Understanding Chuck Size: A Guide to Drill Precision

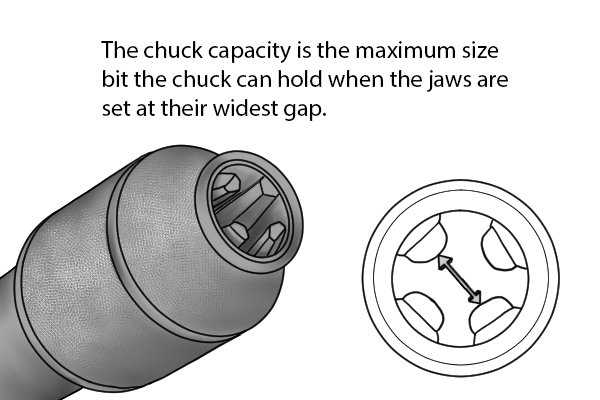

When it comes to choosing the right drill for your projects, understanding the chuck size is crucial for achieving precision and accuracy. The chuck size refers to the diameter of the opening where the drill bit is inserted. It plays a significant role in determining the types and sizes of drill bits that can be used with a particular drill.

Why is chuck size important?

The chuck size determines the maximum diameter of the drill bit that can be used with a drill. For example, a drill with a 1/2-inch chuck can accommodate drill bits with a maximum diameter of 1/2 inch. If you attempt to use a larger drill bit, it will not fit into the chuck, resulting in inaccurate drilling and potential damage to the drill bit.

The different chuck sizes available:

Chuck sizes can vary, but the most common sizes for home use are 1/4 inch, 3/8 inch, and 1/2 inch. The smaller 1/4-inch chuck is typically found on compact drills and is suitable for lighter tasks such as drilling small holes and driving screws. The larger 1/2-inch chuck is found on heavy-duty drills and can handle larger drill bits for drilling bigger holes.

Remember, it’s vital to select a drill with a chuck size that can accommodate the maximum size of drill bits you will be using for your specific project.

Other factors to consider:

While chuck size is an important factor in drill precision, it is not the only factor to consider. The drill’s power and speed settings also play a role in achieving precise drilling. Additionally, the type of drill bit used, such as twist bits or spade bits, can affect the overall precision of drilling.

In conclusion, understanding the chuck size of a drill is essential for selecting the right tool for your projects. It ensures that you can use the appropriate size of drill bits and achieve accurate and precise drilling. Take into account other factors such as power, speed settings, and the type of drill bits to ensure optimal results for each project.

Understanding Chuck Size

When it comes to drill precision, one important factor to consider is the size of the chuck. The chuck is the part of the drill that holds the drill bit in place and allows it to rotate. Different drill sizes have different chuck sizes, and the chuck size determines the maximum diameter of the drill bit that can be used with the drill.

Advantages of a Larger Chuck Size

- A larger chuck size allows you to use larger drill bits, which can be beneficial when drilling larger holes.

- With a larger chuck size, you can also use a wider range of drill bits to accommodate different drilling needs.

- Larger chuck sizes usually indicate more power in the drill, which can be advantageous for tougher drilling tasks.

Advantages of a Smaller Chuck Size

- A smaller chuck size is generally more lightweight and compact, making it easier to handle and maneuver.

- Smaller chuck sizes are typically used for lighter duty tasks, such as drilling small holes in wood or metal.

- Drills with smaller chuck sizes are often more affordable, making them a popular choice for DIYers or occasional use.

Common Chuck Sizes

| Chuck Size | Maximum Drill Bit Diameter |

|---|---|

| 1/4 inch | 1/4 inch |

| 3/8 inch | 3/8 inch |

| 1/2 inch | 1/2 inch |

| 5/8 inch | 5/8 inch |

| 3/4 inch | 3/4 inch |

It’s important to note that while the chuck size indicates the maximum drill bit diameter, it’s always recommended to use a drill bit that is slightly smaller than the chuck size for optimal performance and safety.

A Guide to Drill Precision

Introduction

Drilling precise holes is an essential skill for any woodworker or DIY enthusiast. The ability to drill accurately ensures the stability and durability of the finished product. This guide will provide you with the necessary information and techniques to achieve precise drill holes every time.

Choose the Right Drill Bit

Selecting the right drill bit is crucial for achieving drill precision. The type and size of the drill bit you choose will depend on the material you are drilling into. For wood, a brad point bit or a spade bit is recommended for better accuracy. For metal or other hard materials, a twist bit or a cobalt bit works best.

Secure the Workpiece

To maintain precision, it’s important to secure the workpiece properly. Use clamps or vices to firmly hold the material in place. This will prevent any movement or wobbling during the drilling process, ensuring accurate holes.

Mark the Drilling Points

Before drilling, mark the exact spots where you want to make the holes. Use a pencil or a punch to create small indentations on the surface. These marks will act as a guide and help you drill with precision.

Start with a Pilot Hole

For larger holes, it’s recommended to start with a pilot hole. A pilot hole is a smaller hole that serves as a guide for the larger drill bit. By creating a pilot hole, you can ensure that the drill bit stays on track and doesn’t wander, resulting in more precise holes.

Drill at the Right Speed

Drilling at the correct speed is crucial for drill precision. For wood, a medium speed is usually ideal, while for metal or hard materials, a slower speed is recommended. Adjust the speed of your drill as necessary to ensure accurate and clean holes.

Use a Drill Press

If precision is of utmost importance, consider using a drill press. A drill press provides greater stability and control compared to hand drilling. It allows for more accurate depth and angle adjustments, resulting in precise holes.

Regular Maintenance

To maintain drill precision, it’s important to keep your drill bits and drill press in good condition. Regularly clean the drill bits, remove any debris, and sharpen them if necessary. Lubricate the drill press components to ensure smooth operation and accuracy.

Conclusion

By following these guidelines and practicing your drilling technique, you can achieve drill precision on a consistent basis. Remember to choose the right drill bit, secure the workpiece, mark the drilling points, start with a pilot hole if needed, drill at the right speed, consider using a drill press for greater precision, and perform regular maintenance on your drilling tools. With these tips, you’ll be able to create professional-looking projects with accurate and clean drill holes.

Choosing the Right Chuck Size

When it comes to choosing the right chuck size for your drill, there are a few factors to consider. The chuck size is determined by the maximum diameter of the drill bit it can accommodate. Here are some things to keep in mind:

1. Drill Bit Size

The chuck size you choose should be compatible with the drill bits you plan to use. Different applications require different drill bit sizes. For example, if you primarily work with small diameter drill bits for delicate tasks, a smaller chuck size may be sufficient. However, if you need to drill larger holes, you will need a chuck size that can accommodate larger drill bits.

2. Application

The type of work you do will also play a role in choosing the right chuck size. If you work on a wide variety of projects that require drilling holes of different sizes, you may benefit from a drill with multiple chuck sizes. This will allow you to easily change between different drill bits without needing to switch to a different drill altogether. However, if you specialize in a specific type of work that requires a consistent drill bit size, a drill with a single chuck size may be sufficient.

3. Power and Torque

Consider the power and torque requirements of your projects. Generally, drills with larger chuck sizes tend to have more power and torque capabilities. If you frequently work on heavy-duty projects that require drilling into tough materials, a drill with a larger chuck size and higher power and torque capabilities may be necessary. However, if you mainly work on lighter tasks, a drill with a smaller chuck size and lower power and torque may be more suitable.

4. Availability and Compatibility

Finally, consider the availability and compatibility of drill bits with different chuck sizes. While the most common chuck size is 1/2 inch, there are drills available with chuck sizes ranging from 1/4 inch to 3/4 inch or even larger. Be sure to choose a chuck size that is widely available and compatible with the drill bits you need for your projects.

- Consider the drill bit size and compatibility

- Take into account the applications you work on

- Consider the power and torque requirements of your projects

- Take into account the availability and compatibility of drill bits with different chuck sizes

By considering these factors, you can choose the right chuck size for your drill and ensure that it meets your specific needs and requirements for precision and performance.

Factors to Consider

When choosing the right chuck size for your drill, there are several factors to consider. The chuck size will greatly impact the precision and functionality of your drill, so it’s important to choose wisely.

1. Drill Bit Compatibility

One of the main considerations when selecting a chuck size is the compatibility with the drill bits you plan to use. Different chuck sizes are designed to hold specific sizes of drill bits, so it’s essential to ensure that your chuck can securely hold the drill bits you will be using.

2. Drill Type and Application

The type of drill and the specific application you have in mind will also influence the chuck size you choose. For example, if you are using a smaller handheld drill for general household tasks, a smaller chuck size may be sufficient. On the other hand, if you are using a heavy-duty drill for industrial applications, you may need a larger chuck size to accommodate larger drill bits.

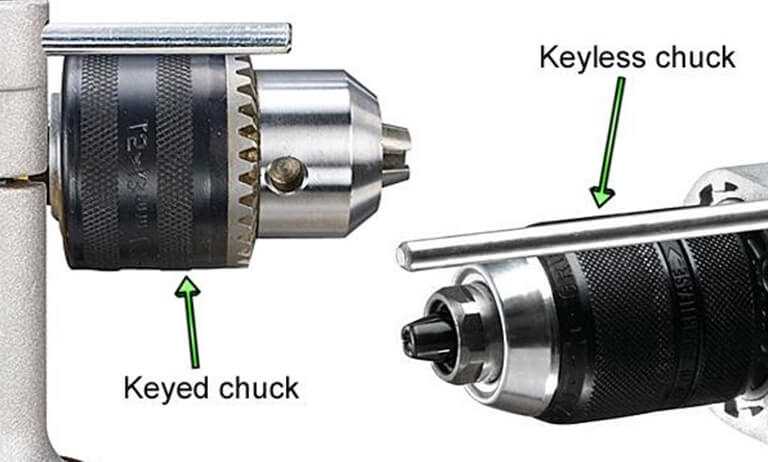

3. Chuck Type

There are various types of chucks available, including keyless chucks, keyed chucks, and SDS chucks. Each type has its own advantages and limitations. Keyless chucks offer quick bit changes without the need for a key, while keyed chucks provide a firmer grip on the drill bit. SDS chucks are specifically designed for rotary hammers and offer additional features for heavy-duty drilling. Consider the chuck type that best suits your needs when selecting a chuck size.

4. Drill Speed and Power

The speed and power of your drill can also affect the chuck size you should choose. Higher power drills may require larger chuck sizes to handle the increased torque and accommodate larger drill bits. Additionally, drills with variable speed settings may be more versatile in terms of the chuck sizes they can accommodate.

5. Budget Constraints

Finally, it’s essential to consider your budget when choosing a chuck size. While larger chuck sizes may offer more versatility, they also tend to be more expensive. Consider your needs and budget constraints to find the right balance between chuck size and cost.

By carefully considering these factors, you can make an informed decision when selecting the right chuck size for your drill. Remember that the chuck size directly affects the precision and functionality of your drill, so it’s worth taking the time to choose the right one for your specific needs.

Chuck Size and Drill Precision

When it comes to drilling, the chuck size plays a crucial role in the precision and accuracy of the drilling process. The chuck size refers to the diameter of the opening in the drill where the drill bit is inserted and secured.

A smaller chuck size generally means a more precise drilling experience. This is because a smaller chuck provides a tighter grip on the drill bit, reducing any wobbling or movement during drilling. This results in cleaner and more accurate holes.

On the other hand, larger chuck sizes are beneficial for drilling larger holes or using larger drill bits. They provide more room for these bigger tools and allow for faster drilling speeds. However, larger chuck sizes may sacrifice some precision and accuracy.

Importance of Chuck Size Selection

Choosing the right chuck size for your drilling needs is essential to achieve the desired precision. Consider the following factors when selecting the chuck size:

- The size of the drill bit: Ensure that the chuck size is compatible with the drill bits you will be using. A smaller chuck cannot accommodate larger drill bits, and vice versa.

- The material being drilled: Different materials require different drill bit sizes. Make sure the chuck size can handle the size needed for the specific material you will be drilling into.

- The level of precision required: If you need high precision and accuracy, opting for a smaller chuck size is recommended.

Chuck Size and Drill Types

The chuck size also varies based on the type of drill. Most handheld drills have a chuck size between 1/4 inch and 1/2 inch. These drills are suitable for general drilling tasks and offer a balance between precision and versatility.

However, for more specialized drilling, such as in woodworking or metalworking, drills with larger chuck sizes are often used to accommodate specific drill bits designed for those applications. These larger chuck sizes allow for easier interchangeability of different drill bits.

Conclusion

Chuck size plays a crucial role in drill precision and accuracy. While larger chuck sizes are beneficial for certain applications, smaller chuck sizes offer greater precision. Understanding your drilling needs and selecting the appropriate chuck size will help you achieve the desired results in your drilling projects.

Importance of Chuck Size

When it comes to drill precision, the size of the chuck plays a crucial role. The chuck is the part of the drill that holds the drill bit in place. It is responsible for securing the bit and allowing it to rotate at high speeds without slipping or wobbling.

The chuck size refers to the maximum diameter of the drill bit that the chuck can accommodate. It is typically measured in inches and is an important factor to consider when choosing a drill. The chuck size determines the flexibility and versatility of the drill, as it determines the range of drill bits that can be used with the tool.

Increased Versatility

A larger chuck size allows for the use of larger drill bits. This means that you can tackle a wider range of drilling tasks, from small and precise holes to larger and more demanding projects. With a larger chuck size, you can easily switch between different drill bits without needing multiple drills, making your work more efficient.

On the other hand, a smaller chuck size limits the size of the drill bits you can use. This can be a drawback if you frequently work on projects that require larger, heavier-duty bits. You may need to invest in a separate drill with a larger chuck size to handle these tasks.

Improved Stability

The chuck size also affects the stability of the drill bit when in use. A larger chuck size provides a stronger grip on the bit, reducing the chances of it slipping or wobbling during drilling. This results in more precise and accurate holes.

Conversely, a smaller chuck size may not provide a secure grip on larger drill bits. This can lead to the bit slipping or wobbling, resulting in less precise holes. It may also increase the risk of accidents or injuries.

Considerations when Choosing Chuck Size

When selecting a drill, it’s important to consider the types of projects you will be working on and the range of drill bits you are likely to use. If you anticipate needing to work with larger drill bits on a regular basis, it’s advisable to choose a drill with a larger chuck size.

Additionally, it’s worth noting that drills with larger chuck sizes tend to be more powerful and better suited for heavy-duty tasks. If you primarily work on small, delicate projects, a drill with a smaller chuck size may be more appropriate.

Overall, the chuck size is a key factor to consider when choosing a drill. It determines the versatility and stability of the tool, and ultimately affects the quality of your work. By understanding the importance of chuck size, you can make an informed decision when selecting the right drill for your needs.

Chuck Size and Drill Speed

The Relationship Between Chuck Size and Drill Speed

When it comes to drilling, the chuck size of your drill plays a crucial role in determining the speed at which you can drill. The chuck size refers to the diameter of the opening in the drill where you attach different drill bits.

Generally, larger chucks allow you to use larger drill bits and therefore drill larger holes. However, chuck size also affects the speed at which the drill operates. This is because larger chucks are typically found on more powerful drills, which can rotate at higher speeds.

If you’re working on a task that requires drilling at high speeds, a drill with a larger chuck size would be more suitable as it can handle the higher speed without damaging the drill or the material being drilled.

Choosing the Right Chuck Size for Your Project

When selecting a drill for your project, it’s important to consider the chuck size and the speed at which you need to drill. Here are a few factors to keep in mind:

- Drill Bit Compatibility: Make sure the chuck size is compatible with the drill bits you plan to use. A chuck size that is too small may not be able to accommodate larger drill bits.

- Material Being Drilled: Different materials require different speeds for drilling. For example, drilling through metal typically requires lower speeds compared to drilling through wood. Consider the specific requirements of your project and choose a chuck size that can handle the appropriate speed.

- Power and Torque: Larger chucks are often found on drills with greater power and torque capabilities. If you need a drill with more power to handle tough materials or heavy-duty tasks, a larger chuck size may be necessary.

Summary

In summary, the chuck size of a drill is closely related to the drill speed. Larger chucks allow for higher drill speeds, which can be beneficial for certain projects. When choosing a drill, consider the compatibility with your drill bits, the material being drilled, and the power and torque requirements of your project. By selecting the right chuck size and drill speed, you can achieve precise and efficient drilling results.

Impact on Drilling Efficiency

Choosing the right chuck size for your drill can have a significant impact on drilling efficiency. The chuck is the part of the drill that holds the drill bit in place, and the size of the chuck determines the range of drill bit sizes that can be used. Here are a few ways in which chuck size can affect drilling efficiency:

1. Versatility

The chuck size determines the range of drill bit sizes that can be used with a particular drill. A larger chuck size allows for the use of larger drill bits, while a smaller chuck size limits the size of drill bits that can be used. Having a wider range of drill bit sizes available can make your drill more versatile and adaptable to various drilling tasks.

2. Precision

The size of the chuck can also impact drilling precision. A smaller chuck size provides a tighter grip on the drill bit, reducing the likelihood of wobbling or slippage during drilling. This can result in more accurate and precise drilling, especially when working with delicate or detailed materials.

3. Speed

In general, larger chuck sizes allow for faster drilling speeds. This is because larger chucks can accommodate larger drill bits, which are often used for drilling larger holes. The larger drill bits have more cutting edges and can remove material more quickly, resulting in faster drilling speeds and increased efficiency.

4. Power and Torque

The chuck size can also have an impact on the power and torque of the drill. A larger chuck size is often associated with more powerful drills that can generate higher levels of torque. This increased power and torque can be beneficial when drilling through tougher materials or when drilling larger holes that require more force.

| Factor | Impact |

|---|---|

| Versatility | Affects range of drill bit sizes that can be used |

| Precision | Can improve accuracy and reduce wobbling |

| Speed | Affects drilling speed, larger chucks can drill faster |

| Power and Torque | Larger chucks often associated with more power and torque |

When selecting a drill and chuck size, it’s important to consider the specific needs of the drilling task at hand. Factors such as the desired drill bit sizes, the level of precision required, and the material being drilled should all be taken into account to ensure optimal drilling efficiency.

Chuck Size and Bit Compatibility

Introduction:

A drill’s chuck size refers to the maximum diameter of the drill bit shank that can fit into the chuck. It is an important specification to consider when choosing the right drill for your project. The chuck size determines the range of drill bits that can be used with the drill, and therefore affects the drill’s versatility and performance.

Standard Chuck Sizes:

The most common chuck sizes for handheld drills are 1/4 inch, 3/8 inch, and 1/2 inch. These sizes refer to the maximum bit shank diameter that the chuck can accommodate. The 1/4 inch chuck is the smallest and is typically found in lighter-duty drills, while the 1/2 inch chuck is the largest and is commonly found in heavy-duty drills.

Bit Compatibility:

The chuck size directly affects the types and sizes of drill bits that can be used with the drill. It is important to choose drill bits that have shank diameters that are compatible with the chuck size of the drill.

For example, a drill with a 1/4 inch chuck can only accept drill bits with shank diameters of 1/4 inch or smaller. Similarly, a drill with a 1/2 inch chuck can accept drill bits with shank diameters of 1/2 inch or smaller.

Adapters and Chuck Key:

If you have a drill with a smaller chuck size but need to use larger drill bits, you can use an adapter. An adapter allows you to use drill bits with larger shank diameters by reducing them to fit the smaller chuck size.

For drills with a chuck size of 3/8 inch or larger, they often come with a chuck key. The chuck key is a small tool used to tighten and loosen the chuck to secure the drill bit. It is an essential accessory for drills with larger chuck sizes, as they may require more torque to tighten the chuck.

Conclusion:

Understanding the chuck size of a drill and its compatibility with different drill bit sizes is crucial for ensuring that you can use the right drill bits for your project. It is recommended to choose a drill with a chuck size that can accommodate a broad range of bit sizes to maximize the versatility of the tool.

Remember to always refer to the manufacturer’s specifications and recommendations when selecting and using drill bits with your drill.

Matching Chuck Size to Bit Type

When it comes to drilling, it is important to use the right type of bit for the job. However, it is equally important to match the size of the chuck on your drill to the size of the bit you are using. Here are some guidelines to help you choose the right chuck size for your bit type:

1. Twist Bits

- Chuck Size: Twist bits can typically be used with chucks ranging from 1/4 inch to 1/2 inch in size.

- Bit Sizes: Twist bits come in a variety of sizes, ranging from very small to large. It is important to choose a chuck that can accommodate the size of the twist bit you are using.

- Chuck Type: A standard keyless chuck is typically used with twist bits.

2. Masonry Bits

- Chuck Size: Masonry bits require a larger chuck size due to their larger diameter. Chucks ranging from 3/8 inch to 1/2 inch are often recommended for masonry bits.

- Bit Sizes: Masonry bits are available in various sizes, depending on the type of material you are drilling into. It is important to choose a chuck that can accommodate the size of the masonry bit you are using.

- Chuck Type: A hammer drill chuck is typically used with masonry bits, as it provides the necessary hammering action for drilling into tough materials.

3. Spade Bits

- Chuck Size: Spade bits can typically be used with chucks ranging from 1/4 inch to 1/2 inch in size.

- Bit Sizes: Spade bits come in various sizes, typically ranging from 1/4 inch to 1-1/4 inch in diameter. It is important to choose a chuck that can accommodate the size of the spade bit you are using.

- Chuck Type: A standard keyless chuck is typically used with spade bits.

It is important to remember that these are general guidelines and may vary depending on the specific drill and bit manufacturers. Always consult the manufacturer’s recommendations for the best chuck size and bit type compatibility.

FAQ:

What is chuck size and why is it important in drilling?

Chuck size refers to the diameter of the opening in the drill where the drill bit is inserted. It is important in drilling because it determines the maximum size of drill bit that can be used with the drill. Different chuck sizes are suitable for different types of drilling tasks.

What are the common chuck sizes for drills?

The common chuck sizes for drills are 1/4 inch, 3/8 inch, and 1/2 inch. These sizes are based on the maximum diameter of drill bit that can be used with the drill.

How do I determine the chuck size of my drill?

To determine the chuck size of your drill, you can measure the diameter of the opening in the chuck where the drill bit is inserted. Alternatively, you can find the chuck size information in the user manual or specifications of the drill.

Can I use a drill bit with a larger diameter than the chuck size?

No, you should not use a drill bit with a larger diameter than the chuck size. The chuck is designed to securely hold drill bits of a specific size. Using a drill bit with a larger diameter could result in the bit slipping or causing damage to the drill.

Are there any adapters available to use different-sized drill bits with a drill?

Yes, there are chuck adapters available that allow you to use different-sized drill bits with a drill. These adapters typically have a larger chuck size on one end and a smaller chuck size on the other end, allowing for compatibility with a wider range of drill bits.

What factors should I consider when choosing the right chuck size for my drill?

When choosing the right chuck size for your drill, you should consider the types of drilling tasks you will be performing. If you will be doing mostly light-duty tasks, a drill with a smaller chuck size may be sufficient. For heavier duty tasks or for working with larger drill bits, a drill with a larger chuck size would be more suitable.

Video: