What is hss drill bit: Everything you need to know

A High-Speed Steel (HSS) drill bit is a versatile and essential tool in any handyman or DIY enthusiast’s toolbox. Made from a high-quality steel alloy, HSS drill bits are specifically designed to withstand high heat and resist wear and tear during drilling tasks. They are commonly used for drilling into metal, plastic, wood, and other materials with ease.

One of the key features of HSS drill bits is their ability to maintain their hardness at high temperatures, which allows them to drill through tough materials without losing their sharpness. This heat-resistance makes HSS drill bits an ideal choice for heavy-duty drilling tasks, especially when compared to regular carbon steel drill bits.

Additionally, HSS drill bits are known for their durability, making them a long-lasting investment. With proper care and maintenance, HSS drill bits can be used for an extended period, making them a cost-effective choice in the long run. The combination of hardness and durability makes HSS drill bits suitable for both professional and amateur users alike.

Furthermore, HSS drill bits come in a variety of shapes and sizes to accommodate different drilling needs. Whether you need to create pilot holes, countersink screws, or enlarge existing holes, there is an HSS drill bit available for the task. Considered the go-to choice for precision drilling, HSS drill bits offer accuracy and control with every use.

So, whether you’re a professional contractor or a DIY enthusiast, having a set of HSS drill bits in your toolbox is a must. They combine durability, heat resistance, and versatility to provide you with the perfect drilling tool for any project you undertake.

Benefits of HSS Drill Bits

HSS (High-Speed Steel) drill bits offer several advantages over regular drill bits. Here are some of the benefits of using HSS drill bits:

- Durability: HSS drill bits are known for their durability and long-lasting performance. They are made from a special type of steel that can withstand high temperatures and resist wear and tear. This makes them ideal for drilling through tough materials like metal, wood, and plastic without losing their sharpness or breaking.

- Higher Speed and Efficiency: As the name suggests, HSS drill bits are designed for high-speed drilling. They can drill through materials much faster and more efficiently than regular drill bits. The high-speed capability of HSS drill bits allows for quicker drilling, reducing the overall time and effort required for a project.

- Versatility: HSS drill bits are versatile and can be used for a wide range of applications. They can effectively drill through various materials, including steel, aluminum, copper, plastic, and wood. This versatility makes them a popular choice among professionals and DIY enthusiasts alike.

- Precision and Accuracy: HSS drill bits are known for their precision and accuracy. They can create clean and precise holes with minimal deviation. This makes them suitable for tasks that require high precision and accuracy, such as drilling holes for dowels or installing hardware.

- Cost-Effective: Despite their superior performance and durability, HSS drill bits are relatively affordable compared to other types of drill bits. They offer excellent value for money, as they can last longer and perform better than cheaper alternatives. Investing in HSS drill bits can save you money in the long run by reducing the need for frequent replacements.

In conclusion, HSS drill bits have numerous benefits that make them a popular choice for professionals and DIY enthusiasts. Their durability, high-speed capability, versatility, precision, and cost-effectiveness make them an essential tool for various drilling applications.

Different Types of HSS Drill Bits

High-speed steel (HSS) drill bits are versatile tools that are widely used in different industries and applications. They are known for their durability, hardness, and heat resistance, making them suitable for drilling through various materials, including metal, wood, and plastic. Here are some of the different types of HSS drill bits:

1. Twist Drill Bits

- Twist drill bits are the most commonly used type of HSS drill bits.

- They have a cylindrical shank and spiral flutes that help in removing the chips from the hole.

- Twist drill bits are available in different sizes and lengths to suit various drilling requirements.

- They can be used with both handheld drills and drill presses.

2. Step Drill Bits

- Step drill bits are designed to create holes with different diameters in a single drilling operation.

- They have multiple cutting edges and gradually increase in size.

- Step drill bits are commonly used for sheet metal and thin materials.

- They are ideal for creating holes for electrical conduit fittings, automotive parts, and so on.

3. Countersink Drill Bits

- Countersink drill bits are used to create a conical recess in the surface of a material.

- They are typically used to prepare holes for countersunk screws or to create a chamfered edge.

- Countersink drill bits have a combination of drill bit and countersink cutter.

- They are commonly used in woodworking and metalworking applications.

4. Forstner Drill Bits

- Forstner drill bits are designed for drilling flat-bottomed holes with clean edges.

- They are commonly used for drilling holes for dowels, hinges, and other woodworking applications.

- Forstner drill bits have a cylindrical shape with a center point and flat cutting edges.

- They can drill holes with a larger diameter than the shank of the drill bit.

5. Hole Saw Drill Bits

- Hole saw drill bits are used to create large-diameter holes in materials like wood and plastic.

- They have a cylindrical shape with a serrated edge and a pilot drill bit in the center.

- Hole saw drill bits are commonly used in plumbing, electrical, and carpentry applications.

- They are available in different sizes to accommodate various hole diameters.

These are just a few examples of the different types of HSS drill bits available. Each type has its own unique design and purpose, allowing users to select the appropriate drill bit for their specific drilling needs.

How to Choose the Right HSS Drill Bit

When it comes to choosing the right High-Speed Steel (HSS) drill bit, there are several factors to consider. HSS drill bits are known for their durability and ability to withstand high temperatures, making them a popular choice for drilling through various materials. Here are some tips to help you choose the right HSS drill bit for your needs:

1. Determine the Material You Will be Drilling

The first step in choosing the right HSS drill bit is to determine the material you will be drilling. HSS drill bits are suitable for a wide range of materials, including wood, metal, plastic, and composites. However, different materials may require different types of HSS drill bits.

2. Consider the Diameter of the Hole

The diameter of the hole you need to drill is another important factor to consider. HSS drill bits come in various sizes, and it’s important to choose a bit with the appropriate diameter for your application. Using a drill bit with the wrong diameter can result in inaccuracies or even damage to your workpiece.

3. Check the Shank Size

Make sure to check the shank size of the HSS drill bit. The shank is the part of the drill bit that fits into the drill chuck. It’s important to choose a drill bit with a shank size that matches the chuck size of your drill. Using a drill bit with an incorrect shank size can lead to poor performance and unnecessary wear and tear on your drill.

4. Consider the Type of Point

HSS drill bits come with different types of points, including twist points, split points, and brad points. The type of point you choose will depend on the material and the type of hole you need to drill. Twist points are versatile and suitable for most drilling applications, while split points and brad points are designed for more precise and accurate drilling.

5. Check the Coating

HSS drill bits may come with a coating to enhance their performance and extend their lifespan. Common coatings include titanium nitride (TiN) and black oxide. The coating can reduce friction, increase the hardness of the drill bit, and improve chip evacuation. Consider the coating options available and choose the one that best suits your needs.

6. Consider the Length and Flute Design

The length and flute design of the HSS drill bit can also influence its performance. Longer drill bits are suitable for deep drilling applications, while shorter ones are more maneuverable. Additionally, the flute design affects chip evacuation and can improve drilling efficiency. Consider these factors based on your specific drilling requirements.

7. Read User Reviews and Recommendations

Lastly, it’s always a good idea to read user reviews and recommendations before purchasing an HSS drill bit. This can provide insights into the quality, durability, and performance of the drill bit from people who have already used it.

By considering these factors and taking the time to choose the right HSS drill bit for your specific needs, you can ensure more accurate and efficient drilling results.

Common Uses for HSS Drill Bits

HSS drill bits, also known as high-speed steel drill bits, are widely used in various industries and applications due to their versatility and durability. Here are some common uses for HSS drill bits:

- Metalworking: HSS drill bits are commonly used in metalworking applications, including drilling holes in metal sheets, pipes, and structures. They are ideal for drilling through materials like steel, stainless steel, aluminum, and cast iron.

- Woodworking: HSS drill bits are also used in woodworking projects. They can be used to drill holes in wooden furniture, cabinets, and other wooden structures. The sharp cutting edges of HSS drill bits allow for precise and clean holes in wood.

- Plastic and Composite Materials: HSS drill bits are suitable for drilling holes in plastic, fiberglass, and other composite materials. They can be used in various applications, such as drilling holes for wiring or creating openings in plastic containers.

- DIY and Home Improvement: HSS drill bits are commonly used by DIY enthusiasts and for home improvement projects. They can be used for tasks like installing shelves, hanging curtains, or assembling furniture.

- Automotive and Aerospace: In the automotive and aerospace industries, HSS drill bits are used for drilling holes in metal components and structures. They are essential for tasks like assembling engine parts, drilling holes for fasteners, or creating openings for wiring in aircraft.

In summary, HSS drill bits are versatile and widely used in industries like metalworking, woodworking, plastic fabrication, and automotive/aerospace. They are essential tools for professionals and DIY enthusiasts alike, providing reliable and efficient drilling performance.

Proper Maintenance and Care for HSS Drill Bits

High-speed steel (HSS) drill bits are known for their durability and ability to cut through a wide range of materials. To keep your HSS drill bits in optimal condition and ensure their longevity, it is important to provide proper maintenance and care.

Cleaning HSS Drill Bits

After each use, it is essential to clean your HSS drill bits to remove any debris, such as wood shavings or metal chips. Use a brush or compressed air to remove the residue from the flute and cutting edges of the bit. This will prevent the accumulation of material that can affect the drill bit’s performance.

Preventing Rust

HSS drill bits are susceptible to rust, especially if they are not stored properly. To prevent rust, make sure to clean your drill bits thoroughly and dry them before storing them. Apply a protective coating of oil or rust inhibitor to the metal surface to provide additional protection against moisture and oxidation.

Sharpening HSS Drill Bits

Over time, HSS drill bits can become dull and less effective. Sharpening the drill bits will restore their cutting ability. You can either use a drill bit sharpener or sharpen them manually using a grinding wheel. Follow the manufacturer’s instructions or seek professional advice to ensure proper sharpening techniques.

Proper Storage

Storing your HSS drill bits correctly is crucial for their longevity. To prevent damage, consider using a drill bit storage case or a magnetic holder to keep them organized and protected. Avoid storing them in an environment with high humidity or extreme temperature fluctuations, as this can lead to rust or loss of temper in the metal.

Using Cutting Fluid

When drilling through hard or heat-sensitive materials, using cutting fluid can greatly improve the performance and lifespan of your HSS drill bits. Cutting fluid lubricates the cutting edges and reduces friction, resulting in smoother drilling and less heat buildup. Make sure to use the appropriate cutting fluid for the specific material you are working with.

Inspecting for Damage

Regularly inspect your HSS drill bits for any signs of damage or wear. If a drill bit is chipped, cracked, or has worn-out cutting edges, it is important to replace it. Continuing to use damaged drill bits can lead to poor results, damage to the material being drilled, and potential injury.

Proper Usage

Lastly, using your HSS drill bits correctly is crucial for their maintenance. Make sure to use the appropriate size and type of HSS drill bit for the material you are drilling. Avoid excessive force or speed, as this can cause overheating and premature wear. Following the manufacturer’s guidelines and best practices for drilling will help keep your HSS drill bits in optimal condition.

By following proper maintenance and care practices, you can ensure the longevity and performance of your HSS drill bits. Regular cleaning, rust prevention, sharpening, proper storage, the use of cutting fluid when needed, damage inspection, and correct usage are all essential for maintaining the quality of your drill bits.

Tips for Using HSS Drill Bits Safely

- Wear appropriate protective equipment, such as safety glasses or goggles, to protect your eyes from flying debris.

- Use a stable work surface or workbench to ensure that the material being drilled is secure and will not move unexpectedly.

- Secure the material being drilled with clamps or a vice to provide extra stability and prevent it from spinning or moving during the drilling process.

- Start drilling at a low speed, gradually increasing the speed as needed to prevent the drill bit from slipping or causing damage to the material being drilled.

- Ensure that the drill bit is sharp and in good condition before using it. Dull or damaged drill bits can cause the drill to work harder and increase the risk of accidents.

- Apply steady and even pressure when drilling to maintain control over the drill and prevent the bit from binding or breaking.

- Take regular breaks during prolonged drilling tasks to prevent fatigue and maintain concentration.

- Keep your hands and fingers away from the drill bit and any moving parts of the drill to avoid injury.

- When not in use, store your HSS drill bits in a secure and organized manner to prevent damage and maintain their sharpness.

- Read and follow the manufacturer’s instructions and safety guidelines for your specific drill and drill bits.

FAQ:

What is an HSS drill bit?

An HSS (High-Speed Steel) drill bit is a type of drill bit made from high-speed steel, which is a type of tool steel that is known for its hardness and ability to withstand high temperatures. HSS drill bits are commonly used in the drilling of metal, wood, and plastic.

What are the advantages of using HSS drill bits?

HSS drill bits have several advantages. Firstly, they are extremely hard and can withstand high temperatures, making them suitable for drilling into materials such as metal. Secondly, they have good heat resistance, allowing them to stay sharp for longer periods of time. Finally, they are suitable for drilling into a wide range of materials including metal, wood, and plastic.

How long do HSS drill bits last?

The lifespan of an HSS drill bit can vary depending on factors such as the material being drilled and the drilling conditions. However, with proper care and maintenance, HSS drill bits can last for a long time. It is important to keep the bit sharp and clean, avoid excessive heat, and use the correct cutting speed for the material being drilled.

Can HSS drill bits be used on concrete?

No, HSS drill bits are not suitable for drilling into concrete. Concrete is a hard and abrasive material, and HSS drill bits are not designed to withstand the intense pressure and friction that come with drilling into concrete. For drilling into concrete, specialized masonry drill bits should be used.

Can HSS drill bits be used with a hand drill?

Yes, HSS drill bits can be used with a hand drill. Hand drills typically have adjustable speed settings, allowing the user to choose the appropriate cutting speed for the material being drilled. HSS drill bits are versatile and can be used with both hand drills and power drills.

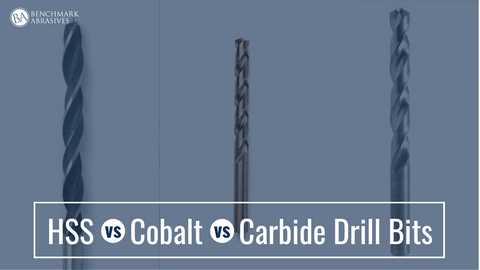

What is the difference between HSS and cobalt drill bits?

The main difference between HSS and cobalt drill bits is the material they are made from. HSS drill bits are made from high-speed steel, while cobalt drill bits are made from a combination of cobalt and high-speed steel. Cobalt drill bits are known for their higher heat resistance and hardness compared to HSS drill bits, making them more suitable for drilling into hard materials like stainless steel.

Are HSS drill bits expensive?

The cost of HSS drill bits can vary depending on factors such as the size and brand. Generally, HSS drill bits are more affordable compared to other types of drill bits, such as carbide or cobalt drill bits. They are a popular choice for general drilling applications due to their versatility and cost-effectiveness.

Video: