Understanding the Quill: What is it and How Does it Work on a Drill Press

The quill is a crucial component of a drill press, a tool used for drilling holes in various materials with precision and accuracy. Understanding how the quill operates is essential for anyone using a drill press, as it enables them to maximize its potential and achieve the desired results.

The quill, also known as the spindle or chuck, is located at the front of the drill press and is responsible for holding and rotating the drill bit. It is connected to the motor of the drill press, which provides the power for the drilling operation. The quill can be raised or lowered to adjust the depth of the hole being drilled, allowing for precise control over the drilling process.

One of the key features of the quill is its ability to move vertically. This movement is controlled by a lever or handle located on the side of the drill press. By adjusting this handle, the user can raise or lower the quill to the desired position. This is particularly useful when drilling holes of different depths, as it allows for accurate and consistent drilling.

In addition to its vertical movement, the quill can also rotate. This rotation is essential for drilling into various materials with different hardness levels. By rotating the quill, the user can ensure that the drill bit cuts through the material effectively, without causing damage or producing poor results.

Overall, the quill is a vital component of a drill press, allowing for precise and controlled drilling operations. By understanding how the quill operates and how to adjust its movement and rotation, users can optimize their drilling experience and achieve professional-level results.

Understanding the Quill: A Comprehensive Guide

Introduction

The quill is an important component of a drill press, also known as a drilling machine. It plays a crucial role in the drilling process and allows for precision and accuracy when drilling holes in various materials. This comprehensive guide will provide an in-depth understanding of the quill, its functions, and how it works.

What is the Quill?

The quill is a vertical spindle that holds the drill chuck and rotates to perform the drilling operation. It is connected to the drill press’s motor by a series of gears and belts, which rotates the quill at different speeds.

Components of the Quill

The quill consists of several important components:

- Drill Chuck: The drill chuck is attached to the lower end of the quill and holds the drill bit securely.

- Feed Handles: The quill is operated using feed handles that are connected to a feed mechanism. These handles allow the user to lower or raise the quill to control the drilling depth.

- Spindle: The spindle is the upper part of the quill that connects to the drill press’s motor. It transfers power from the motor to the quill, allowing it to rotate.

- Depth Stop: Some drill presses have a depth stop feature that can be adjusted to limit the quill’s travel, ensuring consistent drilling depths.

How Does the Quill Work?

The quill is controlled by the user through the feed handles. To drill a hole, the user adjusts the depth stop, if available, to the desired depth. The drill bit is then inserted into the drill chuck, and the quill is lowered until the drill bit touches the material. As the user applies pressure on the feed handles, the quill rotates, causing the drill bit to penetrate the material and create a hole.

Advantages of the Quill

The quill provides several advantages when using a drill press:

- Accuracy: The quill’s vertical movement and precise depth control allow for accurate drilling and consistent hole depths.

- Versatility: Different drill bits can be easily attached to the quill’s chuck, allowing for drilling holes of various sizes and materials.

- Safety: The quill’s design ensures that the drill bit remains stable during the drilling process, reducing the risk of accidents and injuries.

- Ease of Use: The feed handles provide ease of use and control, allowing for smooth and precise drilling operations.

Conclusion

The quill is a fundamental component of a drill press that enables precise and accurate drilling operations. Understanding its functions and how it works is essential for maximizing the drill press’s capabilities and achieving optimal results in various drilling applications.

References

- Smith, John. (2020). The Complete Guide to Drill Presses. Publisher.

- Doe, Jane. (2018). Mastering the Art of Drilling: A Comprehensive Manual. Publisher.

The Basics of a Quill

When working with a drill press, it’s important to understand the various components that make up the machine. One key component is the quill, also known as the spindle or chuck.

What is a Quill?

A quill is a cylindrical metal component that is housed within the drill press head. It is responsible for holding the drill bit in place and allowing it to move up and down during operation. The quill is attached to a motor that drives it and provides the necessary power for drilling.

How Does a Quill Work?

At the top of the quill, there is a chuck that holds the drill bit securely in place. The chuck can typically be tightened or loosened using a key or a keyless mechanism. The quill is connected to a spindle, which is driven by the motor. When the motor is activated, it spins the spindle, which in turn rotates the chuck and the attached drill bit.

One key feature of a quill is its ability to move up and down. This is achieved through a rack and pinion mechanism or a spline shaft. By adjusting the depth stop and the quill feed, operators can control the precise depth of the drill hole.

Advantages of a Quill

The quill offers several advantages when working with a drill press:

- Precision: The quill allows for precise control over the depth of the drill hole, resulting in accurate and consistent drilling.

- Versatility: The quill can accommodate a variety of drill bits, allowing for a wide range of drilling applications.

- Efficiency: By allowing the drill bit to move up and down, the quill enables faster and more efficient drilling.

Conclusion

The quill is a vital component of a drill press and plays a crucial role in its functionality. Understanding the basics of a quill, how it works, and its advantages can help you achieve better results and more efficient drilling with your drill press.

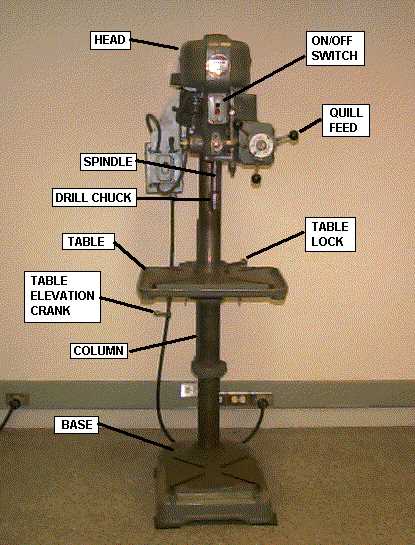

Exploring the Functionality of a Drill Press

What is a Drill Press?

A drill press is a powerful tool that is used to create holes in various materials such as wood, metal, and plastic. It consists of a powerful motor that rotates a drill bit at high speeds, allowing for precise and controlled drilling operations. The drill press also features a stable platform, known as the worktable, and a mechanism for adjusting the height and angle of the drill bit.

How Does a Drill Press Work?

At the heart of a drill press is the motor, which provides the rotational power to the drill bit. The drill bit is securely attached to the chuck, which is located at the end of the motor’s shaft. When the motor is turned on, it rotates the drill bit at high speeds.

To operate the drill press, the user positions the material to be drilled on the worktable and adjusts the height and angle of the drill bit as needed. The user then lowers the drill bit towards the material using the feed handle. The feed handle is connected to a system of gears that controls the movement of the drill bit.

As the drill bit comes into contact with the material, it quickly and efficiently creates a hole. The user can control the speed at which the drill bit penetrates the material by adjusting the feed handle. Once the desired depth is reached, the user raises the drill bit and removes the material from the worktable.

Key Features and Functions

- Adjustable Table: The drill press features a worktable that can be adjusted both in height and angle. This allows for precise drilling on different surfaces and angles.

- Depth Stop: A depth stop mechanism allows the user to set the drilling depth. This is useful when drilling holes that need to be of consistent depth.

- Speed Settings: Drill presses typically have multiple speed settings, which can be adjusted based on the material being drilled. Higher speeds are used for softer materials, while lower speeds are used for harder materials.

- Clamping Mechanism: To ensure stability and accuracy, many drill presses have a clamping mechanism that securely holds the material in place during drilling.

- Laser Guide: Some drill presses include a laser guide that projects a beam onto the workpiece, helping to precisely position the drill bit.

Benefits and Applications

The drill press offers several benefits over handheld drills. Firstly, it provides greater stability and accuracy, thanks to the stationary worktable and adjustable depth control. The ability to set and maintain a consistent drilling depth is particularly useful in woodworking and cabinetry, where precision is crucial.

Drill presses find applications in various fields such as woodworking, metalworking, electrical work, and construction. They are commonly used for tasks such as creating holes for furniture assembly, installing door hinges, drilling precise holes for wiring, and many more.

Conclusion

The drill press is a versatile and powerful tool that allows for precise drilling operations in a variety of materials. With its adjustable table, depth control, and stable platform, it provides greater accuracy and stability compared to handheld drills. Whether you’re a DIY enthusiast or a professional tradesperson, the drill press is an essential tool that should be in every workshop.

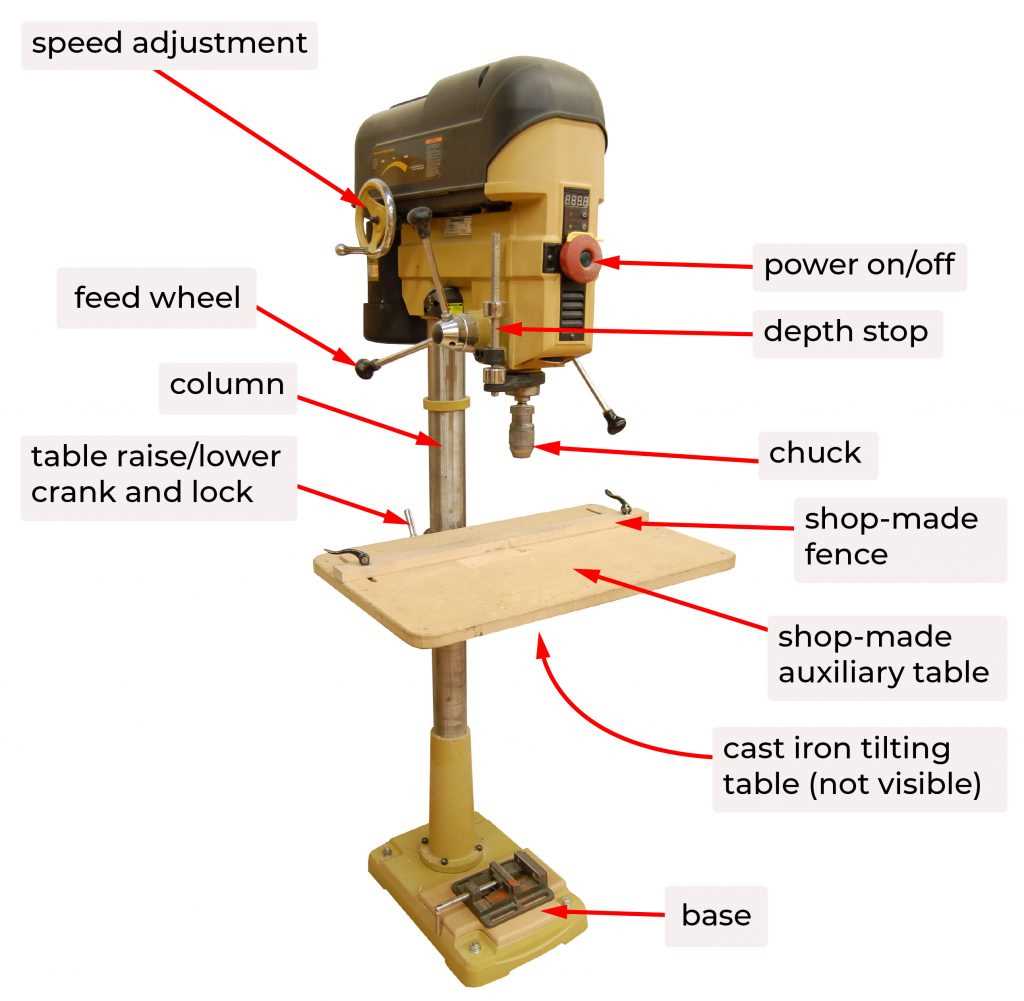

Working Mechanism of a Drill Press Quill

The quill is an essential component of a drill press that enables the drilling operation. It is a vertically moving spindle that holds the drill bit and moves up and down to drill holes in various materials.

Components of a Drill Press Quill

The quill consists of several key components that work together to facilitate the drilling process:

- Quill Housing: The quill housing is the main body of the quill and is attached to the drill press. It provides support and stability to the quill assembly.

- Spindle: The spindle is the rotating shaft that holds the drill bit. It is connected to the quill housing and moves vertically within it.

- Rack and Pinion: The rack and pinion mechanism is responsible for the vertical movement of the spindle. The rack is attached to the spindle, while the pinion is connected to a handle or lever. When the handle is turned, it rotates the pinion, which in turn moves the rack, causing the spindle to move up or down.

- Quill Lock: The quill lock is a locking mechanism that fixes the quill in position. When engaged, it prevents the quill from moving vertically and holds it steady during drilling.

Operation of a Drill Press Quill

When using a drill press, the quill is adjusted to the desired drilling depth using the rack and pinion mechanism. The depth can be set by aligning the depth gauge on the quill housing with the desired marking on the drill press column.

Once the depth is set, the quill lock is engaged to secure the quill at the desired position. This ensures that the drill bit will only penetrate the material up to the set depth.

When the drill press is turned on, the quill remains stationary while the spindle rotates at high speed. The user then lowers the material onto the drill bit, which cuts through the material to create a hole. The depth of the hole is controlled by the set depth on the quill.

Advantages of a Drill Press Quill

The presence of a quill in a drill press offers several advantages:

- Precision: The quill allows for precise control of drilling depth, resulting in accurate and consistent hole depths.

- Stability: The quill lock holds the quill in place, providing stability and minimizing movement during drilling, reducing the chances of errors or accidents.

- Ease of Use: The rack and pinion mechanism makes it easy to adjust the quill to the desired drilling depth, allowing for efficient and effortless drilling operations.

In conclusion, the quill is a crucial component of a drill press that enables the drilling operation. Its working mechanism, consisting of the quill housing, spindle, rack and pinion, and quill lock, allows for precise and stable drilling operations, ensuring accurate and consistent hole depths.

The Importance of the Quill in Drill Press Operations

The quill is a vital component of a drill press that plays a crucial role in the drilling process. It is a vertical shaft or rod that holds the drill bit and enables it to move up and down. Understanding the importance of the quill and how it works is essential for anyone operating a drill press.

1. Height Adjustment

The quill allows for height adjustment, which is necessary when drilling holes of different depths. By adjusting the quill, the user can control how deep the drill bit goes into the material being drilled. This feature is especially crucial when working with delicate materials or when precision is required.

2. Precision Drilling

The quill’s ability to move up and down with precision ensures accurate drilling. This is particularly important when drilling holes that need to be aligned or when creating holes with specific diameters. The user can set the desired depth and control the drilling process accordingly, resulting in precise and consistent holes.

3. Safety

The quill provides an additional layer of safety during drilling operations. It holds the drill bit securely, preventing it from slipping or wobbling during drilling. This reduces the risk of accidents and injuries that could occur if the drill bit were to become dislodged or lose its stability.

4. Efficient Chip Removal

While drilling, chips or debris are generated as the drill bit cuts through the material. The quill’s design often includes flutes or grooves that help facilitate the removal of chips. These flutes allow the chips to escape, preventing them from clogging the hole or causing damage to the drill bit or material being drilled.

5. Support and Stability

The quill provides support and stability to the drill bit, ensuring more accurate drilling. It minimizes vibrations and movement, allowing the drill bit to remain steady while cutting through the material. This stability contributes to improved drilling performance and the overall quality of the drilled holes.

Overall, the quill is an essential part of the drill press, providing height adjustment, precision drilling, safety, efficient chip removal, and support. Understanding its importance and how it functions enables operators to maximize the performance and capabilities of the drill press.

Understanding the Components of a Quill

Introduction

A quill is an essential component of a drill press that allows for precise vertical movement of the drill bit. It is responsible for controlling the depth of the holes being drilled. Understanding the different components of a quill is crucial for properly utilizing a drill press.

Main Components

The main components of a quill are as follows:

- Quill Housing: The quill housing is a cylindrical metal casing that houses the other components of the quill. It acts as a protective cover and provides stability to the quill.

- Spindle: The spindle is the inner part of the quill that holds the drill bit. It connects the drill bit to the drill press motor and enables rotation.

- Feed Handle: The feed handle is a lever or knob that is used to manually control the vertical movement of the quill. Turning the feed handle in one direction raises the quill, while turning it in the opposite direction lowers it.

- Depth Stop: The depth stop is an adjustable component that limits the maximum depth to which the quill can descend. It allows for the precise control of drilling depth, ensuring consistent and accurate holes.

- Locking Mechanism: The locking mechanism is used to securely hold the quill in place at a specific height. It prevents accidental movement during operation, providing stability and accuracy.

Optional Components

In addition to the main components, some drill press quills may include optional components for additional functionality and convenience. These may include:

- Scale or Depth Gauge: A scale or depth gauge is a measuring tool attached to the quill housing. It provides an indication of the depth of the drill bit relative to the workpiece, aiding in precise drilling.

- Laser Guide: A laser guide is a small laser module attached to the quill housing. It emits a beam of light that helps align the drill bit accurately with the desired drilling location.

- Coolant System: Some drill press quills may have a coolant system that sprays a coolant or lubricant onto the drill bit during operation. This helps to reduce heat and friction, prolonging the life of the drill bit and improving drilling performance.

Conclusion

Understanding the components of a quill is essential for utilizing a drill press effectively. By knowing how each component works and interacts with the others, operators can ensure accurate and precise drilling operations. Whether it’s the main components or the optional ones, each part plays a crucial role in the functionality and versatility of a drill press quill.

How to Properly Maintain Your Drill Press Quill

1. Clean and Lubricate Regularly

One of the most important aspects of maintaining your drill press quill is to clean and lubricate it regularly. This will help prevent dirt, debris, and rust from building up and affecting the performance of the quill.

Start by wiping down the outside of the quill with a clean cloth to remove any dust or dirt. Then, use a small brush or toothbrush to clean the interior of the quill. Be sure to reach all the way to the bottom to remove any debris that may have accumulated.

Once the quill is clean, apply a thin layer of lubricant to the exterior and the interior. This will help reduce friction during operation and prevent rust from forming. Be sure to use a lubricant that is compatible with your specific drill press model.

2. Check for Wear and Damage

Regularly inspect the quill for any signs of wear or damage. Look for any cracks, chips, or deformations that may affect its performance. Additionally, check the quill’s alignment to ensure it is straight and centered.

If you notice any wear or damage, it is important to address it promptly. Depending on the severity of the issue, you may need to replace the quill or have it repaired by a professional.

3. Adjust the Quill Depth Stop

The quill depth stop allows you to set the depth of your drilling operation. Over time, the depth stop may become loose or misaligned, affecting its accuracy.

To ensure it is properly maintained, regularly check the quill depth stop for any issues. If it is loose, tighten the set screws or bolts as necessary. If it is misaligned, adjust it using the appropriate adjustment mechanisms according to your drill press manual.

4. Keep the Quill and Chuck Clean

In addition to cleaning the quill, it is important to keep the chuck clean as well. The chuck is the mechanism that holds the drill bits in place and it can accumulate dust, debris, and rust over time.

Periodically remove the chuck from the quill and clean it thoroughly. Use a small brush or toothbrush to remove any dirt or debris. If there is rust, you can use a rust remover or a rust-resistant lubricant to clean it. Be sure to wipe it dry before reattaching it to the quill.

5. Follow Manufacturer’s Recommendations

Lastly, it is important to follow the manufacturer’s recommendations for maintaining your drill press quill. Different models may have specific maintenance requirements, so it is important to refer to your drill press manual for guidance.

Pay attention to any recommended lubricants, cleaning techniques, and inspection procedures specified by the manufacturer. This will help ensure that your drill press quill remains in optimal condition for years to come.

Tips and Tricks for Efficiently Using Quill on a Drill Press

1. Choose the right drill bit

Before using the quill on a drill press, it is important to select the appropriate drill bit for the task at hand. Consider factors such as the material you are drilling into and the desired hole size. Using the wrong drill bit can result in inefficient drilling and potential damage to the workpiece.

2. Adjust the speed and feed rate

When using the quill on a drill press, it is crucial to adjust the speed and feed rate according to the requirements of the material being drilled. Harder materials may require lower speeds and slower feed rates, while softer materials can tolerate higher speeds and faster feed rates. Paying attention to these settings will ensure more efficient drilling and prevent overheating or breaking of the drill bit.

3. Secure the workpiece properly

Before starting any drilling operation, make sure the workpiece is securely clamped or held firmly in place. This will prevent any movement or slipping of the workpiece during drilling, ensuring accurate and efficient drilling. Improperly secured workpieces can lead to misalignment, irregular holes, or even accidents.

4. Use cutting fluid or lubricant

Using cutting fluid or lubricant while drilling can greatly improve the efficiency and quality of the drilling operation. It helps to reduce friction, heat, and tool wear, resulting in smoother and faster drilling. Apply the cutting fluid or lubricant directly to the drill bit and the workpiece, following the manufacturer’s instructions.

5. Clear away chips and debris

During drilling, chips and debris can accumulate around the drill bit and the workpiece, reducing the efficiency of the drilling operation. Periodically stop drilling and clear away the chips to maintain optimal drilling performance. Use a brush or compressed air to remove the chips from the work area.

6. Pay attention to depth control

When using the quill on a drill press, it is important to set the depth stop or adjust the quill travel to the desired drilling depth. This will ensure consistent hole depths and prevent drilling too deep, which can damage the workpiece or the drill bit. Test the drilling depth on a scrap piece of material before drilling into the final workpiece.

7. Maintain the drill press and quill

Regular maintenance of the drill press and quill is essential for efficient and safe operation. Keep the quill clean and free from debris, and lubricate any moving parts according to the manufacturer’s instructions. Additionally, periodically check for any wear or damage to the quill assembly and replace any worn-out parts to ensure optimal performance.

8. Practice proper safety precautions

Finally, always prioritize safety when using the quill on a drill press. Wear appropriate personal protective equipment, such as safety glasses, gloves, and hearing protection. Keep long hair and loose clothing secured to prevent entanglement. Familiarize yourself with the drill press’s safety features and follow all safety instructions provided by the manufacturer.

By following these tips and tricks, you can efficiently and safely utilize the quill on a drill press, ensuring precise and accurate drilling results.

Common Issues and Troubleshooting with Drill Press Quills

1. Quill Stuck or Difficult to Move

If you encounter a problem where the quill of your drill press is stuck or difficult to move, there are a few potential causes and solutions:

- Check for debris or dust: Clean the quill and remove any debris or dust that may be causing friction and hindering its movement.

- Lubrication: Apply a suitable lubricant to the quill to reduce friction and allow for smoother movement.

- Alignment: Check the alignment of the quill and its components. Misalignment can cause binding and make it difficult to move. Adjust and realign if necessary.

- Worn parts: Inspect the quill and its components for signs of wear and tear. Replace any worn parts that may be causing the issue.

2. Quill Wobbles or Vibrates during Operation

If your drill press quill wobbles or vibrates excessively while in use, try the following troubleshooting steps:

- Tighten bolts and screws: Check all the bolts and screws that hold the quill and its components in place. Tighten any that may be loose, as vibrations can be caused by insufficient tightening.

- Check spindle and chuck: Inspect the spindle and chuck for any damage or wear. A damaged or worn spindle can cause the quill to wobble. Replace any faulty components if necessary.

- Check for bent quill: Examine the quill itself for any signs of bending or damage. A bent quill can cause vibrations. If it is bent, replace it with a new one.

- Uneven work surface: Ensure that the work surface is flat and level. An uneven surface can cause the quill to wobble. Use shims or adjust the surface if needed.

3. Quill Does Not Return to its Original Position

If the quill does not automatically return to its original position after drilling, consider the following troubleshooting tips:

- Check return spring: Inspect the return spring for any damage or tension issues. Replace the spring if it is broken or worn out.

- Grease or lubricate return mechanism: Apply grease or a suitable lubricant to the return mechanism to ensure smooth operation. Lack of lubrication can cause the quill to stick or not return properly.

- Adjust return tension: Depending on your drill press model, you may be able to adjust the tension of the return spring. Consult the manual or manufacturer for instructions on how to adjust the tension if needed.

4. Quill Runout

Quill runout refers to the amount of movement or wobble in the quill itself. If you notice excessive quill runout, consider the following steps to troubleshoot the issue:

- Check chuck and spindle: Inspect the chuck and spindle for any damage or wear that may contribute to the quill runout. Replace any faulty parts if necessary.

- Tighten chuck: Ensure that the chuck is securely tightened onto the spindle. A loose chuck can cause runout. Use a chuck key to tighten it properly.

- Balance the quill: If the quill is out of balance, it can cause runout. Balance the quill by adding weights to the opposite side of the heavy spot until it runs smoothly.

5. Quill Depth Measurement Inaccuracy

If you are experiencing inaccuracies in quill depth measurement, try the following troubleshooting steps:

- Check for debris: Ensure that there is no debris or chips blocking the depth gauge or interfering with the quill depth measurement.

- Calibrate depth gauge: If the depth gauge is adjustable, calibrate it according to the manufacturer’s instructions to ensure accurate measurements.

- Inspect depth stop: Check the depth stop mechanism for any damage or misalignment. Adjust or replace it if necessary.

- Use a depth gauge rod: To ensure precise depth measurement, consider using a depth gauge rod instead of relying solely on the built-in depth gauge.

| Issue | Troubleshooting Tips |

|---|---|

| Quill Stuck or Difficult to Move | Check for debris or dust, lubricate, check alignment, inspect for worn parts |

| Quill Wobbles or Vibrates during Operation | Tighten bolts and screws, check spindle and chuck, examine for a bent quill, ensure even work surface |

| Quill Does Not Return to its Original Position | Check return spring, grease or lubricate return mechanism, adjust return tension |

| Quill Runout | Check chuck and spindle, tighten chuck, balance the quill |

| Quill Depth Measurement Inaccuracy | Check for debris, calibrate depth gauge, inspect depth stop, use a depth gauge rod |

FAQ:

What is a quill on a drill press?

The quill is a tubular metal rod that holds the drill chuck and allows it to move up and down vertically.

How does the quill work on a drill press?

The quill is connected to a feed lever that allows the user to control the depth of the drill bit. When the lever is lowered, the quill moves down and the drill bit makes contact with the material being drilled. When the lever is raised, the quill moves up, retracting the drill bit from the material.

What is the purpose of the quill on a drill press?

The quill allows for precise vertical drilling by controlling the depth of the drill bit. It gives the user the ability to drill holes to a specific depth without the risk of drilling too deep or damaging the material being drilled.

Can the quill be adjusted on a drill press?

Yes, the quill can be adjusted on a drill press. Most drill presses have a depth stop feature that allows the user to set a specific depth for drilling. This can be useful when drilling multiple holes to the same depth.

Is the quill interchangeable on drill presses?

The quill is not usually interchangeable on drill presses. It is a fixed component of the drill press design and is not meant to be removed or replaced. However, some drill presses may have adjustable quills that can be repositioned to accommodate different sizes of drill bits.

Video: