Understanding the inner workings of a drill press

A drill press is a versatile tool that is commonly used in woodworking, metalworking, and other projects that require precision drilling. While many people are familiar with the basic function of a drill press, understanding its inner workings can help users make the most of this powerful tool.

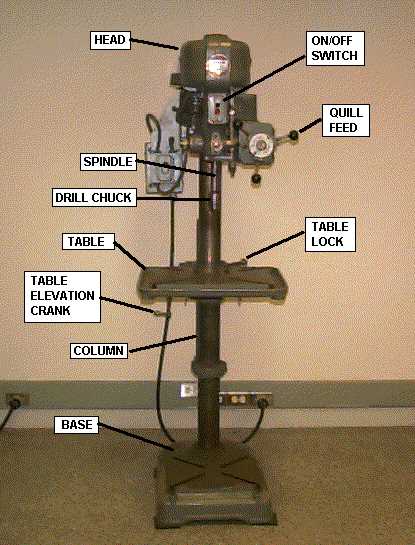

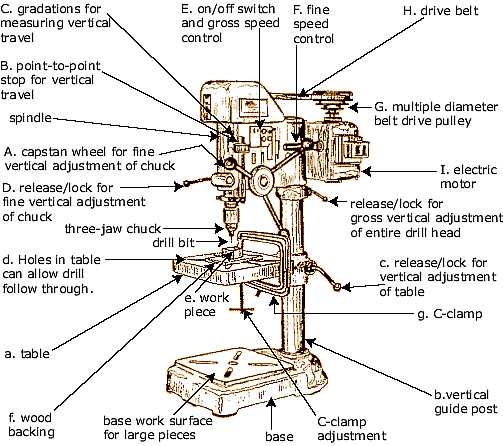

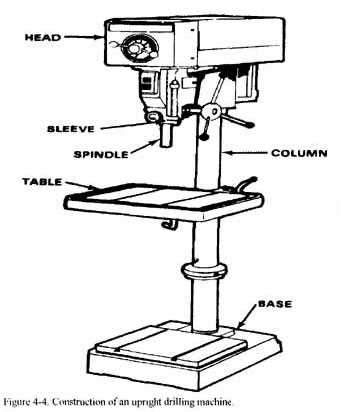

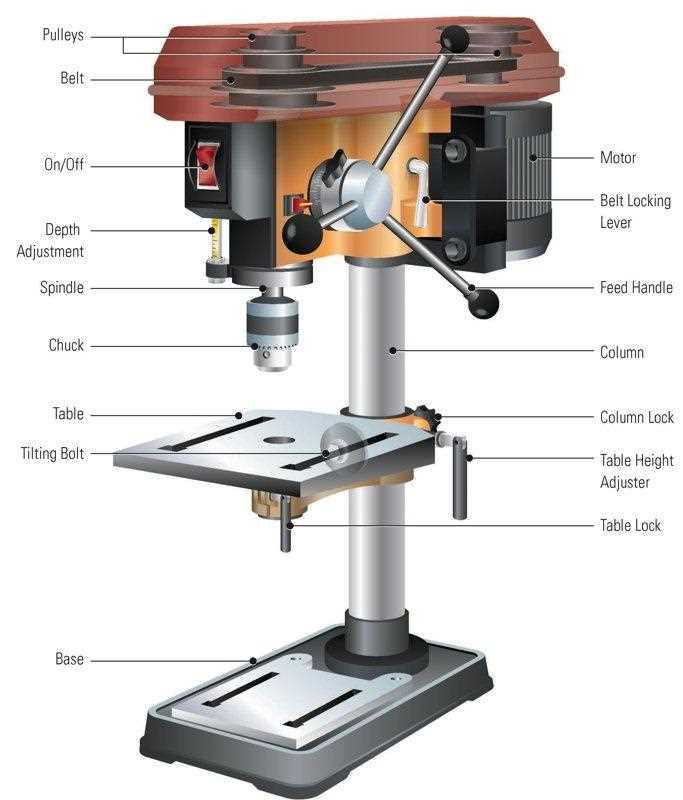

At its core, a drill press is comprised of three main components: the base, the column, and the spindle. The base provides stability and support for the entire machine, while the column is a vertical pillar that connects the base to the head of the drill press. The spindle is the rotating component that holds the drill bit and performs the actual drilling.

The spindle is driven by a motor, which can be operated using either a belt drive system or a direct drive system. In a belt drive system, a belt connects the motor to the spindle, allowing the operator to adjust the speed of the drill press by changing the position of the belt on different-sized pulleys. In a direct drive system, the spindle is directly connected to the motor, providing more power and speed control.

In addition to the motor, a drill press may also have a variety of other features, such as a depth stop, a table, and a fence. A depth stop allows the user to set the drilling depth, ensuring consistency and accuracy. The table provides a flat surface for the workpiece to rest on, while the fence helps guide the workpiece during drilling.

Understanding the inner workings of a drill press can help users understand how to properly operate and maintain this essential tool. By knowing how the various components work together, users can ensure safety, improve efficiency, and achieve better results in their drilling projects.

What is a drill press and how it works

Introduction

A drill press is a powerful and versatile tool that is commonly used in woodworking, metalworking, and other industries. It is a machine that is designed to accurately drill holes in various materials with precision and control. The drill press consists of a base, a column, a worktable, a spindle, and a drill head.

Drill press operation

The drill press works by rotating a cutting tool, usually a drill bit, to remove material and create holes. The material to be drilled is firmly secured on the worktable or held in a drill press vise. The height of the worktable can be adjusted to align the material with the drill bit.

Once the material is properly positioned, the drill bit is brought down by lowering the drill head. The drill head is attached to the spindle, which is connected to a motor. The motor powers the spindle, causing it to rotate the drill bit.

As the drill bit rotates, downward pressure is applied to the material. This pressure is controlled by the operator using the spindle feed handle or a lever. The feed rate determines the speed at which the drill bit cuts into the material. It is important to use the appropriate feed rate to prevent overheating or breaking the drill bit.

Features and accessories

Drill presses often include a variety of features and accessories to enhance their functionality:

- Depth stop: This allows the operator to set the drilling depth, ensuring consistent hole depths.

- Laser guide: Some drill presses have a laser guide that projects a beam onto the material, providing a visual indicator of where the hole will be drilled.

- Variable speed: Many drill presses have variable speed settings, allowing the operator to adjust the speed to match the material being drilled.

- Magnetic base: Some drill presses have a magnetic base attachment, which allows them to be used in conjunction with a magnetic drill press vise for increased stability.

Safety precautions

When operating a drill press, it is important to follow proper safety precautions to prevent accidents and injuries:

- Wear safety goggles: Always wear safety goggles to protect your eyes from flying debris.

- Secure the material: Ensure that the material is securely clamped or held in place to prevent it from moving during drilling.

- Use the appropriate drill bit: Select the correct drill bit for the material being drilled to prevent damage to the drill press or workpiece.

- Keep hands away from the drill bit: Never attempt to manually stop the drill bit or touch it while it is in motion.

- Turn off the drill press when not in use: Always turn off the drill press and unplug it when you are finished using it.

Conclusion

A drill press is an essential tool for anyone working with wood, metal, or other materials that require precision drilling. Understanding how it works and following proper safety precautions ensures successful and safe operation. With its ability to accurately and efficiently create holes, the drill press is a valuable addition to any workshop.

Components of a drill press and their functions

1. Base

The base is the foundation of a drill press, providing stability and support to the machine. It is usually made of cast iron or steel to ensure durability and minimize vibrations during operation. The base is designed to be heavy and rigid, preventing the drill press from moving or tipping over when drilling.

2. Column

The column is a vertical structure that connects the base to the head of the drill press. It provides the necessary height adjustment for the drilling process. The column is typically made of steel or cast iron and has a sturdy construction to maintain stability and accuracy.

3. Head

The head is the upper portion of the drill press that houses the motor, spindle, and other vital components. It is responsible for controlling the speed and depth of the drill bit. The head can usually be moved up and down the column to adjust the drilling height.

4. Motor

The motor is the power source of the drill press. It provides the rotating motion required for drilling and is responsible for the speed and torque control. Electric motors are commonly used in drill presses, with varying power ratings depending on the application.

5. Spindle

The spindle is the rotating shaft in the drill press that holds and drives the drill bit. It is connected to the motor and transfers the rotational force to the drill bit. The spindle is designed to accommodate different sizes of drill bits, allowing for versatility in drilling operations.

6. Table

The table is a flat surface located on the base of the drill press. It provides a stable platform for positioning and supporting the workpiece during drilling. The table can be adjusted in various directions, including height, tilt, and rotation, to accommodate different drilling angles and workpiece sizes.

7. Depth stop

The depth stop is a mechanism that controls the depth of the drill hole. It allows the user to set a specific drilling depth and helps prevent overdrilling, ensuring consistent and accurate hole depths. The depth stop can be adjusted or locked in place depending on the desired depth.

8. Chuck

The chuck is a device located at the end of the spindle that holds the drill bit securely in place. It allows for quick and easy installation and removal of drill bits. Chuck sizes can vary depending on the drill press model, accommodating different sizes of drill bits.

9. Speed control

The speed control feature allows the user to adjust the rotation speed of the drill press. Different drilling operations require different speeds, and the ability to change the speed ensures optimal performance and precision. Speed control can be achieved through pulleys or belts, providing a range of speed options.

10. Safety features

Drill presses often include safety features to protect the user and prevent accidents. These may include a safety switch, which turns off the drill press when released, and a spindle lock, which immobilizes the spindle for easy and safe bit changes. Some drill presses may also have a built-in work light, providing better visibility during drilling.

Choosing the right drill press for your needs

When it comes to choosing a drill press, there are several factors to consider. The drill press is a versatile tool that can be used for a variety of applications, so it’s important to select a model that meets your specific needs. Here are some key points to consider when choosing a drill press:

Type of drill press

There are several types of drill presses available, including benchtop, floor, and magnetic drill presses. Benchtop drill presses are compact and portable, making them a great choice for small workshops or home use. Floor drill presses are larger and more powerful, suitable for heavy-duty drilling tasks. Magnetic drill presses are designed for drilling on metal surfaces and feature a powerful magnetic base.

Chuck size

The chuck size is an important consideration when choosing a drill press. The chuck is the part of the drill press that holds the drill bit in place. The chuck size determines the maximum diameter of the drill bit that can be used with the drill press. Smaller drill presses typically have a chuck size of 1/2 inch, while larger drill presses can have a chuck size of up to 5/8 inch or more. Consider the size of the drill bits you intend to use and choose a drill press with a compatible chuck size.

Motor power

The motor power of a drill press determines its drilling capacity and performance. Higher horsepower motors can handle larger drill bits and provide more torque for tough drilling tasks. Consider the type of materials you will be drilling and choose a drill press with a motor power that suits your needs. Keep in mind that higher motor power usually translates to a higher price.

Speed settings

Drill presses come with multiple speed settings, allowing you to adjust the drilling speed based on the material and size of the drill bit. Some drill presses offer variable speed settings, while others have fixed speed settings. Variable speed settings provide more flexibility and precision, especially when working with different materials. Consider the range of speed settings offered by the drill press and choose one that suits your intended applications.

Table size and adjustability

The table size and adjustability are important factors to consider, especially if you will be working with large or irregularly shaped workpieces. A larger table provides more support and stability, while an adjustable table allows you to position the workpiece at the desired angle. Consider the size and adjustability of the table based on your specific needs.

Additional features

Lastly, consider any additional features that may be important to you. Some drill presses come with built-in work lights for improved visibility, depth stop settings for drilling consistent holes, and laser guides for precision drilling. These additional features can enhance the usability and convenience of the drill press.

By considering these factors, you can choose a drill press that meets your specific needs and provides the performance and versatility required for your projects.

Tips for safe operation and maintenance

1. Read the manual

Before using the drill press, it is important to read the manual provided by the manufacturer. The manual contains important safety instructions and guidance on how to properly operate and maintain the drill press. Familiarize yourself with all the parts and their functions before starting to use the machine.

2. Wear appropriate safety gear

Always wear proper safety gear when operating a drill press. This includes safety glasses or goggles to protect your eyes from flying debris, a dust mask to prevent inhaling dust particles, and hearing protection as drill presses can be noisy. Additionally, avoid wearing loose clothing, jewelry, or anything that could get caught in the machine.

3. Secure the workpiece

Before starting any drilling operation, make sure the workpiece is securely clamped to the drill press table. This will prevent the workpiece from spinning or moving during drilling, reducing the risk of accidents. It is also important to use the appropriate clamps or vise to hold the workpiece firmly in place.

4. Adjust the speed and depth settings

Different drilling tasks require different speeds and depth settings. Refer to the manual to determine the appropriate speed and depth for the material you are drilling. Adjust the settings on the drill press accordingly before starting the operation. Failure to do so can result in damaged workpieces or accidents.

5. Use the right drill bit

Make sure to use the correct drill bit for the material you are drilling. Using the wrong drill bit can result in poor drilling performance or even damage to the workpiece or the drill press itself. Consult the drill bit manufacturer’s guidelines to ensure you are using the right type and size of drill bit.

6. Keep the drill press clean

Maintaining a clean drill press is essential for safe and efficient operation. Regularly remove any debris or chips from the drill press table, chuck, and other parts. Clean the machine using a soft brush or cloth, and lubricate moving parts as recommended by the manufacturer to ensure smooth operation.

7. Avoid distractions

When operating a drill press, it is important to be fully focused and attentive. Avoid distractions such as phone calls, conversations, or loud noises that may divert your attention from the task at hand. Taking breaks when necessary and maintaining a clear and organized work area will help minimize distractions and reduce the risk of accidents.

8. Do not force the drill

Forcing the drill press can cause damage to the machine and may result in personal injury. Let the drill do the work and avoid applying excessive pressure. If you encounter resistance or the drill is not drilling properly, stop the machine and check for any issues such as dull drill bits, improper adjustment of speed or depth settings, or problems with the workpiece.

9. Disconnect power when not in use

When you have finished using the drill press, disconnect the power source or switch off the machine. This will prevent any accidental startup and reduce the risk of injury. Additionally, make sure the drill press is properly stored in a clean and dry area to prevent dust or moisture buildup.

10. Regular maintenance

Perform regular maintenance tasks as specified by the manufacturer to keep the drill press in good working condition. This may include cleaning, lubricating, and inspecting the machine for any wear or damage. Address any issues promptly to ensure safe and efficient operation.

Understanding the different types of drill bits

Drill bits are the cutting tools that are used with a drill press to create holes in various materials. Different types of drill bits are designed to work with specific materials and produce different hole sizes and shapes. Understanding the different types of drill bits will help you choose the right one for your drilling needs.

1. Twist drill bits

Twist drill bits are the most common type of drill bits and are used for general-purpose drilling. They have a spiral or twisted design that helps to remove material from the hole as it is drilled. Twist drill bits are available in various sizes and lengths.

2. Brad point drill bits

Brad point drill bits are designed specifically for woodworking applications. They have a pointed tip that helps to create precise and clean holes in wood. Brad point drill bits also have spurs on the sides to prevent the bit from wandering or slipping. They are available in various sizes.

3. Masonry drill bits

Masonry drill bits are used for drilling holes in bricks, concrete, and other masonry materials. They have a carbide tip that is able to withstand the hardness of these materials. Masonry drill bits are available in various sizes and lengths.

4. Forstner drill bits

Forstner drill bits are used for drilling flat-bottomed holes with clean and precise edges. They are commonly used in woodworking applications for creating holes for dowels, hinges, and other decorative purposes. Forstner drill bits are available in various sizes.

5. Hole saws

Hole saws are specialized drill bits that are used for cutting large holes in materials such as wood and metal. They have a cylindrical shape with a serrated edge and a pilot bit in the center. Hole saws are available in various sizes and are often used in plumbing and electrical work.

6. Countersink drill bits

Countersink drill bits are used to create a recessed hole that allows the head of a screw to sit flush with the surface of the material. They have a tapered design that produces a cone-shaped hole. Countersink drill bits are often used in woodworking applications.

7. Step drill bits

Step drill bits are designed to create different-sized holes in a single operation. They have a cone-shaped design with multiple stepped levels. Step drill bits are commonly used in metalworking and plumbing applications.

8. Auger drill bits

Auger drill bits are used for drilling holes in wood. They have a spiral or corkscrew design that helps to remove material from the hole as it is drilled. Auger drill bits are commonly used in carpentry and woodworking applications.

9. Spade drill bits

Spade drill bits, also known as paddle bits, are used for drilling large diameter holes in wood. They have a flat blade with a sharp point and two cutting edges. Spade drill bits are commonly used in construction and woodworking applications.

10. Specialty drill bits

In addition to the basic types of drill bits mentioned above, there are also specialty drill bits available for specific applications. These include PCB drill bits for drilling printed circuit boards, glass drill bits for drilling holes in glass, and tile drill bits for drilling holes in tiles.

When choosing a drill bit, consider the material you will be drilling, the desired hole size and shape, and the type of drill press or power drill you will be using. Using the right drill bit will help you achieve accurate and clean holes for your specific project.

Common uses and applications of a drill press

A drill press is a versatile tool that can be used for various applications. Here are some common uses of a drill press:

1. Drilling holes

The primary use of a drill press is to drill holes with precision. Whether you are working on wood, metal, or other materials, a drill press allows you to make accurate and straight holes by providing stability and control.

2. Woodworking

Drill presses are commonly used in woodworking projects. They can be used to create dowel joints, bore holes for screws, drill pocket holes, and perform other tasks required in furniture making, cabinetry, and other woodworking projects.

3. Metalworking

A drill press is also indispensable in metalworking projects. It can be used to create precise holes in metal sheets or tubes, remove burrs, and tap threads. Metalworkers often use drill presses for drilling holes in precise locations and maintaining consistent drill depths.

4. Mortising

Mortising is a technique used in woodworking to create square or rectangular holes. A drill press equipped with a mortising attachment can be used to accurately create mortises for joinery purposes, such as making furniture or frames.

5. Sanding and polishing

With the right attachments, a drill press can be used for sanding and polishing tasks. Sanding drums and polishing wheels can be attached to the drill press to smooth out rough surfaces, refine edges, or buff and polish materials.

6. Metal fabrication

In metal fabrication, a drill press is commonly used for tasks such as countersinking holes, spot facing, and chamfering edges. These processes are crucial in ensuring proper fitting and finishing in metal parts and structures.

7. Jewelry making

For jewelry makers, a drill press can be used for drilling small holes in beads, stones, and other jewelry components. It provides the accuracy and control needed for intricate jewelry designs.

8. PCB drilling

In electronics, a drill press can also be used for drilling precise holes on printed circuit boards (PCBs). This is essential in creating circuit boards for electronic devices.

9. Model making

When making scale models or replicas, a drill press is useful for drilling holes for attaching various components, creating intricate details, and ensuring precise alignment of parts.

10. DIY projects

A drill press is a valuable tool in a DIY enthusiast’s workshop. It can be used for a wide range of projects, such as building shelves, installing hardware, crafting decorations, and more.

Overall, the drill press is a versatile tool that is essential in many industries and hobbies. Its precision, stability, and control make it an ideal choice for various drilling and fabrication tasks.

Exploring advanced features and capabilities

1. Variable speed control

The drill press comes with a variable speed control feature that allows the user to adjust the speed of the drill bit rotation. This feature is especially useful when working with different materials or when using different types of drill bits. A slower speed may be required for drilling through metal, while a faster speed may be optimal for drilling through wood.

2. Depth stop

The depth stop feature allows the user to set a specific drilling depth, ensuring consistent and accurate drilling. This is particularly useful when drilling holes of a specific depth for tasks such as creating counterbore or countersink holes. The depth stop can be adjusted by tightening or loosening the locking nut located near the drill press spindle.

3. Laser guide

Some drill presses come equipped with a laser guide that projects a beam onto the workpiece, providing a visual reference for accurate drilling. The laser guide helps the user align the drill bit precisely where it needs to go, minimizing the chance of errors or off-center holes.

4. Table tilt

The table on a drill press can usually be tilted or angled to accommodate angled drilling or drilling at specific angles. This feature is particularly useful when drilling holes at an angle, such as when installing dowels or creating angled joints. The table can typically be locked into place once the desired angle is set.

5. Digital depth gauge

Some drill presses have a built-in digital depth gauge that displays the exact drilling depth in inches or millimeters. This feature allows for precise and accurate drilling, as the user can easily see and adjust the drilling depth based on their requirements.

6. Multiple spindle speeds

Advanced drill presses may offer multiple spindle speeds, allowing the user to select the appropriate speed for the specific task at hand. Different materials and drill bit sizes require different speeds for optimal results, and having multiple spindle speeds ensures versatility and efficiency.

7. Automatic feeding

Some drill presses feature an automatic feeding mechanism that allows for hands-free drilling. This is particularly useful for drilling repetitive holes or when drilling through thick or tough materials. The feeding mechanism can be set to control the drilling speed and depth, reducing operator fatigue and increasing efficiency.

8. Built-in work light

Many modern drill presses come with a built-in work light to enhance visibility and illuminate the drilling area. This is especially useful when working in poorly lit areas or when drilling intricate or small holes that require precision.

Overall, understanding and utilizing the advanced features and capabilities of a drill press can greatly enhance the user’s drilling experience and improve the quality of their work. Whether it’s adjusting the speed, setting the depth, or utilizing additional features like laser guides or automatic feeding mechanisms, these advanced features provide greater control and accuracy for a wide range of drilling tasks.

Frequently asked questions about drill presses

1. What is a drill press?

A drill press, also known as a drilling machine or pedestal drill, is a tool used for drilling holes in various materials such as wood, metal, and plastic. It consists of a base, column, table, and head. The head houses the motor and spindle, which holds the drill bit.

2. How does a drill press work?

A drill press works by rotating a drill bit at high speeds and applying downward pressure on the material being drilled. The drill bit is held securely in the spindle, which is connected to a motor. As the motor spins, it drives the drill bit into the material, creating a hole.

3. What are the advantages of using a drill press?

- Precision: A drill press allows for precise drilling thanks to its stable base, adjustable table, and depth stop.

- Power: Drill presses typically have more power than handheld drills, making them suitable for drilling through tough materials.

- Consistency: The fixed position of the drill bit ensures consistent drilling depth and angle, resulting in uniform holes.

- Safety: Using a drill press reduces the risk of accidents compared to handheld drilling, as both hands are free to hold and guide the material.

4. Can a drill press be used for other tasks besides drilling?

Yes, a drill press can be used for other tasks besides drilling. With the appropriate attachments, a drill press can be used for tasks such as sanding, polishing, grinding, and even mortising.

5. What safety measures should I take when using a drill press?

When using a drill press, it is important to follow these safety measures:

- Wear safety glasses or goggles to protect your eyes from flying debris.

- Securely clamp the material being drilled to the table to prevent it from moving.

- Ensure the drill bit is properly secured in the spindle.

- Adjust the drilling speed according to the material being drilled.

- Avoid wearing loose clothing or jewelry that can get caught in the drill press.

- Keep fingers and hands away from the drill bit and moving parts.

- Turn off the drill press and unplug it when making adjustments or changing the drill bit.

6. How do I maintain a drill press?

To maintain a drill press, you should:

- Clean the drill press regularly, removing any dust or debris that may have accumulated.

- Keep the drill press well-lubricated, particularly the moving parts such as the spindle and feed handles.

- Check the belts and motor regularly for any signs of wear or damage.

- Inspect the drill bits for any dull or damaged edges and replace them as needed.

- Store the drill press in a clean and dry environment to prevent rust or corrosion.

7. What is the difference between a benchtop drill press and a floor-standing drill press?

The main difference between a benchtop drill press and a floor-standing drill press is their size and portability. Benchtop drill presses are smaller, lighter, and designed to be placed on a workbench. Floor-standing drill presses are larger, heavier, and usually come with a stand or pedestal.

Floor-standing drill presses typically have more power and larger drilling capacities, making them suitable for heavy-duty drilling tasks. Benchtop drill presses are more compact and portable, making them ideal for smaller workshops or DIY projects.

8. Can a drill press be used with different types of drill bits?

Yes, a drill press can be used with a variety of drill bits, including twist bits, hole saws, spade bits, Forstner bits, and more. It is important to select the appropriate drill bit for the material being drilled and make sure it is securely held in the spindle before use.

FAQ:

What is a drill press?

A drill press is a type of power tool that is used to drill holes in various materials such as wood, metal, or plastic. It consists of a motor, a spindle, and a drill bit, and is mounted on a stand or a workbench.

How does a drill press work?

A drill press works by rotating the drill bit at a high speed and applying downward pressure on the material being drilled. The motor powers the spindle, which holds the drill bit, and the user can adjust the speed and the depth of the hole by changing the settings on the drill press.

What are the advantages of using a drill press?

There are several advantages of using a drill press. Firstly, it allows for more precise drilling, as the drill bit is held in place and the user can control the speed and depth of the hole. Secondly, it provides stability and reduces the risk of the drill bit slipping or wobbling. Lastly, it can be used for various drilling tasks and is suitable for different materials.

What safety precautions should be taken when using a drill press?

When using a drill press, it is important to follow certain safety precautions. Firstly, always wear safety goggles to protect your eyes from flying debris. Secondly, secure the material being drilled properly to prevent it from moving or spinning. Thirdly, keep your hands away from the drill bit and the rotating parts. Lastly, make sure to turn off the drill press and unplug it when not in use.

Can a drill press be used for other tasks besides drilling?

Yes, a drill press can be used for other tasks besides drilling. With the right attachments, it can be used for sanding, buffing, and even polishing. Some drill presses also have a built-in spindle sander or a mortising attachment, which allows for more versatile use of the tool.

Video: