Tips for Drilling Large Holes in Metal

Drilling large holes in metal can be a challenging task, but with the right tools and techniques, it can be made much easier. Whether you’re a professional or a DIY enthusiast, there are a few tips that can help you achieve better results and avoid common mistakes.

Choose the Right Drill Bit: One of the most important factors to consider when drilling large holes in metal is choosing the right drill bit. For large holes, it is recommended to use a carbide or cobalt drill bit, as they are specially designed to cut through metal efficiently. These drill bits are harder and more durable, allowing them to withstand the high pressure and heat generated during the drilling process.

Use Cutting Fluid: Drilling through metal can generate a significant amount of heat, which can lead to premature wear and tear on your drill bit. To reduce heat buildup and extend the life of your drill bit, it is recommended to use a cutting fluid. This cooling lubricant helps to dissipate heat and also acts as a lubricant, making the drilling process smoother and more efficient.

Start with a Pilot Hole: When drilling larger holes in metal, it is often helpful to start with a smaller pilot hole. A pilot hole provides a guide for the larger drill bit and helps prevent it from wandering off course. This can improve accuracy and reduce the risk of damaging the metal surface. Starting with a smaller drill bit also puts less strain on your drill, making it easier to drill through the metal.

Take Breaks and Gradually Increase Speed: Drilling large holes in metal can be a time-consuming process, especially if the metal is thick or hard. It is important to take breaks as needed to prevent overheating and to allow the drill bit to cool down. Additionally, it can be helpful to gradually increase the speed of your drill as you progress through the drilling process. This can help prevent the drill bit from binding and reduce the chance of it breaking or getting stuck.

Remember, drilling large holes in metal requires patience and attention to detail. By following these tips and using the right tools, you can achieve clean and precise holes in metal without unnecessary frustration or damage.

Understanding the Metal Type

When drilling large holes in metal, it’s important to consider the type of metal you are working with. Different metals have different properties and can require different drilling techniques. Here are some common metal types and how to approach drilling them:

1. Steel

Steel is a commonly used metal in a wide range of applications. When drilling large holes in steel, it’s important to use high-speed steel (HSS) drill bits. These drill bits are specifically designed to withstand the higher temperatures generated when drilling steel. It’s also important to use cutting fluid to cool and lubricate the drill bit, as this can help prolong its life.

2. Aluminum

Aluminum is a lightweight metal that is often used in aerospace and automotive applications. When drilling large holes in aluminum, it’s important to use drill bits specifically designed for use with aluminum. These drill bits often have a high helix angle and a sharp point, which helps to prevent clogging and ensure a clean hole. When drilling aluminum, it’s important to use a slower drilling speed and to apply light pressure to prevent the drill bit from grabbing and causing damage.

3. Stainless Steel

Stainless steel is a durable and corrosion-resistant metal commonly used in applications where hygiene and appearance are important, such as in the food and medical industries. When drilling large holes in stainless steel, it’s important to use cobalt drill bits. These drill bits are specifically designed to drill through hard metals like stainless steel. It’s also important to use cutting fluid and to use a slower drilling speed to prevent overheating and to prolong the life of the drill bit.

4. Brass and Copper

Brass and copper are soft metals that are often used in decorative applications. When drilling large holes in brass or copper, it’s important to use a drill bit specifically designed for use with these softer metals. These drill bits often have a high rake angle and a sharp point, which helps to prevent grabbing and ensures a clean hole. When drilling brass or copper, it’s important to use a faster drilling speed and to apply light pressure to prevent the drill bit from getting stuck or causing damage.

5. Cast Iron

Cast iron is a strong and brittle metal that is often used in construction and automotive applications. When drilling large holes in cast iron, it’s important to use high-speed steel (HSS) drill bits with a TiN (titanium nitride) coating. This coating helps to reduce friction and heat, prolonging the life of the drill bit. It’s also important to use cutting fluid and to use a slower drilling speed to prevent overheating and to ensure a clean hole.

Remember, always wear appropriate safety gear when drilling metal and follow the manufacturer’s instructions for the drill bits and cutting fluid you are using.

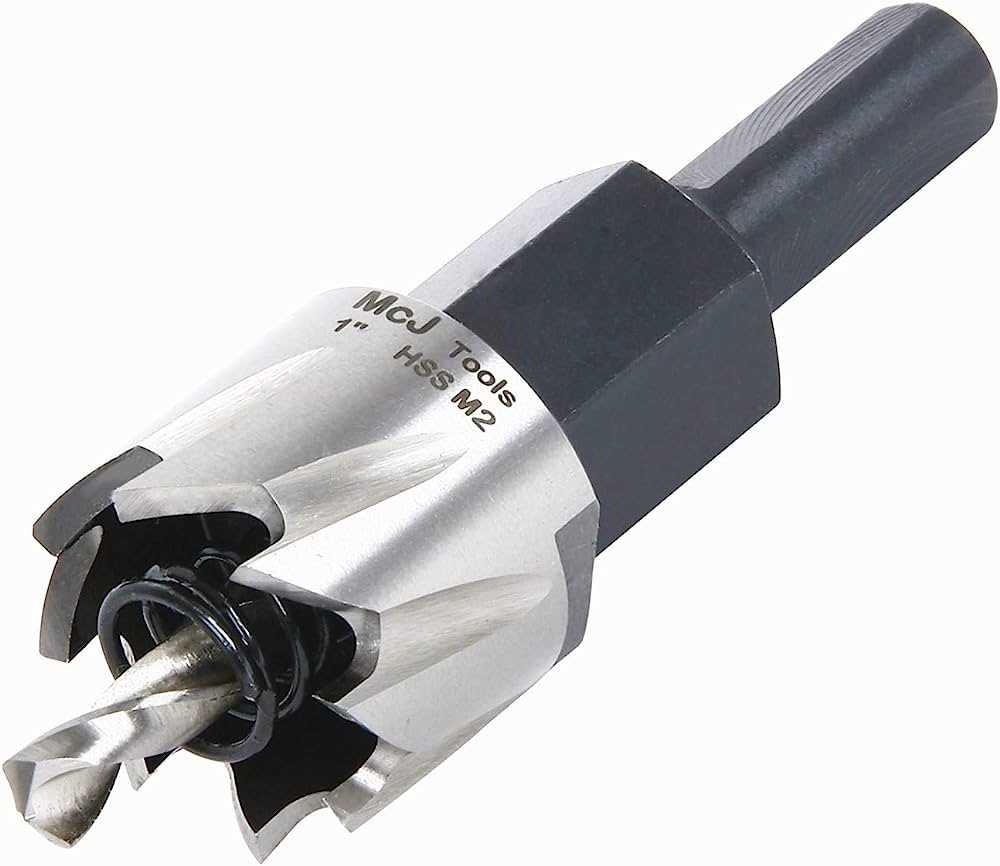

Choosing the Right Drill Bit

When it comes to drilling large holes in metal, choosing the right drill bit is crucial. Using the wrong drill bit can lead to inefficient drilling, damaged equipment, and even personal injury. Here are some important factors to consider when selecting the right drill bit for the job:

1. Material:

The type of metal you are drilling into will determine the type of drill bit you should use. Common types of metal include steel, aluminum, and stainless steel. Each of these metals requires a different type of drill bit, as they have different properties and hardness levels. It is important to choose a drill bit specifically designed for the type of metal you need to drill into to achieve better results.

2. Size:

The size of the hole you need to drill will also determine the size of the drill bit you should use. Drill bits come in a range of sizes, typically measured in diameter in inches or millimeters. It is important to select a drill bit that matches the desired hole size to ensure accuracy and prevent damage to the metal.

3. Coating:

Some drill bits come with specialized coatings that can enhance their performance and durability. Coatings like titanium nitride (TiN) or black oxide can improve the drill bit’s ability to withstand heat and reduce friction during drilling, resulting in longer tool life. Consider choosing a drill bit with a coating if you anticipate drilling a large number of holes or working with tough materials.

4. Shank Type:

The shank of the drill bit is the part that fits into the drill chuck. Different drills have different chuck types, such as a keyed chuck or a keyless chuck. It is important to choose a drill bit with a shank type that is compatible with your drill to ensure a secure fit and prevent accidents during drilling.

5. Point Angle:

The point angle of the drill bit determines the aggressiveness of the drilling action. A larger point angle will result in a more aggressive cutting action, while a smaller point angle will be more precise. Consider the nature of your drilling task and choose a drill bit with an appropriate point angle to achieve the desired results.

By taking into account these factors and selecting the right drill bit for the job, you can ensure safer and more efficient drilling when working with large holes in metal. Remember to always follow proper safety procedures and wear appropriate protective gear when operating power tools.

Using Lubrication for Smooth Drilling

When drilling large holes in metal, using lubrication can greatly improve the drilling process and ensure smooth and precise results. Lubrication helps reduce friction between the drill bit and the metal, which can lead to overheating and dulling of the bit. It also helps to prolong the lifespan of the drill bit and prevent damage to the metal being drilled.

Types of Lubrication

There are several types of lubrication that can be used when drilling large holes in metal:

- Cutting oil: Cutting oil is a specially formulated lubricant that is designed to be used during metal drilling operations. It provides excellent lubrication and cooling properties, which help to reduce heat and friction. Cutting oil comes in different viscosities, so it is important to choose the right one for the specific drilling task.

- Tap Magic: Tap Magic is a popular brand of cutting fluid that is often used for drilling and tapping operations. It is a versatile lubricant that can be used on a variety of metals and drilling applications. Tap Magic is available in different formulations, including one specifically designed for aluminum drilling.

- WD-40: WD-40 is a multipurpose lubricant that can also be used for drilling metal. While it may not provide the same level of lubrication and cooling as cutting oil or Tap Magic, it can still help reduce friction and prevent overheating. WD-40 is commonly used when drilling small holes or for occasional drilling tasks.

How to Apply Lubrication

Applying lubrication is a simple process that can be done before and during the drilling operation:

- Before drilling: Before starting the drilling process, apply a small amount of lubricant to the drill bit. This can be done by dipping the bit into a container of lubrication or by using a brush or applicator to coat the bit.

- During drilling: While drilling, it is important to continuously apply lubrication to the bit and the hole being drilled. This can be done by using a lubrication system built into the drilling machine, or by manually applying lubricant using a brush or applicator. The lubricant should be applied at regular intervals to ensure smooth and efficient drilling.

Benefits of Using Lubrication

Using lubrication when drilling large holes in metal offers several benefits:

- Reduced heat and friction: Lubrication helps to reduce heat and friction between the drill bit and the metal, which prevents overheating and prolongs the lifespan of the bit.

- Improved cutting performance: With reduced friction, the drill bit can cut through the metal more smoothly and quickly, resulting in a cleaner and more precise hole.

- Extended tool life: By reducing heat and friction, lubrication helps to prevent the drill bit from dulling or breaking prematurely, which extends its overall lifespan.

- Prevention of metal damage: Lubrication acts as a protective barrier between the drill bit and the metal being drilled, preventing damage such as scratches and overheating.

| Advantages | Disadvantages |

|---|---|

|

|

Ensuring Proper Clamping

Proper clamping is essential when drilling large holes in metal. Without sufficient clamping, the metal may move or shift during the drilling process, resulting in inaccurate holes or damage to the workpiece. Here are some tips to ensure proper clamping:

1. Choose the Right Clamping Method

There are various clamping methods available, depending on the type of workpiece and the drilling setup. Some common clamping methods include:

- Using a vise: A vise provides a secure grip on the workpiece and allows for easy clamping and unclamping.

- Using clamps: Clamps can be used to secure the workpiece to a workbench or drilling table.

- Using magnetic clamps: Magnetic clamps are ideal for holding down flat, ferrous metal workpieces.

- Using a drill press vise: A drill press vise is specifically designed for use with a drill press and provides a stable platform for drilling.

2. Ensure Proper Positioning

Before clamping the workpiece, ensure that it is properly positioned to avoid any interference with the drill or other components. The workpiece should be aligned and centered with the drilling point to ensure accurate drilling.

3. Use Adequate Clamping Force

Apply sufficient clamping force to securely hold the workpiece in place. However, be cautious not to over-tighten the clamps, as this can deform the workpiece or cause it to crack.

4. Check for Stability

After clamping the workpiece, check for stability by lightly tapping on it. If the workpiece moves or vibrates, adjust the clamping setup to ensure a stable position.

5. Consider Supporting the Workpiece

If you are drilling large holes close to the edges of the workpiece, it may be helpful to provide additional support. This can be done by using blocks or shims to stabilize the workpiece and prevent any bending or flexing during drilling.

By following these tips, you can ensure proper clamping when drilling large holes in metal. This will result in accurate and clean holes, minimizing the risk of errors or damage to the workpiece.

Applying the Right Pressure

1. Start with a Pilot Hole

When drilling large holes in metal, it is important to start with a pilot hole. A pilot hole is a smaller hole drilled before the larger hole. This helps guide the larger drill bit and prevents it from wandering off course. When drilling the pilot hole, apply light pressure and gradually increase it as the hole gets larger.

2. Use a Lubricant

Applying a lubricant to the drill bit and the metal surface can help reduce friction and heat buildup. This not only makes the drilling process smoother but also extends the life of the drill bit. Apply the lubricant to the drill bit and the surface of the metal before drilling.

3. Maintain a Steady Speed

Drilling large holes in metal requires a steady speed to prevent the drill bit from overheating. Too much speed can cause the drill bit to become dull or even break. Keep the drill at a manageable speed and avoid applying excessive force. Let the drill bit do the work.

4. Use a Clamping Device

To ensure stability and accuracy during the drilling process, use a clamping device to secure the metal in place. This will prevent the metal from moving or vibrating while drilling and reduce the risk of the drill bit binding or breaking.

5. Take Breaks

Large hole drilling can be a labor-intensive task, especially when drilling through thick metal. Taking breaks during the process is essential to give both the drill bit and the operator a rest. This prevents overheating and reduces the risk of fatigue or injury.

6. Choose the Right Drill Bit

Using the right drill bit for the job is crucial when drilling large holes in metal. For softer metals, such as aluminum or copper, high-speed steel (HSS) drill bits work well. For harder metals, such as steel or iron, carbide-tipped drill bits are recommended. Using the correct drill bit ensures cleaner holes and reduces the risk of the bit dulling or breaking.

7. Safety Precautions

When drilling large holes in metal, it is important to take safety precautions. Wear appropriate safety gear, including safety glasses, gloves, and hearing protection. Always work in a well-ventilated area to avoid inhaling dust or fumes. Be cautious of flying metal shavings and keep a fire extinguisher nearby as a precaution.

By following these tips and applying the right pressure, you can effectively drill large holes in metal with precision and efficiency.

Using a Pilot Hole for Accuracy

When drilling large holes in metal, it can be difficult to achieve precision and accuracy. One effective technique to improve accuracy is to use a pilot hole. A pilot hole is a smaller hole drilled into the metal before drilling the final large hole. This initial hole helps guide the drill bit, providing a more precise starting point and reducing the chance of the drill bit wandering off course.

Benefits of using a pilot hole:

- Better accuracy: The pilot hole acts as a guide for the drill bit, ensuring it starts in the desired location and drills straight.

- Reduced chance of wandering: Without a pilot hole, the drill bit may wander or slip, leading to an inaccurate hole. Using a pilot hole minimizes this risk.

- Improved control: The pilot hole allows for better control over the drilling process, making it easier to drill larger holes accurately.

Steps to use a pilot hole:

- Choose the appropriate size drill bit for the pilot hole according to the diameter of the larger hole you plan to drill.

- Mark the center of the desired hole location on the metal surface using a punch or marker.

- Secure the metal firmly in place using clamps or a vise to prevent it from moving during drilling.

- Attach the correctly sized drill bit to the drill and position it over the marked center point.

- Apply steady pressure on the drill and begin drilling slowly, ensuring the bit remains perpendicular to the metal surface.

- Continue drilling until the pilot hole reaches the desired depth, removing the drill bit occasionally to clear away debris.

- Once the pilot hole is complete, switch to a larger bit and use the pilot hole as a guide to drill the final large hole with greater accuracy.

Using a pilot hole is a simple yet effective technique to improve accuracy when drilling large holes in metal. By following these steps and taking the time to create a pilot hole, you can ensure that your final hole is precisely where you want it, reducing the risk of mistakes and achieving better results.

Knowing the Speed and Feed Rate

When drilling large holes in metal, it is important to understand and adjust the speed and feed rate to ensure optimal results. The speed and feed rate refer to how fast the drill is rotating and how fast it is being fed into the metal, respectively. These two factors can greatly impact the efficiency and the quality of the drilling process.

Speed

- High Speed: When drilling large holes in metal, a higher speed is generally recommended. The higher speed helps to prevent the drill bit from getting bogged down or overheated during the drilling process.

- Material-Specific Speed: It is important to consider the specific type of metal being drilled. Different metals have varying hardness and density, which may require different drilling speeds. For example, softer metals like aluminum can be drilled at a higher speed, while harder materials like stainless steel may require a slightly lower speed.

Feed Rate

- Slow Feed: For drilling larger holes, using a slower feed rate is generally recommended. This allows the drill bit to remove material more efficiently and reduces the chance of the drill bit chattering or breaking.

- Consistent Feed: Maintaining a consistent and steady feed rate is important for creating clean and precise holes. Rapidly changing the feed rate can lead to uneven hole diameter or even damage to the drill bit.

Considerations

It is important to note that the speed and feed rate are not the only factors to consider when drilling large holes in metal. The hardness and thickness of the material, as well as the type of drill bit being used, also play significant roles in achieving the desired results.

It is recommended to refer to the manufacturer’s guidelines or seek advice from experienced professionals to determine the appropriate speed and feed rate for specific drilling situations. Additionally, conducting tests on a scrap piece of metal can help to determine the optimal settings before drilling the actual workpiece.

| Metal | Speed | Feed Rate |

|---|---|---|

| Aluminum | Higher speed | Slow feed |

| Steel | Slightly lower speed | Slow feed |

| Stainless Steel | Lower speed | Slow feed |

Taking Safety Precautions

1. Wear Protective Gear

Before you begin drilling large holes in metal, it is important to wear appropriate protective gear to ensure your safety. Some essential items to wear include:

- Safety glasses or goggles to protect your eyes from flying debris

- A face shield for added protection

- Heavy-duty gloves to protect your hands from sharp edges and heat

- Earplugs or earmuffs to protect your hearing from loud noise

- A dust mask or respirator to protect your lungs from metal shavings or dust

2. Secure the Workpiece

Before drilling, it is important to securely fasten the workpiece to prevent any movement or slipping during the drilling process. Use clamps or a vise to firmly hold the metal in place. This will not only prevent accidents but also ensure clean and precise holes.

3. Choose the Right Drill Bit

Using the correct drill bit for the specific metal you are drilling into is crucial for safety and efficiency. Consider the following factors when selecting a drill bit:

- Material: Different drill bits are designed for different types of metal, such as steel, aluminum, or stainless steel. Choose a drill bit that is specifically designed for the type of metal you are working with.

- Size: Select a drill bit that is suitable for the size of the hole you need to drill. Using the wrong size can result in excessive friction, breakage, or an inaccurate hole.

- Coating: Some drill bits have coatings that can increase their durability and reduce friction. Look for coated drill bits for extended tool life and smoother drilling.

4. Use Cutting Fluid

When drilling large holes in metal, it is recommended to use cutting fluid or lubricant to reduce friction and heat. Apply a small amount of cutting fluid to the drill bit and the surface of the metal to improve cutting performance, prolong tool life, and prevent overheating.

5. Maintain a Stable Stance

When operating the drill, maintain a stable stance by standing with your feet shoulder-width apart. This will provide better balance and control while drilling. Avoid leaning or overreaching, as it can lead to loss of stability and increased risk of accidents.

6. Proceed with Caution

Take your time and proceed with caution when drilling large holes in metal. Apply steady and consistent pressure to the drill, avoiding excessive force that may cause the bit to break or damage the material. Keep your hands clear of the drill bit and any moving parts.

7. Clean up Properly

After drilling is complete, make sure to clean up the work area properly. Remove any metal shavings, dust, or debris to maintain a safe and clutter-free workspace.

By following these safety precautions, you can ensure a safer and more successful experience when drilling large holes in metal.

FAQ:

What size drill bit should I use for drilling large holes in metal?

The size of the drill bit you should use for drilling large holes in metal depends on the specific hole size you need. It is recommended to start with a smaller drill bit and gradually increase the size until you reach the desired diameter. This will prevent the drill bit from getting stuck or breaking.

What type of drill should I use for drilling large holes in metal?

For drilling large holes in metal, it is best to use a drill press or a magnetic drill. These drills provide more stability and power, making it easier to drill precise and clean holes. Hand drills can also be used, but they may require more effort and may not provide as accurate results.

What speed should I set my drill to when drilling large holes in metal?

The speed at which you should set your drill when drilling large holes in metal depends on the type of metal you are drilling. Generally, a slower speed is recommended for harder metals such as stainless steel or iron, while a faster speed can be used for softer metals like aluminum or copper. It is best to consult the manufacturer’s instructions for the specific drill and metal being used.

How can I prevent the drill bit from overheating when drilling large holes in metal?

To prevent the drill bit from overheating when drilling large holes in metal, you can use a cutting lubricant or coolant. Applying the lubricant or coolant to the drill bit and the metal surface will help to reduce friction and heat buildup. It is important to periodically pause and allow the drill bit and metal to cool down during the drilling process to prevent overheating.

What safety precautions should I take when drilling large holes in metal?

When drilling large holes in metal, it is important to wear safety goggles to protect your eyes from flying metal particles. Additionally, wearing gloves and a long-sleeved shirt can help protect your hands and arms from potential injury. It is also important to secure the workpiece properly and use clamps or a vise to prevent it from moving or spinning during drilling.

Video: