What Size Hole to Drill for 3/8 Lag Bolt

When it comes to securing heavy objects or structures, lag bolts are often the fasteners of choice. These large, sturdy bolts are designed to provide a strong and secure connection. However, in order for lag bolts to be effective, it’s important to drill the right size hole.

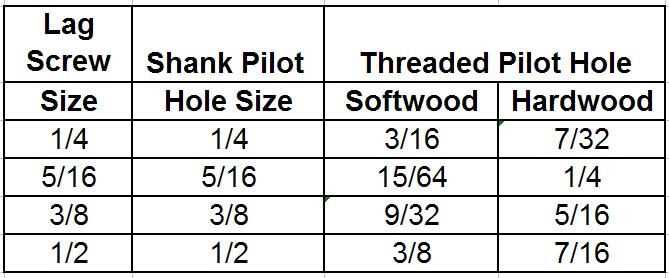

The size of the hole you need to drill for a 3/8 lag bolt depends on several factors, including the type of wood you are working with and the specific application. In general, it is recommended to drill a pilot hole that is slightly smaller than the diameter of the lag bolt. This ensures a tight fit and prevents the wood from splitting.

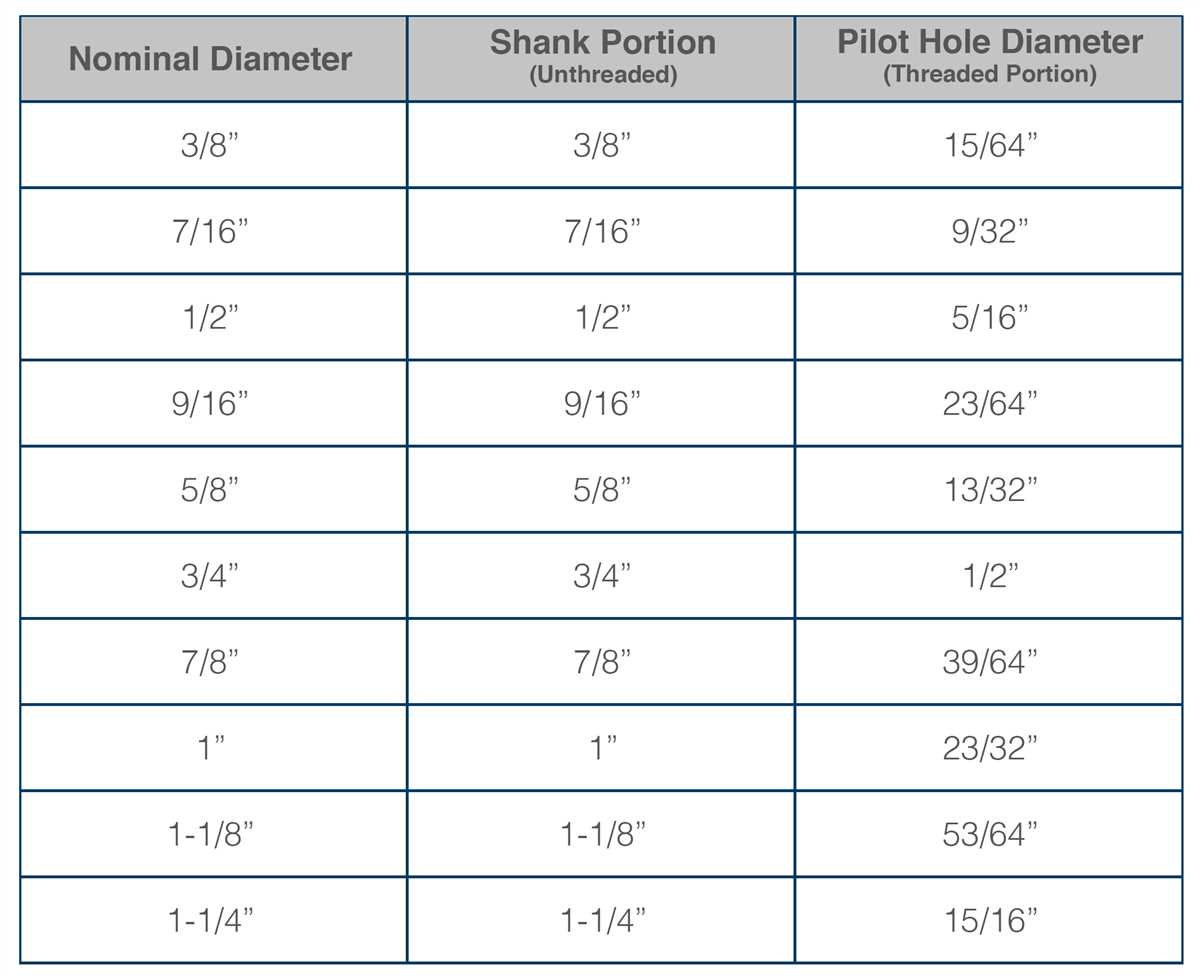

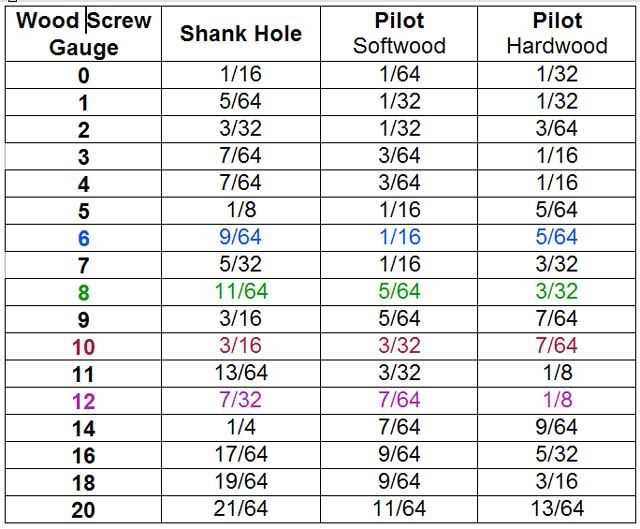

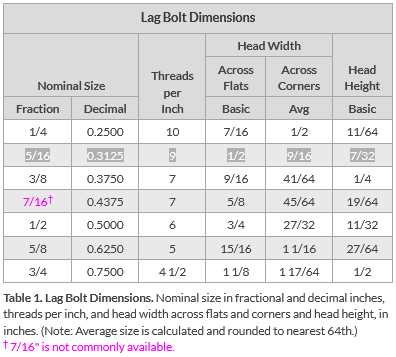

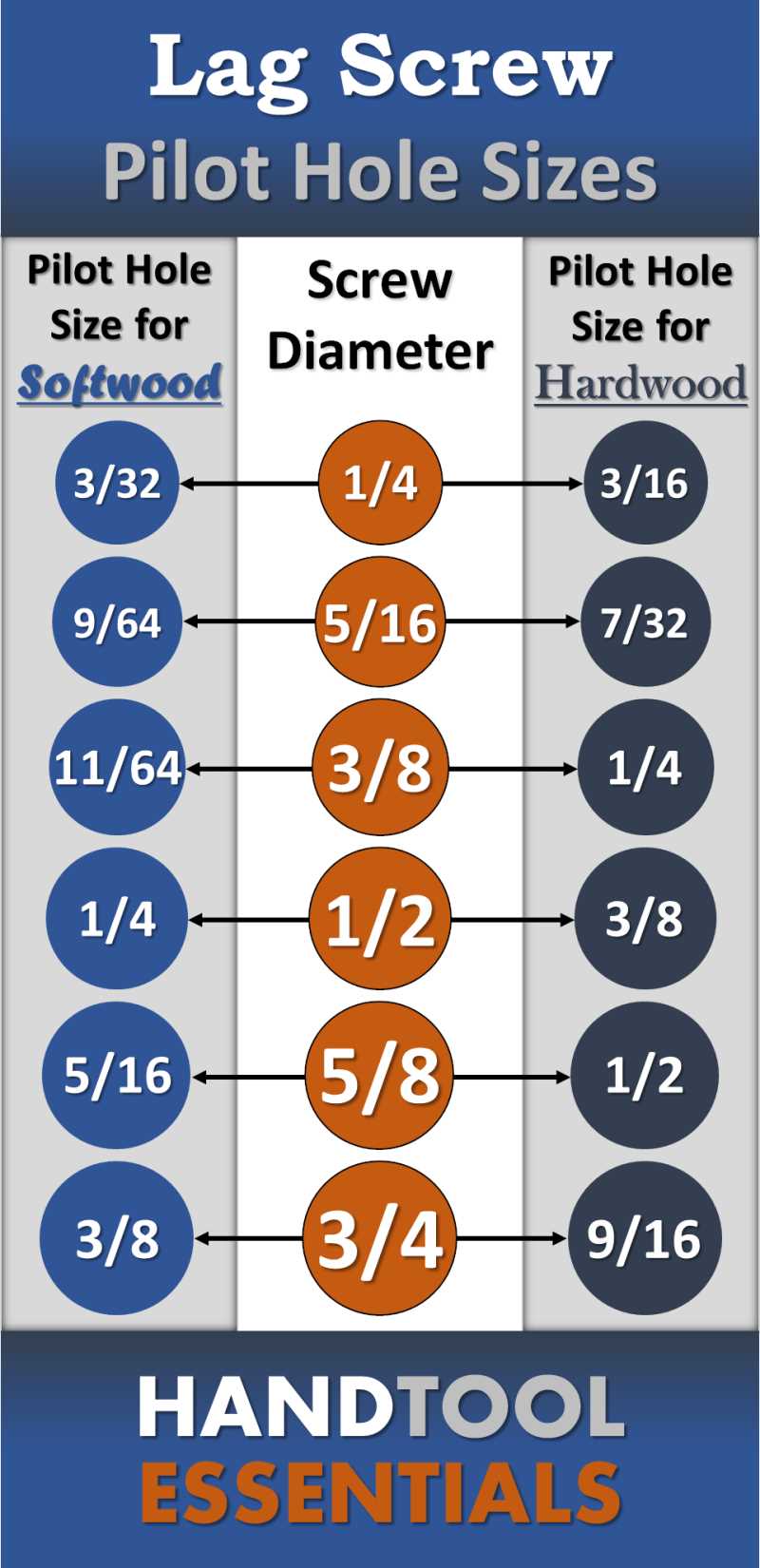

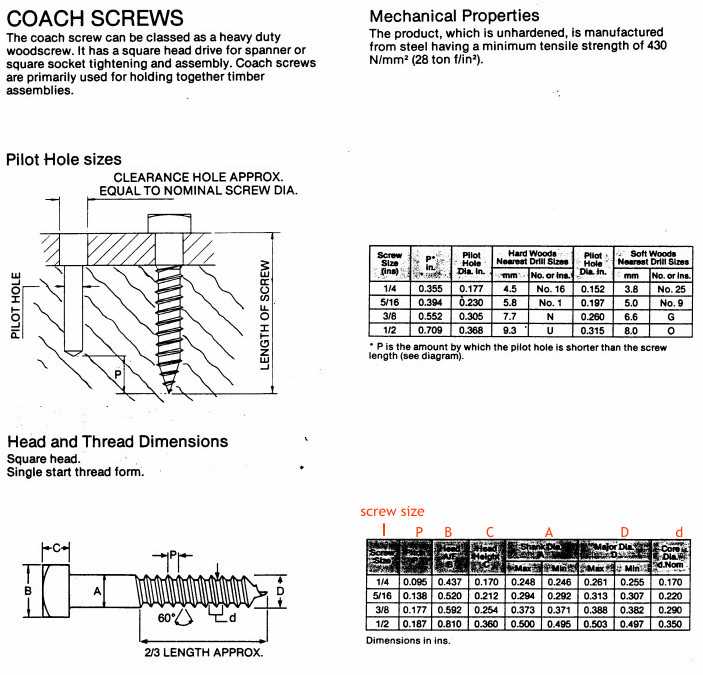

To determine the exact size of the pilot hole, you can refer to a lag bolt pilot hole size chart. This chart will provide you with the recommended pilot hole size based on the diameter of the lag bolt and the type of wood you are working with. It’s important to note that different types of wood require different pilot hole sizes to ensure a secure connection.

Drilling the right size hole for a 3/8 lag bolt is crucial for ensuring a strong and secure connection. By referencing a lag bolt pilot hole size chart and taking into account the type of wood you are working with, you can confidently drill the appropriate hole size for your specific application.

Choosing the Right Size Hole

When it comes to drilling a hole for a 3/8 lag bolt, it is important to choose the right size to ensure that the bolt fits securely and provides the necessary support. The size of the hole will depend on the material you are drilling into and the specific requirements of your project.

Consider the Material

The first step in choosing the right size hole for a 3/8 lag bolt is to consider the material you will be drilling into. Different materials have different densities and strengths, which will impact the size of the hole needed.

If you are drilling into wood, a general rule of thumb is to use a drill bit approximately 1/16 inch larger than the diameter of the lag bolt. For a 3/8 lag bolt, this would require a drill bit around 13/32 inch in diameter.

For drilling into metal, it is important to consult a drill bit size chart that matches the specific metal you are working with. This will provide recommendations for the appropriate size hole based on the diameter of the lag bolt.

Consider the Project Requirements

In addition to considering the material, it is important to consider the specific requirements of your project. This may include factors such as load capacity, shear strength, and the need for a tight fit or for movement within the hole.

If you require a tight fit, it may be necessary to use a slightly smaller drill bit size to ensure a snug fit for the lag bolt. Similarly, if you need some movement or play within the hole, using a slightly larger drill bit size may be appropriate.

Consult an Expert or Reference a Guide

If you are unsure about the appropriate size hole for your specific project, it is always recommended to consult an expert or reference a guide. There are resources available, such as drill bit size charts, that can provide guidance based on the specific material and diameter of lag bolt you are using.

By choosing the right size hole for your 3/8 lag bolt, you can ensure a secure and reliable connection that will meet the requirements of your project. Taking the time to accurately measure and drill the hole will result in a stronger and more durable installation.

Factors to Consider

When determining the size of the hole to drill for a 3/8 lag bolt, there are several factors that should be taken into consideration:

- Material: The type of material into which the lag bolt will be inserted plays a crucial role in determining the hole size. Different materials have different strengths and characteristics, which may affect the size of the hole.

- Load: The weight or load that will be placed on the lag bolt is another important factor. If the load is heavy, a larger hole may be necessary to ensure proper support and prevent overloading of the bolt.

- Shear Strength: The shear strength of the material being connected is important to consider. If the shear strength is low, a larger hole may be required to prevent the material from failing under stress.

- Installation Method: The method used to install the lag bolt should also be considered. If the bolt will be driven in with an impact driver, a smaller hole may be necessary to ensure a tight fit. On the other hand, if the bolt will be hammered in, a slightly larger hole may be required to accommodate for any slight misalignment during installation.

- Environmental Factors: Environmental factors, such as temperature and humidity, can also affect the size of the hole. Materials may expand or contract under different conditions, so it is important to take these factors into account when determining the appropriate hole size.

By considering these factors, you can ensure that the hole size you drill for a 3/8 lag bolt is appropriate for the specific application and materials involved, providing a secure and reliable connection.

Recommended Drill Bit Size

When drilling holes for 3/8 lag bolts, it is important to use the correct drill bit size. The size of the drill bit will depend on the specific requirements of the project, such as the type of material being drilled into and the intended use of the lag bolt.

For most applications, a 9/32 inch drill bit is recommended for drilling holes for 3/8 lag bolts. This drill bit size provides enough clearance for the lag bolt to be inserted without being too loose or too tight.

However, it is always a good idea to check the manufacturer’s recommendations and guidelines for the specific lag bolts being used. Some manufacturers may recommend a slightly different drill bit size depending on the type of material or the specific application.

Additionally, it is important to note that drilling pilot holes is essential when using lag bolts. Pilot holes help prevent the wood from splitting and provide a guide for the lag bolt to follow. The size of the pilot hole should be slightly smaller than the diameter of the lag bolt.

| Material | Recommended Drill Bit Size |

|---|---|

| Wood | 9/32 inch |

| Metal | 21/64 inch |

| Concrete | 3/8 inch |

These recommended drill bit sizes are general guidelines and may vary depending on the specific project and requirements. It is always best to consult the manufacturer’s recommendations and guidelines for the most accurate information.

Alternative Drill Bit Sizes

While the standard drill bit size for a 3/8 lag bolt is typically 5/16, there are some alternative sizes that can also be used depending on the specific requirements of your project.

1/4 Drill Bit

A 1/4 drill bit can be used as an alternative to a 5/16 bit. This slightly smaller size may be suitable for softer or less dense materials or when a tighter fit is desired.

11/32 Drill Bit

For a slightly larger hole, an 11/32 drill bit can be used. This can provide a looser fit for the lag bolt, which may be preferable for certain applications where expansion and contraction of materials is a concern.

3/8 Step Drill Bit

A step drill bit is a specialized tool that can create multiple hole sizes with a single bit. A 3/8 step drill bit can be used to achieve the proper hole size for a 3/8 lag bolt, as well as smaller sizes if needed.

Other Sizes

There are numerous other drill bit sizes that can be used as alternatives to the standard 5/16 size. These include 21/64, 23/64, and 3/8. The specific size to use will depend on factors such as the material being drilled and the desired fit of the lag bolt.

It’s important to note that the size of the pilot hole should always match the size of the shank of the lag bolt. Using the correct size drill bit will ensure a strong and secure connection.

| Alternative Sizes |

|---|

| 1/4 |

| 11/32 |

| 3/8 Step Drill Bit |

| 21/64 |

| 23/64 |

| 3/8 |

Importance of Correct Hole Size

When it comes to drilling holes for 3/8 lag bolts, the size of the hole plays a crucial role in ensuring the strength and stability of the connection. Using the correct hole size is important for several reasons.

1. Proper Grip

One of the main reasons why the correct hole size is important is to ensure a proper grip between the lag bolt and the material it is being fastened into. If the hole is too small, the threads of the lag bolt may not engage properly, resulting in a weakened connection. On the other hand, if the hole is too large, the lag bolt may not have enough material to grip onto, leading to a loose or ineffective connection.

2. Preventing Splitting

Using the correct size hole also helps prevent splitting of the material being fastened. When drilling a hole for a lag bolt, it is essential to choose a bit size that is slightly smaller than the diameter of the bolt’s body. This allows the threads to grip the material tightly without causing excessive stress that could lead to splitting.

3. Load Distribution

The proper hole size ensures that the load applied to the lag bolt is distributed evenly across the material. If the hole is too small, the load may concentrate on a smaller area, increasing the risk of failure. Conversely, if the hole is too large, the load may not be distributed effectively, resulting in weakened holding power.

4. Maximum Strength

Using the correct hole size helps maximize the strength of the connection. When the hole is properly sized, the threads of the lag bolt can engage securely with the material, providing optimal holding power. This is particularly important for applications where high strength and stability are required, such as in construction or heavy-duty installations.

Conclusion

Drilling the correct hole size for a 3/8 lag bolt is essential for ensuring a strong and secure connection. It enables a proper grip, prevents splitting, distributes the load evenly, and maximizes the overall strength of the connection. Taking the time to carefully select and drill the correct hole size is a small but crucial step in achieving a successful and reliable installation.

Tools You Will Need

Before you start drilling holes for your 3/8 Lag Bolt, make sure you have the following tools:

- Tape Measure: This tool will help you measure the depth of the hole.

- Marker or Pencil: You will need a marker or pencil to make marks on the surface where you want to drill the hole.

- Power Drill: A power drill is necessary for drilling the hole. Make sure you have the correct drill bit size for a 3/8 Lag Bolt.

- Drill Bit: You will need a drill bit that is the same size as the Lag Bolt you are using. In this case, you will need a 3/8 inch drill bit.

- Depth Gauge or Piece of Tape: This tool will help you determine the desired depth of the hole. You can use a depth gauge or simply mark the desired depth on the drill bit with a piece of tape.

- Clean Cloth: It’s always a good idea to have a clean cloth on hand to wipe away any dust or debris that may accumulate during the drilling process.

- Protective Eyewear: Safety should be a priority when using power tools. Wear protective eyewear to protect your eyes from any flying debris.

- Gloves: Gloves will provide you with a better grip on the drill and protect your hands from any sharp edges.

Having these tools ready before you start drilling will ensure that you have a smooth and successful drilling process.

Step-by-Step Guide

1. Gather the necessary materials

Before you begin drilling the hole for your 3/8 lag bolt, make sure you have all the necessary materials:

- Measuring tape or ruler

- Marker or pencil

- Drill

- 3/8 drill bit

- Protective eyewear

- Work gloves

2. Determine the depth of the hole

Using your measuring tape or ruler, determine the length of the 3/8 lag bolt that you will be using. This will help you determine the depth of the hole you need to drill.

3. Mark the drilling spot

Once you have determined the depth, use your marker or pencil to mark the spot where you will be drilling the hole. Make sure to choose a spot that is appropriate for the specific application.

4. Put on protective gear

Before you start drilling, put on your protective eyewear and work gloves to ensure your safety during the process.

5. Start drilling

Attach the 3/8 drill bit to your drill and position it at the marked spot. Apply steady pressure and begin drilling into the material. Make sure to keep the drill level and perpendicular to the surface to ensure a straight hole.

6. Monitor the drilling progress

As you drill, pay attention to the progress and depth of the hole. Stop drilling once you have reached the desired depth for the 3/8 lag bolt.

7. Clean up the debris

After drilling the hole, use a brush or compressed air to remove any debris or dust from the hole. This will ensure a clean and secure fit for the lag bolt.

8. Test the fit

Before inserting the 3/8 lag bolt, test the fit by inserting it partially into the hole. It should fit snugly without being too tight or loose.

9. Insert the 3/8 lag bolt

Once you are satisfied with the fit, fully insert the 3/8 lag bolt into the hole. Use a wrench or socket to tighten it securely, ensuring it is flush with the surface.

10. Double-check the installation

After tightening the lag bolt, double-check the installation to ensure it is secure and flush with the surface. If necessary, make any adjustments to achieve the desired outcome.

11. Clean up

Finally, clean up the work area and put away your tools. Dispose of any debris properly and store your drill and drill bits in a safe place.

12. Enjoy the results

Now that you have successfully drilled the hole for your 3/8 lag bolt, you can enjoy the secure and stable installation of your project.

FAQ:

What size hole should I drill for a 3/8 lag bolt?

To accommodate a 3/8 lag bolt, you should drill a hole with a diameter slightly smaller than the bolt. Specifically, a 5/16 inch drill bit should be used to create the pilot hole. This will allow the bolt to grip the wood securely.

What happens if the hole is too small for a 3/8 lag bolt?

If the hole is too small for a 3/8 lag bolt, it may not be possible to insert the bolt into the wood. This could prevent you from fastening or anchoring anything securely. It is important to ensure that the hole is the correct size to avoid any issues.

Can I use a 3/8 lag bolt without drilling a hole?

No, it is not recommended to use a 3/8 lag bolt without drilling a hole. The purpose of drilling a hole is to create a pilot hole that allows the bolt to be easily inserted into the wood. Without a hole, it would be difficult or impossible to fasten the bolt securely and could potentially damage the wood.

What happens if the hole is too big for a 3/8 lag bolt?

If the hole is too big for a 3/8 lag bolt, the bolt may not have enough grip on the wood to secure it properly. This can lead to a weak or unstable connection, as the bolt may not be able to hold as much weight or withstand as much force. It is important to ensure that the hole is the correct size to ensure the bolt’s effectiveness.

Can I use a smaller drill bit for a 3/8 lag bolt?

No, it is not recommended to use a smaller drill bit for a 3/8 lag bolt. Using a smaller drill bit will result in a hole that is too small for the bolt, which can prevent the bolt from being inserted properly or securely. It is important to use the correct size drill bit to ensure the best results.

Is there a general rule for drilling holes for lag bolts?

Yes, there is a general rule for drilling holes for lag bolts. The diameter of the hole should be slightly smaller than the diameter of the bolt. For a 3/8 lag bolt, a 5/16 inch drill bit should be used to create the pilot hole. This ensures that the bolt will fit securely in the wood and provide a strong connection.

Video: