What does a drill bit for metal look like

When it comes to drilling through metal, using the right drill bit is essential. Metal drill bits are specifically designed to cut through various types of metal, including steel, aluminum, and brass. These drill bits are constructed with materials that can withstand the high temperatures and pressures that are generated during the drilling process.

A typical metal drill bit has a cylindrical shape and a sharp, pointed tip. The tip is usually made of a hard material, such as tungsten carbide, which can easily penetrate through the metal surface. The body of the drill bit is usually made of high-speed steel or cobalt steel, which provides the required strength and durability.

Metal drill bits may also have special features to enhance their drilling performance. For example, some drill bits have flutes, or spiral grooves, along the body. These flutes help to remove the metal chips and debris from the hole, preventing clogging and ensuring a smooth drilling process. Other drill bits may have a coating, such as titanium nitride or black oxide, to reduce friction and increase the lifespan of the bit.

Overall, a drill bit for metal is designed to be strong, durable, and efficient. It should be able to penetrate through the metal surface easily, remove the chips effectively, and provide a clean and precise hole. By using the right drill bit for the job, you can ensure that your metal drilling tasks are completed efficiently and effectively.

The Appearance of Metal Drill Bits

Metal drill bits are designed specifically for drilling through various types of metal. They have a distinct appearance that sets them apart from drill bits used for other materials. Here are some key visual features of metal drill bits:

Color

Metal drill bits are typically silver or grey in color. This is due to the material they are made from, usually high-speed steel or cobalt. These materials are chosen for their durability and ability to withstand the heat generated during drilling.

Shank

The shank, or the portion of the drill bit that is inserted into the drill chuck, is usually cylindrical in shape. It is smooth and lacks any specialized features or coatings.

Flutes

Metal drill bits have flutes, which are the spiral or helical grooves that run along the length of the bit. These flutes help to remove chips and debris from the hole as the drill bit rotates. The number of flutes can vary depending on the size of the drill bit, with common options being two or four flutes.

Point Angle

The point angle of a metal drill bit refers to the angle formed by the cutting edges at the tip of the bit. It is typically between 118 and 135 degrees. The point angle affects the behavior and performance of the drill bit, with sharper angles being more suitable for softer metals, while larger angles are better for harder metals.

Coatings

Some metal drill bits may have specialized coatings to enhance their performance. These coatings can provide benefits such as increased hardness, improved lubricity, and reduced friction and heat. Common coatings include titanium nitride (TiN), titanium aluminum nitride (TiAlN), and black oxide.

Sizes

Metal drill bits are available in a wide range of sizes to accommodate different drilling needs. They can range from small diameters, such as 1/16 inch or 1.5 millimeters, to larger sizes like 1 inch or 25 millimeters. The size of the drill bit is typically marked on its shank.

- Silver or grey color

- Cylindrical shank

- Flutes for chip removal

- Point angle between 118 and 135 degrees

- Possible coatings for enhanced performance

- Available in a wide range of sizes

These visual features make metal drill bits easily distinguishable from drill bits used for other materials. By understanding the appearance of metal drill bits, users can easily identify and select the appropriate tool for their metal drilling tasks.

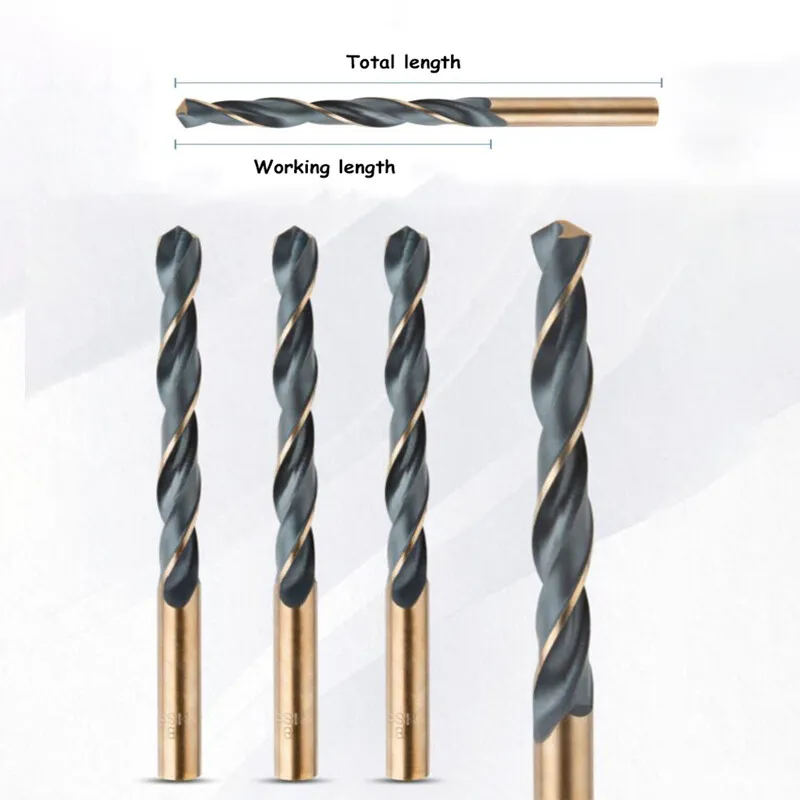

The Basic Structure

A drill bit for metal is specifically designed for drilling holes in metal surfaces. It has a basic structure that allows it to effectively penetrate and remove metal chips while minimizing heat buildup.

1. Shank

The shank is the part of the drill bit that is inserted into the drill chuck or collet. It is usually cylindrical in shape and can be held securely in the drill’s chuck for rotation.

2. Body

The body of the drill bit is the main portion that does the drilling. It typically has a cylindrical shape with flutes or grooves running along its length. These flutes help to remove the metal chips created during the drilling process, preventing them from clogging the hole and reducing heat buildup.

3. Point

The point of the drill bit is the sharpened tip that initiates the hole. It is typically shaped to have a chisel-like edge or a split point. This allows for easier penetration into the metal and helps to reduce the amount of force required during drilling.

4. Helix Angle

The helix angle refers to the angle at which the flutes are cut into the body of the drill bit. In drill bits for metal, a higher helix angle is often used to improve chip evacuation and reduce heat buildup. This angle helps to ensure smooth cutting and minimize the chance of the drill bit getting stuck in the hole.

5. Coating

Some drill bits for metal may come with a coating to improve their durability and performance. Common coatings include titanium nitride (TiN), titanium carbonitride (TiCN), and black oxide. These coatings provide increased hardness and reduce friction, allowing for faster drilling and longer bit life.

6. Size Markings

Drill bits for metal are typically labeled with size markings, which indicate the diameter of the bit. These markings can be in inches or millimeters and are helpful for selecting the appropriate drill bit for a specific drilling application.

It’s important to use the correct type and size of drill bit for metal to ensure accurate and efficient drilling. Additionally, using coolant or lubricant during the drilling process can help to prolong the life of the drill bit and improve drilling performance.

| Size (Inch) | Size (mm) |

|---|---|

| 1/16″ | 1.59 mm |

| 1/8″ | 3.18 mm |

| 3/16″ | 4.76 mm |

| 1/4″ | 6.35 mm |

| 5/16″ | 7.94 mm |

Material Composition

A drill bit for metal is typically made from a combination of different materials to ensure durability and efficiency during drilling operations. The materials used in the composition of a metal drill bit may vary depending on the specific application and the manufacturer’s preferences. Here are some common materials that are often used:

- High-Speed Steel (HSS): This is the most common material used in drill bits for metal. HSS drill bits are known for their high heat resistance and hardness, which allows them to cut through various types of metal without losing their sharpness.

- Cobalt: Cobalt drill bits are known for their superior strength and heat resistance. They are often used for drilling into hard metals such as stainless steel and cast iron.

- Carbide: Carbide drill bits are extremely hard and are great for drilling into materials like hardened steel and cast iron. They have a sharp cutting edge that stays sharp for a long time.

- Titanium: Titanium-coated drill bits are highly corrosion-resistant and can withstand high temperatures. This coating helps reduce the friction and heat generated during drilling, resulting in better performance and longer lifespan.

Some drill bits for metal may also have a combination of these materials, such as HSS drill bits with a titanium coating or carbide-tipped drill bits. The choice of material composition depends on factors such as the type of metal being drilled, the desired drilling speed, and the expected wear and tear.

| Material | Advantages | Disadvantages |

|---|---|---|

| High-Speed Steel (HSS) | Good heat resistance and hardness | May lose sharpness more quickly than other materials |

| Cobalt | Superior strength and heat resistance | Can be relatively expensive |

| Carbide | Extremely hard and stays sharp for a long time | Brittle and can be prone to chipping |

| Titanium | Corrosion-resistant and reduces friction | Coating may wear off over time |

Understanding the material composition of a drill bit for metal can help you choose the right tool for your specific drilling needs and ensure optimal performance and longevity.

Shank Types

Drill bits for metal can have different types of shanks, which are the sections of the bit that fit into the drill chuck. The shank type determines how the bit is secured in the drill and affects its stability and performance during drilling.

Straight Shank

- A straight shank is the most common type of shank used for drill bits for metal.

- It is cylindrical in shape with a constant diameter.

- The straight shank fits into the chuck of a drill or drill press and is secured by tightening the chuck.

- Straight shank drill bits are versatile and can be used with different types of drills.

Hex Shank

- A hex shank has a hexagonal shape, which allows for better grip and prevents the bit from slipping in the chuck.

- Hex shank drill bits are commonly used with impact drivers and high-torque drills.

- The hexagonal shape makes it easier to change the drill bit quickly.

SDS Shank

- SDS (Slotted Drive System) shank is a specialized shank used for heavy-duty applications.

- It has a slot in the shank that allows for quick and easy bit changes.

- SDS shank drill bits are commonly used in rotary hammers and hammer drills.

- They provide more stability and better power transfer compared to other shank types.

Morse Taper Shank

- Morse taper shank is a shank type used primarily for large metal drill bits and drill presses.

- The shank has a tapering shape that fits into the spindle of a drill press or other similar machines.

- Morse taper shank drill bits are held in place by tightening the spindle.

- This shank type provides excellent stability and precision for heavy-duty drilling.

Reduced Shank

- A reduced shank, also known as a “step” shank, has a larger diameter at the base and a smaller diameter near the tip.

- Reduced shank drill bits are used when drilling holes with larger diameters than the capacity of the drill’s chuck.

- The bit is inserted into the reduced shank, which then fits into the drill’s chuck.

- The reduced shank provides a secure fit and allows the drill to handle larger drill bits.

Quick-Change Shank

- The quick-change shank is a specialized shank that allows for rapid changes of drill bits.

- It has a built-in mechanism that allows the user to insert and release the bit without the need for tightening or loosening the chuck.

- Quick-change shanks are commonly used in combination with quick-change drill chucks or bit holders.

- They are particularly useful in applications where frequent bit changes are required.

Choosing the right shank type for your metal drill bit is important to ensure optimal performance and stability during drilling. Consider the type of drill and the specific application to select the most suitable shank type.

Flute Design

A flute is the spiral groove on the surface of a drill bit that allows for the removal of the material being drilled. In the case of a drill bit for metal, the flute design is crucial to ensure efficient and effective drilling.

Types of Flute Designs

There are several common flute designs for metal drill bits:

- Straight Flutes: These are the simplest flute design, with a straight groove running along the length of the bit. They are typically used for drilling soft metals like aluminum.

- Spiral Flutes: Spiral flutes have a helical groove that wraps around the bit. This design helps to improve chip evacuation, reducing the likelihood of clogging and overheating during drilling.

- Parabolic Flutes: Parabolic flutes have a deeper and wider groove compared to spiral flutes. This design allows for increased chip evacuation and faster drilling speeds, making them suitable for drilling harder metals.

- Axial Flutes: Axial flutes have a straight groove that runs parallel to the axis of the bit. This design is often used for drilling large-diameter holes in metal.

Choosing the Right Flute Design

When selecting a drill bit for metal, it’s important to consider the type of metal being drilled and the desired drilling speed:

- For soft metals like aluminum or brass, a drill bit with straight flutes or spiral flutes may be sufficient.

- For harder metals like steel or stainless steel, a drill bit with parabolic flutes or axial flutes may provide better performance.

- The flute design will also impact the drilling speed. Spiral and parabolic flutes generally offer faster drilling speeds compared to straight or axial flutes.

Maintaining Flute Design

Proper maintenance and care of metal drill bits are essential to ensure their longevity and performance:

- Regularly clean the flute grooves to remove any debris and prevent clogging.

- Use cutting fluid or lubricant when drilling metal to reduce heat and friction, which can cause damage to the drill bit.

- Inspect and replace drill bits with worn or damaged flutes to maintain optimal drilling performance.

By understanding the different flute designs and their applications, you can choose the right drill bit for metal and achieve efficient and accurate drilling results.

Point Angle

The point angle is an important feature of a drill bit for metal. It refers to the angle formed by the cutting edges at the tip of the bit. The point angle plays a crucial role in the drilling process as it determines the type of material the bit is best suited for and affects the chip formation and drilling efficiency.

There are different point angles available for metal drill bits, including 118 degrees, 135 degrees, and 142 degrees. The most common point angle used for drilling metal is 118 degrees, which is also referred to as a standard point angle. This angle is suitable for general-purpose drilling in various metals and alloys.

The 135-degree point angle, sometimes called a split point or self-centering point, is designed to reduce the tendency of the drill bit to wander or walk on the surface of the metal. This point angle is commonly used for harder metals or when precise positioning is required.

The 142-degree point angle is specifically designed for drilling hardened or tough metals, such as stainless steel or cast iron. This point angle provides improved cutting performance and chip evacuation, making it ideal for heavy-duty applications.

It is important to select the appropriate point angle based on the type of metal being drilled and the desired drilling application. Using the wrong point angle can result in poor performance or even damage to the bit or workpiece. Therefore, it is recommended to consult the manufacturer’s recommendations or seek professional advice to ensure the correct point angle is chosen for a specific drilling task.

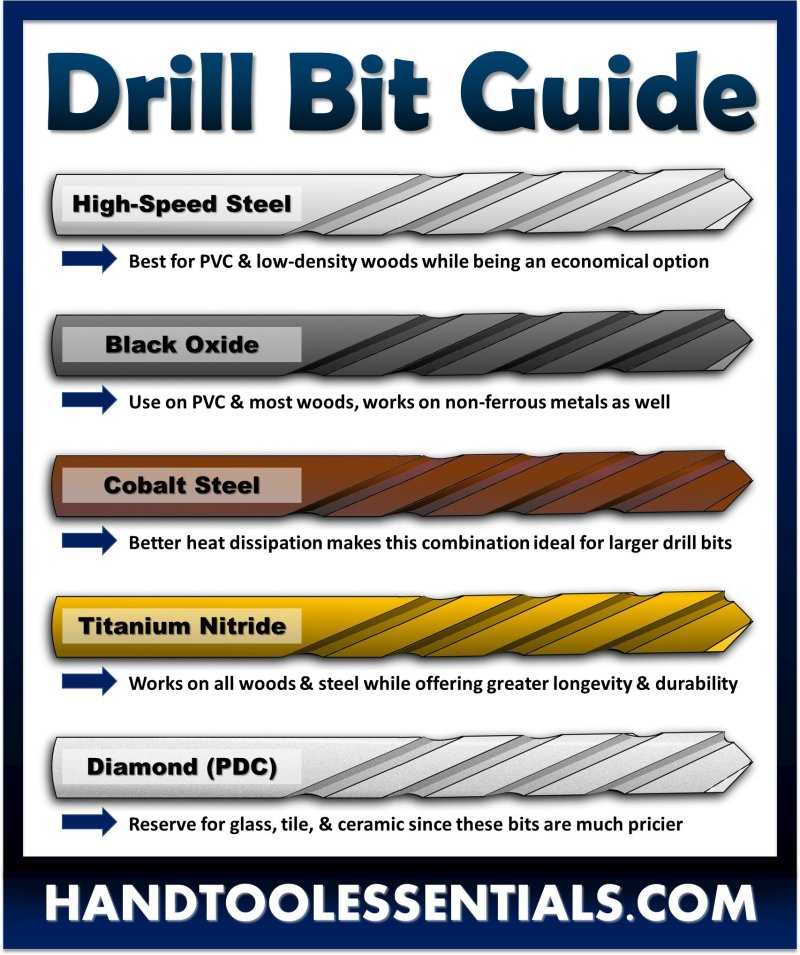

Coating Options

When it comes to drilling through metal, having the right coating on your drill bit can make a significant difference in both the speed and efficiency of your drilling. Different coatings offer various benefits, such as increased durability, higher cutting speeds, and improved chip evacuation. Here are some common coating options for drill bits used on metal:

Titanium Nitride (TiN) Coating

- Description: Titanium nitride coating is a popular choice due to its high resistance to wear and increased hardness. It has a gold color, which allows for easy identification.

- Benefits:

- Improved cutting speeds due to reduced friction.

- Enhanced corrosion resistance.

- Increased tool life.

- Reduced heat buildup during drilling operations.

Titanium Carbonitride (TiCN) Coating

- Description: Titanium carbonitride coating offers similar benefits to TiN coating but has an additional carbon component, which enhances its toughness and lubricity.

- Benefits:

- Increased durability and toughness.

- Improved resistance to high temperatures.

- Enhanced lubricity for smoother drilling operations.

- Excellent adhesion to the drill bit surface.

Cobalt Coating

- Description: Cobalt coating is a popular choice for drilling hard metals, as it offers superior hardness and heat resistance.

- Benefits:

- Higher cutting speeds and improved chip evacuation.

- Enhanced heat resistance, reducing the risk of overheating the drill bit.

- Increased tool life.

- Excellent wear resistance.

Black Oxide Coating

- Description: Black oxide coating is a cost-effective option that provides limited protection against wear and corrosion.

- Benefits:

- Affordable choice for general-purpose drilling applications.

- Improved lubricity for reduced friction.

- Aesthetically pleasing black finish.

- Reasonable resistance to corrosion.

High-Speed Steel (HSS) Coating

- Description: High-speed steel coating is a standard option for drill bits used on metal.

- Benefits:

- Affordable and widely available.

- Suitable for general-purpose drilling.

- Good resistance to wear.

- Can handle a wide range of metal materials.

Choosing the right coating option for your drill bit depends on the specific metal material you’re drilling into and the desired outcomes. Consider factors such as cutting speed, durability, heat resistance, and corrosion resistance when selecting the appropriate coating option.

Sizes and Diameters

Drill bits for metal come in a variety of sizes and diameters, allowing you to choose the best one for your specific project or application. Here are some common sizes and diameters you may come across:

- 1/16 inch: This is one of the smallest drill bit sizes for metal. It is commonly used for precise drilling and creating small holes.

- 1/8 inch: This size is slightly larger than 1/16 inch and is suitable for drilling small to medium-sized holes in metal.

- 1/4 inch: A 1/4 inch drill bit is considered a standard size for many metal drilling tasks. It is versatile and can be used for a wide range of applications.

- 3/8 inch: This drill bit size is larger and is ideal for drilling larger holes in metal.

- 1/2 inch: A 1/2 inch drill bit is quite large and is used for drilling large holes or creating larger openings in metal.

It’s important to choose the right drill bit size for your project to ensure accurate and efficient drilling. Depending on the size of hole you need and the thickness of the metal, you may need to consider using smaller or larger drill bits.

Additionally, there are also drill bits available in metric sizes, such as 3mm, 6mm, and 10mm, for those who prefer working with metric measurements.

Keep in mind that the material of the drill bit can also affect its performance and durability when drilling into metal. High-speed steel (HSS) and cobalt drill bits are commonly used for metal drilling due to their hardness and heat resistance.

| Size (inch) | Size (mm) |

|---|---|

| 1/16 | 1.59 |

| 1/8 | 3.18 |

| 1/4 | 6.35 |

| 3/8 | 9.53 |

| 1/2 | 12.70 |

These are just a few examples of the drill bit sizes and diameters available for metal. Make sure to choose the appropriate size based on your specific drilling needs to ensure the best results.

Common Uses

A drill bit for metal is designed to cut through various types of metal materials. It is commonly used in industries such as construction, metalworking, automotive, and fabrication. Here are some common uses of drill bits for metal:

1. Metal Fabrication

Drill bits for metal are extensively used in metal fabrication processes. They are used to create holes in metal sheets, plates, and other metal components. These holes are often required for joining metal pieces together, inserting screws or bolts, or for attaching accessories or fixtures to metal structures.

2. Machining

In machining processes, drill bits for metal are used to create holes in metal workpieces. These holes may be required for various purposes such as creating accurate dimensions, accommodating fasteners, or facilitating the flow of fluids or gases within the metal part.

3. Automotive Applications

Drill bits for metal are commonly used in the automotive industry for repairs, maintenance, and customization. They are used to drill holes in metal components such as engine parts, body panels, and suspension components. These holes may be required for repairs, modifications, or installation of additional components.

4. Construction

In the construction industry, drill bits for metal are used for various tasks such as installing electrical wiring, plumbing, or ventilation systems. These drill bits are used to create holes in metal beams, frames, or other structural components to accommodate these systems.

5. Metalworking and Jewelry Making

In metalworking and jewelry making, drill bits for metal are used to create holes in metal pieces for various design and functional purposes. They are essential tools for artisans and craftsmen working with metals. These drill bits are commonly used to create intricate patterns, shapes, or designs in metal pieces.

Overall, drill bits for metal have a wide range of applications in various industries and can be found in both professional and DIY settings. They are essential tools for any task that requires drilling through metal materials.

FAQ:

What is a drill bit for metal?

A drill bit for metal is a tool specifically designed for drilling through metal surfaces. It is made of a hard material, such as high-speed steel or cobalt, which allows it to cut through metal effectively and efficiently.

Do drill bits for metal look different than regular drill bits?

Yes, drill bits for metal do look different than regular drill bits. They are typically shorter and stouter in design, with a flatter tip and a more pronounced cutting edge. This design allows them to withstand the high heat and pressure generated while drilling through metal.

What are the different types of drill bits for metal?

There are several types of drill bits for metal, including twist drill bits, step drill bits, and hole saws. Twist drill bits are the most common type and can be used on various types of metal. Step drill bits are designed for drilling multiple-sized holes in metal, while hole saws are used for creating larger diameter holes.

Do I need a special drill to use a drill bit for metal?

No, you do not necessarily need a special drill to use a drill bit for metal. However, it is recommended to use a drill with a variable speed setting and a high torque motor. This will provide better control and prevent the drill bit from overheating while drilling through metal.

Video: