What is a drill driver used for?

A drill driver is a versatile power tool that combines the functions of a drill and a screwdriver. It is commonly used in a variety of DIY projects and professional construction applications. The main purpose of a drill driver is to drill holes and drive screws into different materials, such as wood, metal, and plastic.

With its adjustable chuck, a drill driver can accommodate various sizes of drill bits and screwdriver bits, making it suitable for a wide range of tasks. The drill function allows you to create holes of different sizes and depths, while the screwdriver function enables you to insert and remove screws with ease.

One of the primary advantages of using a drill driver is its speed and efficiency. Unlike traditional manual screwdrivers, a drill driver can rapidly drive screws into any surface, saving you time and effort. Additionally, the variable speed settings allow you to control the speed of the drill, providing you with greater precision and control over your work.

Furthermore, a drill driver is designed to be portable and lightweight, making it easy to handle and maneuver. This makes it ideal for both small-scale projects around the house and larger construction jobs. Some models also come with additional features like LED lights, which provide better visibility in dimly lit areas, and built-in levels for accurate drilling and screwdriving.

In conclusion, a drill driver is a versatile and essential tool for any DIY enthusiast or professional contractor. Its ability to drill holes and drive screws quickly and efficiently makes it indispensable in a wide range of applications. Whether you’re assembling furniture, installing shelves, or working on a construction site, a drill driver is a reliable and convenient tool that will help you get the job done with ease.

Overview of a Drill Driver

A drill driver is a versatile power tool that combines the functions of a drill and a screwdriver. It is used for drilling holes in various materials and driving screws into them.

Key Features

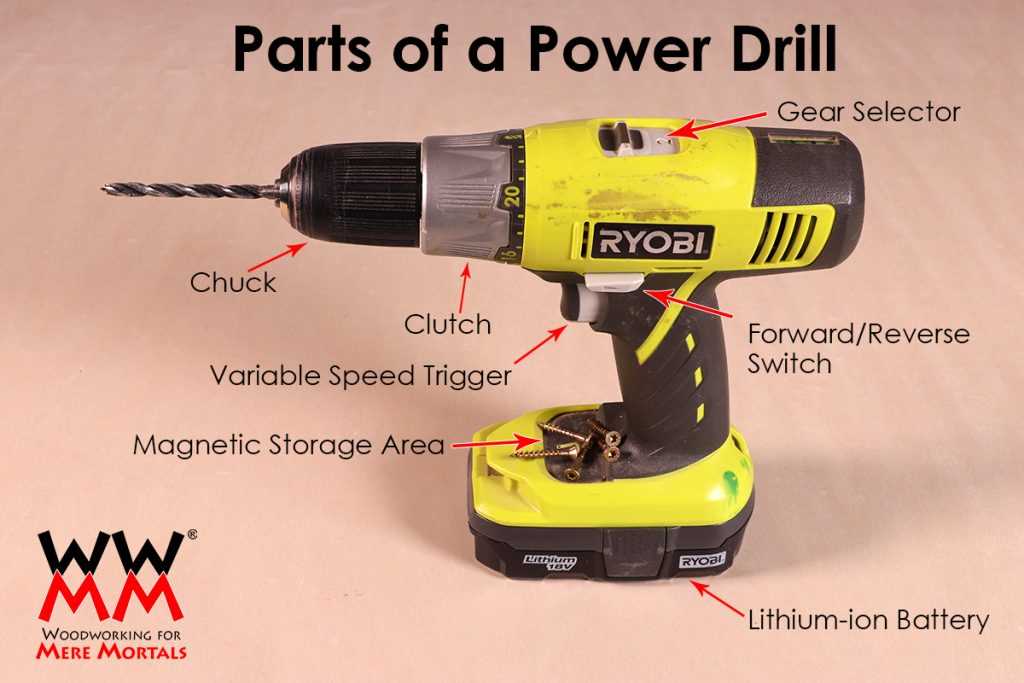

- Chuck: A drill driver typically comes with a keyless chuck, which allows for quick and easy bit changes.

- Speed: Most drill drivers offer multiple speed settings to accommodate different materials and drilling or driving tasks.

- Torque Control: Some drill drivers have torque control settings that allow you to adjust the amount of force applied when driving screws, preventing over tightening or stripping.

- Handle: Drill drivers usually have a pistol grip handle that provides a comfortable and secure grip during operation.

- Battery: Many drill drivers are cordless and powered by rechargeable batteries, offering greater mobility and convenience.

Uses

A drill driver is an essential tool for numerous applications, including:

- Drilling holes in wood, metal, plastic, and other materials.

- Driving screws into a variety of surfaces.

- Assembling furniture or other DIY projects.

- Installing shelves, cabinets, or other fixtures.

- Repairing or replacing hardware or small appliances.

- Creating holes for electrical wiring or plumbing pipes.

Accessories

To enhance the functionality of a drill driver, there are various accessories available, such as:

- Drill Bits: Different types of drill bits are used for various materials, including wood, metal, masonry, and more.

- Screwdriver Bits: These bits allow you to drive different types and sizes of screws.

- Countersink Bits: Used to create holes with a wider opening at the surface for countersinking screws.

- Spade Bits: Designed for drilling larger diameter holes in wood.

- Auger Bits: Used for drilling deep holes or creating holes in thick materials.

- Extension Bits: These extensions help reach deeper or more confined spaces.

Tips for Use

- Always wear appropriate safety gear, including safety glasses and hearing protection.

- Select the right drill bit or screwdriver bit for the task at hand and ensure it is securely fastened in the chuck.

- Align the drill driver perpendicular to the surface when drilling to prevent the bit from slipping or wandering.

- Apply steady pressure and let the drill driver do the work. Avoid applying excessive force, which can lead to overheating or damaging the tool.

- When driving screws, adjust the torque settings to prevent stripping or damaging the screw or the material.

- Maintain the drill driver by cleaning it regularly and storing it in a dry place.

By following these tips and exploring the various features and uses of a drill driver, you can make the most out of this versatile tool for your drilling and screwdriving needs.

Key Features and Functions

1. Versatility

One of the key features of a drill driver is its versatility. This tool is designed to perform both drilling and driving functions, making it a versatile choice for a wide range of tasks. Whether you need to drill holes in wood or drive screws into metal, a drill driver can handle it with ease.

2. Power

A drill driver is equipped with a powerful motor that provides the necessary force required to drill holes and drive screws. The power output of a drill driver is typically measured in volts, with higher voltage models offering more power. This allows you to complete tasks quickly and efficiently.

3. Speed and Torque Control

Most drill drivers feature adjustable speed settings, allowing you to choose the optimal speed for the task at hand. Low speeds are ideal for drilling into harder materials like metal, while higher speeds are more suitable for drilling into softer materials like wood. Additionally, drill drivers often have torque control settings, which allow you to adjust the level of force applied to the screw.

4. Compact and Portable

Drill drivers are typically designed to be compact and lightweight, making them easy to maneuver and carry around. This makes them ideal for both professional and DIY use, as they can be easily transported to different job sites.

5. Battery-Powered

Many drill drivers are powered by rechargeable batteries, making them cordless and portable. This eliminates the need for a power outlet and allows for greater freedom of movement. Battery-powered drill drivers are especially useful in situations where access to electricity is limited or when working on outdoor projects.

6. Additional Features

Some drill drivers come with additional features that enhance their functionality. These may include built-in LED lights for improved visibility in dark work areas, built-in level indicators for accurate drilling, and removable chucks for easy bit changes.

In conclusion, a drill driver is a versatile and powerful tool that combines drilling and driving functions. With adjustable speed and torque control, compact design, battery-powered operation, and additional features, drill drivers are essential tools for a variety of tasks.

Types of Drill Drivers

There are several types of drill drivers available in the market, each with its own unique features and applications. Here are some of the most common types:

1. Cordless Drill Drivers

Cordless drill drivers are powered by rechargeable batteries, making them portable and convenient to use. They provide the freedom to move around without being limited by a power cord. Cordless drill drivers are available in various sizes and power capacities to suit different needs.

2. Corded Drill Drivers

Corded drill drivers, on the other hand, need to be plugged into a power source to function. They provide a constant power supply, eliminating the need to recharge batteries. Corded drill drivers are typically more powerful and suitable for heavy-duty applications.

3. Impact Driver Drill Combo

An impact driver drill combo combines the functionalities of both a drill driver and an impact driver. It can drill holes and drive screws, making it a versatile tool for various tasks. The impact driver feature allows for high torque and quick fastening, while the drill driver feature provides precision and control.

4. Hammer Drill Drivers

Hammer drill drivers, also known as rotary hammer drills, are designed for drilling through tough materials like concrete and masonry. They feature a hammering action that generates rapid impacts while rotating, allowing for efficient drilling in hard surfaces.

5. Right Angle Drill Drivers

Right angle drill drivers are compact and versatile tools that can reach tight and confined spaces where a regular drill driver cannot. They have a 90-degree angled head, allowing for easy access in narrow areas.

6. Magnetic Drill Drivers

Magnetic drill drivers, also known as mag drills, are specialized tools used for drilling large and heavy workpieces. They use a magnetic base to securely attach to metal surfaces, providing stability and precision while drilling.

7. Pistol Grip Drill Drivers

Pistol grip drill drivers are named after their pistol-like shape, with the handle located at the rear of the tool. They are ergonomic and easy to handle, providing comfort and control during drilling operations.

8. T-handle Drill Drivers

T-handle drill drivers have a T-shaped handle that provides a firm grip and greater control. They are well-suited for heavy-duty drilling tasks that require more force and stability.

These are just a few examples of the different types of drill drivers available. Each type has its own advantages and applications, so it’s important to choose the right one based on your specific needs and preferences.

Advantages of Using a Drill Driver

Versatility

A drill driver is an incredibly versatile tool that can be used for a wide range of tasks. It can be used for drilling holes into various materials such as wood, metal, and plastic. Additionally, it can also be used for driving screws and other fasteners into those same materials. This versatility makes a drill driver a must-have tool for any DIY enthusiast or professional tradesperson.

Efficiency

Using a drill driver can significantly increase your work efficiency. With its powerful motor and adjustable speed settings, you can quickly and easily drill holes or drive screws into materials without having to exert excessive force. This not only saves you time and effort but also helps to prevent fatigue during long periods of use.

Compact and Portable

A drill driver is usually compact and lightweight, making it easy to transport and maneuver. Its compact size allows you to access tight spaces and work in confined areas where larger tools may not be able to reach. Whether you are working on a construction site or doing repairs around the house, its portability makes it a convenient tool to have on hand.

Multiple Power Options

Drill drivers have multiple power options available, including corded and cordless models. Corded drill drivers provide a continuous power supply, ensuring you can work without interruption. On the other hand, cordless drill drivers offer the advantage of increased mobility and flexibility since they are not restricted by a power cord. You can easily move around and work in different areas without the need for a nearby electrical outlet.

Ease of Use

Drill drivers are designed to be user-friendly, with intuitive controls and ergonomic handles. This makes them easy to operate, even for those who have little experience with power tools. The controls allow you to adjust the speed and torque settings according to the requirements of your task, providing you with the necessary power and control.

Cost-Effective

Investing in a drill driver can be a cost-effective choice. By having a single tool that can perform both drilling and driving functions, you can save money on purchasing separate tools. Additionally, the versatility and efficiency of a drill driver can help you complete tasks more quickly, potentially saving you time and labor costs in the long run.

Conclusion

A drill driver offers numerous advantages, including versatility, efficiency, portability, multiple power options, ease of use, and cost-effectiveness. Whether you are a DIY enthusiast, a professional tradesperson, or someone who simply needs a reliable power tool, a drill driver is an essential tool that can make your work easier and more efficient.

Common Uses of a Drill Driver

A drill driver is a versatile tool that is used for a variety of tasks. Here are some common uses of a drill driver:

1. Drilling Holes

One of the primary uses of a drill driver is drilling holes. It can drill holes in a range of materials such as wood, plastic, metal, and concrete. Whether you are installing shelves, hanging curtains, or building furniture, a drill driver can quickly and efficiently create the necessary holes.

2. Driving Screws

A drill driver is also commonly used for driving screws. With its adjustable torque settings, it allows you to control the amount of force applied when driving screws. This helps prevent overtightening or stripping the screws, and makes the task of installing screws much easier and faster.

3. Home Improvement Projects

A drill driver is an essential tool for any home improvement project. From assembling furniture to installing cabinets, a drill driver can handle a wide range of tasks. Its versatility allows you to easily switch between drilling and screwdriving, making it a convenient tool to have on hand for various projects.

4. DIY Crafts and Projects

Many DIY crafts and projects require the use of a drill driver. From building wooden shelves to creating custom signs, a drill driver can help you bring your creative ideas to life. It can accurately drill holes and drive screws in different materials, allowing you to easily customize and build your own creations.

5. Professional Construction

In the construction industry, a drill driver is a staple tool for professionals. It is used for a wide range of tasks, from framing and drywall installation to electrical and plumbing work. Its power and versatility make it an essential tool for professionals who need to drill holes and drive screws on a daily basis.

6. General Repairs and Maintenance

Whether you need to fix a loose hinge or replace a doorknob, a drill driver can come in handy for general repairs and maintenance tasks around the house. It allows you to quickly and accurately drill holes and drive screws, making it easier to complete small repairs without calling a professional.

Overall, a drill driver is a versatile tool that can be used for a wide range of tasks. From drilling holes and driving screws to tackling home improvement projects and DIY crafts, it is a valuable tool to have in your toolbox.

Tips for Using a Drill Driver

Using a drill driver can make many projects and tasks much easier. Whether you are a beginner or an experienced DIY enthusiast, these tips will help you make the most out of your drill driver:

1. Choose the right drill bit

Make sure you have the right drill bit for the material you are drilling into. Different materials require different types of drill bits, such as wood, metal, or concrete. Using the wrong drill bit can result in damage to the material or the drill itself.

2. Use the proper speed and torque settings

Most drill drivers have adjustable speed and torque settings. It’s important to use the proper settings for the task at hand. Higher speed and torque settings are suitable for drilling through tough surfaces, while lower settings are better for delicate materials or driving screws.

3. Start with a pilot hole

When drilling into wood or other hard materials, it’s helpful to start with a pilot hole. A pilot hole acts as a guide and prevents the drill bit from slipping or wandering off track. It also helps reduce the risk of splitting the material.

4. Use the right drill driver technique

Hold the drill driver with a firm grip and position it perpendicular to the surface you are drilling into. Apply steady pressure and let the drill do the work. Avoid applying excessive force, as it can cause the drill bit to overheat or break.

5. Take safety precautions

Whenever you use a drill driver, it’s important to wear safety goggles to protect your eyes from flying debris. If you are working on a dusty surface, consider wearing a face mask to avoid inhaling particles. Additionally, make sure the work area is clean and free from clutter to prevent accidents.

6. Keep your drill driver well-maintained

Regularly inspect your drill driver for any signs of wear or damage. Clean the chuck and drill bits after each use to remove any debris. Lubricate the chuck periodically to ensure smooth operation. If you notice any issues with your drill driver, have it serviced or repaired as soon as possible.

7. Practice on scrap material

If you are new to using a drill driver or trying out a new technique, it’s always a good idea to practice on scrap material first. This allows you to get a feel for the drill driver and make any necessary adjustments before working on your actual project.

8. Store your drill driver properly

When not in use, store your drill driver in a dry and secure place. Keep the batteries or power cord separate from the drill to prevent accidental activation. This will help prolong the life of your drill driver and prevent any potential accidents.

By following these tips, you can improve your drilling skills and make your projects more efficient and successful.

Buying Guide for a Drill Driver

Considerations before purchasing a drill driver

Before buying a drill driver, there are several important factors to consider:

- Power: Determine the power needs for your projects. Higher voltage means more power, but also a heavier tool.

- Battery: Consider battery type, capacity, and runtime. Lithium-ion batteries are preferred for their long-lasting power and quick recharge times.

- Chuck size: Choose a drill driver with a chuck size suitable for the type of work you will be doing. 3/8″ and 1/2″ chucks are common sizes.

- Speed and torque: Look for a drill driver with multiple speed settings and adjustable torque control for versatility.

- Ergonomics: Consider the weight, grip, and overall comfort of the drill driver, as you will be holding it for extended periods of time.

- Additional features: Some drill drivers come with built-in LED lights, a belt clip, or a magnetic bit holder. Consider these features based on your needs.

Types of drill drivers

There are a few different types of drill drivers available, each suited for specific tasks:

- Standard drill drivers: These are versatile tools suitable for drilling holes and driving screws in a variety of materials.

- Hammer drill drivers: These drill drivers combine a drilling and hammering action, making them ideal for drilling into masonry and concrete.

- Impact drill drivers: These drill drivers deliver a powerful rotational and concussive force, making them great for heavy-duty applications like driving large screws and bolts.

Additional accessories

When purchasing a drill driver, consider investing in some additional accessories to enhance your drilling experience:

- Drill bits: Choose a variety of drill bits suitable for different materials like wood, metal, and masonry.

- Screwdriver bits: Invest in various screwdriver bits for different types of screws, including Phillips, flathead, and hex.

- Extra batteries and charger: Having extra batteries and a charger on hand ensures uninterrupted work.

- Carrying case: A durable carrying case helps organize and protect your drill driver and accessories.

- Work gloves and safety glasses: Protect yourself against potential hazards by wearing appropriate safety gear.

Price range

The price of a drill driver can vary depending on the brand, features, and quality. Generally, drill drivers range from $50 to $300. It’s important to find a balance between your budget and the features you require for your projects.

Comparing different brands

When comparing drill drivers from different brands, consider factors such as reputation, customer reviews, warranties, and available customer support.

Conclusion

A drill driver is a versatile tool that can tackle a wide range of tasks. By considering factors such as power, battery, chuck size, speed, and ergonomics, you can find the right drill driver for your needs. Remember to also invest in additional accessories and safety gear to enhance your drilling experience.

Maintenance and Care for a Drill Driver

Cleaning

Regular cleaning is essential for maintaining the performance and longevity of a drill driver. After each use, wipe down the exterior of the drill driver with a clean cloth to remove any dust, debris, or oil. Pay special attention to the chuck, handle, and ventilation holes.

If the drill driver becomes caked with dirt or debris, use a soft brush or toothbrush to gently scrub away the buildup. Avoid using harsh chemicals or solvents that may damage the tool’s surface.

Lubrication

Proper lubrication is crucial for the smooth operation of a drill driver. Apply a small amount of lubricating oil to the chuck regularly to ensure it remains in good working condition. Additionally, lubricate any moving parts or gears according to the manufacturer’s instructions.

Be careful not to over-lubricate the tool, as excess oil can attract dirt and hinder performance. Always use the recommended type of oil and follow the manufacturer’s guidelines.

Battery Maintenance

For cordless drill drivers, proper battery maintenance is essential. Always use the charger provided by the manufacturer and avoid overcharging the battery. When not in use, store the battery in a cool, dry place to prevent damage.

Inspect the battery regularly for any signs of damage, such as cracks or leaks. If any issues are found, replace the battery immediately to prevent safety hazards.

Storage

When not in use, store the drill driver in a dry and secure location. Avoid exposing it to extreme temperatures, humidity, or direct sunlight, as these conditions can negatively affect the tool’s performance and lifespan.

Consider using a protective case or storage box to prevent any accidental damage or impact. Keep the drill driver away from children to avoid any potential accidents.

Regular Maintenance Checks

Periodically inspect the drill driver for any signs of wear, loose parts, or malfunctions. Check the cord, switch, and connectors for any fraying or damage. If any issues are detected, discontinue use and have the tool serviced by a qualified technician.

Follow the manufacturer’s recommended maintenance schedule for routine tune-ups or servicing. This will help ensure the drill driver performs optimally and remains safe to use.

FAQ:

What is a drill driver used for?

A drill driver is a versatile power tool that is used for drilling holes and driving screws and bolts. It combines the functions of a drill and a screwdriver, making it a useful tool for both DIY enthusiasts and professionals.

Can a drill driver be used for heavy-duty applications?

Yes, a drill driver can be used for heavy-duty applications. However, for tasks that require more power and torque, such as drilling through concrete or metal, it is recommended to use a dedicated hammer drill or an impact driver.

Is it necessary to use a drill driver for assembling furniture?

No, using a drill driver is not necessary for assembling furniture. However, it can make the task faster and easier, especially when driving screws into hard materials or assembling large pieces of furniture.

Can a drill driver be used for removing screws?

Yes, a drill driver can be used for removing screws. Most drill drivers have a reverse function that allows you to easily remove screws by rotating them in the opposite direction.

Can a drill driver be used for drilling into concrete?

A drill driver can be used for drilling into concrete, but it may not be as efficient as a dedicated hammer drill. If you need to drill multiple holes in concrete, it is recommended to use a hammer drill for better performance.

Is it possible to use a drill driver for woodworking?

Yes, a drill driver can be used for woodworking. It is commonly used for drilling pilot holes and driving screws in wood. However, for more precise and specialized woodworking tasks, it is advisable to use a drill press or a dedicated woodworking tool.

Can a drill driver be used for automotive repairs?

Yes, a drill driver can be used for automotive repairs. It can be used for drilling holes, removing and installing screws, and performing various tasks in auto body repair and maintenance. However, for certain automotive applications, such as tightening lug nuts, it is better to use a impact wrench.

Video: