Understanding the Mechanics of a Drill Press

A drill press is a versatile and essential tool for any workshop or garage. It allows you to drill precise holes in various materials with ease. Understanding the mechanics of a drill press is important for maximizing its potential and ensuring safe and efficient use.

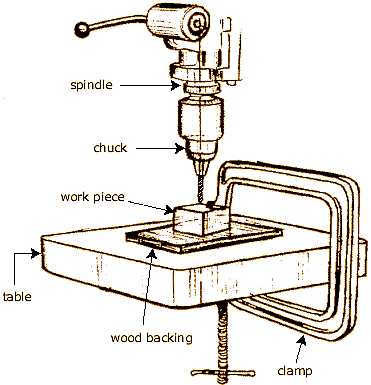

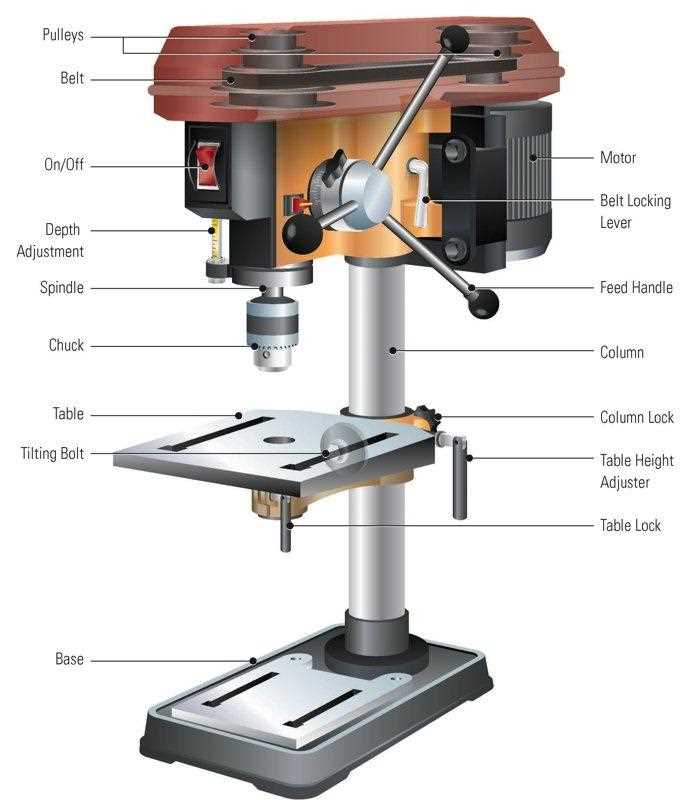

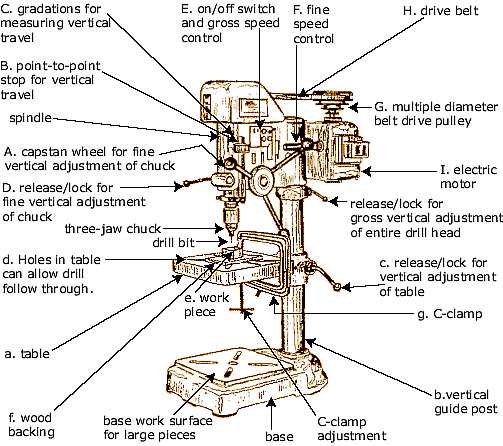

The core components of a drill press include the base, column, table, spindle, and chuck. The base provides stability and support, while the column houses the motor and allows for vertical movement. The table can be adjusted up and down, as well as tilted to accommodate different drilling angles. The spindle holds the drill bit and rotates at high speeds, while the chuck securely fastens the drill bit in place.

One of the key features of a drill press is its ability to control the drilling depth. This is achieved through the use of a depth stop, which can be adjusted to limit how far the drill bit penetrates the material. Some drill presses also have a depth gauge, which provides a visual indication of the drilling depth.

Another important aspect of a drill press is its speed. Most drill presses have multiple speed settings, allowing you to choose the appropriate speed for the material and drill bit being used. Higher speeds are typically used for drilling through metal, while lower speeds are better suited for woodworking and softer materials.

When operating a drill press, it is important to follow all safety precautions and wear protective gear, such as safety goggles and ear protection. Always secure the workpiece firmly in place and make sure the drill bit is properly aligned before beginning drilling. Additionally, make sure to clean and maintain your drill press regularly to prolong its lifespan and ensure optimal performance.

What is a Drill Press and How Does it Work?

A drill press is a tool that is used to make holes in different materials, such as wood, metal, or plastic. It is typically mounted on a stand or a workbench and consists of a drill head, a spindle, a table, and a motor.

Components of a Drill Press

- Drill Head: The drill head contains the motor, which powers the drilling action. It also houses the spindle and the chuck.

- Spindle: The spindle is the rotating shaft that holds the drill bit and transfers the rotational motion to it.

- Chuck: The chuck is a specialized clamp that holds the drill bit securely in place. It allows for easy installation and removal of drill bits.

- Table: The table is a flat, adjustable surface where the workpiece is placed to support it during drilling. It can be adjusted in height, angle, and position to accommodate different sizes and shapes of materials.

- Motor: The motor provides the power required to rotate the spindle and drill through the material being worked on.

Working Principle

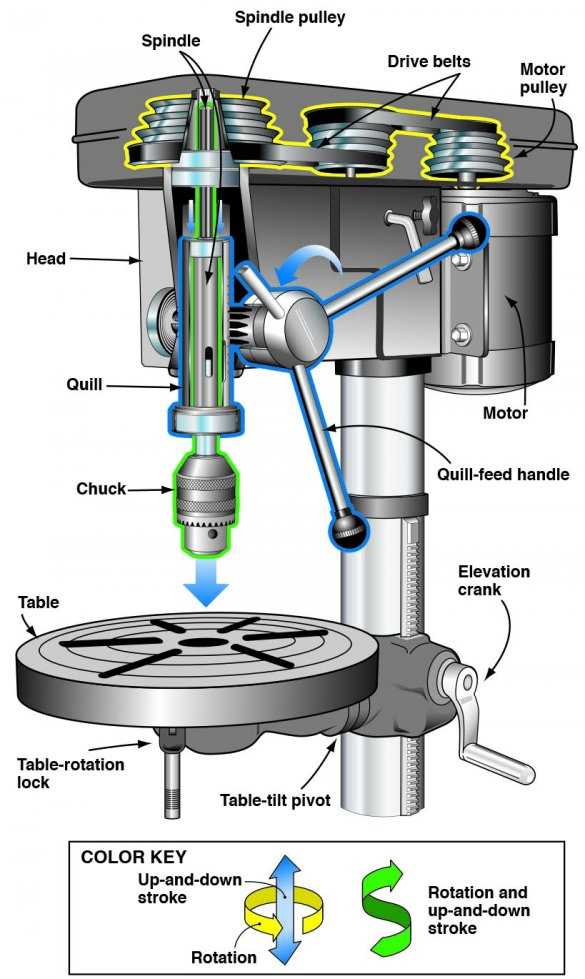

When the drill press is switched on, the motor starts rotating the spindle. The operator selects the desired drill bit and installs it securely into the chuck. The workpiece is then positioned on the table and aligned with the drill bit.

As the operator lowers the drill bit towards the workpiece, the rotation of the spindle causes the drill bit to penetrate the material. The downward force applied by the operator determines the depth of the hole.

Drill presses often have variable speed settings to accommodate different materials and drill bit sizes. The speed can be adjusted using a speed control knob or lever, which alters the motor’s RPM (rotations per minute).

Advantages of Using a Drill Press

- Accuracy: The drill press allows for precise and accurate drilling, thanks to its stable and stationary design.

- Consistency: The drill press ensures consistent hole depths and angles, resulting in uniform workpieces.

- Safety: With its built-in safety features, such as adjustable depth stops and clamps, the drill press minimizes the risk of accidents and injuries.

- Versatility: Drill presses can be used for various applications, including drilling, sanding, or even mortising.

Overall, a drill press is a valuable tool in any workshop or fabrication setting. Its ability to perform precise and reliable drilling operations makes it an essential piece of equipment for both professionals and hobbyists alike.

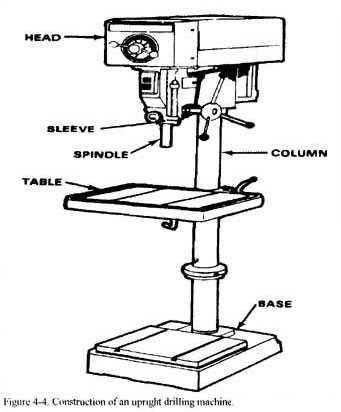

Understanding the Basic Components

The Base

The base is the bottom part of the drill press that provides stability and support for the entire machine. It is usually made of heavy cast iron or steel to ensure stability and minimize vibrations during operation.

The Column

The column is a vertical post that connects the base to the head of the drill press. It provides the necessary support and stability for the drilling operation. The height of the column can be adjusted to accommodate different workpieces or drilling needs.

The Head

The head is the upper part of the drill press that houses the motor and the spindle assembly. It is connected to the column and can be moved up and down to adjust the drilling depth. The head also contains the control panel for operating the drill press.

The Table

The table is the flat surface where the workpiece is placed during drilling. It is attached to the column and can be adjusted in various directions to accommodate different drilling angles and positions. The table usually has slots or holes to allow clamping or securing the workpiece in place.

The Spindle

The spindle is the rotating shaft that holds the drill bit. It is located in the head of the drill press and is driven by the motor. The spindle rotates at a high speed to allow for efficient drilling. It can be equipped with different types and sizes of drill bits to accommodate various drilling needs.

The Feed Handles

The feed handles are used to control the movement of the spindle and the drilling process. There are usually two feed handles: one for moving the spindle up and down (quill feed) and another for moving the table in different directions (table feed). These handles allow for precise control over the drilling depth and position.

The Depth Stop

The depth stop is a mechanism that allows the operator to set a specific drilling depth. It helps ensure consistent and accurate drilling by preventing the spindle from going beyond the desired depth. The depth stop can be adjusted and locked in place to control the drilling depth.

The Speed Control

The speed control allows the operator to adjust the rotational speed of the spindle. Different types of materials and drill bits require different speeds for optimal drilling. The speed control on a drill press can be adjusted using pulleys, belts, or a digital control panel, depending on the model.

The Emergency Stop

The emergency stop is a safety feature that immediately stops all machine operations in case of an emergency or accident. It is usually a large red button located on the control panel or close to the operator. Pressing the emergency stop button shuts off the power supply to the drill press to prevent any further damage or injury.

The Workpiece Clamp

The workpiece clamp is a device used to secure the workpiece to the table during drilling. It helps prevent the workpiece from moving or vibrating during the drilling process, ensuring accurate and safe drilling. The workpiece clamp can be adjusted and tightened to accommodate different sizes and shapes of workpieces.

Types of Drill Presses Available

There are several types of drill presses available on the market today, each designed for specific applications and needs. Here is a brief overview of some of the most common types:

Benchtop Drill Press

A benchtop drill press is a compact and portable option that can be conveniently placed on a workbench. It is typically used for light to medium-duty drilling tasks and is suitable for hobbyists and DIY enthusiasts.

Floor Drill Press

A floor drill press is a larger and more powerful option that is designed for heavy-duty drilling tasks. It is mounted on a sturdy stand or pedestal and is commonly used in professional workshops or industrial settings.

Magnetic Drill Press

A magnetic drill press, also known as a mag drill, is specifically designed for drilling through metal. It uses a powerful magnet to secure the drill press to the workpiece, allowing for precise drilling in vertical, horizontal, or angled positions.

Radial Arm Drill Press

A radial arm drill press features a long, adjustable arm that is attached to a column. This design allows for greater flexibility and reach, making it ideal for drilling holes in large workpieces or in hard-to-reach areas.

Mini Drill Press

A mini drill press is a small and compact option that is perfect for delicate and intricate drilling tasks. It is commonly used in jewelry making, model building, and other precision-based applications.

Variable Speed Drill Press

A variable speed drill press allows the user to adjust the speed of the drill bit rotation. This feature is essential for different drilling materials and applications, as it ensures optimal performance and prevents damage to the workpiece.

Drill Press with Laser Guide

Some drill presses come equipped with a laser guide, which projects a beam of light onto the workpiece to provide enhanced accuracy and precision. This is especially useful for drilling precise holes or aligning multiple holes.

Drill Press with Digital Display

A drill press with a digital display allows the user to monitor and adjust the drilling speed, depth, and other settings more accurately. This feature is particularly beneficial for professionals and those working on complex projects.

When selecting a drill press, it is important to consider the specific requirements of your drilling tasks, as well as your budget and workspace limitations. There are many reputable brands and models available, so be sure to do your research and choose a drill press that best suits your needs.

Choosing the Right Size and Power

When selecting a drill press, it is important to consider the size and power of the machine. These factors will determine the types of projects you can tackle and the efficiency of your work. Here are some key points to consider when choosing the right size and power for your drill press:

1. Size:

The size of a drill press refers to the distance between the drill bit and the support column. This measurement is known as the throat depth. It determines the maximum size of workpiece that can be accommodated by the drill press. For example, a drill press with a throat depth of 12 inches can accommodate a workpiece that is 12 inches away from the support column.

Consider the types of projects you will be working on and the size of the materials you will be drilling. If you primarily work with small to medium-sized materials, a drill press with a throat depth of 8-12 inches should be sufficient. However, if you frequently work with larger materials, you may need a drill press with a larger throat depth.

2. Power:

The power of a drill press is determined by its motor size and horsepower (HP). Higher horsepower drill presses can handle tougher materials and larger drill bits. They also tend to have higher spindle speeds, which can increase drilling efficiency.

If you primarily work with soft materials like wood or plastic, a drill press with 1/2 HP should be sufficient. However, if you work with harder materials like metal or regularly use large drill bits, you may want to consider a drill press with a higher horsepower.

It is also important to pay attention to the spindle speeds available on a drill press. Higher spindle speeds are better suited for drilling smaller holes or using smaller drill bits, while lower speeds are better for drilling larger holes or working with larger bits.

3. Additional Features:

In addition to size and power, there are other features to consider when choosing a drill press. Some drill presses come with adjustable tables, depth stops, laser guides, and other features that can enhance your drilling experience. Consider what additional features are important to you and your projects.

By considering the size, power, and additional features of a drill press, you can ensure that you choose the right machine for your needs. Whether you are a hobbyist or a professional, selecting the right drill press will improve the precision and efficiency of your drilling operations.

Drill Press Accessories and Attachments

A drill press is a versatile tool that can be used for a variety of tasks. However, with the right accessories and attachments, it can become even more useful. Here are some common accessories and attachments that can enhance the capabilities of a drill press:

1. Drill Press Vise

A drill press vise is a clamping device that is used to secure the workpiece in place while drilling. It provides stability and prevents the workpiece from moving or spinning during the drilling process. A vise is essential when working with heavy or bulky materials that cannot be held by hand.

2. Drill Bits

Drill bits are the cutting tools that are used to create holes in different materials. While most drill presses come with a standard set of drill bits, additional drill bits of various sizes and types can be purchased separately. These include twist drill bits, spade bits, hole saws, and Forstner bits, among others.

3. Drill Press Table

A drill press table is an accessory that provides a larger and more stable work surface than the built-in table of a drill press. It usually features T-slots or clamp rails for attaching and securing workpieces, as well as adjustable fences for accurate and repeatable drilling. Some drill press tables also have built-in measuring scales and guides.

4. Depth Stop

A depth stop is an attachment that allows the user to set a specific drilling depth. It helps achieve consistent and precise hole depths, which is especially useful when drilling holes to a certain depth or when working on projects that require uniform hole depths.

5. Drum Sander Attachment

A drum sander attachment is used to sand curved or irregular-shaped workpieces. It consists of a sanding drum that is mounted on the drill press. The drum spins as the drill press is turned on, allowing for controlled and efficient sanding. This attachment is commonly used in woodworking projects.

6. Mortising Attachment

A mortising attachment is used to create square or rectangular mortises, which are commonly used in woodworking joinery. It typically includes a chisel and a fence that guides the chisel to create precise cuts. The mortising attachment is mounted on the drill press and is operated by lowering the quill.

7. Laser Guide

A laser guide is a helpful accessory that projects a laser beam onto the workpiece, indicating the exact point where the drill bit will make contact. It provides visual guidance and helps align the workpiece for accurate drilling. Laser guides are particularly useful when drilling precise holes or when working with small or delicate materials.

8. Sanding Drum Kit

A sanding drum kit includes a variety of drum sizes and grits for sanding applications. The drum is attached to the drill press and spins as the drill press is turned on, allowing for controlled and efficient sanding. Sanding drum kits are commonly used for smoothing edges, shaping curves, and removing excess material.

9. Dust Collection System

A dust collection system is an accessory that helps remove dust and debris generated during the drilling process. It is particularly useful when working with materials that produce a large amount of dust, such as wood or metal. A dust collection system helps keep the work area clean and protects the user from inhaling harmful particles.

10. Circle Cutting Jig

A circle cutting jig is an accessory that enables the user to cut perfect circles of various sizes with a drill press. It is typically used in woodworking and metalworking projects. The jig consists of an adjustable pivot point and a guide system that allows precise control over the radius of the circle being cut.

These are just a few examples of the many accessories and attachments available for a drill press. The right accessories can greatly expand the capabilities of a drill press and make it a more versatile and efficient tool for various applications.

Drill Bit Selection and Maintenance

Factors to Consider When Choosing a Drill Bit

- Material: Different drill bits are designed to work with specific materials. For example, wood drill bits have a different design compared to metal drill bits.

- Size: The size of the hole you need to drill will determine the size of the drill bit you should choose. Drill bits are available in various sizes, typically measured in inches or millimeters.

- Drill Speed: Depending on the type of material you’re working with, the drill speed should be adjusted accordingly. Some drill bits are designed for high-speed drills, while others work better with slower speeds.

- Drill Type: There are different types of drill bits available, such as twist bits, spade bits, and hole saws. The type of drill bit you choose depends on the specific task and material.

Maintaining Drill Bits

To ensure optimal performance and longevity, it’s important to properly maintain and care for your drill bits. Here are some maintenance tips:

- Clean Regularly: After each use, clean the drill bits to remove any debris or material buildup. This can be done using a brush or compressed air.

- Sharpen When Dull: Over time, drill bits can become dull, leading to inefficient drilling. Sharpening the bits using a sharpening tool will help restore their sharpness.

- Store Properly: When not in use, store drill bits in a clean and dry place to prevent rusting or damage.

- Replace when Necessary: If a drill bit is damaged or worn out beyond repair, it’s important to replace it with a new one. Using worn-out drill bits can result in poor performance and potential accidents.

Drill Bit Types

| Drill Bit Type | Application |

|---|---|

| Twist Bits | General purpose drilling in wood, plastic, and metal |

| Spade Bits | Rapid drilling larger holes in wood |

| Forstner Bits | Clean, flat-bottomed holes in wood |

| Hole Saws | Cutting large-diameter holes in wood and metal |

| Step Bits | Drilling holes with different diameter sizes |

Proper Safety Measures

1. Protective Gear

When operating a drill press, it is important to always wear the appropriate protective gear to prevent any potential injuries. This includes safety goggles to protect your eyes from flying debris, and ear protection to prevent hearing damage from the loud noise generated by the machine.

2. Machine Inspection

Prior to using a drill press, it is essential to inspect the machine for any signs of damage or wear. This includes checking the power cord, ensuring it is not frayed or damaged, and inspecting the drill bit to make sure it is in good condition without any cracks or chips.

3. Secure Workpiece

Before starting the drilling process, always ensure that the workpiece is securely clamped or held in place. This prevents the workpiece from moving or spinning during drilling, which can cause accidents or damage to the drill press.

4. Adjust Speed and Depth

Depending on the material being drilled, it is important to adjust the speed and depth settings of the drill press accordingly. This prevents overheating or excessive pressure on the drill bit, reducing the risk of it breaking or getting stuck in the workpiece.

5. Keep Hands Away

Never place your hands near the drill bit or the moving parts of the drill press while it is operating. Always keep a safe distance and use appropriate tools or clamps to hold the workpiece in place.

6. Disconnect Power

After completing the drilling process, always disconnect the power source and wait for the machine to come to a complete stop before removing the workpiece or making any adjustments. This prevents accidental starts or injuries during handling.

7. Clean and Maintain

Regularly clean and maintain your drill press to ensure it is in proper working condition. This includes removing any dust or debris, lubricating the moving parts, and checking for loose or worn-out components. Proper maintenance helps prevent malfunctions and prolongs the lifespan of the machine.

8. Training and Supervision

If you are new to using a drill press, it is important to undergo proper training and supervision by an experienced individual. This helps familiarize you with the machine’s operation and safety procedures, reducing the risk of accidents or misuse.

By following these proper safety measures, you can ensure a safe and productive experience when using a drill press.

Common Applications and Uses

- The drill press is commonly used in woodworking projects, such as drilling holes for dowels or screws in furniture and cabinets.

- It is also widely used in metalworking applications, for tasks like drilling precision holes in metal sheets or creating threaded holes for bolts and screws.

- In the construction industry, the drill press is used for drilling holes in concrete, brick, and other masonry materials.

- Many DIY enthusiasts and hobbyists use the drill press for various projects, such as creating holes for arts and crafts, or drilling holes in plastic materials for model-making.

- The drill press is particularly useful for tasks that require high precision and accuracy, thanks to its ability to hold the workpiece firmly and its adjustable depth stop.

- It is often employed in metal fabricating shops for drilling holes in metal frames, pipes, and other components.

- When equipped with special drill bits, the drill press can be used for tasks like sanding, buffing, and polishing.

- With the appropriate attachments, the drill press can be used for tapping threads, mortising, and even milling operations.

In summary, the drill press is a versatile tool that finds applications in various industries and projects, thanks to its ability to provide precise and accurate drilling operations. Whether you are a professional craftsman or a DIY enthusiast, the drill press is an essential tool that can greatly simplify your drilling tasks and improve the quality of your work.

Tips and Tricks for Efficient Drilling

1. Choose the Right Drill Bit

Choosing the right drill bit is crucial for efficient drilling. Different materials require different types of drill bits. For example, wood drill bits are designed to cut through wood fibers, while masonry bits are designed for drilling in brick or concrete. Using the wrong type of drill bit can result in poor performance and potentially damage both the drill bit and the material being drilled.

2. Secure Your Workpiece

Before starting drilling, make sure your workpiece is securely clamped or held in place. This will prevent the workpiece from moving or spinning during drilling, ensuring more accurate and efficient drilling. You can use clamps or a vise to hold the workpiece in place.

3. Mark Your Drilling Depth

When drilling holes, it can be helpful to mark the drilling depth on the drill bit. This can be done using a piece of tape wrapped around the drill bit at the desired depth. By doing this, you can easily see when you’ve reached the desired depth during drilling, preventing over-drilling and ensuring consistent hole depths.

4. Use Cutting Fluid for Metal Drilling

If you’re drilling through metal, using a cutting fluid can greatly improve the efficiency of the drilling process. Cutting fluids act as lubricants, reducing friction and heat buildup during drilling. This can reduce wear on the drill bit and improve cutting performance. Make sure to use a cutting fluid that is compatible with the type of metal you’re drilling.

5. Start with a Pilot Hole

For larger or deeper holes, it’s often a good idea to start with a pilot hole. A pilot hole is a smaller hole that acts as a guide for the larger drill bit. By starting with a pilot hole, you can ensure more accurate drilling and reduce the risk of the drill bit wandering off target.

6. Use Proper Speed and Pressure

When drilling, it’s important to use the proper speed and pressure. Using too much pressure can overheat the drill bit and cause it to wear out more quickly. On the other hand, using too little pressure can result in slow and inefficient drilling. Experiment with different speeds and pressures to find the optimal combination for the material being drilled.

7. Clear Chips and Dust

Regularly clearing chips and dust from the drilling area can help maintain efficient drilling. Accumulated chips and dust can clog the flutes of the drill bit, reducing its cutting ability. Use a brush or compressed air to remove chips and dust from the hole and the workpiece surface.

8. Take Breaks for Cooling

If you’re drilling for an extended period of time, it’s important to take breaks to allow the drill bit to cool down. Continuous drilling can cause the drill bit to overheat, leading to reduced performance and potentially damaging the bit. If you notice the drill bit getting hot to the touch, stop drilling and let it cool down before continuing.

By following these tips and tricks, you can ensure efficient drilling and achieve precise and accurate results with your drill press.

FAQ:

What is a drill press?

A drill press is a machine tool used for drilling holes in various materials such as wood, metal, or plastic. It consists of a base, column, spindle, and a worktable.

How does a drill press work?

A drill press works by using a rotating cutting tool called a drill bit to create a hole in a workpiece. The drill bit is mounted on the spindle, which is driven by a motor. The workpiece is clamped to the worktable, and the operator lowers the drill bit into the material using a handle or control lever.

What are the advantages of using a drill press?

There are several advantages of using a drill press. Firstly, it provides more precise and accurate drilling compared to handheld drills. It also allows for the drilling of large and deep holes with ease. Additionally, a drill press provides better control and stability, reducing the risk of accidents.

What are the different types of drill presses?

There are several types of drill presses available, including benchtop drill presses, floor-standing drill presses, magnetic drill presses, and radial drill presses. Benchtop drill presses are smaller and more portable, while floor-standing drill presses are larger and more powerful.

What safety precautions should I take when using a drill press?

When using a drill press, it is important to wear appropriate safety gear such as safety glasses and ear protection. The workpiece should be securely clamped to the worktable, and the drill bit should be properly secured in the spindle. It is also important to keep hands and fingers away from the drill bit and moving parts.

Can a drill press be used for other operations besides drilling?

Yes, a drill press can be used for other operations besides drilling. With the appropriate attachments and accessories, it can be used for tasks such as sanding, grinding, buffing, and even tapping threads into a hole. However, it is important to use the right tool and technique for each operation.

Video: