What Size Hole Do You Drill for a 3/8 Tap?

Drilling holes is an essential skill for anyone working with metal or woodworking. When it comes to tapping holes, accuracy is crucial to ensure that the threads properly engage. If you are using a 3/8 tap, you need to know the correct size hole to drill in order to achieve the best results.

The size of the hole you need to drill for a 3/8 tap depends on the type of thread you want to create. There are two common thread types: coarse and fine. Coarse threads are used for general applications, while fine threads are preferred for tighter fits and higher torque applications.

For a 3/8 coarse tap, the recommended drill bit size is usually 5/16 inch. This allows for adequate clearance for the tap to cut the threads while still providing enough material for a strong connection. If you are using a 3/8 fine tap, a drill bit size of 21/64 inch is typically recommended for the best results.

It is important to note that these recommended sizes are just guidelines, and the specific requirements may vary depending on the material you are working with and the specific application. Always consult a tap drill chart or a knowledgeable expert to ensure you are using the appropriate size hole for your specific needs.

Choosing the Right Hole Size for a 3/8 Tap: A Comprehensive Guide

Introduction

When it comes to drilling holes for a 3/8 tap, choosing the right size is crucial. A properly sized hole ensures that the tap can thread smoothly into the material without any excessive friction or binding. This comprehensive guide will help you determine the correct hole size for a 3/8 tap, taking into consideration factors such as tap type, material, and desired thread engagement.

Tap Type and Material

The first consideration when choosing the hole size for a 3/8 tap is the type of tap you are using. Taps come in various styles, including plug taps, bottoming taps, and taper taps. Each type requires a slightly different hole size for optimal performance.

Another important factor to consider is the material you are tapping into. Different materials have different properties, such as hardness and brittleness, which can affect the required hole size. Harder materials may require slightly larger holes to accommodate the tap, while softer materials may require smaller holes.

Thread Engagement

The desired thread engagement is another crucial factor to consider when determining the hole size for a 3/8 tap. Thread engagement refers to the amount of thread that will be embedded in the tapped hole.

If you require maximum thread engagement, you will need to drill a hole closer to the tap’s minor diameter. This ensures that more threads will be engaged, resulting in a stronger and more secure connection. However, keep in mind that drilling a hole too close to the minor diameter may weaken the material and increase the risk of thread stripping.

On the other hand, if you only need a partial thread engagement, you can drill a larger hole, closer to the tap’s major diameter. This allows for fewer threads engaged, but can still provide sufficient strength for many applications.

Recommended Hole Sizes for a 3/8 Tap

Here are some commonly recommended hole sizes for a 3/8 tap:

| Tap Type | Material | Recommended Hole Size |

|---|---|---|

| Taper Tap | Steel | 5/16 inch (0.3125 inches) |

| Plug Tap | Aluminum | 21/64 inch (0.3281 inches) |

| Bottoming Tap | Brass | 23/64 inch (0.3594 inches) |

Please note that these are just general recommendations and may need to be adjusted based on your specific requirements and materials. It is always best to consult a tap drill chart or consult with a specialist for precise recommendations.

Conclusion

Choosing the right hole size for a 3/8 tap is essential for achieving successful and secure threading. Consider the tap type, material, and desired thread engagement to determine the optimal hole size. Remember to consult tap drill charts or seek expert advice for precise recommendations. Following these guidelines will help ensure a smooth and efficient tapping process.

The Importance of Hole Size in Tapping

Tapping is a process used to create internal threads in a hole, allowing for the connection of screws, bolts, or other fastening elements. One crucial factor in successfully tapping a hole is ensuring that the hole size matches the tap size. In the case of a 3/8 tap, it is essential to drill the appropriate hole size to achieve proper thread engagement.

Benefits of Using the Correct Hole Size

- Optimal Thread Engagement: Using the correct hole size ensures that the tap can fully engage with the material and create solid threads. This prevents the threads from being too loose or too tight, promoting secure connections.

- Improved Tap Life: When the tap is used with the correct hole size, it experiences less stress and strain during the tapping process. This prolongs the tap’s life by reducing the chances of breakage or premature wear.

- Efficient Chip Removal: The correct hole size allows for efficient chip evacuation during the tapping process. Chips are the debris generated when the tap cuts into the material. Proper evacuation of chips prevents clogging, which can lead to tap breakage or poor thread formation.

How to Determine the Hole Size for a 3/8 Tap?

The hole size required for a 3/8 tap can be determined using a tap and drill size chart. This chart provides the appropriate hole diameter based on the desired thread and tap size. For a 3/8 tap, the recommended hole size is typically around 5/16 inch or 8mm.

However, it’s important to note that the specific material being tapped may require adjustments to the hole size. Softer materials may require a slightly smaller hole, while harder materials may require a slightly larger one. Consulting the manufacturer’s recommendations or testing on a sample piece of the material can help determine the ideal hole size for a specific application.

Conclusion

Drilling the correct hole size when tapping is crucial for achieving proper thread engagement, prolonging the life of the tap, and ensuring efficient chip removal. Investing time in determining and using the correct hole size for a 3/8 tap can significantly improve the quality and reliability of the threaded connections.

Understanding the Basics of Tapping

Introduction

Tapping is a common process used in various industries for creating internal threads in a hole. Whether you are tapping a hole for a bolt or a screw, understanding the basics of tapping is essential for achieving accurate and functional threads.

The Tapping Process

Tapping involves cutting threads into a pre-drilled hole using a tap. The tap is a tool with a series of cutting edges or teeth that are designed to match the thread profile required for a specific purpose.

Before tapping, you need to drill a hole of an appropriate size to accommodate the tap. The hole size is crucial as it determines the quality and strength of the resulting threads. The diameter of the hole should be slightly smaller than the desired thread size to allow for proper thread engagement.

Drilling for a 3/8 Tap

When drilling for a 3/8 tap, the recommended drill bit size is typically 5/16 inch or 8 mm. This size ensures that the hole diameter is slightly smaller than the tap size, allowing for effective thread formation. It is important to use the correct drill bit size to achieve the desired thread size and avoid damaging the tap.

Steps for Tapping

Once you have drilled the appropriate hole size, follow these steps to tap the hole:

- Secure the workpiece in a vise or clamp to prevent movement during tapping.

- Apply cutting fluid or lubricant to the hole and tap to reduce friction and extend tool life.

- Align the tap with the hole and start turning it clockwise. Apply steady pressure while ensuring the tap remains perpendicular to the hole.

- Continue turning the tap until the desired depth is reached. This can be determined by using a depth gauge or by referring to the tap’s specifications.

- Reverse the tap’s direction to remove any chips or debris from the threads.

- Inspect the threads for any defects or inaccuracies.

Conclusion

Understanding the basics of tapping is crucial for creating accurate and functional threads. By drilling the appropriate hole size and following the proper tapping techniques, you can ensure the success of your tapping operations.

Factors to Consider Before Drilling a Hole

Before drilling a hole, there are several factors that you should consider to ensure a successful outcome. These factors include:

- Material type: The type of material you are drilling into will determine the appropriate drill bit and drilling technique. For example, drilling into wood requires a different approach than drilling into metal or concrete.

- Bit size: The size of the drill bit should be chosen based on the desired hole diameter. Different tap sizes require different hole sizes, so it is important to select the appropriate bit size for your specific tapping needs.

- Hole depth: Consider the required depth of the hole. This will determine the length of the drill bit needed to achieve the desired depth.

- Drilling speed: The speed at which you drill can affect the quality of the hole and the lifespan of the drill bit. Different materials require different drilling speeds to achieve optimal results.

- Cooling and lubrication: Some materials, such as metal, generate heat during drilling. Using a lubricant or coolant can help reduce heat and prolong the life of the drill bit.

It is important to carefully consider these factors before drilling a hole to ensure that you use the correct tools and techniques for the job. Taking these factors into account will help you achieve better results and minimize any potential damage to the material being drilled.

Calculating the Ideal Hole Diameter

When tapping a hole for a 3/8 tap, it is crucial to drill the hole with the correct diameter to ensure proper thread engagement and strength. The ideal hole diameter should be calculated based on the desired thread engagement length, material type, and tap type.

Factors to Consider

Before calculating the ideal hole diameter, there are a few factors that need to be considered:

- Thread Engagement Length: The thread engagement length refers to the portion of the tap that is threaded into the hole. The longer the engagement, the stronger the connection.

- Material Type: Different materials have different thread characteristics and require different hole diameters for optimal results.

- Tap Type: Different tap types, such as bottoming taps or plug taps, require different hole diameters to achieve the desired thread engagement length.

Calculating the Hole Diameter

Calculating the ideal hole diameter for a 3/8 tap involves a few simple steps:

- Determine the desired thread engagement length based on the application requirements.

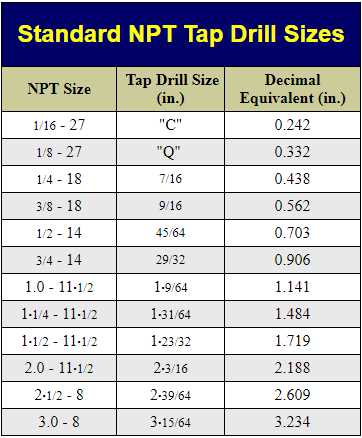

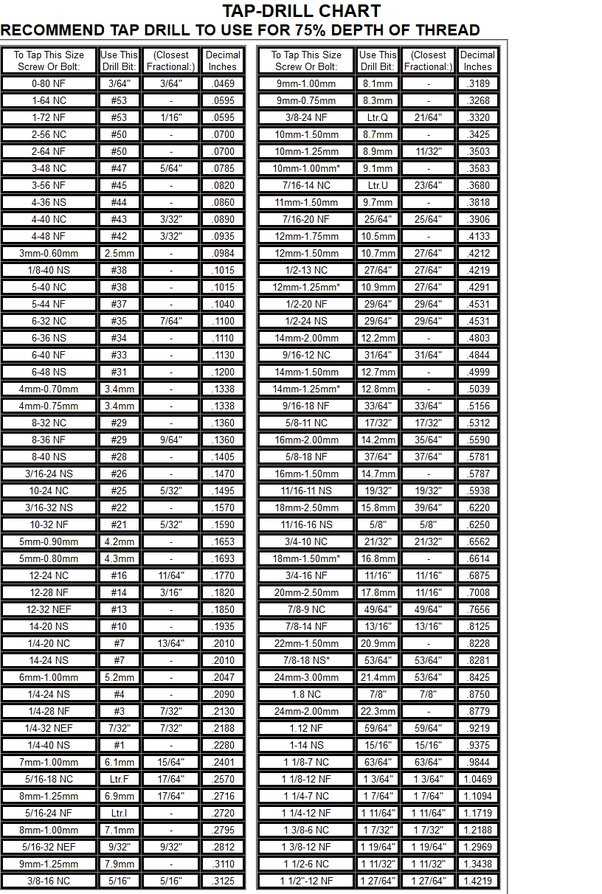

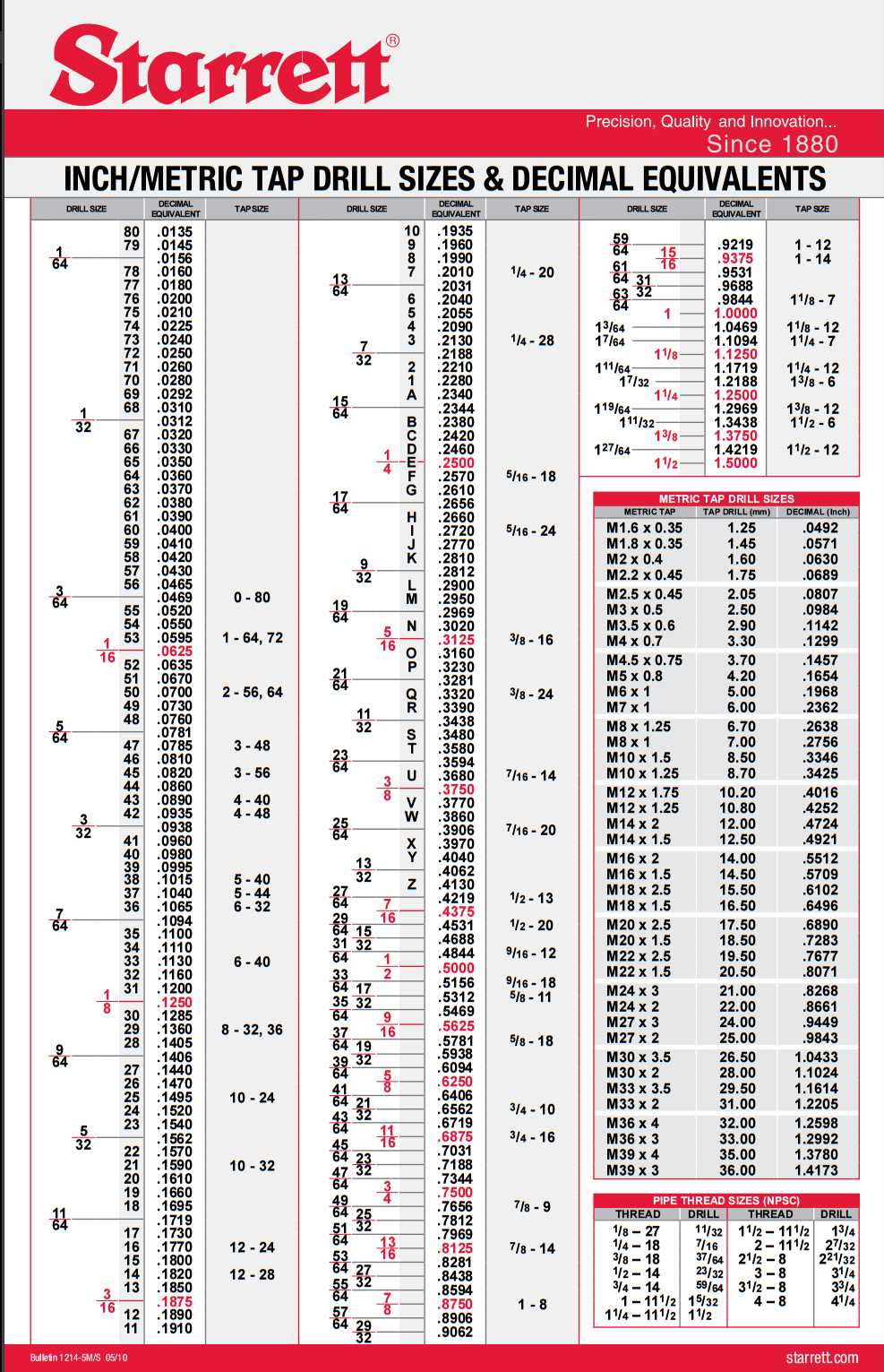

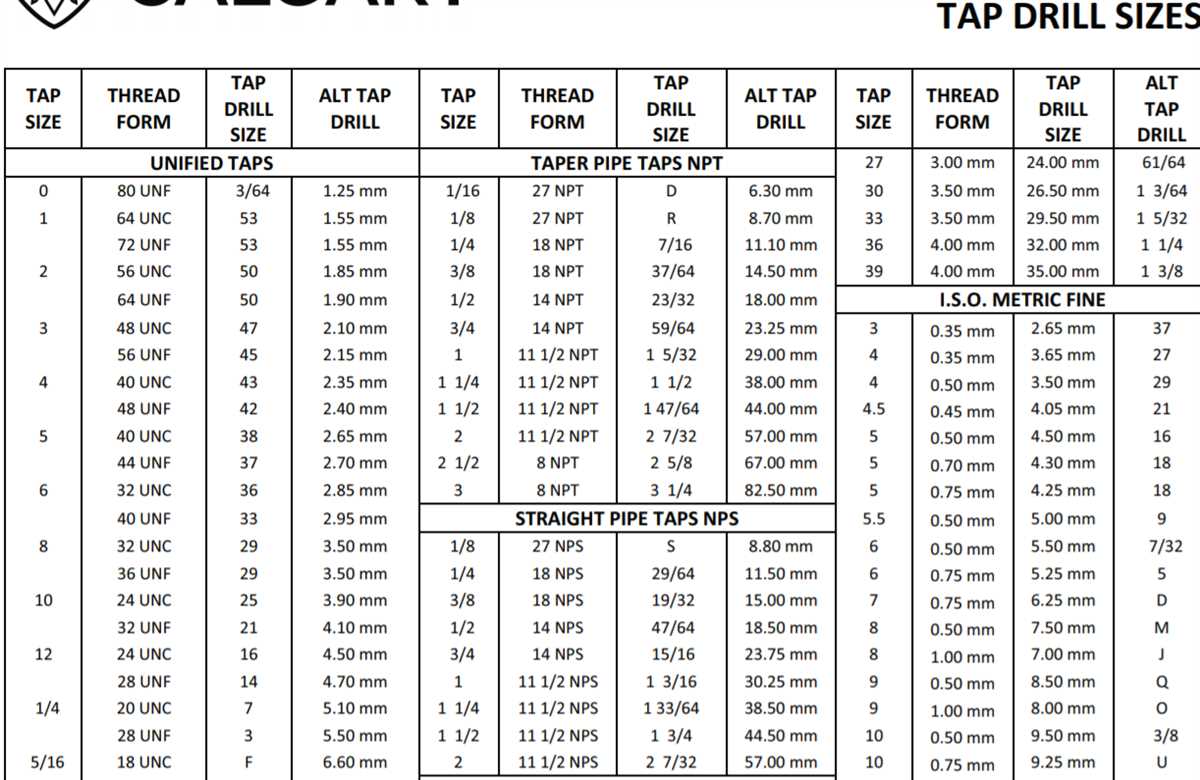

- Consult a tap drill chart specific to the material being tapped to find the recommended drill size for a 3/8 tap.

- Adjust the drill size based on the tap type. For bottoming taps, the hole diameter should be slightly larger than the recommended drill size. For plug taps, the recommended drill size can be used.

It is important to note that these calculations provide a starting point, and adjustments may need to be made based on practical considerations and experience.

Example Calculation

Let’s say we need to tap a hole for a 3/8 tap with a desired thread engagement length of 0.5 inches in aluminum. Consulting a tap drill chart for aluminum, we find that a #29 drill size is recommended for a 3/8 tap.

Since we are using a plug tap, we can use the recommended drill size without adjustment.

Conclusion

Calculating the ideal hole diameter for a 3/8 tap involves considering factors such as thread engagement length, material type, and tap type. By following the steps outlined above and consulting tap drill charts, you can ensure proper thread engagement and create strong, reliable connections.

The Role of Tap Geometry in Hole Diameter Selection

When drilling a hole for a 3/8 tap, it is important to consider the tap’s geometry in order to determine the appropriate hole diameter. The geometry of the tap, including its flute design and thread pitch, plays a crucial role in achieving proper tapping results.

Flute Design

The flute design of a tap refers to the shape and arrangement of the cutting flutes along its length. Different flute designs are optimized for specific materials and tapping applications. The flute design affects chip evacuation, cutting performance, and torque requirements.

For example, taps with straight flutes are commonly used for through-hole tapping. These taps have flutes that run continuously from the shank to the tip, allowing chips to flow out of the hole easily. On the other hand, spiral-fluted taps are designed for blind-hole tapping. These taps have flutes that spiral up the tap body, helping to lift chips out of blind holes.

Thread Pitch

The thread pitch of a tap refers to the distance between threads and is expressed as the number of threads per inch. The thread pitch determines the size and shape of the chips that are produced during the tapping process.

Coarser thread pitches result in larger chips, while finer thread pitches produce smaller chips. It is crucial to select the appropriate hole diameter based on the tap’s thread pitch in order to ensure proper chip formation and evacuation.

Tap Drill Size Chart

The following table provides a general guideline for selecting the correct hole diameter for a 3/8 tap based on common thread pitch sizes:

| Thread Pitch (TPI) | Hole Diameter (Inches) |

|---|---|

| 16 | 11/32 |

| 18 | 23/64 |

| 20 | 25/64 |

| 24 | 13/32 |

| 28 | 7/16 |

| 32 | 29/64 |

It is important to note that these hole diameter recommendations are general guidelines and may need to be adjusted based on specific tapping requirements, material properties, and tap manufacturers’ recommendations.

Overall, considering the tap’s geometry, including flute design and thread pitch, is essential in determining the appropriate hole diameter for a 3/8 tap. This ensures efficient chip evacuation and proper tapping results.

Common Mistakes to Avoid When Selecting a Hole Size

1. Not considering the tap size

One common mistake is not taking into account the size of the tap when selecting a hole size. The hole should be slightly smaller than the tap to allow enough material for threading. If the hole is too big, the tap will not be able to create secure threads, leading to loose connections.

2. Relying solely on standard size charts

While standard size charts can provide a general guideline for selecting a hole size, they may not always be the best choice for your specific application. Factors such as materials, thread type, and intended use may require adjustments to the recommended hole size. It’s important to consider these factors and make necessary adjustments to ensure optimal thread engagement and strength.

3. Ignoring the material properties

The material in which you are drilling the hole can significantly affect the hole size selection. Softer materials, such as aluminum or plastic, may require larger holes for the tap to properly engage and form threads. On the other hand, harder materials, like steel or cast iron, may require smaller holes to ensure sufficient thread engagement. Ignoring the material properties can lead to weak or stripped threads.

4. Overlooking the desired thread engagement

When selecting a hole size, it’s essential to consider the desired thread engagement. Thread engagement refers to the number of threads that fully engage with the material. Insufficient thread engagement can result in weak connections, while excessive engagement can lead to increased torque requirements or difficulty in threading. It’s important to find the right balance based on the specific application.

5. Not testing the hole size

Lastly, failing to test the hole size before committing to a larger production run can be a costly mistake. It’s recommended to drill a test hole and tap it to verify the fit and strength of the threads. This allows for any necessary adjustments to the hole size to be made before the final production stage, avoiding potential issues and rework.

Avoiding these common mistakes can help ensure proper hole size selection when drilling for a 3/8 tap, resulting in secure and reliable threaded connections.

Tools and Techniques for Drilling the Perfect Hole

1. Choosing the Right Drill Bit

When drilling a hole, it’s essential to select the right drill bit for the material you’re working with. There are various types of drill bits available, such as twist bits, spade bits, and hole saws. Each type is designed for specific applications and materials, so be sure to choose the appropriate one.

2. Selecting the Correct Drill Speed

Drilling at the right speed is crucial for achieving a clean and accurate hole. Different materials require different drill speeds. For example, metal usually requires a slower speed, while wood can be drilled at a higher speed. Consult the drill bit manufacturer’s guidelines or do some research to determine the ideal speed for your specific project.

3. Marking the Hole

Before drilling, it’s important to mark the exact location where you want the hole. Use a pencil or a center punch to create a small indentation in the material. This will help keep the drill bit centered and prevent it from wandering off course.

4. Securing the Workpiece

When drilling, it’s crucial to secure the workpiece to prevent it from moving or spinning. Use clamps or a vise to hold the material firmly in place. This will ensure a more stable drilling process and help you achieve a clean and accurate hole.

5. Applying Proper Pressure

When drilling, it’s important to apply consistent and steady pressure to the drill. Pushing too hard can cause the drill bit to become stuck or break, while not applying enough pressure can result in a slow drilling process. Find the right balance and maintain a steady hand while drilling the hole.

6. Using Coolant (if necessary)

For certain materials, such as metal, using a coolant can help reduce heat and extend the life of the drill bit. Coolant can be applied during the drilling process to keep the temperature down and lubricate the bit, allowing for smoother drilling.

7. Clearing the Chips

As you drill, chips and debris will accumulate in the hole. It’s important to clear these chips periodically to prevent them from clogging the hole and causing the drill bit to bind. Use compressed air, a brush, or simply retract the drill bit to remove the chips and keep the drilling process smooth.

8. Testing the Hole Size

Before using a tap or inserting a fastener, it’s essential to check the hole size. Use a caliper or a drill gauge to measure the hole diameter and ensure it matches the required size for your specific application.

9. Experimenting with Pilot Holes

In some cases, using a pilot hole can help guide the drill bit and prevent it from wandering. A pilot hole is a small-diameter hole drilled before the main hole to provide a better starting point. Experiment with pilot holes to determine if they improve the accuracy and performance of your drilling.

10. Safety Precautions

Finally, always prioritize safety when drilling. Use safety glasses or goggles to protect your eyes from flying debris. If drilling metal or other materials that create sparks, wear flame-resistant clothing and have a fire extinguisher nearby. Follow all manufacturer’s guidelines and instructions when operating power tools.

Final Thoughts and Additional Resources

Summary

When drilling a hole for a 3/8 tap, it is important to use the correct size drill bit to ensure proper thread engagement. The recommended drill bit size for a 3/8 tap is 5/16 inch or 0.3125 inches. This will allow the tap to create accurate and strong threads in the drilled hole.

Importance of Thread Engagement

Proper thread engagement is crucial for a strong and secure connection between threaded components. If the drilled hole is too large, there won’t be enough material for the tap to cut threads into, resulting in a weak connection. On the other hand, if the hole is too small, the tap may bind or break due to excessive resistance, leading to a failed thread. Therefore, using the correct drill bit size for a 3/8 tap is essential for achieving optimal thread engagement and a reliable connection.

Additional Resources

If you are looking for more information on tapping holes or working with different tap sizes, here are some additional resources that you may find helpful:

- McMaster-Carr – McMaster-Carr is a well-known supplier of industrial tools and equipment. They offer a wide range of tap sets, drill bits, and other machining tools.

- Machine Mart – Machine Mart is another reputable supplier that offers a variety of tap sets and drill bits suitable for different applications.

- Engineer’s Edge – Engineer’s Edge is an online resource for engineers, providing informative articles, calculators, and reference materials for various machining and engineering topics.

- YouTube – Tapping Basics – This YouTube video provides a visual demonstration and explanation of the basics of tapping holes, including drill bit sizes and tap selection.

By referring to these additional resources, you can gather more knowledge and guidance on tapping holes for different tap sizes, allowing you to expand your understanding and improve your machining skills.

FAQ:

What is a 3/8 tap?

A 3/8 tap refers to a type of threading tool used to create internal threads in a hole. It is commonly used in machining and metalworking to make threads suitable for bolts or screws with a diameter of 3/8 inch.

What size hole do you need for a 3/8 tap?

To drill a hole for a 3/8 tap, you will typically need to start with a hole diameter slightly smaller than the tap size. In this case, since the tap is 3/8 inch in diameter, you would typically drill a hole with a diameter of around 5/16 inch as a starting point. This allows room for the tap to create threads without removing too much material.

Can I use a 3/8 tap on a smaller hole?

Technically, it is possible to use a 3/8 tap on a smaller hole, but it may not provide optimal results. If the hole is significantly smaller than the tap size, it may be difficult for the tap to effectively create threads. It’s generally recommended to use a starting hole diameter that is slightly smaller than the tap size to ensure proper thread formation.

What happens if the hole is too large for a 3/8 tap?

If the hole diameter is too large for a 3/8 tap, the threads created by the tap may not have enough material to bite into, resulting in weak or ineffective threads. This can lead to issues such as stripped threads or fasteners that do not secure properly. It’s important to ensure the hole size is appropriate for the tap to achieve the desired thread quality and strength.

Video: