What Are Forstner Drill Bits Used For?

Forstner drill bits are specialized cutting tools that are used in woodworking and carpentry. They are designed to create clean and precise holes in wood, and are particularly useful for drilling large diameter holes, flat-bottomed holes, and overlapping holes. These drill bits are named after Benjamin Forstner, the Austrian inventor who patented them in the mid-19th century.

One of the main advantages of using Forstner drill bits is their ability to create flat-bottomed holes. Unlike regular twist drill bits, which have a pointed tip and leave a conical-shaped hole, Forstner bits have a flat circular cutting edge that allows for a clean and level bottom. This makes them ideal for applications such as installing hinges, creating mortises for joinery, and drilling pocket holes for screws.

Another advantage of Forstner drill bits is their ability to cut overlapping holes. Since they have a cylindrical cutting edge, they can be used to create holes that partially or fully overlap with each other. This is particularly useful for tasks such as creating decorative patterns, making flutes or channels, and forming recesses for inlays or inserts.

Forstner drill bits come in a variety of sizes, typically ranging from 1/4-inch to 2 inches in diameter. They are commonly used in woodworking projects such as cabinetry, furniture making, and joinery. When using Forstner drill bits, it is important to use them with a drill press or a handheld drill with a low speed setting, as their design requires a relatively low rotational speed to achieve optimal results.

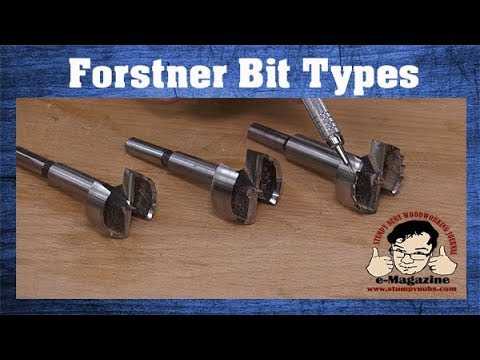

What are Forstner drill bits?

A Forstner drill bit is a type of woodworking tool that is used to create clean, flat-bottomed holes in various materials, including wood, plastic, and some metals. These drill bits are named after Benjamin Forstner, the inventor who patented the design in the mid-19th century.

Forstner drill bits are distinguishable by their design, which consists of a cylindrical body with a center point, a pair of cutting edges, and often a circular-shaped web or rim around the edges. This unique design allows for precise drilling and cutting of clean, flat-bottomed holes without splintering or tearing the material.

How do Forstner drill bits work?

When using a Forstner drill bit, the center point is placed on the desired drilling location, and the bit is rotated at a low speed. The cutting edges slice away the material, while the web or rim creates a smooth and flat bottom in the hole. The cylindrical body of the bit helps to guide and stabilize the drilling process.

Forstner drill bits can be used in both handheld drills and drill presses, depending on the size and type of project. They are commonly used in woodworking applications, such as creating recessed holes for hinges and hardware, drilling holes for dowels, and making decorative details like flutes and indentations.

Advantages of using Forstner drill bits

Forstner drill bits offer several advantages over other types of drill bits, including:

- Clean and precise holes: The sharp cutting edges and flat-bottomed design of Forstner drill bits result in clean and precise holes without splintering or tearout.

- Ability to drill overlapping holes: The flat-bottomed design of Forstner drill bits allows for drilling overlapping holes without creating a large hole at the intersection, making them ideal for creating mortises and other joinery techniques.

- Wide range of sizes: Forstner drill bits come in a wide range of sizes, allowing for versatility in hole diameter and depth.

- Can be resharpened: Forstner drill bits can be resharpened, extending their lifespan and providing cost savings over time.

Overall, Forstner drill bits are a valuable tool for woodworkers and other craftsmen who require precise and clean drilling operations. Their unique design and functionality make them an essential part of any workshop arsenal.

Advantages of Forstner drill bits

- Precision: Forstner drill bits are known for their exceptional precision. They can create clean and accurate holes with smooth edges, which is crucial for woodworking projects that require precise measurements.

- Versatility: Forstner drill bits are versatile tools that can be used for a wide range of applications. They can drill flat-bottomed holes, partial holes, angled holes, overlapping holes, or holes with unusual sizes and shapes. This versatility makes them suitable for various woodworking projects, such as creating mortises, drilling holes for dowels, or making pocket holes.

- Clean finish: One of the major advantages of using Forstner drill bits is the clean finish they provide. Since they create flat-bottomed holes without tearing the wood fibers, the end result is a smooth and professional-looking hole. This is particularly important when working with visible surfaces or when joining pieces of wood together with dowels.

- Reduced splintering: Forstner drill bits are designed with a sharp center point and peripheral cutting edges that slice through the wood rather than simply boring a hole. This unique design reduces splintering and tear-out, resulting in cleaner holes with minimal damage to the surrounding wood.

- Efficiency: Forstner drill bits are efficient when compared to other drilling tools. They often require less force and effort to operate, thanks to their design and cutting geometry. This efficiency helps reduce user fatigue and allows for faster drilling, making them a popular choice among woodworkers.

- Multiple materials: Forstner drill bits can be used on a variety of materials, including wood, plastic, and certain types of metal. This versatility allows woodworkers to use the same drill bit for different projects and materials, making them a valuable addition to any toolbox.

- Durable: Forstner drill bits are typically made from high-quality materials, such as high-speed steel or carbide. These materials enhance their durability and longevity, ensuring they can withstand the rigors of drilling on a regular basis. With proper maintenance and care, Forstner drill bits can last for a long time, making them a cost-effective choice in the long run.

Types of materials suitable for Forstner drill bits

Forstner drill bits are versatile tools that can be used to drill holes in a variety of materials. The unique design of Forstner bits allows them to drill clean, precise holes with minimal tear-out. Here are some of the materials that Forstner drill bits are commonly used for:

1. Wood:

Forstner drill bits are particularly well-suited for drilling holes in wood. They can create flat-bottomed holes with smooth sides, making them ideal for tasks such as creating recesses for hinges or drilling holes for dowels.

2. Plywood:

Forstner bits can also be used to drill holes in plywood. The clean holes they produce make them perfect for tasks like installing cabinet hardware or creating custom joinery in plywood projects.

3. MDF:

Medium-density fiberboard (MDF) is another material that Forstner bits can handle effectively. The sharp center point of the bit helps to prevent the bit from wandering or “walking” on the surface, ensuring accurate hole placement.

4. Laminates:

Forstner bits are suitable for drilling holes in laminated materials such as countertops or tabletops. The precise cutting action of the bit helps to avoid chipping or splintering the laminate surface.

5. Soft Metals:

While Forstner bits are primarily designed for drilling in wood, they can also be used for soft metals like aluminum or brass. However, caution should be exercised when drilling metals, as excessive heat can damage the bit or the material being drilled.

Overall, Forstner drill bits are designed to provide clean and precise holes in a variety of materials, making them a versatile tool for woodworking and other applications.

Applications of Forstner drill bits

Forstner drill bits are versatile tools that can be used for a wide range of applications. Here are some common uses:

- Woodworking: Forstner drill bits are commonly used in woodworking projects. They are ideal for creating clean, flat-bottomed holes with a smooth finish. These bits are often used for drilling holes for dowels, hinges, and other hardware.

- Cabinetmaking: Forstner drill bits are frequently used in cabinetmaking to create holes for hinges, shelf pins, and handles. They produce clean, precise holes that are necessary for ensuring a professional finish.

- Door and window installation: Forstner drill bits are useful for drilling holes for the installation of door locks and window hardware. These bits can create a hole with a flat bottom, which is essential for proper installation and operation of locks and hardware.

- Router table use: Forstner drill bits can be used with a router table to create unique decorative inlays and mortises. These bits are capable of producing precise, clean holes with flush sides, making them ideal for intricate woodworking designs.

- Woodturning: Forstner drill bits can be used in woodturning projects to create recesses for inlays or to create holes for projects like salt and pepper shakers. The clean, precise holes produced by Forstner bits are perfect for these types of projects.

Overall, Forstner drill bits are a valuable tool for any woodworker or craftsman. They provide accuracy, precision, and versatility, making them a must-have for various applications.

How to use Forstner drill bits

Forstner drill bits are specialized cutting tools used in woodworking to create clean, flat-bottomed holes with smooth sides. Here is a step-by-step guide on how to properly use Forstner drill bits:

- Choose the right size: Forstner drill bits come in various sizes, so it’s important to select the appropriate one for your project. Consider the size of the hole you need to create and choose a Forstner bit that matches that diameter.

- Secure the workpiece: Before drilling, make sure your workpiece is securely clamped or held down to prevent it from moving. This will ensure accuracy and safety during drilling.

- Mark the drilling location: Use a pencil or marker to clearly mark the center point of the hole you want to create. This will serve as a guide for positioning the Forstner bit.

- Position the Forstner bit: Place the Forstner bit in the drill chuck and tighten it securely. Position the tip of the bit over the marked center point on the workpiece.

- Adjust the drilling depth: Most Forstner bits have an adjustable depth stop or a set screw that allows you to control the drilling depth. Adjust the depth according to your requirements and tighten the depth stop or set screw.

- Start drilling: Activate the drill and apply gentle pressure to the workpiece. Start drilling slowly to prevent any tear-out or splintering. Keep the drill aligned with the marked center point and apply steady and even pressure.

- Clear away the chips: As you continue drilling, periodically lift the drill out of the hole to clear away the wood chips and dust. This will ensure smooth drilling and prevent the bit from getting clogged.

- Complete the drilling: Continue drilling until you reach the desired depth. Once the drilling is complete, release the trigger and wait for the bit to stop spinning completely before removing it from the drilled hole.

- Clean the hole: After drilling, use a brush or compressed air to remove any remaining wood chips and dust from the drilled hole. This will help create a clean and precise finish.

- Inspect the hole: Once the hole is clean, inspect it to ensure it meets your desired specifications. If necessary, make any adjustments or refinements to achieve the desired result.

By following these steps, you can effectively and safely use Forstner drill bits to create precise and clean holes in your woodworking projects.

Tips for using Forstner drill bits

- Choose the right size: Before using a Forstner drill bit, it’s important to choose the right size for your project. Forstner drill bits come in various sizes, so make sure to select one that matches the diameter you need.

- Secure your workpiece: To prevent the workpiece from moving while drilling, secure it firmly using clamps or a vise. This will ensure clean and accurate holes.

- Mark the center: Before drilling, mark the center of the hole on the workpiece. This will help you accurately position the Forstner bit and ensure that the hole is drilled in the desired location.

- Use a drill press: Forstner drill bits work best when used with a drill press. A drill press provides stability and precision, making it easier to control the drilling depth and produce clean holes.

- Control the speed: When using a Forstner drill bit, it’s important to control the speed of the drill. High speeds can cause the bit to overheat and burn the wood, while low speeds can result in poor cutting performance. Find the right speed based on the type of material you’re drilling into.

- Apply consistent pressure: Apply steady and consistent pressure while drilling. This will help the Forstner bit cut smoothly and prevent it from getting stuck or causing splintering.

- Clear the chips: Clear the wood chips regularly to prevent them from clogging the hole and affecting the drilling performance. Use a brush or compressed air to remove the chips as you drill.

- Practice on scrap wood: If you’re new to using Forstner drill bits, it’s a good idea to practice on a scrap piece of wood before working on your actual project. This will help you get a feel for the tool and improve your technique.

- Maintain the bit: After each use, clean the Forstner drill bit to remove any wood residue. You can use a brush or a cloth to clean the cutting edges. Additionally, keep the bit sharp by sharpening it as needed.

Maintenance and care of Forstner drill bits

Proper maintenance and care of Forstner drill bits is essential to ensure their longevity and optimal performance. Here are some tips to help you take care of your Forstner drill bits:

Clean the drill bits after use

- After each use, it is important to clean the drill bits to remove any debris or buildup that may have accumulated during drilling. Use a stiff brush or a toothbrush to scrub away any dirt or dust.

- Forstner drill bits often have a small centering spur that needs to be cleaned as well. Make sure to remove any wood chips or other materials that may be stuck to the centering spur.

Inspect the drill bits regularly

- Regularly inspect the cutting edges of the Forstner drill bits for any signs of damage or dullness. Look for chips, cracks, or excessive wear on the cutting edges.

- If you notice any damage or dullness, it is important to address it promptly. Dull drill bits can affect the quality of your drilling and increase the risk of accidents. Damaged drill bits should be replaced.

Store the drill bits properly

- When not in use, store your Forstner drill bits in a clean and dry place. Avoid storing them in damp or humid environments, as this can cause rust and corrosion.

- Consider using a drill bit organizer or case to keep your Forstner drill bits organized and protected from damage. This will also make it easier to find the drill bit you need for a specific project.

Sharpen the drill bits when necessary

- Over time, Forstner drill bits can become dull and less effective. When this happens, it is important to sharpen them to restore their cutting performance.

- There are various methods for sharpening Forstner drill bits, including using a bench grinder or a sharpening stone. Follow the manufacturer’s instructions or seek professional advice if you are unsure how to sharpen your drill bits.

By following these maintenance and care tips, you can prolong the lifespan of your Forstner drill bits and ensure that they remain sharp and efficient for all your woodworking projects.

FAQ:

What are the main uses for Forstner drill bits?

Forstner drill bits are primarily used to create flat-bottomed holes in wood. They are often used in furniture making, cabinetry, and other woodworking projects where precise and clean holes are required.

Are Forstner drill bits suitable for drilling through other materials besides wood?

While Forstner drill bits are specifically designed for use on wood, they can also be used on other materials such as plastic and some soft metals. However, they may not be the best choice for harder materials like steel.

Can Forstner drill bits be used with hand drills or are they only for use with drill presses?

Forstner drill bits can be used with both hand drills and drill presses. However, they tend to work best when used with a drill press because the stationary nature of the press allows for more precise control and stability.

What sizes do Forstner drill bits come in?

Forstner drill bits come in a variety of sizes, ranging from as small as 1/4 inch to as large as 2 1/2 inches in diameter. The size you choose will depend on the specific project and hole size you need.

How do Forstner drill bits create flat-bottomed holes?

Forstner drill bits have a unique design that includes a center pilot point and circular cutting edges. As the bit spins, the cutting edges slice through the wood, while the center point helps guide the bit and keep it centered. This combination of features allows the bit to create a clean, flat-bottomed hole.

Can Forstner drill bits be resharpened if they become dull?

Yes, Forstner drill bits can be resharpened if they become dull. However, it is important to note that resharpening Forstner bits requires specific equipment and skills. It is often more cost-effective and convenient to simply replace a dull bit with a new one.

Video: