What Materials are Drill Bits Made of?

Drill bits are essential tools used in construction, woodworking, metalworking, and other industries where drilling holes is required. These versatile cutting tools are available in various shapes and sizes, but they are typically made from a range of different materials to suit different applications.

One of the most common materials used for drill bits is high-speed steel (HSS). HSS drill bits are hardened to provide excellent heat resistance and durability. They are suitable for drilling into most materials, including wood, plastic, and mild steel. HSS drill bits are known for their affordability and are widely available.

Another popular material for drill bits is carbide. Carbide drill bits are made from a combination of powdered tungsten carbide and binder. These bits are known for their extreme hardness and are capable of drilling into hard materials such as hardened steel, ceramics, and composites. Carbide drill bits are generally more expensive than HSS drill bits but offer superior performance and longer lifespan.

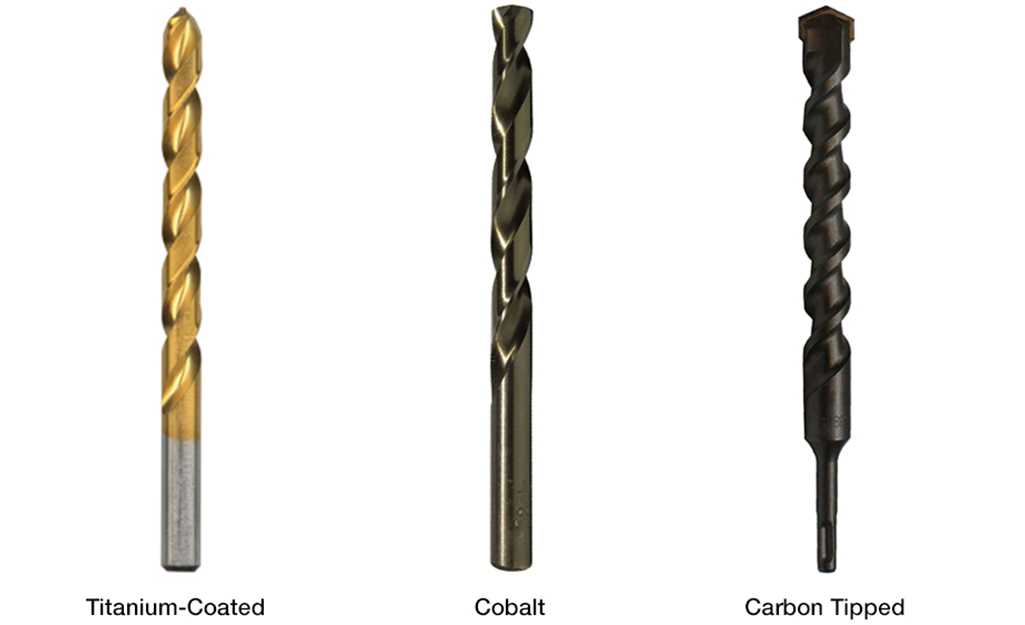

In addition to HSS and carbide, there are also specialty drill bits made from materials such as cobalt, diamond, and titanium. Cobalt drill bits, which have a high cobalt content, are ideal for drilling into stainless steel and other tough materials. Diamond drill bits are used for drilling into glass, ceramics, and other brittle materials. Titanium drill bits have a coating of titanium nitride, which provides increased hardness and heat resistance.

When choosing a drill bit, it is important to consider the material you will be drilling into and the type of hole you need. Different materials require different types of drill bits to achieve the best results. By understanding the different materials used in drill bit manufacturing, you can select the right tool for your specific drilling needs.

Types of Materials Used in Drill Bits

Metal Drill Bits

Metal drill bits are commonly made from a variety of high-speed steel (HSS) alloys. These alloys typically contain a combination of elements such as tungsten, cobalt, and vanadium. Metal drill bits are known for their hardness, heat resistance, and ability to cut through tough materials like metal.

Carbide Drill Bits

Carbide drill bits are made from a type of cemented carbide, which is a composite material composed of tungsten carbide particles bonded together with a metallic binder. These bits are extremely hard and often used for drilling through harder materials like concrete, masonry, and tiles.

Diamond Drill Bits

Diamond drill bits are made with a synthetic diamond coating on the tip. These bits are commonly used for drilling through extremely hard materials such as glass, ceramics, and stone. Diamond drill bits offer excellent precision and durability.

Cobalt Drill Bits

Cobalt drill bits are made from a high-speed steel alloy that contains a significant amount of cobalt. These bits are known for their hardness, heat resistance, and ability to drill through tough metals like stainless steel and cast iron.

Titanium Drill Bits

Titanium drill bits are made from high-speed steel coated with titanium nitride. This coating enhances the hardness and heat resistance of the drill bit. These bits are often used for drilling through softer materials like wood and plastic.

Wood Drill Bits

Wood drill bits are typically made from high-speed steel or carbon steel. These bits have a sharp, twisted design and are used for drilling through various types of wood and other soft materials. They are known for their efficiency and precision when working with wood.

Masonry Drill Bits

Masonry drill bits are made from high-speed steel or carbide. These bits are specially designed for drilling through bricks, concrete, and other types of masonry. They have a carbide tip for increased durability and performance in tough materials.

Auger Drill Bits

Auger drill bits are commonly used for drilling large holes in wood and other soft materials. These bits typically have a spiral shape with a sharp center point and cutting edges along the spiral. They are often made from carbon steel or high-speed steel.

Step Drill Bits

Step drill bits are designed for drilling multiple hole sizes with a single bit. These bits have a stepped design with gradually increasing diameters. They are commonly made from high-speed steel or cobalt and can be used for various materials, including metal and plastic.

Overall, the choice of drill bit material depends on the specific application and the type of material being drilled. Each material offers unique properties and advantages, allowing for efficient and precise drilling in different scenarios.

Steel

Steel is one of the most commonly used materials for drill bits due to its durability and strength. It is a type of alloy made primarily from iron and carbon, with small amounts of other elements added to enhance its properties.

There are several different types of steel used for drill bits, each with its own composition and characteristics:

- High-speed steel (HSS): This type of steel is the most common choice for drill bits. It contains a combination of iron, carbon, tungsten, and other elements to create a strong and heat-resistant material. HSS drill bits can withstand high temperatures generated during drilling and are suitable for a wide range of applications.

- Cobalt steel: Cobalt steel drill bits are made by adding cobalt to the alloy mixture. This increases their hardness and heat resistance, making them ideal for drilling in tough materials such as stainless steel and cast iron. Cobalt steel bits are often used in industrial settings.

- Carbon steel: Carbon steel drill bits are less expensive compared to HSS or cobalt steel. They are suitable for drilling in softer materials such as wood or plastic. However, they are not as durable as other types of steel bits and may wear out more quickly.

- Black oxide-coated steel: This type of steel is coated with a layer of black oxide, which provides lubrication and corrosion resistance. Black oxide-coated drill bits have a longer lifespan compared to plain steel bits and are commonly used in general-purpose drilling applications.

In addition to these common types of steel, there are also specialized alloys and coatings used to enhance the performance and lifespan of drill bits in specific applications.

Overall, steel drill bits are versatile and widely used due to their strength, durability, and suitability for various drilling tasks. However, it is important to choose the right type of steel drill bit based on the specific material you are drilling into to ensure optimal performance.

High-Speed Steel (HSS)

High-speed steel (HSS) is one of the most common materials used for drill bits. It is a type of tool steel that has been specially designed to withstand high heat and wear. HSS drill bits are made by combining several elements, including carbon, tungsten, chromium, vanadium, and molybdenum. These elements provide HSS drill bits with exceptional hardness, strength, and heat resistance.

High-speed steel drill bits are popular because they can be used to drill through a wide range of materials, including wood, metal, plastic, and composites. They are also known for their durability and versatility, making them suitable for both professional and DIY use.

Advantages of High-Speed Steel Drill Bits

- Hardness: High-speed steel drill bits have a high level of hardness, allowing them to cut through tough materials without getting dull quickly.

- Heat resistance: HSS drill bits can withstand high temperatures generated during drilling, reducing the risk of the bit becoming soft or losing its hardness.

- Versatility: HSS drill bits can be used for drilling various materials, making them a versatile option for different projects.

- Durability: HSS drill bits are known for their durability, meaning they can last for a long time with proper use and maintenance.

Limitations of High-Speed Steel Drill Bits

- Slower cutting speed: Compared to some other materials, such as carbide, HSS drill bits tend to have a slower cutting speed.

- May require sharpening: Over time, HSS drill bits may become dull and require sharpening to maintain their cutting efficiency.

- Not suitable for extreme hardness: High-speed steel drill bits may not be the best choice for drilling extremely hard materials, such as hardened steel or ceramic.

Conclusion

High-speed steel (HSS) is a popular material used for drill bits due to its hardness, heat resistance, versatility, and durability. While it may have some limitations, HSS drill bits are suitable for a wide range of drilling applications and provide reliable performance for most projects.

Cobalt

Cobalt is a popular material used in the production of drill bits. It is known for its high heat resistance and hardness, making it suitable for drilling through tough materials.

Here are some key points about cobalt drill bits:

- Composition: Cobalt drill bits are made from a blend of cobalt and steel. The cobalt content can range from 5% to 8%, while the rest of the composition is steel.

- Heat resistance: Cobalt has excellent heat resistance properties, allowing the drill bits to withstand high temperatures during drilling operations. This makes them suitable for use with materials such as stainless steel and cast iron, which generate a lot of heat during drilling.

- Hardness: The addition of cobalt to steel increases the hardness of the drill bits. This hardness allows them to maintain their cutting edge even when subjected to high drilling forces.

- Longevity: Cobalt drill bits are known for their durability and long lifespan. Due to their high hardness and heat resistance, they are less prone to wear and can withstand repeated use without losing their cutting efficiency.

- Applications: Cobalt drill bits are commonly used in various applications, including metalworking, automotive repairs, and construction. They are particularly suitable for drilling through hardened materials, such as stainless steel, cast iron, and titanium.

In summary, cobalt drill bits are a popular choice for drilling through tough materials due to their high heat resistance, hardness, and durability. They are essential tools for professionals and DIY enthusiasts working with hard metals.

Carbide

Carbide is one of the most commonly used materials for drill bits. It is a composite material that consists of a metal matrix with embedded carbide particles. The metal matrix provides strength and durability while the carbide particles provide hardness and wear resistance.

Properties of Carbide

- Hardness: Carbide is an extremely hard material, ranking higher on the Mohs scale of hardness than most other materials.

- Wear resistance: Due to its hardness, carbide drill bits are highly resistant to wear, allowing them to maintain their cutting edge and performance for extended periods of time.

- Heat resistance: Carbide can withstand high temperatures generated during drilling, making it suitable for use in various applications, including machining and metalworking.

- Chemical resistance: Carbide is resistant to chemical reactions, allowing it to withstand exposure to corrosive substances without significant degradation.

Uses of Carbide Drill Bits

Due to their exceptional hardness and wear resistance, carbide drill bits are widely used in various industries and applications. Some of the common uses of carbide drill bits include:

- Drilling hard materials such as metals, alloys, and composites.

- Machining operations that require high precision and durability.

- Woodworking, especially for drilling through hardwoods and dense materials.

- Drilling in masonry and concrete.

Maintenance and Care

To ensure the longevity and performance of carbide drill bits, it is essential to properly maintain and care for them. Here are some tips:

- Regularly clean the drill bits to remove debris and build-up that may affect their cutting ability.

- Use cutting lubricants or coolant when drilling to reduce heat and prolong the life of the carbide bits.

- Store the drill bits in a dry and protected environment to prevent moisture or rust formation.

- Inspect the bits for any signs of wear or damage and replace them as needed.

Following these maintenance practices will help maximize the lifespan and efficiency of carbide drill bits, ensuring optimal performance for your drilling needs.

Advantages and Disadvantages of Each Material

1. High-Speed Steel (HSS)

HSS is one of the most commonly used materials for drill bits. It has several advantages:

- Advantages:

- HSS drill bits are relatively inexpensive compared to other materials.

- HSS bits are versatile and can be used for drilling a wide range of materials, including wood, plastic, and metal.

- They have good heat resistance, which allows them to retain their hardness and shape even at high temperatures.

- HSS drill bits can be easily sharpened, extending their lifespan.

However, HSS drill bits also have some disadvantages:

- Disadvantages:

- They are not as durable as some other materials, such as carbide or cobalt.

- HSS drill bits may dull more quickly when used on hard materials like stainless steel.

- They might require frequent sharpening or replacement during heavy use.

2. Carbide

Carbide drill bits offer some unique advantages:

- Advantages:

- Carbide bits are extremely hard and can handle high-speed drilling without losing their sharpness.

- They are perfect for drilling hard materials, including concrete, stone, and tiles.

- Carbide drill bits tend to last longer and require less maintenance compared to HSS bits.

However, there are a few disadvantages to using carbide drill bits:

- Disadvantages:

- They are more expensive than HSS bits.

- Carbide drill bits are more brittle and can break if not properly used or handled.

- They are not suitable for drilling softer materials like wood or plastic.

3. Cobalt

Cobalt drill bits are known for their durability and strength. Here are some advantages of using cobalt bits:

- Advantages:

- Cobalt bits can withstand high temperatures and maintain their hardness, making them ideal for heavy-duty drilling.

- They are often used for drilling hard metals like stainless steel and cast iron.

- Cobalt bits tend to have a longer lifespan compared to HSS or carbide bits.

However, using cobalt drill bits also comes with a few disadvantages:

- Disadvantages:

- They are more expensive than HSS or carbide bits.

- Cobalt bits may not perform as well when used on softer materials like wood or plastic.

- They require proper cooling and lubrication during use to prevent overheating and premature wear.

4. Diamond

Diamond drill bits are known for their exceptional hardness and ability to drill through extremely hard materials. Here are some advantages of diamond bits:

- Advantages:

- Diamond bits can drill through materials like glass, ceramic, and concrete with ease.

- They have a long lifespan and can withstand high-speed and high-temperature drilling.

- Diamond drill bits create clean and precise holes without the need for excessive pressure.

However, there are a few drawbacks to using diamond drill bits:

- Disadvantages:

- They are significantly more expensive than other types of drill bits.

- Diamond bits are highly specialized and may not be suitable for drilling softer materials.

- They require proper technique and cooling to prevent overheating and potential damage to the bit.

Conclusion

Each material has its own advantages and disadvantages when it comes to drill bits. The choice of material depends on the specific drilling application and the type of material being drilled. Consider factors such as cost, durability, versatility, and the need for specialized drilling when selecting the appropriate drill bit material.

Steel Drill Bits

Steel drill bits are one of the most common and widely used types of drill bits. They are known for their durability and versatility, making them suitable for a wide range of drilling tasks.

Steel drill bits are typically made from high-speed steel (HSS) or carbon steel. HSS drill bits contain a higher percentage of carbon and other elements, which increases their hardness and heat resistance. Carbon steel drill bits, on the other hand, are slightly less durable but are more affordable.

Steel drill bits are available in various sizes and shapes, including twist drills, brad point drills, and spade drills. Twist drills are the most common type of steel drill bits, featuring a spiral groove that helps to remove material as the drill rotates. Brad point drills have a sharp point at the tip, which makes them ideal for drilling precise holes in wood. Spade drills have a flat, paddle-like shape and are used for drilling large, shallow holes in wood and other soft materials.

Regardless of the type and shape, steel drill bits can be used with a wide range of materials, including wood, metal, plastic, and concrete. They are suitable for both hand-held drilling and drilling machines, making them a versatile choice for DIY enthusiasts and professional users alike.

| Advantages | Disadvantages |

|---|---|

|

|

Overall, steel drill bits are a reliable and cost-effective choice for most drilling applications. By selecting the right size and shape for your specific task, you can achieve efficient and precise drilling results.

High-Speed Steel (HSS) Drill Bits

High-Speed Steel (HSS) is a popular material used for drill bits due to its excellent performance and durability. HSS drill bits are made from an alloy of carbon steel and other elements, such as tungsten, molybdenum, chromium, and vanadium. These added elements enhance the hardness, strength, and heat resistance of the drill bits.

Here are some key characteristics and benefits of HSS drill bits:

- High Hardness: HSS drill bits are extremely hard, making them suitable for drilling through various materials, including metal, wood, and plastic.

- Heat Resistance: HSS drill bits can withstand high temperatures generated during drilling. This allows for faster drilling speeds and prevents the bits from becoming dull or deforming.

- Durable: Due to their hardness and heat resistance, HSS drill bits have a longer lifespan compared to other types of drill bits.

- Versatility: HSS drill bits can be used for a wide range of applications, from general-purpose drilling to specific tasks like drilling through hardened steel.

HSS drill bits are available in various types and sizes, including twist drills, jobber drills, and reduced shank drills. They are compatible with most drilling machines and can be used for both hand drilling and machine drilling.

It is important to note that while HSS drill bits are highly versatile, they may struggle with some tough materials, such as hardened steel or concrete. In such cases, specialized drill bits, like carbide-tipped or diamond-coated ones, may be more suitable.

Cobalt Drill Bits

Cobalt drill bits are a popular choice for drilling through hard materials such as stainless steel and cast iron. They are made from cobalt steel, which is an alloy composed of cobalt, tungsten, and other metals. Cobalt drill bits are known for their high heat resistance and durability, making them suitable for heavy-duty drilling tasks.

One of the key advantages of cobalt drill bits is their ability to maintain their hardness even at high temperatures. This is particularly important when drilling through tough materials, as lower quality drill bits may become dull or break under the heat and pressure. Cobalt’s high melting point allows the drill bit to withstand the heat generated during drilling and ensures a longer lifespan.

Cobalt drill bits also have a higher degree of rigidity compared to other types of drill bits. This allows for more accurate and precise drilling, reducing the likelihood of wandering or deviation from the desired drilling path. The rigidity of cobalt drill bits also helps to reduce the risk of breakage when drilling through tough materials.

In addition to their heat resistance and rigidity, cobalt drill bits also have excellent cutting performance. The cobalt alloy used in these drill bits provides a good balance between hardness and toughness, allowing them to effectively cut through hard materials with ease.

When using cobalt drill bits, it is important to use adequate lubrication to prevent overheating and prolong the life of the drill bit. This can be achieved by using cutting oil or a lubricating compound specifically designed for drilling purposes.

| Advantages | Disadvantages |

|---|---|

|

|

Carbide Drill Bits

Carbide drill bits are known for their durability and ability to withstand high heat and pressure. They are commonly used for drilling hard materials such as metal, concrete, and masonry. Carbide, also known as tungsten carbide or cemented carbide, is a compound made up of tungsten and carbon particles.

The tungsten carbide particles are held together by a binder material, typically cobalt or nickel. This combination of tungsten carbide and binder creates a strong and rigid drill bit that can effectively cut through tough materials.

Carbide drill bits have a unique cutting edge geometry, with sharp and angled edges that allow for efficient drilling. The sharp cutting edges of carbide drill bits help to reduce the amount of force required to cut through the material, making them more efficient and less likely to overheat.

Carbide drill bits are available in various sizes and styles to accommodate different drilling needs. They can be used with hand drills or power drills, depending on the size and type of the drill bit. Some carbide drill bits also feature specialized coatings, such as titanium nitride, to further enhance their performance and extend their lifespan.

When using carbide drill bits, it is important to use proper drilling techniques and cooling methods to prevent overheating and prolong the lifespan of the drill bit. Lubricating the drill bit with cutting oil or using a coolant can help to dissipate heat and reduce friction during the drilling process.

In summary, carbide drill bits are highly durable and efficient tools for drilling hard materials. Their unique composition and cutting edge geometry make them ideal for tough drilling applications. By using proper techniques and cooling methods, carbide drill bits can provide long-lasting performance and reliable drilling results.

FAQ:

What materials are drill bits made of?

Drill bits are typically made of high-speed steel (HSS), cobalt steel, carbide, or diamond.

Why are high-speed steel drill bits popular?

High-speed steel (HSS) drill bits are popular because they are affordable, durable, and can easily cut through most common materials.

What are cobalt steel drill bits used for?

Cobalt steel drill bits are specifically designed for drilling hard materials such as stainless steel and cast iron. They have excellent heat resistance and can maintain their hardness at high temperatures.

What are the advantages of carbide drill bits?

Carbide drill bits are extremely hard and can be used to drill through tough materials like concrete, tile, and masonry. They also have a longer lifespan compared to other types of drill bits.

Are diamond drill bits only used for drilling diamonds?

No, diamond drill bits are not only used for drilling diamonds. They are commonly used for drilling through hard materials such as glass, ceramic, and stone. Diamond bits are known for their ability to provide clean and precise cuts.

Can drill bits be made of other materials?

Yes, besides the commonly used materials mentioned earlier, drill bits can also be made of titanium nitride (TiN), cobalt alloy, or even wood and plastic. The choice of material depends on the specific application and the type of material being drilled.

What type of drill bit should I use for woodworking?

For woodworking, it is recommended to use drill bits made of high-speed steel (HSS) or carbon steel. These types of drill bits are sharp, durable, and can be easily sharpened when needed.

Video:

![[2022 Upgraded]Depvko 3Pcs Nail Drill Bits Set, 5 in 1 Drill Bits for Nails 3/32 Inches, Tapered Barrel and Cone Shape Carbide Nail Drill Bits for Acrylic or Gel Remover (Rainbow)](https://m.media-amazon.com/images/I/41viJkqtyrL._SS520_.jpg)