Understanding Tapping Drill: Everything You Need to Know

When it comes to metalworking and engineering, one important process is tapping. Tapping involves creating internal threads in a hole so that a threaded fastener can be inserted. This allows for easy assembly and disassembly of parts, making it an essential technique in many industries.

But in order to tap a hole, you need to use the right tapping drill. The tapping drill is the size of the hole that needs to be drilled before tapping can occur. It is crucial to choose the correct size, as using the wrong size drill can lead to improper threads or damaged components.

There are several factors to consider when selecting a tapping drill, including the thread size and pitch, material being tapped, and desired thread engagement. Different standards, such as the Unified National Thread (UNC/UNF) or the Metric Thread, have specific recommendations for tapping drill sizes.

Understanding tapping drill sizes and their significance is essential to ensure successful tapping operations. In this article, we will delve into everything you need to know about tapping drills, including how to determine the correct size, common sizes used, and best practices for tapping different materials.

What Is a Tapping Drill?

A tapping drill, also known as a tap drill, is a type of drill bit used to create a hole in a workpiece that will accommodate a tap. A tap is a tool used to cut threads into a hole, allowing for the insertion of screws, bolts, or other threaded fasteners.

The tapping drill is designed to create a hole with the correct dimensions for the specific tap being used. It is important to use the appropriate tapping drill size to ensure proper thread engagement and a secure fit for the fastener.

How Does a Tapping Drill Work?

When using a tapping drill, the drill bit is first used to create a hole in the workpiece. The size of the hole should be slightly smaller than the desired size of the finished thread. This allows for room for the tap to cut the threads without damaging the surrounding material.

After drilling the hole, the tap is inserted into a tap handle or a tapping machine. The tap is then rotated clockwise into the hole, cutting threads as it goes. This process is often referred to as tapping.

Choosing the Right Tapping Drill Size

Choosing the correct tapping drill size is crucial for creating threads that will securely hold the fastener. The size of the tapping drill will depend on the type of tap being used and the material of the workpiece.

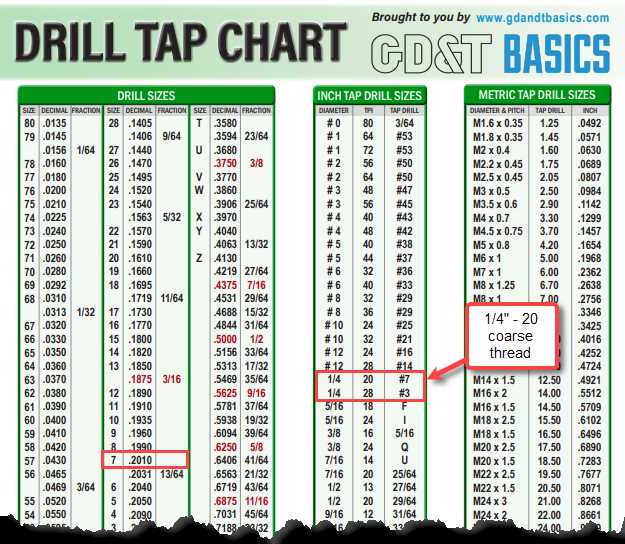

The tapping drill size is usually determined by consulting a tap drill chart, which provides guidelines for matching the tap size to the corresponding tapping drill size. These charts can be found online or in machining reference books.

Tapping Drill Sizes and Standards

Tapping drill sizes are standardized and often follow international standards, such as ISO or ANSI. These standards specify the recommended tapping drill sizes for various tap sizes and thread types.

It is important to follow these standards to ensure compatibility between taps and tapping drills. Using the correct tapping drill size will result in properly formed threads that are strong and secure.

Tapping Drill Considerations

When using a tapping drill, it is important to consider the material of the workpiece, the type of tap being used, and the desired strength of the threads. Different materials may require different drill speeds and feeds, and certain taps may have specific requirements.

Additionally, the depth of the hole created by the tapping drill should be considered, as it will affect the amount of engagement between the tap and the workpiece. Over-tapping or under-tapping can result in insufficient thread engagement or damaged threads.

| Tapping Drill Diameter | Tap Size (Metric) | Tap Size (Imperial) |

|---|---|---|

| 2.5mm | M3 | #4 |

| 3.3mm | M4 | #8 |

| 4.2mm | M5 | #10 |

| 5.0mm | M6 | #12 |

| 6.8mm | M8 | 1/4″ |

Note: The above table provides some common examples of tapping drill sizes for reference only. Always consult a tap drill chart or machining reference for precise tapping drill sizes.

How Does a Tapping Drill Work?

A tapping drill is a type of drill bit specifically designed for creating threads inside a pre-drilled hole, allowing screws or bolts to be accurately fastened. understanding the mechanics of how a tapping drill works can help you make the most of this essential tool.

Tapping Process

The tapping process involves three main steps:

- Preparation: First, a hole is drilled into the workpiece using a standard drill bit. The size of this hole should match the diameter of the tapping drill, allowing for the creation of threads.

- Tapping: The tapping drill, often referred to as a tap, is inserted into a tap wrench or tapping machine. It is then carefully aligned with the drilled hole and slowly rotated into the workpiece. As it rotates, the tap cuts threads into the walls of the hole.

- Finishing: Once the threads are formed, the tap is removed from the hole. This leaves behind a threaded hole, allowing for the attachment of screws or bolts.

Functions of a Tapping Drill

When used correctly, a tapping drill performs several important functions:

- It creates threads inside a pre-drilled hole, making it easier to fasten screws or bolts securely.

- It ensures the threads are properly aligned and sized for the chosen screw or bolt.

- It reduces the risk of over-tightening or damaging the workpiece by providing a pre-determined thread depth.

- It allows for the creation of threads in a variety of materials, including metal, wood, and plastic.

Choosing the Right Tapping Drill

Choosing the correct tapping drill is crucial for achieving the desired thread size and strength. Here are some factors to consider:

- Material: Different materials require different tapping drills. Harder materials may require a harder drill bit material or specialized coatings to withstand the cutting forces.

- Thread size: The tapping drill you choose should be matched to the desired thread size. Using the incorrect drill size can result in weak or improperly aligned threads.

- Thread pitch: The pitch of the desired thread should also be considered to ensure a proper fit with the tapping drill.

- Hole depth: The length of the hole will determine the necessary length of the tapping drill.

Conclusion

A tapping drill is an essential tool for creating accurate threads in pre-drilled holes. By understanding the process and functions of a tapping drill, you can choose the right drill for your needs and achieve strong, properly aligned threads.

Benefits of Using a Tapping Drill

Using a tapping drill can offer several benefits in various applications. Whether you are working on a DIY project or a professional machining task, incorporating a tapping drill can save you time, effort, and ensure better results. Here are some key advantages of using a tapping drill:

1. Improved Thread Quality

One of the main benefits of using a tapping drill is that it helps to create high-quality threads. The tap drill ensures that the hole is properly aligned and sized for the tap to produce a precise thread. This results in stronger, more durable threads that are less likely to strip or break.

2. Increased Efficiency

Using a tapping drill can significantly improve efficiency in the tapping process. The drill bit creates a starting hole that guides the tap, making it easier to begin the tapping process. This eliminates the need for manual alignment and reduces the risk of the tap wandering off-center. By reducing setup time and improving accuracy, a tapping drill can help you complete your task faster.

3. Reduces Material Waste

With a tapping drill, you can ensure that the hole is drilled to the appropriate depth for the tap, minimizing the waste of material. By using the correct tap drill size, you can avoid drilling excessive holes, which can result in unnecessary material removal and increased expenses.

4. Versatility

A tapping drill can be used in a wide range of materials, including metals, plastics, and wood. This versatility makes it a valuable tool for various applications, from automotive repair to woodworking projects. Having a tapping drill in your toolbox allows you to tackle different projects with ease.

5. Cost-effective

Investing in a tapping drill can be a cost-effective solution in the long run. By using a tap drill, you can prevent costly mistakes such as stripped threads or improperly aligned holes. The improved thread quality also reduces the risk of fastener failure, which can save you money on repairs or replacements.

In conclusion, using a tapping drill offers several benefits, including improved thread quality, increased efficiency, reduced material wastage, versatility, and cost-effectiveness. Incorporating a tapping drill into your tasks can help you achieve better results and save time and effort in the process.

Different Types of Tapping Drills

When it comes to tapping, there are several different types of drills that can be used. Each type of drill is designed for specific applications and materials. Here are some of the most common types of tapping drills:

1. Hand Tapping Drills

Hand tapping drills are designed to be used manually, without the need for a power tool. These drills typically have a square end that allows for easy gripping and turning. They are commonly used for small-scale projects and in situations where precision is required.

2. Machine Tapping Drills

Machine tapping drills are designed to be used with a power tool, such as a drill press or a tapping machine. These drills typically have a fluted design, which allows for better chip evacuation and helps prevent the drill from binding in the hole. Machine tapping drills are commonly used in high-volume manufacturing and production settings.

3. Spiral Point Tapping Drills

Spiral point tapping drills, also known as gun taps, have a spiral flute design that pushes the chips forward, away from the cutting edges. This design allows for faster and more efficient chip evacuation, reducing the risk of chip buildup and breakage. Spiral point taps are commonly used for through-hole tapping applications.

4. Spiral Flute Tapping Drills

Spiral flute tapping drills, also known as spiral flute taps, have a spiral flute design that pulls the chips upward, towards the shank. This design helps prevent chip buildup and provides better control over chip evacuation. Spiral flute taps are commonly used for blind-hole tapping applications.

These are just a few examples of the different types of tapping drills available. The type of drill you choose will depend on factors such as the material being tapped, the size of the hole, and the desired thread type.

It is important to select the right type of tapping drill for your specific application to ensure accurate and efficient results. Consult the manufacturer’s guidelines and recommendations for the best performance and longevity of your tapping drill.

Common Mistakes to Avoid When Using a Tapping Drill

1. Incorrect Drill Size

One common mistake when using a tapping drill is using the incorrect drill size. The drill size should match the size of the tap being used. Using a drill that is too small will result in a hole that is too small for the tap to fit properly. On the other hand, using a drill that is too large can weaken the threads created by the tap.

2. Not Using Lubrication

Lubrication is crucial when using a tapping drill. It helps reduce friction and heat generated during the drilling process, which can damage both the tap and the workpiece. Using a tapping fluid or cutting oil will not only make the process smoother but also prolong the life of the tap.

3. Excessive Force

Applying excessive force when using a tapping drill can lead to several problems. It can cause the tap to break or strip the threads. It is important to use a steady and controlled force when operating the tap to avoid any damage and ensure clean and accurate threads.

4. Improper Alignment

Improper alignment of the tap can result in crooked or misaligned threads. It is essential to align the tap properly with the hole before starting the tapping process. Using a center punch or drilling a pilot hole can help ensure proper alignment and prevent any issues.

5. Not Clearing Chips

During the tapping process, chips and debris can accumulate in the hole. Failing to clear these chips regularly can lead to clogging, which can hinder the tapping process and cause damage to the tap. It is important to clear the chips periodically to ensure smooth and efficient tapping.

6. Over-tightening

Over-tightening the tap can cause the threads to strip or break. It is important to stop turning the tap once the desired depth is reached. Using a torque wrench or applying the appropriate amount of force can help prevent over-tightening and ensure the longevity of the tap.

7. Inadequate Depth

Not reaching the proper depth when tapping can result in incomplete threads. It is crucial to drill the hole to the appropriate depth before starting the tapping process. Using depth stops or measuring tools can help ensure the correct depth is achieved.

8. Inconsistent Speed and Feed Rate

Using inconsistent speed and feed rate can lead to uneven and poor-quality threads. It is important to maintain a consistent speed and feed rate throughout the tapping process. This can be achieved by using appropriate drilling equipment and adjusting the settings accordingly.

9. Ignoring Tap Maintenance

Ignoring tap maintenance can result in dull or damaged taps, leading to poor-quality threads. It is important to clean and sharpen the tap regularly to ensure optimal performance. Additionally, using tap lubrication and avoiding excessive force can help prolong the life of the tap.

10. Lack of Proper Training

Using a tapping drill without proper training and knowledge can lead to mistakes and accidents. It is important to receive proper training or guidance before using a tapping drill. This will ensure that you have the necessary skills and knowledge to use the tool safely and effectively.

Tips for Choosing the Right Tapping Drill

Choosing the right tapping drill is essential to ensure successful tapping and threading operations. Here are some tips to help you choose the correct tapping drill:

1. Refer to a Tapping Drill Chart

Consult a tapping drill chart or table that provides the recommended drill sizes for various tap sizes and materials. These charts are readily available online or in machining reference books. They take into account factors such as the diameter and type of tap, as well as the material being threaded.

2. Consider the Tap Type

The type of tap you are using will influence the selection of the tapping drill. Different tap types, such as bottoming taps, taper taps, and plug taps, have different requirements for the size and alignment of the pilot hole. Refer to the tap manufacturer’s specifications for guidance on the appropriate tapping drill size.

3. Material Considerations

The material you are working with plays a significant role in determining the correct tapping drill size. Harder materials may require a larger pilot hole diameter to accommodate the tap, while softer materials may require a smaller pilot hole to ensure proper thread engagement. Consider the material’s characteristics, such as hardness and brittleness, when selecting the tapping drill.

4. Test and Adjust

It’s always a good practice to test the tapping drill size on a scrap piece of material before performing the actual tapping operation. This allows you to assess the fit and thread quality and make any necessary adjustments. It is better to err on the side of using a slightly smaller pilot hole and progressively increase the size if needed.

5. Seek Expert Advice

If you are uncertain about the appropriate tapping drill size, consult with machining experts or experienced professionals in the field. They can provide valuable insights and recommendations based on their knowledge and experience.

By following these tips, you can improve the accuracy and effectiveness of your tapping and threading operations. Choosing the right tapping drill is crucial for creating strong and reliable threads.

Understanding Tapping Drill Sizes

Tapping drill sizes are an important aspect of the tapping process. They determine the diameter of the hole that needs to be drilled before tapping can take place. The correct tapping drill size ensures that threads are properly formed in the material and that the tapped hole can accommodate the desired screw or bolt.

Choosing the Right Tapping Drill Size

Choosing the right tapping drill size depends on various factors, including the type of material being tapped, the size of the screw or bolt being used, and the type of thread being formed. Different materials and thread sizes may require different tapping drill sizes.

It is important to consult a tapping drill size chart or guide to determine the correct size for a given application. These charts provide information on the recommended drill sizes for different screw sizes and thread types.

Factors Affecting Tapping Drill Size

There are several factors that can affect the tapping drill size needed:

- Material hardness: Harder materials typically require larger tapping drill sizes compared to softer materials.

- Thread type: Different thread types, such as coarse or fine threads, may require different tapping drill sizes.

- Screw or bolt size: The size of the screw or bolt being used will determine the appropriate tapping drill size.

- Tap type: Different types of taps, such as taper taps or bottoming taps, may require specific tapping drill sizes.

Tapping Drill Size Chart

A tapping drill size chart provides a reference for the recommended tapping drill sizes based on the screw or bolt size and thread type. Here is an example of a tapping drill size chart for metric threads:

| Metric Thread Size | Tapping Drill Size (mm) |

|---|---|

| M2 | 1.6 |

| M2.5 | 2.05 |

| M3 | 2.5 |

| M4 | 3.3 |

| M5 | 4.2 |

It is important to note that tapping drill sizes can vary depending on the thread standards used in different regions, such as metric or imperial threads. Consulting a tapping drill size chart specific to the thread standard being used is crucial.

Conclusion

Understanding tapping drill sizes is essential for achieving proper threaded holes in materials. Choosing the correct tapping drill size based on material hardness, thread type, screw or bolt size, and tap type is crucial for successful tapping operations. Referring to tapping drill size charts specific to the thread standard being used is highly recommended.

Frequently Asked Questions about Tapping Drills

1. What is a tapping drill?

A tapping drill, also known as a tap drill or a pilot hole, is a hole drilled to provide a starting point for a tap to thread into a material. It is designed to ensure proper alignment and prevent the tap from wandering or breaking during the tapping process.

2. What is the purpose of a tapping drill?

The main purpose of a tapping drill is to create an accurate and properly sized hole that allows a tap to cut threads into a material. By drilling a smaller hole before tapping, the tap has a better chance of threading smoothly and creating strong, functional threads in the material.

3. How is the size of a tapping drill determined?

The size of a tapping drill is determined by the size of the tap being used. It is typically smaller than the tap’s cutting thread size to ensure that the threads are properly formed. The recommended tapping drill size for each tap is specified in tap drill charts, which provide guidelines based on the thread size and material being tapped.

4. What happens if the wrong size tapping drill is used?

If the wrong size tapping drill is used, it can lead to several issues. Using a drill that is too small may cause the tap to bind or break due to excessive pressure. Conversely, using a drill that is too large may result in weak or incomplete threads, reducing the overall strength and functionality of the tapped hole.

5. Can I use a tapping drill without a tap?

While it is technically possible to use a tapping drill without a tap, the drill alone cannot create threads in a material. The purpose of a tapping drill is to provide a starting point for the tap, which is responsible for cutting the threads. Therefore, using a tapping drill without a tap would not yield the desired threaded hole.

6. Can I use a tap without a tapping drill?

Using a tap without a tapping drill is possible in some cases, especially for softer materials or when tapping by hand. However, using a tapping drill is generally recommended to ensure accurate alignment, easier cutting, and better thread quality. For most applications, it is best to use a tapping drill before tapping.

7. Can I use any type of drill bit as a tapping drill?

While it is possible to use certain types of drill bits as tapping drills, it is generally recommended to use a specific type of bit called a “taper tap drill.” Taper tap drills have a specific flute design that helps guide the tap into the material and prevent chip clogging. Using a regular twist drill bit may not provide the same level of accuracy and ease of use when tapping.

8. Can I use a tapping drill for different types of taps?

Yes, a tapping drill can be used for different types of taps, as long as the thread sizes match. However, it is important to note that different types of taps may require different drilling techniques and depths. Refer to tap drill charts or manufacturer guidelines to ensure the proper use of a tapping drill with different types of taps.

FAQ:

What is a tapping drill?

A tapping drill is a tool used in metalworking to create holes that will eventually be threaded.

How does a tapping drill work?

A tapping drill is designed with specific dimensions and angles to create a hole that is the correct size and shape to accommodate a threaded fastener. The drill is used to create the initial hole, and then a tap is used to cut the threads.

Why is it important to use the correct tapping drill?

Using the correct tapping drill is important because it ensures that the hole is the correct size and shape to properly accommodate the threaded fastener. If the hole is too small, the tap may not be able to cut the threads. If the hole is too large, the threads may not have enough material to properly grip.

What factors should be considered when choosing a tapping drill?

When choosing a tapping drill, factors such as the material being drilled, the size and type of fastener being used, and the desired thread depth should be considered. Different materials and fasteners may require different drill sizes and thread depths for optimal performance.

Video: