What Does Brushless Drill Mean?

A brushless drill is a type of power tool that is designed to eliminate the need for brushes and commutators found in traditional drills. This innovative design allows for a more efficient and durable operation, making brushless drills a popular choice among professionals and DIY enthusiasts.

The main difference between a brushless drill and a traditional drill is the way they are powered. While traditional drills use a brush and commutator to transfer electrical current to the motor, brushless drills use a circuit board and magnets. This eliminates the need for maintenance and reduces the risk of wear and tear, resulting in a longer lifespan for the tool.

One of the major advantages of brushless drills is their increased power and performance. The brushless motor delivers more torque, allowing for faster drilling and increased efficiency. Additionally, brushless drills are often lighter and more compact, making them easier to use in tight spaces or for extended periods of time.

In conclusion, a brushless drill represents the next generation of power tools. With their efficient and durable design, brushless drills offer a superior performance compared to traditional drills. Whether you are a professional contractor or a DIY enthusiast, investing in a brushless drill can greatly enhance your drilling experience.

Definition of a Brushless Drill

A brushless drill, also known as a brushless motor drill or simply a brushless driver, is a type of power tool that utilizes a brushless motor. Unlike traditional drills that use brushed motors, brushless drills are powered by a motor that does not require physical brushes to transfer electrical current to the rotor.

How does a brushless drill work?

- A brushless motor utilizes a circuit board to control the flow of electrical current to the rotor.

- The stator, which consists of stationary coils, creates a rotating magnetic field.

- The rotor, which contains permanent magnets, spins in response to the magnetic field.

- By eliminating the brushes, brushless drills can operate more efficiently, generate less heat, and have a longer lifespan.

Advantages of a brushless drill

There are several advantages to using a brushless drill:

- Increased efficiency: Brushless drills are more energy efficient than brushed drills because they reduce the amount of energy lost as heat.

- Longer lifespan: Since there are no brushes to wear down, brushless drills generally have a longer lifespan than brushed drills.

- Higher power output: Brushless drills can deliver more power to the drill bit due to their improved efficiency.

- Compact and lightweight: Brushless drills are typically smaller and lighter than their brushed counterparts, making them easier to handle and maneuver.

- Reduced maintenance: Without brushes to replace, brushless drills require less maintenance and have fewer parts that can wear out over time.

Applications of brushless drills

Brushless drills are widely used in various applications, including:

- Construction

- Woodworking

- Automotive repair

- DIY projects

- Plumbing

- Electrical work

Due to their efficiency, durability, and versatility, brushless drills have become a popular choice among professionals and homeowners alike.

Advantages of Brushless Drills

1. Increased Efficiency

One of the main advantages of brushless drills is their increased efficiency compared to brushed drills. Unlike brushed drills which rely on brushes to transmit power, brushless drills use electronic circuits and magnets to generate power. This design eliminates the friction and energy loss associated with brushes, resulting in more efficient operation.

2. Extended Battery Life

Since brushless drills are more efficient in converting electric power into mechanical power, they require less energy to perform the same tasks as brushed drills. As a result, brushless drills can provide longer battery life, allowing users to work for extended periods of time without needing to recharge the batteries. This makes brushless drills ideal for heavy-duty and long-duration applications.

3. Higher Torque

Brushless drills are known for their high torque output, making them suitable for demanding tasks. The absence of brushes allows for better control of the motor’s rotational speed, resulting in increased torque. This makes brushless drills capable of drilling through tough materials and driving screws with ease. Whether you’re working on woodworking projects or construction sites, the high torque of brushless drills will come in handy.

4. Reduced Maintenance

Brushed drills require regular maintenance due to the wear and tear of brushes, which may need to be replaced periodically. On the other hand, brushless drills eliminate the need for brush replacements, significantly reducing maintenance requirements. This not only saves time and effort but also reduces the overall cost of owning and operating a brushless drill.

5. Smoother Operation

Brushless drills provide smoother and more consistent operation compared to brushed drills. The absence of brushes reduces the vibrations and noise associated with brushed motors, resulting in a quieter and more comfortable working environment. Additionally, the precise control of motor speed in brushless drills allows for smoother drilling and screwdriving, enhancing the overall user experience.

6. Increased Durability

Brushless drills are generally more durable compared to brushed drills. The absence of brushes eliminates the risk of brush wear and the associated decrease in performance over time. This makes brushless drills a reliable and long-lasting choice for both professional and DIY applications.

7. Advanced Features

Brushless drills often come with advanced features such as electronic control systems, variable speed settings, and intelligent power management. These features provide enhanced control, versatility, and safety during operation. Some brushless drills even offer built-in LED lights for improved visibility in dark or confined spaces.

8. Eco-Friendly

Brushless drills are more environmentally friendly compared to brushed drills. The reduction in energy loss and increased efficiency of brushless motors result in lower energy consumption. This not only saves money on electricity bills but also reduces the carbon footprint associated with power tool usage.

In conclusion, brushless drills offer numerous advantages over brushed drills, including increased efficiency, extended battery life, higher torque, reduced maintenance, smoother operation, increased durability, advanced features, and eco-friendly operation. These benefits make brushless drills a popular choice among professionals and DIY enthusiasts alike.

How Brushless Drills Work

Introduction

Brushless drills are a type of power tool that have become increasingly popular in recent years. Unlike traditional brushed drills, brushless drills operate without the use of brushes or commutators, resulting in improved efficiency and durability.

Brushless Motor

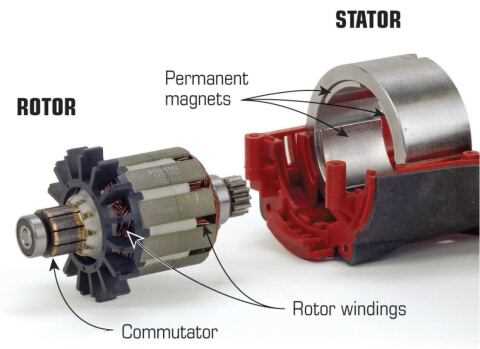

The key component of a brushless drill is its brushless motor. This motor consists of a rotor and stator, much like a traditional motor, but without the brushes. Instead, the rotor is made up of a series of permanent magnets, while the stator contains multiple windings. These windings are energized with electricity from the drill’s battery, creating a magnetic field that causes the rotor to rotate.

One of the main advantages of a brushless motor is that it operates with less friction and heat generation compared to a brushed motor. This leads to increased efficiency and longer motor life.

Sensor and Control System

In order to work efficiently, brushless drills rely on a sensor and control system. The sensor monitors the position and speed of the rotor and relays this information to the control system. The control system then adjusts the power supplied to the windings in order to optimize the motor’s performance.

This sensor and control system work together to provide a more precise and responsive motor, resulting in better power delivery and control during drilling tasks.

Benefits of Brushless Drills

There are several benefits to using a brushless drill:

- Increased Power: Brushless drills typically provide more power and torque compared to brushed drills of similar size.

- Longer Battery Life: The more efficient operation of brushless drills leads to less power wastage, resulting in longer battery life.

- Reduced Maintenance: Without brushes to wear out, brushless drills require less maintenance and have a longer lifespan.

- Improved Durability: The absence of brushes and commutators in brushless drills reduces the risk of component failure due to wear and tear.

Conclusion

Brushless drills represent a significant advancement in power tool technology. Their brushless motors and advanced control systems offer greater efficiency, durability, and power compared to traditional brushed drills. For professionals and DIY enthusiasts alike, brushless drills are a worthwhile investment.

Differences Between Brushed and Brushless Drills

When it comes to power tools, drills are one of the most commonly used. However, not all drills are created equal. Brushed and brushless drills are two different types of drills, each with their own advantages and disadvantages. Here are some key differences between the two:

Brushed Drills

- Design: Brushed drills have a motor that contains carbon brushes, which make contact with the commutator to transfer current and create the rotational force.

- Performance: Brushed drills are typically less efficient and generate more heat than brushless drills. They also tend to have a shorter lifespan due to the wear on the brushes.

- Noise and Vibration: Brushed drills can be noisier and produce more vibration compared to brushless drills.

- Price: Brushed drills are generally less expensive than their brushless counterparts.

Brushless Drills

- Design: Brushless drills have a motor that uses a sensor and a controller to determine how much current is needed, eliminating the need for brushes and commutators.

- Performance: Brushless drills are more efficient and generate less heat, resulting in better performance and longer tool life. They also provide more consistent power and torque throughout use.

- Noise and Vibration: Brushless drills are generally quieter and produce less vibration compared to brushed drills.

- Price: Brushless drills are typically more expensive than brushed drills due to the advanced technology involved.

Overall, the choice between a brushed and brushless drill depends on the specific needs and budget of the user. While brushed drills may be more affordable, brushless drills offer superior performance and durability. It’s important to consider the intended use and longevity of the drill before making a decision.

Applications of Brushless Drills

1. Construction and Carpentry

Brushless drills are widely used in construction and carpentry applications. Their high torque and power make them ideal for drilling into various materials, such as wood, metal, and concrete. They can be used for tasks such as drilling holes, driving screws, and fastening bolts.

2. Automotive and Mechanical Work

Brushless drills are also commonly used in automotive and mechanical applications. They provide the necessary power and precision for tasks such as drilling holes for bolts, removing and installing parts, and assembling components. Their compact size and versatility make them suitable for working in tight spaces.

3. Electrical and Plumbing

Brushless drills are valuable tools in electrical and plumbing work. They can be used for drilling holes for wires and pipes, as well as driving screws for fixtures and fittings. Their power and speed control allow for precise drilling and fastening in delicate electrical and plumbing installations.

4. DIY and Home Improvement

Brushless drills are popular among DIY enthusiasts and homeowners for various home improvement projects. From assembling furniture to hanging shelves and pictures, these drills provide the necessary power and control for a wide range of tasks. They are also suitable for drilling holes in walls, wood, and other surfaces for installation and repairs.

5. Manufacturing and Production

In manufacturing and production environments, brushless drills are often utilized for repetitive drilling and fastening operations. Their durability and high performance make them reliable tools for increasing productivity and efficiency in assembly lines and production processes.

Factors to Consider When Buying a Brushless Drill

1. Power and Performance

When purchasing a brushless drill, it is important to consider the power and performance of the tool. Look for a drill that offers high RPM (rotations per minute) and a high torque rating. This will ensure that the drill is capable of handling a wide range of tasks, from drilling holes to driving screws.

2. Battery Type and Capacity

Another important factor to consider is the type and capacity of the drill’s battery. Brushless drills are typically powered by lithium-ion batteries, which offer longer run times and faster charging compared to other battery types. Look for a drill with a high-capacity battery to ensure that you have enough power to complete your tasks.

3. Ergonomics and Comfort

When using a drill for extended periods of time, comfort is key. Look for a brushless drill that has a comfortable grip and ergonomic design. This will help reduce fatigue and strain on your hands and arms, allowing you to work more efficiently and comfortably.

4. Durability and Reliability

Investing in a high-quality brushless drill is essential. Look for a drill that is made from durable materials and has a reputation for reliability. You want a drill that can withstand regular use and handle tough tasks without breaking or malfunctioning.

5. Additional Features

Consider any additional features that may be useful to you. Some brushless drills come with built-in LED lights to illuminate your work area, while others may have a built-in level or adjustable clutch settings. Think about your specific needs and choose a drill that offers the features that will make your work easier.

6. Price

Lastly, consider your budget when buying a brushless drill. While it is important to invest in a high-quality tool, you don’t want to break the bank. Compare prices and features to find a drill that offers the best value for your money.

By considering these factors when buying a brushless drill, you can ensure that you choose a tool that meets your needs and provides reliable performance for years to come.

Tips for Using a Brushless Drill Safely

Using a brushless drill can make your DIY projects much easier and efficient. However, it’s important to use it safely to avoid accidents and injuries. Here are some tips to help you use a brushless drill safely:

1. Read the Manual

Before using a brushless drill, carefully read the instruction manual. Familiarize yourself with the drill’s features, capabilities, and safety precautions. Pay attention to any specific guidelines or warnings provided by the manufacturer.

2. Wear Protective Gear

Always wear appropriate protective gear when using a brushless drill. This may include safety glasses, ear protection, and gloves. Make sure your clothing is fitted and doesn’t have loose ends that could get caught in the drill.

3. Inspect the Drill

Before each use, inspect the brushless drill for any signs of damage or wear. Check the power cord, chuck, and battery (if applicable) for any issues. If you notice any problems, do not use the drill and have it repaired or replaced.

4. Secure the Workpiece

When using a brushless drill, always secure the workpiece properly. Use clamps or vise grips to secure the workpiece firmly in place. This will prevent it from moving or spinning, reducing the risk of accidents.

5. Use the Right Drill Bit

Ensure you are using the correct type and size of drill bit for the material you are working with. Using the wrong drill bit can result in damage to the material or the drill. Consult the manual or an expert if you are unsure about the appropriate drill bit for your project.

6. Maintain Control

When using a brushless drill, always maintain a firm grip on the handle and maintain control over the tool. Avoid applying excessive pressure or force, as this can cause the drill to kick back or slip. Use two hands when necessary, and be mindful of your body position and posture.

7. Avoid Overheating

Extended use of a brushless drill can cause it to overheat. To prevent overheating, avoid constantly running the drill at maximum speed for long periods of time. Take breaks to allow the drill to cool down and prevent potential damage to the motor.

8. Store Safely

After using a brushless drill, store it in a dry and secure place. Keep it out of the reach of children and pets to prevent accidents. Store the drill in a case or on a shelf to protect it from damage and dust.

By following these safety tips, you can use your brushless drill with confidence and minimize the risk of accidents or injuries.

FAQ:

What is a brushless drill?

A brushless drill is a type of power drill that does not use carbon brushes to transfer electricity to the motor. Instead, it uses electronic circuitry and magnets to create magnetic fields that drive the motor.

What are the advantages of a brushless drill?

One advantage of a brushless drill is that it has a longer lifespan compared to traditional brushed drills. Brushless motors also tend to be more efficient, which means they can provide more power and run for longer periods of time. Additionally, brushless drills are generally more compact and lightweight.

How does a brushless drill work?

A brushless drill works by using electronic sensors and magnets to create rotational motion. When electricity flows through the electronic circuitry, it creates a magnetic field that interacts with the magnets, causing the motor to spin. Unlike traditional drills, there are no carbon brushes in a brushless drill, which eliminates the friction and wear associated with them.

Are brushless drills more expensive than brushed drills?

Yes, brushless drills are typically more expensive than brushed drills. This is because the technology used in brushless drills is more advanced and requires more precise manufacturing. However, the longer lifespan and improved performance of brushless drills often make up for the higher initial cost.

Can I use brushless drill bits with a regular drill?

Yes, you can use brushless drill bits with a regular drill. The type of drill bit you use is not dependent on whether the drill is brushless or not. Brushless drills are compatible with all standard drill bits, so you can use them interchangeably.

Video: