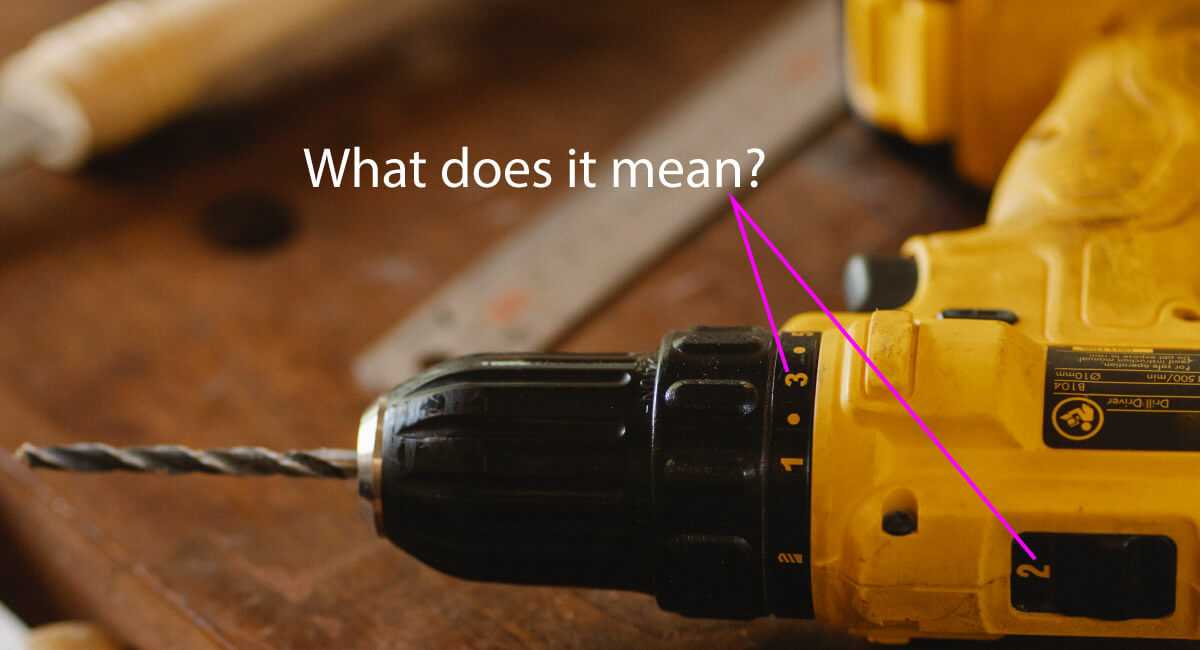

Understanding the Meaning Behind the Numbers on a Power Drill

Power drills are an essential tool in any DIY enthusiast’s arsenal. They can be used for a wide range of projects, from simple home repairs to complex woodworking. However, understanding the numbers on a power drill can be confusing for beginners. Each number represents a different feature or specification of the drill, and knowing what they mean is crucial for selecting the right tool for the job.

One of the most important numbers to consider is the drill’s voltage. This refers to the amount of electrical power that the drill can handle. Higher voltage usually means more power and faster drilling. However, higher voltage also means a heavier and more expensive drill. It’s important to find a balance between power and convenience when choosing a drill.

Another key number to pay attention to is the drill’s torque. Torque measures the amount of rotational force that the drill can apply. This is important for tasks that require drilling through tough materials, such as concrete or metal. Higher torque means the drill can handle more resistance and is less likely to stall or burn out. However, high torque drills are generally heavier and more expensive, so it’s important to consider the specific needs of each project.

Finally, the drill’s speed is represented by the number of rotations per minute (RPM). This determines how quickly the drill bit spins. Faster speeds are useful for tasks that require precision, such as drilling small holes or driving screws. However, for larger holes or tasks that require more force, slower speeds may be more effective. Some drills offer adjustable speed settings, allowing the user to switch between high and low speeds as needed.

In conclusion, understanding the meaning behind the numbers on a power drill is essential for selecting the right tool for the job. By considering factors such as voltage, torque, and speed, DIY enthusiasts can ensure that they have the right drill to tackle any project. It’s important to strike a balance between power and convenience, and to choose a drill that meets the specific requirements of each task.

The Importance of Understanding the Numbers on a Power Drill

1. Enhanced Performance:

Understanding the numbers on a power drill is important for maximizing its performance. Each number corresponds to a specific feature or capability of the drill. For example, the drill’s voltage determines its power and torque. The higher the voltage, the more powerful the drill. By understanding the voltage rating, users can ensure that they choose a drill with sufficient power for their needs.

2. Precision and Control:

The numbers on a power drill also indicate its speed settings. The speed at which the drill rotates can be adjusted to suit different materials and tasks. By selecting the appropriate speed, users can achieve better precision and control. For example, lower speeds are ideal for driving screws, while higher speeds are more suitable for drilling through tough materials like metal or concrete. Understanding the speed settings allows users to tailor the drill’s performance to the specific task at hand.

3. Safety and Compatibility:

Another important aspect of understanding the numbers on a power drill is ensuring safety and compatibility. The drill’s chuck size is represented by a number, typically in millimeters, indicating the maximum diameter of the drill bit it can accommodate. Using a drill bit that exceeds the chuck size can lead to accidents and damage to the drill. By understanding the chuck size, users can select compatible drill bits and ensure safe operation.

4. Battery Life and Portability:

For cordless power drills, understanding the numbers related to battery capacity and voltage is crucial. The battery capacity is often measured in amp-hours (Ah) and determines how long the drill can be used before recharging is required. Additionally, the voltage determines the power output and affects the overall performance of the drill. By understanding these numbers, users can choose a drill with adequate battery life and power for their needs.

5. Productivity and Efficiency:

Understanding the numbers on a power drill can also contribute to increased productivity and efficiency. For example, some drills have multiple gears that can be adjusted to suit different tasks. By understanding the gear settings, users can switch between high-torque and high-speed modes as needed, allowing them to complete tasks more efficiently. Knowing the numbers and features of a power drill can help users select the most suitable tool for their specific needs, ultimately saving time and effort.

Conclusion:

Understanding the numbers on a power drill is essential for maximizing its performance, ensuring safety, and achieving desired results. By familiarizing themselves with the voltage, speed settings, chuck size, battery capacity, and other relevant numbers, users can select the most suitable drill for their needs, operate it correctly, and achieve optimal outcomes in their projects.

How to Read the Numbers on a Power Drill

Introduction

When shopping for a power drill, you may come across a variety of numbers and specifications that can be confusing if you are not familiar with them. This guide will help you understand the meaning behind the numbers on a power drill, so you can make an informed decision when purchasing one.

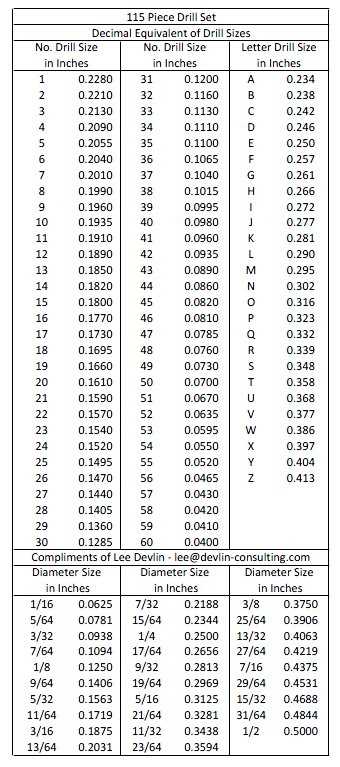

Chuck Size

The chuck size refers to the diameter of the hole in the front of the drill where you insert the drill bit. The chuck size is usually expressed in inches or millimeters. Common chuck sizes for power drills include 1/4″, 3/8″, and 1/2″. The larger the chuck size, the larger the drill bit you can use.

Power Rating

Power rating refers to the amount of power the drill motor can generate. It is typically measured in watts or amps. Higher power ratings indicate a more powerful drill that can handle tougher materials and larger drill bits. However, keep in mind that higher power ratings also mean heavier and bulkier drills.

Speed

The speed of a power drill is measured in revolutions per minute (RPM). This number indicates how fast the drill bit rotates. Power drills usually have variable speed settings, allowing you to adjust the RPM according to your needs. Higher RPMs are suitable for drilling softer materials like wood, while lower RPMs are better for drilling metal or masonry.

Torque

Torque refers to the rotational force generated by the drill motor. It is measured in inch-pounds (in-lbs) or Newton meters (Nm). Higher torque ratings indicate a drill that can handle tougher drilling tasks and drive screws more efficiently. If you plan to use your power drill for heavier applications, look for a model with higher torque.

Battery Voltage

If you are considering a cordless power drill, you will come across battery voltage ratings. Battery voltage affects the drill’s power and runtime. Higher voltage batteries generally provide more power, but they also add weight to the drill. Common battery voltages for cordless drills include 12V, 18V, and 20V. Consider the intended use and duration of your drilling tasks when choosing the battery voltage.

Conclusion

Understanding the numbers on a power drill is essential for selecting the right tool for your needs. By knowing the chuck size, power rating, speed, torque, and battery voltage, you can choose a drill that is suitable for your intended applications. Remember to consider the tasks you plan to tackle, as well as your personal preferences for weight and size, to find the perfect power drill for your toolbox.

Understanding Voltage and Amps

What is Voltage?

Voltage, also known as electrical potential difference, is the measure of electric potential energy per unit charge. It is usually measured in volts (V) and determines the force or pressure of electric current flowing through a circuit. In the context of power drills, voltage refers to the amount of electrical potential difference provided by the power source.

What is Amps?

Amperes, also known as amps (A), is the unit of electric current. It measures the rate of flow of electric charge or the number of electrons passing through a circuit per second. Amps determine the strength or intensity of an electric current. In the context of power drills, amps refer to the amount of current the drill motor draws from the power source.

Relationship between Voltage and Amps

There is a direct relationship between voltage and amps in an electrical circuit. According to Ohm’s Law, the current flowing through a circuit is directly proportional to the voltage applied to the circuit and inversely proportional to the resistance of the circuit.

In simpler terms, increasing the voltage in a circuit will cause the current (amp) to increase as long as the resistance remains constant. Similarly, decreasing the voltage will cause a decrease in current, again assuming the resistance remains constant.

How Voltage and Amps Impact Power Drills

In the context of power drills, voltage and amps play crucial roles in determining the drill’s performance and capabilities.

- Voltage: Higher voltage power drills provide more power and torque, making them suitable for heavy-duty tasks such as drilling through tough materials. However, higher voltage also means a heavier and bulkier drill. Common voltage ratings for power drills include 12V, 18V, and 20V.

- Amps: The amp rating of a power drill motor determines how much current it draws from the power source. Generally, power drills with higher amp ratings can handle heavier workloads without straining the motor. This is beneficial when drilling through dense materials or using the drill for extended periods. Typical amp ratings for power drills range from 4A to 12A.

When choosing a power drill, it is important to consider the voltage and amp ratings that suit your specific needs. Higher voltage and amp ratings can provide more power and performance but may come at the expense of weight and size.

Interpreting RPM and Torque Ratings

RPM (Revolutions Per Minute) and torque ratings are two important factors to consider when choosing a power drill. These specifications provide insights into the drill’s performance and capabilities.

RPM Ratings

RPM refers to the number of times the drill bit rotates per minute. It indicates the speed at which the drill can operate. Higher RPM values generally mean faster drilling, as the bit completes more rotations within a given time frame.

When choosing a power drill, consider the RPM rating that aligns with your intended use. Higher RPM values are typically suitable for tasks that require fast drilling or cutting, such as drilling through thin materials or making quick holes. On the other hand, lower RPM values are ideal for tasks that require more control or power, such as drilling through thick or hard materials.

Torque Ratings

Torque refers to the drill’s twisting force or rotational power. It determines the drill’s ability to drive screws or bore holes into various materials. Torque ratings are typically measured in inch-pounds (in-lbs) or Newton-meters (Nm).

A higher torque rating means the drill has more power and can handle heavier and tougher tasks. If you frequently work with dense or difficult materials, such as concrete or hardwood, a drill with a higher torque rating would be preferable.

However, it’s important to note that higher torque ratings can also make the drill more challenging to control, especially when working with delicate materials or driving small screws. In these cases, a drill with adjustable torque settings may be beneficial, as it allows you to fine-tune the torque according to the task at hand.

Matching RPM and Torque Ratings to Your Needs

When selecting a power drill, it’s crucial to consider both the RPM and torque ratings in relation to your specific needs. A drill with a higher RPM rating may offer fast drilling speed, but if it lacks sufficient torque, it may struggle with tougher materials.

Conversely, a drill with high torque but a low RPM rating may provide ample power but be slower in completing tasks that require speed. Consider your typical drilling tasks, the materials you work with, and your desired drilling speed to find a drill that strikes the right balance between RPM and torque ratings.

It’s also worth noting that some power drills come with adjustable RPM and torque settings, allowing you to customize the drill’s performance for different tasks. These drills offer greater versatility, but they may come at a higher cost.

| RPM | Torque |

|---|---|

| 1000-2000 | Low |

| 2000-3000 | Medium |

| 3000+ | High |

The table above provides a general guideline for interpreting RPM and torque ratings:

- Low RPM (e.g., 1000-2000): Suitable for tasks that require more power and control, such as drilling through hard materials or using hole saws.

- Medium RPM (e.g., 2000-3000): Appropriate for general drilling tasks, such as drilling through wood or metal.

- High RPM (e.g., 3000+): Ideal for tasks that require speed, such as drilling through soft materials or using spade bits.

Remember, the specific RPM and torque requirements can vary based on the drill’s make and model, so always consult the manufacturer’s specifications for accurate information.

Choosing the Right Power Drill for Your Needs

Consider Your Projects

When choosing a power drill, it’s important to consider the projects you plan to tackle. Different power drills are designed for different types of projects, so it’s crucial to choose one that is suitable for your needs.

For example, if you’re mainly working on light-duty tasks around the house, a cordless drill with a lower voltage may be sufficient. On the other hand, if you’re tackling heavy-duty projects or working with hard materials, you may need a corded drill with a higher voltage.

Power Source

Power drills can be either corded or cordless, each with its own advantages and disadvantages.

- Corded drills: These drills offer unlimited power supply as they are connected directly to an electrical outlet. They are generally more powerful and suitable for heavy-duty tasks. However, they are less portable due to the cord.

- Cordless drills: These drills run on batteries, which allow for greater portability. They are suitable for light to medium-duty tasks and are more convenient for use in tight spaces. However, they may have limited battery life and may not have as much power as corded drills.

Chuck Size

The chuck size refers to the diameter of the opening where the drill bit is inserted. It’s important to choose a power drill with the appropriate chuck size for your projects.

Smaller chuck sizes, such as ⅜ inch, are suitable for lighter tasks and allow for more precision. Larger chuck sizes, such as ½ inch, are better for heavy-duty tasks and can accommodate larger drill bits.

Speed and Torque

Power drills come with adjustable speed and torque settings, which determine how quickly the drill bit rotates and how much twisting force it can apply. The speed is measured in revolutions per minute (RPM), while torque is measured in Newton meters (Nm).

If you plan to work with a variety of materials, it’s recommended to choose a power drill with multiple speed settings. Higher speed settings are suitable for drilling through softer materials, while lower speed settings provide more control when drilling into harder materials.

Additional Features

Consider any additional features that may be beneficial for your projects. Some power drills come with built-in LED lights, which illuminate the work area, making it easier to see. Others may have a hammer function, allowing the drill to also function as a hammer drill for masonry work.

Conclusion

Choosing the right power drill for your needs involves considering your projects, power source, chuck size, speed and torque settings, and any additional features. By taking these factors into account, you can select a power drill that is well-suited to your specific requirements and ensure successful and efficient completion of your projects.

Common Misconceptions About Power Drill Numbers

When it comes to selecting a power drill, many people rely solely on the numbers provided by the manufacturer. While these numbers can provide some useful information, they are often misunderstood or misinterpreted. Here are some common misconceptions about power drill numbers:

1. Voltage Equals Power

One of the most common misconceptions is that the voltage rating of a power drill indicates its overall power or capability. While it is true that higher voltage drills often have more power, there are other factors at play. The drill’s design, motor efficiency, and battery technology all contribute to its performance. A lower voltage drill with a well-designed motor may outperform a higher voltage drill with a less efficient motor.

2. Amps and Battery Life

Another common misconception is that the amp rating of a power drill determines its battery life. While it is true that higher amp batteries can potentially last longer, this is not the only factor to consider. The efficiency of the motor, the workload, and the battery technology also play a significant role in determining battery life. It’s essential to consider all these factors and not rely solely on the amp rating when evaluating battery life.

3. More Speeds Means Better Performance

Some power drills come with multiple speed settings, leading to the misconception that more speeds translate to better performance. While having more speed options can be beneficial for different drilling tasks, it doesn’t necessarily mean better overall performance. The power, torque, and control of the drill are more critical factors to consider when evaluating performance.

4. Higher Torque is Always Better

It is easy to assume that a power drill with higher torque will always perform better. While torque is crucial for tasks that require high drilling or driving force, it is not the only factor to consider. The drill’s design, speed settings, and overall power also determine its performance. It’s important to choose a drill with the right balance of torque and power for the tasks at hand.

5. Heavy Drills are More Powerful

Many people associate the weight of a power drill with its power capabilities. However, this is not necessarily true. The weight of a drill can vary based on factors such as the battery type and the overall design. A lightweight drill can still deliver high performance and power, especially if it has a well-designed motor and durable components.

6. Drill Bits Determine Drill Performance

While the type and quality of drill bits are important for achieving accurate and efficient drilling, they do not solely determine the overall performance of a power drill. The power, torque, and control of the drill itself are equally important factors. It’s crucial to select the right drill for the job and pair it with appropriate drill bits for optimal performance.

| Number | Misconception |

|---|---|

| 1 | Voltage equals power |

| 2 | Amps determine battery life |

| 3 | More speeds mean better performance |

| 4 | Higher torque is always better |

| 5 | Heavy drills are more powerful |

| 6 | Drill bits determine drill performance |

Understanding the meaning behind the numbers on a power drill requires looking beyond the surface and considering various factors that contribute to its performance. By debunking these common misconceptions, users can make more informed decisions when selecting a power drill that meets their specific needs.

FAQ:

What do the numbers on a power drill mean?

The numbers on a power drill indicate the drill’s speed or torque settings. Higher numbers generally mean faster speeds or more power.

How do I know which number to use on a power drill?

The number you should use on a power drill depends on the specific task you are performing. Higher numbers are typically used for drilling through harder materials, while lower numbers are used for tasks that require more precision.

Can I use a power drill with a lower number for a task that requires a higher number?

Using a power drill with a lower number for a task that requires a higher number may result in slower drilling speeds or less power. It’s best to use the recommended number for the specific task you are performing.

Are there any other factors I should consider when using a power drill?

Aside from the numbers on a power drill, you should also consider factors such as the type of drill bit being used, the material you are drilling into, and any safety precautions you need to take. It’s always important to read the manual and follow the manufacturer’s guidelines.

Video: