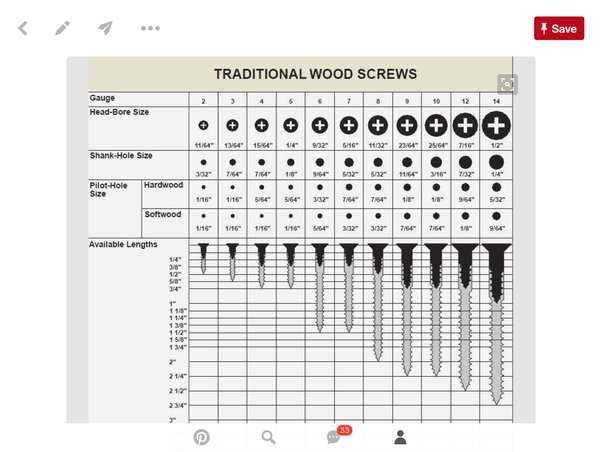

Choosing the Right Size for Wood

When it comes to drilling pilot holes in wood, selecting the correct size is crucial. A pilot hole is a small hole drilled into the material before inserting a screw or nail. This hole helps prevent the wood from splitting and allows for easier insertion of the fastener.

Factors to Consider

Several factors should be taken into account when choosing the right size for a pilot hole in wood:

- Wood Type: Different types of wood have varying densities and strengths. Hardwoods generally require larger pilot holes than softwoods.

- Screw or Nail Size: The size of the fastener you plan to use will determine the size of the pilot hole. It is important to match the diameter of the hole to the outer diameter of the fastener thread.

- Wood Thickness: Thicker pieces of wood generally require larger pilot holes to reduce the risk of splitting.

General Guidelines

While specific guidelines may vary depending on the project and the materials being used, the following general guidelines can help you determine the appropriate size for a pilot hole:

- Choose a drill bit that is slightly smaller than the outer diameter of the screw or nail you will be using. This will allow the fastener to grip the wood securely.

- If drilling into softwood, select a drill bit that is approximately 75% of the screw or nail diameter. For hardwood, choose a bit that is approximately 50-60% of the fastener diameter.

- For thicker pieces of wood, increase the pilot hole diameter to reduce the risk of splitting.

Benefits of Using the Right Size

Using the appropriate size for a pilot hole offers several benefits:

- Prevents Splitting: By drilling a pilot hole, you reduce the chances of the wood splitting when you insert the screw or nail.

- Easier Fastener Insertion: A pilot hole allows the fastener to be inserted smoothly and with less effort.

- Stronger Connections: When the screw or nail is securely seated in the pilot hole, it creates a stronger and more stable connection between the pieces of wood.

Conclusion

Choosing the right size for a pilot hole in wood is essential to ensure a successful and secure fastening. By considering factors such as wood type, fastener size, and wood thickness, you can select an appropriate drill bit size. Following general guidelines and using the right size pilot hole can help prevent splitting, ease fastener insertion, and create stronger connections.

Choosing the Right Size for Metal

When drilling holes in metal, it is important to choose the right size for the pilot hole. The size of the pilot hole will depend on the type of metal you are working with and the size of the screw or drill bit you will be using.

Here are some guidelines for choosing the right size pilot hole for different metals:

Soft metals like aluminum and brass:

- For screws with a diameter of 0-14, use a pilot hole that is 60-70% of the diameter of the screw.

- For screws with a diameter of 14-20, use a pilot hole that is 50-60% of the diameter of the screw.

- For screws with a diameter of 20 or larger, use a pilot hole that is 40-50% of the diameter of the screw.

Hard metals like steel and iron:

- For screws with a diameter of 0-14, use a pilot hole that is 30-40% of the diameter of the screw.

- For screws with a diameter of 14-20, use a pilot hole that is 25-35% of the diameter of the screw.

- For screws with a diameter of 20 or larger, use a pilot hole that is 20-30% of the diameter of the screw.

It is important to note that these are general guidelines and may vary depending on the specific application or the type of metal being used. It is always a good idea to consult the manufacturer’s guidelines or seek professional advice when drilling holes in metal.

Using the right size pilot hole is essential for ensuring that the screws or drill bits can be inserted smoothly and securely into the metal. It helps prevent the metal from cracking or splitting, and ensures that the fasteners are held securely in place.

| Screw Diameter | Soft Metals (%) | Hard Metals (%) |

|---|---|---|

| 0-14 | 60-70 | 30-40 |

| 14-20 | 50-60 | 25-35 |

| 20+ | 40-50 | 20-30 |

Choosing the Right Size for Plastic

Introduction

Drilling pilot holes in plastic can be a tricky task, as the material is softer and more prone to cracking compared to wood or metal. To ensure a clean and secure fastening, it is important to choose the right size for the pilot hole. This guide will help you determine the appropriate size for drilling pilot holes in plastic.

Factors to Consider

There are several factors to consider when choosing the right size for a pilot hole in plastic:

- Type of Plastic: Different types of plastic have different hardness levels. Hard plastics such as acrylic or polycarbonate require smaller pilot holes compared to softer plastics like PVC or HDPE.

- Diameter of Fastener: The size of the fastener you are using will determine the diameter of the pilot hole. It is important to choose a pilot hole size that matches the diameter of the fastener to ensure a snug fit.

- Thickness of Plastic: Thicker plastic sheets will require larger pilot holes to allow for easy insertion of fasteners. A rule of thumb is to choose a pilot hole diameter that is approximately half the thickness of the plastic.

Pilot Hole Size Chart

Here is a general guideline for choosing the right pilot hole size for plastic:

| Plastic Type | Fastener Diameter | Pilot Hole Diameter |

|---|---|---|

| Hard Plastic (e.g., acrylic, polycarbonate) | Up to 1/4 inch | 1/16 inch |

| Soft Plastic (e.g., PVC, HDPE) | Up to 1/4 inch | 1/8 inch |

| Hard Plastic (e.g., acrylic, polycarbonate) | Up to 1/2 inch | 3/32 inch |

| Soft Plastic (e.g., PVC, HDPE) | Up to 1/2 inch | 5/32 inch |

Conclusion

Choosing the right size for a pilot hole is crucial when drilling into plastic. By considering the type of plastic, diameter of the fastener, and thickness of the plastic, you can ensure a secure and reliable fastening. Refer to the pilot hole size chart as a reference guide, but always test on a scrap piece of plastic before drilling into your final project.

Common Pilot Hole Sizes

Pilot holes are often used to pre-drill holes in wood or other materials before inserting screws or nails. The size of the pilot hole is important to ensure that the screw or nail is properly secured without splitting the wood. Here are some common pilot hole sizes and their recommended uses:

| Diameter (inches) | Recommended Screw Size | Recommended Use |

|---|---|---|

| 1/32″ | #2 or #3 | Very small screws or nails |

| 1/16″ | #5 or #6 | Small screws or nails |

| 3/32″ | #8 or #10 | Medium-sized screws or nails |

| 1/8″ | #12 or #14 | Large screws or nails |

| 3/16″ | #16 or #18 | Very large screws or nails |

| 1/4″ | #20 or #24 | Extra-large screws or nails |

These sizes are general recommendations and may vary depending on the specific material and application. It’s always a good idea to test the size of the pilot hole on a scrap piece of wood or inconspicuous area before drilling into the final workpiece.

Remember to adjust the pilot hole size if you are using a different type of screw or nail. It’s also important to use a drill bit that matches the diameter of the pilot hole for best results.

Tips for Drilling Pilot Holes

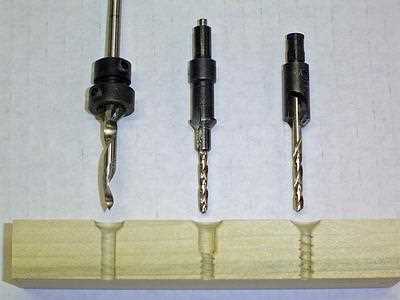

- Use the Right Drill Bit: When drilling pilot holes, it’s important to use the right size drill bit. The size of the drill bit should match the size of the screw you plan to use.

- Choose the Right Depth: The depth of the pilot hole should be slightly shorter than the length of the screw. This will ensure that the screw secures properly without splitting the wood.

- Mark the Hole: Before drilling, mark the spot where you want to drill the pilot hole. This will help ensure accuracy and prevent any mistakes.

- Start Slowly: When drilling pilot holes, start at a slow speed. This will prevent the drill bit from slipping and damaging the wood.

- Use a Clamped Workpiece: If possible, clamp the workpiece down before drilling pilot holes. This will prevent any movement or slipping while drilling.

- Clear the Dust: After drilling the pilot hole, clear away any dust or debris before inserting the screw. This will ensure a clean and secure fit.

- Consider Lubrication: If you’re drilling pilot holes in hardwood or dense wooden materials, consider using a lubricant to reduce friction and make drilling easier.

- Practice on Scrap Wood: If you’re new to drilling pilot holes, practice on scrap wood first. This will help you get a feel for the process and improve your technique.

By following these tips, you can ensure that your pilot holes are drilled accurately and effectively, making your woodworking projects easier and more successful.

FAQ:

What size pilot hole should I drill for a #8 screw?

For a #8 screw, you should generally drill a pilot hole that is about 3/32 of an inch in diameter.

What size pilot hole should I drill for a #10 screw?

For a #10 screw, a pilot hole with a diameter of approximately 1/8 of an inch is recommended.

What size pilot hole should I drill for a 1/4-inch screw?

When using a 1/4-inch screw, it is advisable to drill a pilot hole that is around 3/16 of an inch in diameter.

What size pilot hole should I drill for a 1/2-inch screw?

If you are working with a 1/2-inch screw, it is best to drill a pilot hole that is approximately 5/16 of an inch in diameter.

Video: