What Size Hole Do You Drill for Electrical Wire?

When it comes to running electrical wire through walls, one of the most important steps is drilling the proper size hole. The size of the hole will depend on the type and size of the wire being used. By drilling the right size hole, you can ensure that the wire fits properly and does not become damaged or compromised.

For most residential electrical wire, such as Romex, a 1/2 inch hole is typically sufficient. This allows enough space for the wire to move freely without being pinched or crimped. It also provides enough room for the wire to be easily pulled through the hole without causing any damage to the insulation.

However, if you are using larger gauge wire or multiple wires, you may need to drill a larger hole. For example, if you are running a 10-gauge wire or multiple 12-gauge wires, a 3/4 inch hole would be more appropriate. This allows for enough space to accommodate the larger size or multiple wires.

It is important to note that when drilling the hole, you should avoid drilling directly into any studs or other structural elements. Instead, you should aim to drill through the space between the studs or use a stud finder to locate the best spot for drilling.

Choosing the Right Hole Size for Electrical Wire

When installing electrical wires, it is essential to choose the right hole size for running the wires through walls, floors, or ceilings. Using the correct hole size ensures that the wires are properly protected and allows for efficient installation.

Finding the Right Hole Size

There are several factors to consider when determining the appropriate hole size for electrical wire installation:

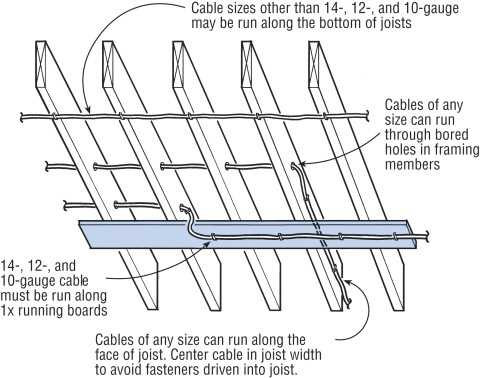

- Wire Gauge: The size of the wire determines the diameter of the hole. Different wire gauges require different hole sizes to accommodate their width. Refer to a wire gauge chart to identify the proper hole size for the specific wire gauge.

- Type of Wiring: The type of wiring being used also influences the hole size. For example, non-metallic sheathed cables (NM) and armored cables (AC) may require different hole sizes due to differences in their construction.

- Spacing and Clearance: It is crucial to consider the required spacing and clearance for electrical wires. Certain codes and regulations specify the minimum distance between wires and other materials. Ensure that the chosen hole size allows for proper spacing and clearance.

Tools for Drilling Holes

Once you have determined the appropriate hole size, you will need the right tools to drill the holes. Here are some common tools used for drilling holes for electrical wires:

- Power Drill: A power drill is necessary for drilling the holes quickly and efficiently. Make sure to use an appropriate drill bit size for the chosen hole diameter.

- Drill Bits: Drill bits come in various sizes and types. Choose the right drill bit size that matches the required hole diameter for the electrical wire.

- Measuring Tape: A measuring tape helps determine the accurate placement and spacing of the holes. Measure and mark the locations for drilling before starting the drilling process.

Best Practices for Hole Size Selection

Here are some best practices to consider when selecting the hole size for electrical wire installation:

- Always consult local electrical codes and regulations to ensure compliance with the requirements for hole size and wire installation.

- Take into account the specific characteristics of the wires being used, such as gauge and type, to select the appropriate hole size.

- Consider future needs and potential upgrades when determining the hole size. Leaving some extra space in the hole can allow for additional wires or modifications in the future.

- Make sure the chosen hole size provides sufficient protection and support for the wires, preventing damage and maintaining their integrity.

- Regularly inspect the drilled holes for any damage or deterioration to ensure the long-term safety and functionality of the electrical wiring.

By following these guidelines and considering the relevant factors, you can choose the right hole size for electrical wire installation. Proper planning and adherence to safety standards are essential to ensure the efficient and effective installation of electrical wiring.

Understanding Wire Sizes and Applications

When it comes to electrical wiring, understanding the different wire sizes and their applications is crucial. Wire sizes are measured by their gauge, which refers to the diameter of the wire. The smaller the gauge number, the larger the wire.

Here are some common wire sizes and their applications:

1. 14-Gauge Wire

The 14-gauge wire is commonly used for general household electrical circuits. It can handle a maximum of 15 amps of current and is suitable for most lighting and outlet circuits.

2. 12-Gauge Wire

The 12-gauge wire is thicker than the 14-gauge wire and can handle a maximum of 20 amps of current. It is commonly used for larger lighting circuits, as well as kitchen, bathroom, and laundry room circuits.

3. 10-Gauge Wire

The 10-gauge wire is thicker than the 12-gauge wire and can handle a maximum of 30 amps of current. It is commonly used for heavy-duty appliances, such as electric dryers and electric ranges.

4. 8-Gauge Wire

The 8-gauge wire is thicker than the 10-gauge wire and can handle a maximum of 40 amps of current. It is commonly used for larger appliances, such as air conditioners and electric water heaters.

5. 6-Gauge Wire

The 6-gauge wire is thicker than the 8-gauge wire and can handle a maximum of 55 amps of current. It is commonly used for larger appliances, such as electric furnaces and electric hot tubs.

It is important to note that these wire sizes are general guidelines and may vary depending on local electrical codes and specific applications. Always consult a qualified electrician or refer to local regulations when determining the appropriate wire size for your specific project.

Considerations for Hole Size Selection

Drilling holes for electrical wires requires careful consideration of various factors to ensure the safety and efficiency of the wiring installation. Here are some key points to consider when selecting the size of the hole for electrical wires:

Wire Size

The size of the wire being used is an important factor in determining the size of the hole. Different wire sizes have different diameter requirements to ensure proper fitting and protection. It is essential to consult the National Electrical Code (NEC) or consult with an electrician to determine the minimum hole size required for the specific wire size being used.

Conduit Size

If the wires are being installed in a conduit, the size of the conduit should also be taken into account. The hole size should be selected to accommodate not only the wire size but also the conduit size to ensure smooth installation and prevent any potential damage to the wires.

Allowable Fill Capacity

The allowable fill capacity of the hole should be considered to ensure that the wires can be easily placed without damaging the insulation or causing excessive friction. The NEC provides guidelines on the maximum number and sizes of wires that can be installed in a specific size and type of hole.

Spacing and Separation

Proper spacing and separation between the wires should be maintained to avoid excessive heat buildup and ensure effective heat dissipation. The hole size should be selected to allow for adequate spacing between the wires, as specified in the NEC or regional electrical codes.

Future Expansion

If there is a possibility of future expansion or addition of more wires, it is important to consider this when selecting the hole size. A larger hole may be required to accommodate potential future wiring needs, minimizing the need for additional drilling or rework.

Environmental Factors

Environmental factors such as moisture, temperature, and exposure to chemicals or corrosive substances should also be taken into consideration. The selection of the hole size should ensure proper protection of the wires against these environmental factors to maintain their integrity and prevent any future damage.

Compliance with Codes and Standards

Lastly, it is crucial to ensure compliance with local, regional, and national electrical codes and standards when selecting the hole size. These codes and standards provide guidelines and requirements to ensure the safety and functionality of electrical installations.

By considering these various factors, proper hole size selection can be made, resulting in a safe and efficient electrical wiring installation.

Using NEC Guidelines for Hole Sizing

When drilling holes for electrical wire, it is important to adhere to the guidelines set forth by the National Electrical Code (NEC). The NEC provides specific recommendations for hole sizing to ensure the safe and efficient installation of electrical wiring.

Importance of Following NEC Guidelines

Following the NEC guidelines for hole sizing is crucial for several reasons:

- Fire safety: Properly sized holes prevent damage to the insulation of electrical wires, reducing the risk of fire caused by short circuits or electrical arcing.

- Efficiency: Using the correct hole size allows electrical wires to be easily pulled through conduits or routed through studs and joists, saving time and effort during installation.

- Compliance: Adhering to the NEC guidelines ensures that electrical installations meet the minimum safety standards mandated by regulatory authorities.

NEC Guidelines for Hole Sizing

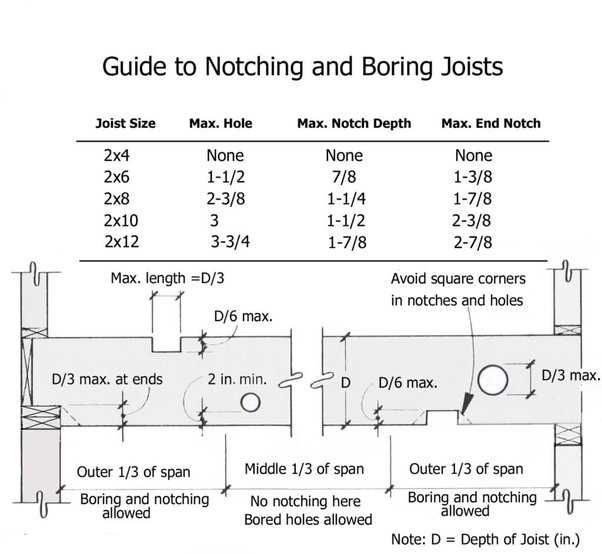

The NEC provides recommendations for hole sizing based on several factors, including the size and type of electrical wire, the material being drilled through, and the specific application. Here are some general guidelines to follow:

- For non-metallic sheathed cables (NM or Romex), the hole size should be at least 1/4 inch larger than the diameter of the cable.

- When drilling through wood framing members, the hole should be centered vertically and horizontally, and at least 1 1/4 inches away from the edge of the framing member.

- For drilling through metal framing members, consult the manufacturer’s guidelines for recommended hole sizes.

- When drilling through concrete or masonry, use appropriate masonry bits and consider using conduit as a protective sleeve for the electrical wire.

Additional Considerations

While the NEC provides general guidelines for hole sizing, it is important to consult local building codes and regulations, as they may have specific requirements that supersede the NEC recommendations. In addition, always consider the specific application and consult with a qualified electrician or building professional if you have any doubts or questions.

By following the NEC guidelines for hole sizing, you can ensure the safe and efficient installation of electrical wiring, minimizing the risk of fire hazards and ensuring compliance with relevant regulations.

Drilling Holes for Different Wire Sizes

When it comes to electrical wiring, it’s important to properly drill holes to accommodate the different wire sizes. Using the correct size hole ensures that the wires are protected and allows for proper installation. Here are some guidelines for drilling holes for different wire sizes:

1. Small Wire Sizes (e.g., 14 and 16 gauge)

- For small wire sizes, the recommended hole size is usually about 3/4 inch (19mm) in diameter.

- These wire sizes are typically used for lighting circuits, receptacles, and switches.

- Drill the holes carefully to avoid damaging the wires or other electrical components.

2. Medium Wire Sizes (e.g., 12 and 10 gauge)

- For medium wire sizes, a slightly larger hole is required, usually around 7/8 inch (22mm) in diameter.

- These wire sizes are commonly used for larger appliances, such as air conditioners and refrigerators.

- Ensure that the holes are neatly drilled to prevent any potential hazards.

3. Large Wire Sizes (e.g., 8 and 6 gauge)

- Large wire sizes require bigger holes, typically around 1 inch (25mm) in diameter.

- These wire sizes are usually used for high-powered appliances, such as electric heaters and water heaters.

- Be careful when drilling larger holes as they may require more effort and precision.

It’s important to note that these are general guidelines, and you should always consult the local electrical codes and regulations for specific requirements in your area. Additionally, it’s recommended to use a conduit or protective sleeve when running wires through drilled holes to provide further protection.

| Wire Size (Gauge) | Recommended Hole Size (inches) |

|---|---|

| 14, 16 | 3/4 |

| 12, 10 | 7/8 |

| 8, 6 | 1 |

Remember, safety should always be a priority when working with electrical wiring. If you are unsure or uncomfortable drilling holes for electrical wires, it’s best to hire a licensed electrician to handle the installation.

Tools and Techniques for Drilling Electrical Holes

1. Electric Drill

The most essential tool for drilling electrical holes is an electric drill. A corded or cordless drill can be used, depending on the accessibility of a power source. Make sure you have a drill bit suitable for the material you are drilling into.

2. Drill Bits

Drill bits are available in various sizes and shapes. For drilling electrical holes, a spade bit or hole saw would be appropriate. Spade bits are ideal for drilling small to medium-sized holes, while hole saws are suitable for larger holes.

3. Measuring Tape

Before drilling electrical holes, it is important to measure and mark the exact location where the hole needs to be drilled. A measuring tape will help ensure accuracy.

4. Pencil or Marker

Use a pencil or marker to mark the spot where you will be drilling the hole. This will serve as a guide to prevent you from deviating from the desired location.

5. Safety Equipment

When drilling electrical holes, it is essential to wear proper safety equipment such as safety goggles and ear protection to protect yourself from any potential hazards.

6. Technique

When drilling electrical holes, it is important to apply steady pressure while drilling to prevent the drill bit from slipping or getting stuck. Start drilling at a slow speed to create a pilot hole, then gradually increase the speed.

7. Clean-Up

After drilling the electrical hole, use a vacuum or brush to remove any debris or dust that may have accumulated. This will help ensure a clean and safe working environment.

8. Hole Size

The size of the hole you drill for electrical wire will depend on the diameter of the wire. It is important to choose a drill bit that is slightly larger than the diameter of the wire to allow for easy installation.

9. Depth of the Hole

The depth of the hole will depend on the specific requirements of the electrical installation. It is important to drill the hole deep enough to accommodate the wire and any necessary connectors, while ensuring that the wire is properly secured and protected.

10. Consult a Professional

If you are unsure about drilling electrical holes or if the project requires advanced electrical work, it is always best to consult a professional electrician. They will have the knowledge and experience to ensure the job is done safely and correctly.

By using the right tools and techniques, you can drill electrical holes with ease and precision, ensuring a safe and efficient electrical installation.

Common Mistakes to Avoid when Drilling Holes for Electrical Wire

1. Not Choosing the Right Size Hole

One of the most common mistakes when drilling holes for electrical wire is not selecting the correct size. It is essential to choose a hole size that accommodates the wire comfortably without being too tight or too loose. Using a hole that is too small can damage the wire insulation, while a hole that is too large can allow the wire to move and potentially cause damage or short circuits.

2. Not Drilling Straight Holes

Another mistake to avoid is not drilling straight holes. It is important to take the time to ensure the hole is drilled with precision and is perpendicular to the surface. Drilling at an angle can cause the wire to be improperly positioned and increase the risk of damage or difficulty when making connections.

3. Ignoring Obstructions

Ignoring obstructions is a common mistake made when drilling holes for electrical wire. Before drilling, it is crucial to identify any obstructions such as pipes, studs, or other utilities behind the surface. Failure to do so can lead to accidentally piercing or damaging existing structures, which can be costly and time-consuming to repair.

4. Not Using Proper Safety Equipment

Safety should always be a top priority when drilling holes for electrical wire. It is essential to wear protective goggles to prevent dust or debris from entering your eyes. Additionally, using ear protection is crucial when using power tools that create high levels of noise. Wearing gloves can also provide added protection while handling the drill and other tools.

5. Skipping the Pilot Hole

Avoid the mistake of skipping the pilot hole. A pilot hole is a smaller hole drilled before the main hole to guide the drill bit and ensure accuracy. Without a pilot hole, the drill bit may wander, resulting in an off-center or sloppily drilled hole that can cause problems when fishing or pulling the electrical wire through.

6. Not Cleaning up the Dust and Debris

After drilling the hole, it is important to clean up any dust and debris left behind. Failing to do so can lead to poor wire installation, damage to the wire insulation, or even create fire hazards. Use a vacuum cleaner or a brush to remove any dust and debris from the drilled hole and the surrounding area.

7. Using Incorrect Drill Bits

Using the wrong drill bits can also lead to mistakes when drilling holes for electrical wire. It is crucial to select the appropriate type of drill bit for the material you’re working with, such as wood, metal, or concrete. Choosing the wrong drill bit can result in damaged or uneven holes, which can impact the wire’s installation and overall safety.

8. Overdrilling

Overdrilling is a common mistake made by inexperienced individuals. It occurs when the hole is drilled deeper than necessary, resulting in wasted time and effort. Before drilling, carefully measure and mark the desired depth to avoid overdrilling and ensure a secure installation of the electrical wire.

9. Rushing the Process

One of the most significant mistakes to avoid is rushing the drilling process. Take the time to plan, measure, and assess the drilling area before starting. Rushing can lead to errors, accidents, and damage to the wire, the surface, or other nearby structures. By taking your time, you can ensure a safe and accurate drilling process.

10. Forgetting to Test the Wire

Before completing the drilling process, it is essential to test the wire to ensure it is in proper working condition. Use a voltage tester or multimeter to check for any shorts or faulty connections. Testing the wire can identify any issues early on and prevent potential problems or accidents down the line.

Avoiding these common mistakes when drilling holes for electrical wire can save time, prevent accidents, and ensure the safety and integrity of your electrical installations.

Ensuring Safety and Compliance

1. Follow Local Electrical Codes

When drilling holes for electrical wires, it is important to ensure that you comply with local electrical codes. These codes provide guidelines and regulations to ensure the safety of electrical installations. Each municipality or region may have its own set of codes, so it is essential to familiarize yourself with the specific regulations in your area.

2. Use the Proper Drill Bit Size

Using the correct drill bit size is crucial for ensuring the safety and integrity of electrical wire installations. The hole should be just large enough to accommodate the wire without damaging it or leaving excessive gaps. The size of the drill bit will depend on the gauge of the wire being used.

- For 14-gauge wire, use a 7/8 inch or 22 mm drill bit.

- For 12-gauge wire, use a 1 inch or 25 mm drill bit.

- For 10-gauge wire, use a 1 1/8 inch or 29 mm drill bit.

Always refer to the wire manufacturer’s recommendations and consult local codes to determine the appropriate drill bit size for the specific wire being installed.

3. Secure Wires Properly

Once the hole is drilled, it is important to secure the wires properly to prevent any damage or hazards. The wires should be secured using appropriate clamps, straps, or staples according to local electrical codes. This will help keep the wires in place and prevent them from rubbing against the surrounding materials, which could lead to insulation damage or electrical shorts.

4. Use Grommets for Metal or Sharp Surfaces

If the hole is drilled through a metal surface or any sharp-edged material like wood, it is advisable to use grommets to protect the wires. Grommets are small rubber or plastic inserts that cover the sharp edges and provide insulation and protection for the wires passing through. This helps prevent any abrasion or cutting of the wire insulation.

5. Test the Electrical Installation

After drilling the holes and installing the wires, it is essential to test the electrical installation to ensure everything is working correctly and no issues are present. Using a multimeter or other electrical testing equipment, check for continuity, proper grounding, and correct voltage levels.

Additionally, it may be necessary to have the installation inspected by a qualified electrician or local authorities to ensure compliance with electrical codes and regulations.

6. Seek Professional Assistance if Unsure

If you are unsure about any aspect of drilling holes for electrical wires, it is always best to seek professional assistance. Electricians or other qualified professionals have the expertise and experience necessary to ensure the safety and compliance of electrical installations.

Remember, safety should always be the top priority when working with electricity. Following proper procedures and guidelines will help ensure a safe and compliant electrical installation.

FAQ:

What size hole should I drill for electrical wire?

The size of the hole you should drill for electrical wire depends on the size of the wire. Typically, a 1/2-inch hole is sufficient for 14-gauge wire, while a 5/8-inch hole is suitable for 12-gauge wire. It’s important to check the specific guidelines provided by your local building codes and the manufacturer of the wire for the correct hole size.

Do I need to use a different size hole for different gauge wires?

Yes, you should use a different size hole for different gauge wires. The size of the hole should match the thickness of the wire to ensure that it fits properly. For example, a 14-gauge wire requires a 1/2-inch hole, while a 12-gauge wire needs a 5/8-inch hole.

Can I use a larger hole for smaller gauge wires?

No, it is not recommended to use a larger hole for smaller gauge wires. The hole should be appropriately sized to prevent the wire from being loose or getting damaged. Using a larger hole can also pose safety risks and may not comply with building codes.

What happens if I drill a hole that is too small for the wire?

If you drill a hole that is too small for the wire, you may have difficulty fitting the wire through the hole. This can lead to frustration and wasted time. Additionally, forcing the wire through a small hole can cause damage to the insulation, which can be dangerous and affect the wire’s performance.

Do I need any special tools to drill a hole for electrical wire?

No, you typically do not need any special tools to drill a hole for electrical wire. A standard drill with the appropriate drill bit size for the hole you need should be sufficient. It is important to use a sharp drill bit and apply even pressure while drilling to ensure a clean and accurate hole.

Can I use a hole saw to drill a hole for electrical wire?

Yes, you can use a hole saw to drill a hole for electrical wire. Hole saws are often used for larger diameter holes and can provide a clean and precise cut. However, it is important to select the correct size of the hole saw to match the diameter of the wire you are installing.

Are there any safety precautions I should take when drilling a hole for electrical wire?

Yes, there are several safety precautions you should take when drilling a hole for electrical wire. Make sure to wear protective eyewear to shield your eyes from any debris. Additionally, it is important to turn off the power to the electrical circuit before drilling the hole to prevent any accidents or electrical shocks. If you are not confident in your ability to safely complete the task, it is recommended to hire a professional electrician.

Video: