What is a spot drill?

A spot drill is a type of cutting tool that is used to create a shallow hole or spot on a workpiece. It is often used in machining operations where precision is crucial, such as drilling, milling, and turning. The purpose of a spot drill is to accurately mark the location where a larger drill bit or other cutting tool will be used.

The design of a spot drill is quite different from a regular drill bit. It typically has a shorter length and a larger diameter, allowing it to create a wider and shallower hole. This is because the primary function of a spot drill is not to remove material, but rather to accurately mark the location for subsequent drilling or machining.

Spot drills are commonly used in industries such as aerospace, automotive, and manufacturing, where precision and accuracy are of paramount importance. They are often made from high-speed steel or carbide materials to ensure durability and long-lasting performance. Some spot drills also feature a chamfer or countersink at the tip, which helps to prevent the drill bit from wandering or slipping during the drilling process.

In conclusion, a spot drill is a specialized cutting tool that is used to create a precise and shallow hole or spot on a workpiece. It is an essential tool in machining operations where accuracy is crucial, and is commonly used in industries such as aerospace, automotive, and manufacturing.

Purpose and Function of Spot Drills

A spot drill is a specialized cutting tool that is used in machining operations to create precisely positioned holes. It is commonly used in metalworking applications such as drilling, reaming, and milling.

1. Accurate Hole Positioning

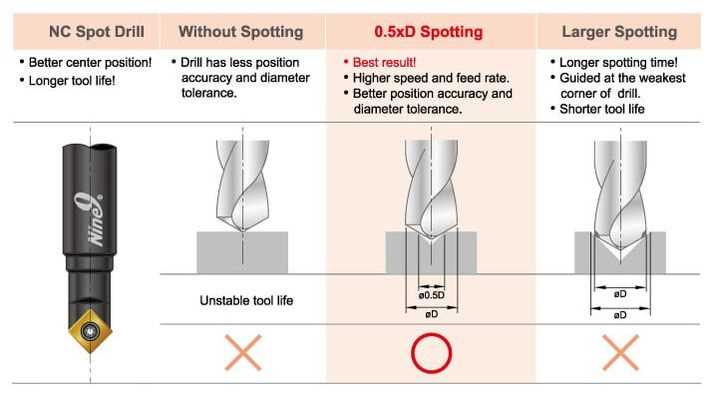

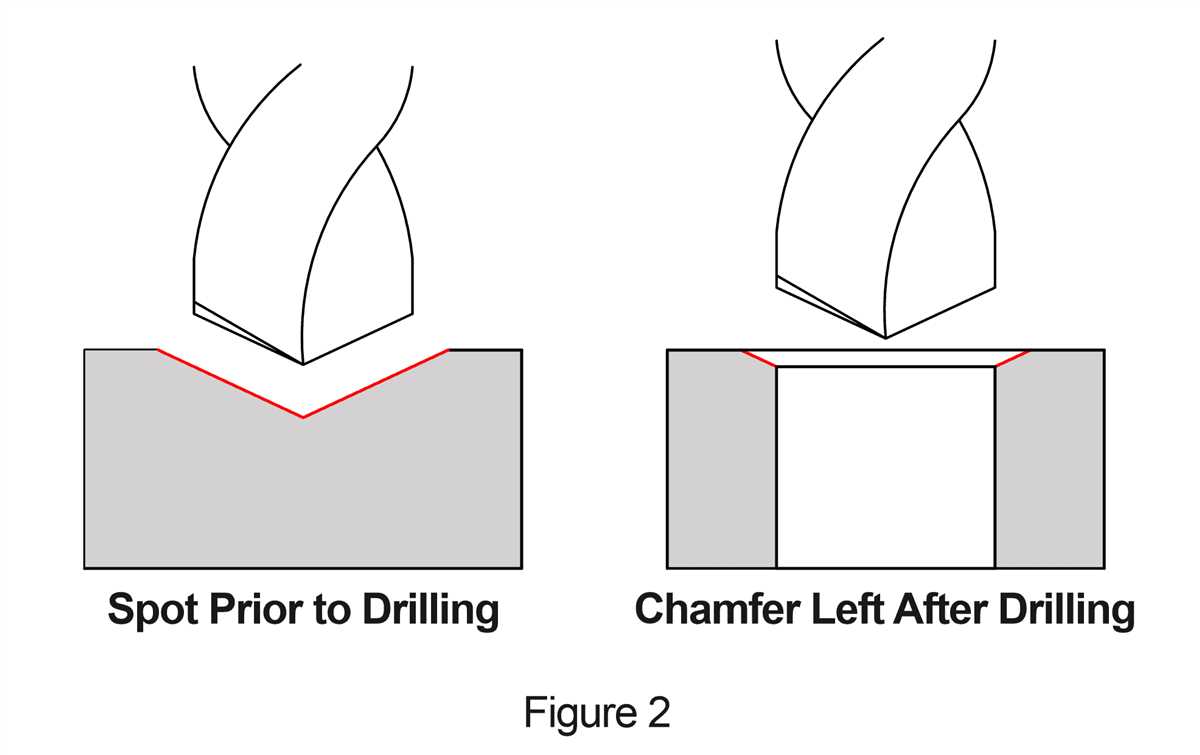

The primary purpose of a spot drill is to accurately position the center of a hole to be drilled. When starting a hole, it is crucial to create a small, shallow dimple in the material before drilling the final hole. This dimple, created by the spot drill, serves as a guide or pilot hole for the drill bit, ensuring that the drill starts at the desired location and does not wander or deviate from the intended path.

2. Preventing Drill Bit Wander

By using a spot drill, the operator can prevent the drill bit from wandering or “walking” on the material surface. The spot drill creates a small cavity with a flat bottom, giving the drill bit a precise starting point. This feature helps to maintain the accuracy of the hole, especially when drilling on curved or irregular surfaces.

3. Enhancing Hole Quality

Spot drilling can significantly improve the quality of the final drilled hole. By using a spot drill to create a pilot hole, the operator can minimize burrs, reduce chipping, and achieve a cleaner hole entrance. The spot drill also helps to break the surface tension of the material, allowing the subsequent drill bit to cut more smoothly and with less force.

4. Extending Tool Life

Spot drilling can help extend the life of cutting tools, such as drill bits and end mills. By utilizing a spot drill, the cutting forces are distributed over a smaller area, reducing the tool wear and extending its lifespan. This is especially important when working with harder materials or when using high-speed machining techniques.

5. Providing Versatility

Spot drills come in various sizes, angles, and materials, making them versatile tools in machining operations. They can be used in conjunction with different types of drill bits, reamers, or end mills to accommodate specific machining requirements. This versatility allows operators to perform various drilling operations with precision and efficiency.

Conclusion

Spot drills play a crucial role in achieving accurate and high-quality holes in metalworking applications. Their ability to accurately position the center, prevent drill bit wander, enhance hole quality, extend tool life, and provide versatility makes them indispensable tools in the machining industry.

Types of Spot Drills

Spot drills are a specialized type of drill bit that are used to create an indentation or shallow hole on a workpiece. This indentation serves as a starting point for a drill bit, helping to prevent the drill bit from wandering and providing better accuracy. There are several types of spot drills available, each with its own specific purpose and design.

Spot Drill with Flat Bottom

This is the most common type of spot drill and features a flat-bottomed design. The flat bottom allows for easy alignment and positioning of the drill bit. These spot drills are suitable for general-purpose drilling applications and are commonly used in machine shops and manufacturing industries.

Spot Drill with Center Drill

Spot drills with center drills have a center drill bit on the tip of the spot drill. This center drill creates a small pilot hole at the center of the indentation. These spot drills are commonly used in applications where precise centering is required, such as when creating holes for dowel pins or when preparing holes for further drilling.

Spot Drill with Countersink

Spot drills with countersinks are designed to create both an indentation and a countersink at the same time. The countersink helps to chamfer the edge of the hole, providing a more finished look and allowing for easy insertion of screws or other fasteners. These spot drills are commonly used in woodworking and carpentry applications.

Spot Drill with Step Drill

Spot drills with step drills feature a stepped profile on the cutting edge. This design allows for drilling holes with different diameters in one operation. These spot drills are commonly used in sheet metal fabrication, electrical work, and plumbing applications where multiple hole sizes are required.

Spot Drill with Carbide Insert

Spot drills with carbide inserts are designed for use with harder materials, such as stainless steel or hardened steel. The carbide insert provides increased durability and cutting performance. These spot drills are commonly used in aerospace, automotive, and other industries that require drilling into tough materials.

| Type | Features | Applications |

|---|---|---|

| Spot Drill with Flat Bottom | Flat-bottomed design for easy alignment and positioning | General-purpose drilling |

| Spot Drill with Center Drill | Center drill for precise centering | Holes for dowel pins, preparing for further drilling |

| Spot Drill with Countersink | Creates indentation and countersink at the same time | Woodworking, carpentry |

| Spot Drill with Step Drill | Stepped profile for drilling different hole diameters | Sheet metal fabrication, electrical work, plumbing |

| Spot Drill with Carbide Insert | Carbide insert for drilling into harder materials | Aerospace, automotive |

Materials Used in Spot Drills

A spot drill is a type of drill bit that is specifically designed to create a shallow hole, known as a spot or center, on the surface of a workpiece. It is commonly used in machining operations to provide a precise and accurate starting point for a subsequent drill or milling operation.

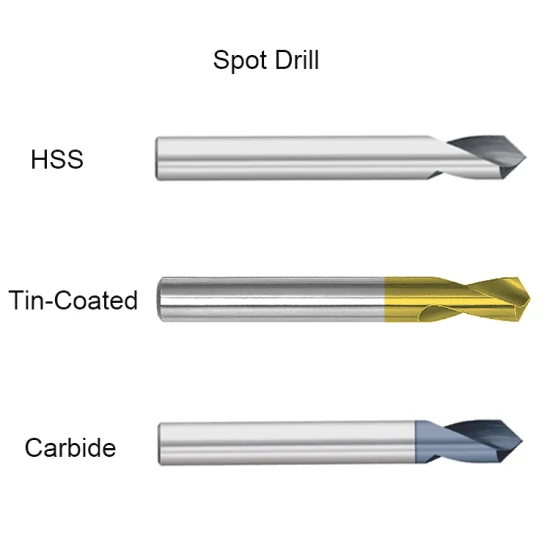

High-Speed Steel (HSS)

High-speed steel is a common material used in the manufacturing of spot drills. It is a type of tool steel that contains various alloying elements, such as molybdenum and tungsten, to enhance its hardness, wear resistance, and heat resistance. HSS spot drills are suitable for a wide range of machining applications and can withstand high cutting speeds.

Carbide

Carbide is another popular material choice for spot drills due to its excellent hardness and wear resistance. It is a composite material made up of tungsten carbide particles bonded together with a metallic binder, such as cobalt or nickel. Carbide spot drills are particularly well-suited for machining hard materials, such as stainless steel, cast iron, and titanium.

Cobalt

Cobalt is often used as a coating material for spot drills to enhance their performance and durability. It is applied as a thin layer on the surface of the drill bit through a process called physical vapor deposition (PVD) or chemical vapor deposition (CVD). Cobalt coatings improve the tool’s hardness, lubricity, and resistance to heat and wear, allowing for prolonged tool life and increased productivity.

Other Materials

In addition to HSS, carbide, and cobalt, spot drills can also be made from other materials such as high-speed steel with a cobalt coating or solid carbide with various coatings. These different materials and coatings offer different advantages and are selected based on the specific machining requirements, workpiece material, and desired results.

| Material | Advantages |

|---|---|

| High-Speed Steel (HSS) |

|

| Carbide |

|

| Cobalt |

|

Benefits of Using Spot Drills

Spot drills are specially designed cutting tools used in machining operations to create a small pilot hole or “spot” on a workpiece surface. While primarily used in metalworking applications, spot drills can also be used on other materials such as wood or plastic. There are several benefits to using spot drills in machining operations:

- Improved accuracy: Spot drills are designed to create precise and centered holes, ensuring accuracy in subsequent drilling or milling operations. By creating a small pilot hole, spot drills help guide the cutting tool, reducing the chances of drilling inaccurately or off-center. This leads to better alignment and overall precision in the final workpiece.

- Reduced chip damage: When drilling into a workpiece, chips are often created as a byproduct. These chips can damage the surface and compromise the integrity of the hole. Spot drills help reduce chip damage by creating a small, shallow hole that serves as a guide for the cutting tool. This allows for better chip evacuation and reduces the chances of chip clogging or buildup, which can cause damage to both the tool and the workpiece.

- Increased tool life: Spot drills are typically made from high-speed steel (HSS) or carbide, both of which are known for their hardness and wear resistance. By using a spot drill, the main cutting tool, such as a drill bit or end mill, can be guided more accurately and efficiently, reducing the chances of tool wear or breakage. This ultimately leads to increased tool life and cost savings for the machinist.

- Enhanced surface finish: By first using a spot drill to create a pilot hole, the subsequent drilling or milling operation can achieve a smoother and more precise surface finish. This is especially important when working with sensitive materials or when a high degree of surface finish is required for the final product. Spot drilling helps prevent the cutting tool from wandering or chattering, resulting in a cleaner and more professional finish.

- Time and cost savings: Spot drills can help streamline machining operations by reducing the need for additional setup and alignment steps. By creating a small pilot hole, the machinist can ensure accurate placement of subsequent tools, saving time and minimizing the chances of errors. Additionally, the improved accuracy and surface finish achieved through spot drilling can reduce the need for secondary operations or rework, resulting in overall cost savings.

In conclusion, spot drills offer several benefits in machining operations, including improved accuracy, reduced chip damage, increased tool life, enhanced surface finish, and time and cost savings. Incorporating spot drilling into the machining process can contribute to better-quality workpieces and increased efficiency in the workshop.

How to Use a Spot Drill

Step 1: Gather the Necessary Materials

Before using a spot drill, you will need to gather the following materials:

- Spot drill bit

- Drill press or milling machine

- Workpiece

- Clamps or vise

Step 2: Secure the Workpiece

Place the workpiece onto the drill press table or milling machine bed. Use clamps or a vise to secure the workpiece in place. Make sure it is tightly secured to prevent any movement during the drilling process.

Step 3: Choose the Right Spot Drill Bit

Select the appropriate spot drill bit based on the diameter and depth required for your drilling operation. Refer to the machining specifications or consult the manufacturer’s guidelines for the correct size.

Step 4: Set the Speed and Feed Rates

Consult the spot drill bit manufacturer’s recommendations or refer to machining charts to determine the appropriate speed and feed rates for the specific material being drilled. Set these parameters on the drilling machine before proceeding.

Step 5: Position the Spot Drill Bit

Position the spot drill bit in the chuck of the drill press or milling machine. Tighten the chuck securely to ensure the bit doesn’t come loose during operation. Align the bit with the desired spot on the workpiece.

Step 6: Begin Drilling

Turn on the drill press or milling machine and slowly lower the spot drill bit into the workpiece. Apply steady and even pressure as the drill advances. Keep the drill bit straight and perpendicular to the workpiece to ensure accurate drilling.

Step 7: Remove the Spot Drill Bit

Once the drilling operation is complete, turn off the drill press or milling machine. Carefully retract the spot drill bit from the workpiece, ensuring that it is clear of any obstructions. Avoid touching the drill bit, as it may be hot.

Step 8: Clean and Inspect the Workpiece

After removing the spot drill bit, inspect the drilled hole for any rough edges or burrs. Use a deburring tool or sandpaper to smooth out any imperfections. Clean the workpiece to remove any debris or cutting fluid residue.

Step 9: Proceed with Further Machining Operations

If necessary, continue with additional machining operations, such as drilling, reaming, or tapping, using the drilled hole as a guide. Ensure that the subsequent machining operations are properly aligned with the spot-drilled hole for accurate results.

| Guideline | Explanation |

|---|---|

| Use short spot drill bits | Shorter spot drill bits provide better stability and accuracy while reducing the risk of tool breakage. |

| Use a center punch | Before spot drilling, use a center punch to create a small indentation on the workpiece. This will help the spot drill bit stay centered and prevent it from drifting during drilling. |

| Apply cutting fluid | When drilling hard or heat-resistant materials, apply cutting fluid to lubricate the spot drill bit and reduce heat build-up, improving tool life and hole quality. |

Important Considerations for Spot Drilling

When it comes to spot drilling, there are several important considerations to keep in mind in order to achieve the best results. Spot drilling is a machining operation that creates a small shallow hole at a specific location on the workpiece. This hole is then used as a starting point for other drilling operations or as a guide for subsequent machining processes.

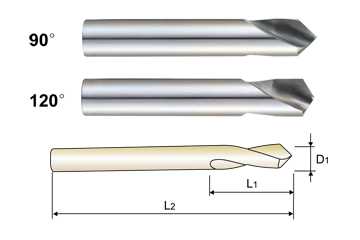

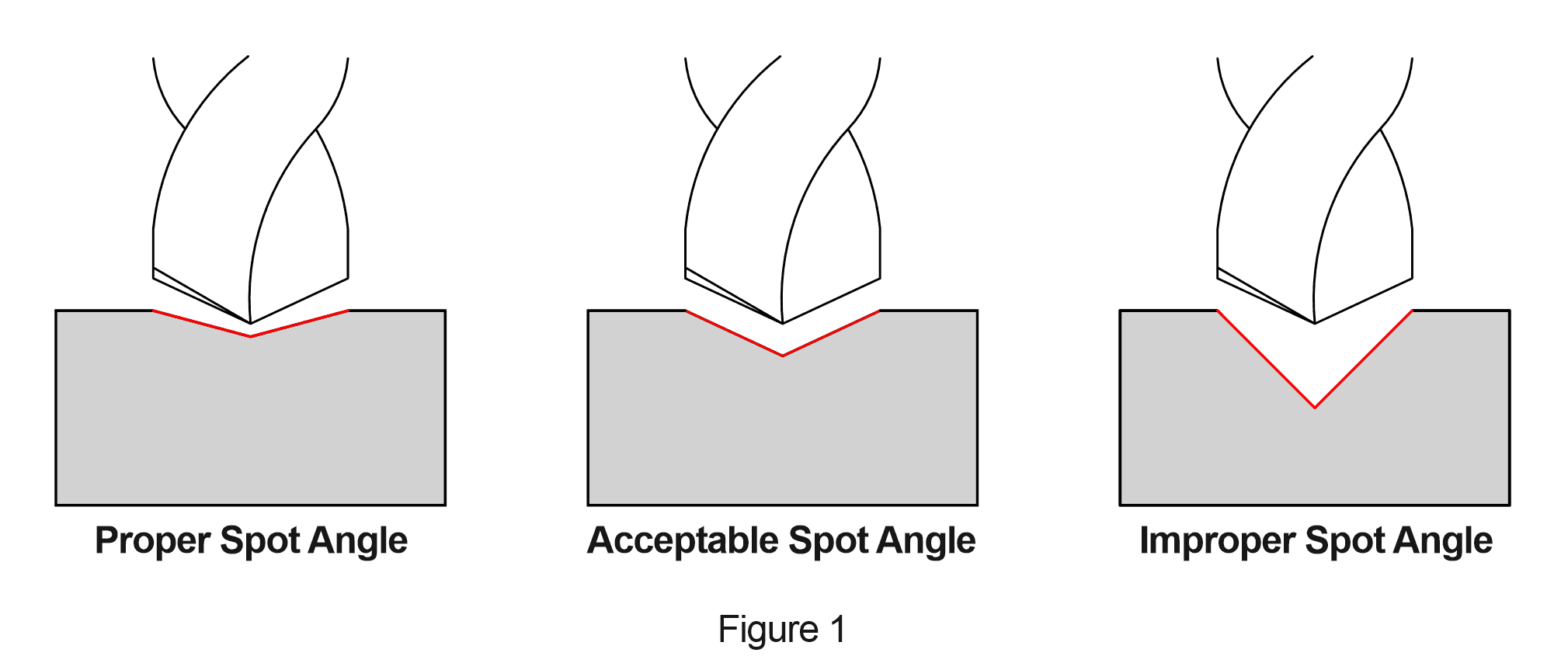

1. Proper tool selection

- Selecting the right tool for spot drilling is crucial. The tool should have a pilot point or a center-cutting feature to ensure accurate positioning of the hole.

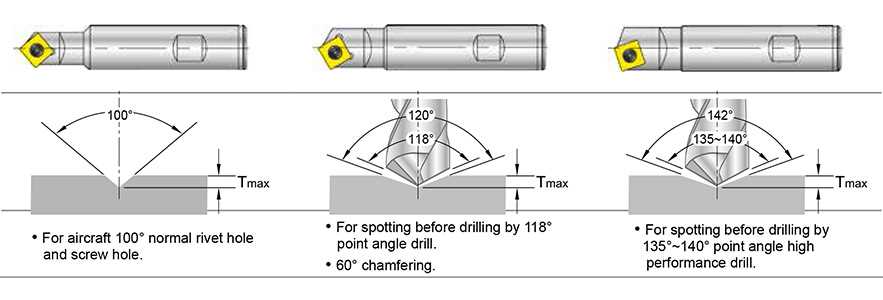

- A spotting drill with a 90-degree point angle is commonly used for spot drilling. However, other angles can also be used depending on the specific requirements of the application.

2. Feed and speed rates

- It is important to use appropriate feed and speed rates when spot drilling. Feeds that are too low may cause the drill to rub against the workpiece, leading to poor hole quality and increased tool wear. On the other hand, feeds that are too high may result in chip clogging and reduced tool life.

- Speed rates should be selected based on the type of material being drilled. Harder materials require lower speeds, while softer materials can be drilled at higher speeds.

3. Workpiece preparation

- Prior to spot drilling, it is important to properly prepare the workpiece. This includes ensuring that the workpiece is securely clamped to prevent any movement during drilling.

- Additionally, the workpiece surface should be clean and free from any contaminants that may interfere with the drilling process.

4. Chip evacuation

- Effective chip evacuation is essential in spot drilling to prevent chip buildup and ensure smooth drilling operation.

- Using appropriate cutting fluid or lubrication can help facilitate chip evacuation and improve cutting performance.

5. Depth control

- When spot drilling, it is important to control the depth of the hole. This can be achieved by using depth stop mechanisms or by closely monitoring the drilling process.

- Accurate depth control helps ensure consistent hole depths and prevents overdrilling or underdrilling.

By considering these important factors, spot drilling can be performed efficiently and effectively, resulting in precise and accurate holes that meet the requirements of the machining application.

Safety Precautions When Using Spot Drills

1. Wear Personal Protective Equipment (PPE)

When using spot drills, it is crucial to wear appropriate personal protective equipment (PPE) to minimize the risk of injury. This includes safety glasses or goggles to protect your eyes from flying debris, gloves to protect your hands from sharp edges or hot materials, and ear protection if there is excessive noise.

2. Inspect the Spot Drill

Prior to using a spot drill, it is important to inspect it for any signs of damage or wear. Check for any cracks or defects that may affect its performance or safety. If you notice any issues, do not use the spot drill and replace it with a new one.

3. Use the Correct Spot Drill Size

Using the correct spot drill size is essential for achieving accurate and safe results. Ensure that you select the appropriate spot drill size for the specific task at hand. Using an incorrect size can lead to improper hole preparation and increase the risk of accidents.

4. Securely Fasten the Workpiece

Before using a spot drill, make sure the workpiece is securely fastened in place. This will prevent any movement or slippage during the drilling process, reducing the risk of accidents or injuries. Use clamps or vises to hold the workpiece firmly in place.

5. Maintain a Clear Work Area

Keep your work area clear of any clutter or obstructions that may interfere with the spot drilling process. Remove any loose objects, tools, or debris from the vicinity to prevent accidents or injuries. Additionally, ensure that there is proper lighting in the work area for better visibility.

6. Follow Proper Operating Procedures

Always follow the manufacturer’s instructions and recommended operating procedures when using a spot drill. This includes the correct speed and feed rate, as well as the appropriate cutting fluid or lubricant to be used. Deviating from these guidelines may result in unsafe conditions or poor drilling performance.

7. Take Breaks and Stay Alert

Spot drilling can be a repetitive task that requires concentration. Take regular breaks to rest your body and mind, particularly if you are spending a prolonged amount of time using a spot drill. It is important to stay alert and focused to minimize the risk of accidents.

8. Seek Proper Training and Supervision

If you are new to using spot drills or any other machining tools, seek proper training and supervision from experienced individuals. They can provide guidance on proper techniques, safety precautions, and help identify potential hazards.

9. Keep First Aid Kit Handy

In case of any accidents or injuries, it is important to have a first aid kit readily available in your work area. Familiarize yourself with its contents and know how to use them properly. Prompt medical attention can minimize the severity of any injuries.

10. Regularly Maintain and Inspect Equipment

Regular maintenance and inspection of your spot drilling equipment can help identify any issues before they become safety hazards. Clean and lubricate the equipment as recommended by the manufacturer, and replace any worn or damaged parts promptly. This will ensure that your spot drills are in optimal working condition and reduce the risk of accidents.

FAQ:

What is a spot drill and what is its purpose?

A spot drill is a type of drill bit that is used to create a small hole called a “spot” on the surface of a workpiece. Its purpose is to provide a starting point or guide for a larger drill bit or tap.

How is a spot drill different from a regular drill bit?

A spot drill is designed to create a shallow hole with a specific diameter, typically smaller than the final hole size. Regular drill bits are used to create holes of various diameters and depths. Spot drills provide more precision and accuracy in drilling.

When is it necessary to use a spot drill?

A spot drill is necessary when you need to create a precise starting point for drilling or tapping operations. It is commonly used in metalworking and machining to ensure accurate hole placement and prevent drill wandering.

Can spot drills be used on different materials?

Yes, spot drills can be used on various materials such as metal, wood, and plastic. However, they are most commonly used in metalworking applications, as they are particularly effective in creating accurate starting points on metal surfaces.

What are the different types of spot drills?

There are several types of spot drills available, including solid carbide spot drills, cobalt spot drills, and high-speed steel spot drills. The choice of spot drill depends on the specific material being drilled and the desired performance.

Are spot drills expensive?

The cost of spot drills can vary depending on the brand, material, and size. However, in general, spot drills are relatively inexpensive compared to other types of cutting tools. It is always a good idea to compare prices and quality before making a purchase.

Video: