What is a countersink drill bit used for?

A countersink drill bit is a specialized tool used in woodworking, metalworking, and other industries to create a conical hole on the surface of a material. The purpose of this hole is to allow the head of a fastener, such as a screw or a bolt, to sit flush with the surface.

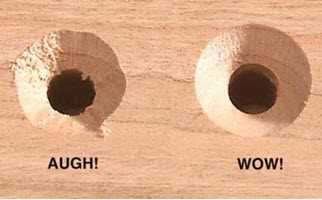

When a fastener is driven into a material without a countersink hole, it tends to sit above the surface or create a raised bump. This can be unsightly, unprofessional, and in some cases, it can even compromise the strength and stability of the joint.

A countersink hole is wider at the top and narrows towards the bottom, creating a cone-shaped recess where the head of the fastener can sit. This allows the fastener to be driven below the surface of the material, providing a smooth and flush finish. Additionally, the cone shape of the hole allows the fastener to grip the material more securely, improving the strength of the joint.

What is a countersink drill bit?

A countersink drill bit is a specialized type of drill bit that is designed to create a conical hole in a material. It is commonly used in woodworking, metalworking, and other applications where a screw or fastener needs to be flush or below the surface of the material.

The countersink bit has a pointed tip and fluted body, which allows it to cut a tapered hole with a wider entrance and a narrower bottom. This shape helps to accommodate the head of a screw or fastener, allowing it to sit flush with or below the surface of the material.

Countersink drill bits are available in a variety of sizes and designs to accommodate different screw sizes and materials. They can be used with a handheld drill or a drill press, depending on the specific application.

How does a countersink drill bit work?

When using a countersink drill bit, the process typically involves the following steps:

- Choose the appropriate size countersink drill bit based on the screw size and material.

- Secure the material to be drilled, if necessary.

- Insert the countersink bit into the drill chuck.

- Align the tip of the countersink bit with the desired location for the hole.

- Start the drill at a slow speed and gradually increase the speed as the hole is being created.

- Apply gentle pressure to the drill to create the countersink hole.

- Continue drilling until the desired depth is reached.

Once the hole is created, it can be filled with a screw or fastener, which will sit flush or below the surface of the material, providing a clean and finished appearance.

Benefits of using a countersink drill bit

- Flush or recessed fasteners: Countersink drill bits allow for the creation of holes that accommodate the heads of screws or fasteners, allowing them to sit flush with or below the surface of the material. This provides a smooth and finished look.

- Prevents splitting: By creating a cone-shaped hole, countersink drill bits help to prevent the material from splitting when a screw or fastener is inserted.

- Improved stability: The tapered shape of the countersink hole provides improved stability and contact between the screw or fastener and the material, resulting in a stronger and more secure connection.

- Professional finish: Countersink drill bits help to achieve a professional and finished appearance in woodworking, metalworking, and other applications where hiding fasteners is desired.

Overall, countersink drill bits are an essential tool for creating clean and precise holes that accommodate screws or fasteners, while providing a finished and professional look to the material.

How does a countersink drill bit work?

A countersink drill bit is a special type of drill bit that is used to create a conical hole in a material. This conical hole allows the flat head of a screw or a fastener to sit flush with the surface of the material, creating a smooth and seamless finish.

The countersink drill bit is designed with a sharp, tapered point at the tip. When the drill bit is inserted into a drill or a drill press, the sharp point helps to guide the bit into the material and create a small hole. As the bit continues to drill, the wider flutes of the bit widen the hole to create the desired conical shape.

Once the conical hole is created, it provides a recessed area for the head of the screw or fastener to sit. This allows the screw or fastener to be driven into the material without protruding above the surface, giving a clean and professional appearance.

Countersink drill bits are commonly used in woodworking, metalworking, and other applications where flush fastenings are desired. They can be used with a variety of materials, including wood, metal, plastic, and composites.

It’s important to choose the right size of countersink drill bit for the fastener you are using. The diameter of the countersink should match the diameter of the screw or fastener head, ensuring a proper fit and flush finish.

Overall, a countersink drill bit is a versatile tool that helps to create a neat and professional finish when fastening materials. It simplifies the process of countersinking and allows for a seamless and flush appearance of the fasteners.

Types of countersink drill bits

1. Single-flute countersink drill bits

A single-flute countersink drill bit is the most common type and is designed with a single cutting edge. It is used to create a chamfer or countersink hole with a flat bottom. This type of drill bit is versatile and can be used on various materials, including wood, plastic, and metal.

2. Multi-flute countersink drill bits

A multi-flute countersink drill bit has multiple cutting edges and is used for creating a more precise and cleaner chamfer or countersink hole. The multiple flutes help to reduce chatter and ensure a smooth cutting action. This type of drill bit is commonly used in high-speed drilling operations and on harder materials like stainless steel and aluminum.

3. Adjustable countersink drill bits

An adjustable countersink drill bit allows the user to adjust the size of the countersink hole. It typically has a sleeve that can be moved up or down to control the depth of the hole. This type of drill bit is useful when you need to create countersink holes of different sizes without changing the drill bit.

4. Combination countersink drill bits

A combination countersink drill bit combines a countersink bit with a drill bit. It is designed to create a countersunk hole and a pilot hole in one step. This type of drill bit is commonly used in woodworking applications where a pilot hole is required before driving screws or nails.

5. Interchangeable countersink drill bits

Interchangeable countersink drill bits consist of a holder and multiple interchangeable drill bits. The drill bits can be easily swapped out according to the desired countersink size. This type of drill bit offers versatility and is suitable for working with different sized screws or bolts.

Materials that can be used with a countersink drill bit

Countersink drill bits are versatile tools that can be used with a variety of materials. Here are some common materials that can be effectively used with a countersink drill bit:

1. Wood

- Countersink drill bits are commonly used in woodworking projects. They can create recessed holes or countersinks in wood to allow screws to sit flush with the surface.

- They can be used with various types of wood, including softwoods like pine and hardwoods like oak.

- When working with wood, it’s important to choose a countersink drill bit that matches the size of the screw you are using, to ensure a proper fit.

2. Metal

- Countersink drill bits can also be used with metal materials, such as steel and aluminum.

- When working with metal, it’s important to use a countersink drill bit that is designed specifically for metal, as these bits are typically made of high-speed steel or cobalt for increased durability.

- Countersinking in metal is often done to create a recessed hole for fasteners or to prepare the surface for subsequent processes, such as welding.

3. Plastic

- Countersink drill bits can be used with various types of plastic materials, including acrylic, PVC, and polycarbonate.

- When working with plastic, it’s important to choose a countersink drill bit that is suitable for the specific type of plastic being used, as different plastics require different drilling techniques.

- Countersinking in plastic is often done to create a flush surface for fasteners or to provide a smooth finish.

4. Composite materials

- Countersink drill bits are also commonly used with composite materials, such as fiberglass and carbon fiber.

- These materials can be difficult to work with due to their hardness and tendency to splinter, but countersink drill bits designed for composite materials can help overcome these challenges.

- Countersinking in composites is often done to create a smooth and even surface for fasteners or to ensure a flush fit.

Overall, countersink drill bits can be used with a wide range of materials, making them an essential tool in various industries, including woodworking, metalworking, and plastics manufacturing.

Benefits of using a countersink drill bit

Using a countersink drill bit offers several benefits and advantages, making it a valuable tool in various applications. Here are some of the key benefits:

1. Professional and finished appearance

A countersink drill bit creates a beveled opening at the surface of the material being drilled, allowing screws or fasteners to sit flush with the material’s surface. This creates a professional and finished appearance, especially when working on woodworking or carpentry projects.

2. Prevents splitting of material

When using a countersink drill bit, it helps prevent the splitting of material, especially in wood or other soft materials. By creating a countersink hole, the material is relieved of stress, reducing the likelihood of cracks or splits when inserting screws.

3. Enhances screw grip

By using a countersink drill bit, it provides a snug fit for screws or fasteners. The beveled opening allows the screw to sit securely in place, enhancing its grip and preventing it from moving or loosening over time.

4. Saves time and effort

Using a countersink drill bit saves time and effort by eliminating the need for additional steps to create a clean and professional finish. It removes the need to manually countersink the hole using other tools, reducing the overall time spent on a project.

5. Versatile applications

Countersink drill bits have versatile applications and can be used in various materials such as wood, metal, plastic, and composites. This makes them suitable for a wide range of projects in different industries, including construction, woodworking, metalworking, and DIY projects.

6. Improved accuracy

Using a countersink drill bit improves accuracy in drilling holes. The beveled opening ensures that the screw or fastener is aligned correctly and sits flush with the material’s surface. This helps make precise and uniform holes, especially when a clean look is desired.

7. Compatibility with different screw sizes

Countersink drill bits are available in various sizes and can accommodate different screw sizes. This allows flexibility in fastening options and ensures a proper fit for different projects and materials.

8. Long-lasting and durable

Many countersink drill bits are made from high-quality materials such as high-speed steel (HSS) or carbide, making them long-lasting and durable. This ensures that the drill bit remains sharp and effective, providing reliable performance over time.

9. Ease of use

Countersink drill bits are easy to use, even for beginners. They can be used with a standard drill or drill press, requiring no specialized skills or knowledge. Simply insert the drill bit into the chuck, adjust the depth, and start drilling.

10. Cost-effective

Despite their many benefits, countersink drill bits are relatively affordable and cost-effective tools. They offer significant value for money and are a wise investment for anyone regularly working on projects that require countersinking.

In conclusion, a countersink drill bit is a versatile and valuable tool that provides a range of benefits. From creating a professional appearance to preventing material splitting and enhancing screw grip, using a countersink drill bit improves the overall quality and efficiency of various projects.

Common applications of countersink drill bits

Carpentry and woodworking

In carpentry and woodworking, countersink drill bits are commonly used to create a recessed hole with a conical shape on the surface of a material. This allows for the flush installation of screws, ensuring a smooth and professional finish. Countersink drill bits are often used in projects such as cabinetry, furniture making, and finishing work.

They are particularly useful when working with hardwoods, where the use of regular screws without countersinking can lead to splitting and damage to the material.

Metalworking

Countersink drill bits are also used in metalworking applications. They are used to create countersunk holes in metal materials, such as steel or aluminum, where flush installation of screws or rivets is required. This is often done to create a smooth and streamlined surface, improve the appearance of the metalwork, and reduce the risk of snagging on the protruding fasteners.

Countersink drill bits are commonly used in industries such as aerospace, automotive, and fabrication, where precision and aesthetics are important.

Deburring and chamfering

Countersink drill bits are also useful for deburring and chamfering sharp edges on materials. When used carefully, they can remove burrs or sharp edges left after cutting or machining processes. This helps to improve safety, prevent injury, and create a more refined and finished appearance.

Additionally, countersink drill bits can be used to create chamfered edges on materials, where a beveled or angled edge is desired. This can be decorative or functional, as chamfered edges can help prevent splintering or damage to the material.

Composite materials

Countersink drill bits are frequently used in applications involving composite materials. These materials, which are typically made of a combination of fibers and resins, require special tools and techniques for drilling and fastening. Countersink drill bits allow for the proper installation and seating of fasteners in composite materials without causing damage, delamination, or weakening of the structure.

Examples of composite materials where countersink drill bits are used include fiberglass, carbon fiber, and various composite panels and sheets.

Plastic and PVC

When working with plastic and PVC materials, countersink drill bits are used to create countersunk holes for screws or other fasteners. This ensures that the fasteners are flush with the surface, preventing them from sticking out or creating a bumpy finish. Countersinking is especially important when working with thin plastic materials that may crack or break if screws are driven into them without a countersunk hole.

Countersink drill bits can be used in various plastic applications, such as electronics enclosures, signage fabrication, and plastic sheeting installations.

Other applications

Aside from the mentioned applications, countersink drill bits can also be utilized in various other tasks and materials. These include woodworking during construction projects, metal fabrication, DIY home improvement projects, and general repair and maintenance work.

Whether you need to create recessed holes for screws, deburr sharp edges, create chamfered edges, or work with specific materials, countersink drill bits are versatile tools that can be used in a wide range of applications.

Tips for using a countersink drill bit

When using a countersink drill bit, it is important to follow certain techniques and precautions to ensure a successful and professional outcome. Here are some tips to keep in mind:

- Choose the right drill bit size: Select a countersink drill bit that matches the size of the screw you are using. This will ensure a proper fit and prevent the screw from protruding above the surface.

- Set the depth: Adjust the drill bit to the desired depth, usually just enough to allow the screw head to sit flush with the surface. Be sure to mark the desired depth on the drill bit or use a depth stop to ensure consistency.

- Secure the workpiece: Clamping the workpiece securely in place will prevent it from moving during the countersinking process. This will help maintain accuracy and prevent any damage or mishaps.

- Start with a pilot hole: It is recommended to start with a pilot hole before using the countersink drill bit. This will help guide the drill bit and prevent any wandering or slipping.

- Drill at a slow speed: Use a low speed setting on your drill to prevent overheating or splintering of the material. This will also allow for better control and accuracy.

- Apply consistent pressure: Apply a steady and consistent pressure when drilling to prevent the drill bit from grabbing or causing any damage. Let the tool do the work and avoid forcing it.

- Clear the debris: Regularly clear the drill bit of any debris or chips to maintain optimal performance. This can be done by blowing or brushing away the waste material.

- Test fit: After countersinking, test the fit of the screw head in the hole. It should sit flush with the surface without any gaps or protrusions. Make any necessary adjustments before proceeding.

- Safety precautions: Always wear appropriate protective gear, such as safety glasses, when using a drill. Additionally, follow any safety guidelines specified by the manufacturer of the drill and drill bit.

By following these tips, you can achieve clean and professional results when using a countersink drill bit.

FAQ:

What is a countersink drill bit?

A countersink drill bit is a type of drill bit that is designed to create a conical-shaped hole in a material. This hole allows for the head of a screw or bolt to sit flush or below the surface of the material.

How do I use a countersink drill bit?

To use a countersink drill bit, you first need to choose the appropriate size drill bit for your screw or bolt. Then, you would drill a pilot hole with a regular drill bit. After that, you would switch to the countersink drill bit and use it to create a conical-shaped hole around the pilot hole. This will allow the head of the screw or bolt to sit flush or below the surface of the material.

What materials can I use a countersink drill bit on?

A countersink drill bit can be used on a variety of materials, including wood, metal, plastic, and composite materials. It is important to choose the appropriate countersink bit based on the material you are working with to ensure clean and accurate results.

Can I use a countersink drill bit on glass or ceramic?

No, a countersink drill bit is not suitable for use on glass or ceramic materials. These materials require special drill bits that are designed specifically for glass or ceramic drilling. Using a countersink drill bit on glass or ceramic can result in cracking or shattering of the material.

Why would I use a countersink drill bit instead of a regular drill bit?

A countersink drill bit is used when you want the head of a screw or bolt to sit flush or below the surface of the material you are working with. This can be beneficial for aesthetic reasons, to prevent the screw or bolt from catching on clothing or other objects, or to create a smooth surface for painting or finishing.

Can I use a countersink drill bit on screws with different head shapes?

Yes, you can use a countersink drill bit on screws with different head shapes, such as flat head screws, oval head screws, or round head screws. The countersink drill bit will create a conical-shaped hole that will accommodate the shape of the screw head and allow it to sit flush or below the surface of the material.

Are there different types of countersink drill bits?

Yes, there are different types of countersink drill bits available, including single-flute countersink drill bits, multi-flute countersink drill bits, and combination countersink drill bits. These different types of countersink drill bits are designed for specific applications and offer different cutting configurations for optimal performance.

Video: