Tips for Drilling Hard Steel

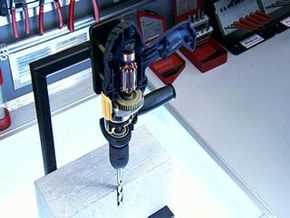

Drilling through hard steel can be a daunting task, but with the right techniques and tools, it can be accomplished successfully. Whether you are working on a DIY project or a professional job, having the proper knowledge and preparation can make all the difference in the outcome.

Choose the Right Drill Bit: When it comes to drilling hard steel, not all drill bits are created equal. It’s important to choose a high-quality bit that is specifically designed for drilling through metal. Look for bits made from cobalt or carbide, as they are known for their durability and ability to withstand high heat. Additionally, make sure the bit is sharp and in good condition to ensure clean and efficient drilling.

Use Lubrication: One of the main challenges when drilling through hard steel is the amount of heat that is generated. This heat can cause the bit to dull quickly and can also damage the workpiece. To combat this, it is crucial to use a lubricant while drilling. Applying a lubricant such as cutting oil or lubricating spray will help to cool the bit and reduce friction, making the drilling process smoother and more effective.

Go Slow and Steady: When drilling through hard steel, it is important to take your time and work at a slower speed. Rushing the process can result in overheating and can cause the bit to become dull or break. Use steady pressure and allow the bit to do the work at its own pace. Applying excessive force or pushing too hard can lead to unnecessary damage.

Secure the Workpiece: To ensure accuracy and prevent slipping or movement, it is essential to secure the workpiece properly. Use clamps or a vise to hold the steel firmly in place, allowing for stable and controlled drilling. This will not only improve safety but will also result in cleaner and more precise holes.

Wear Proper Safety Gear: Drilling through hard steel can produce metal shavings and flying debris, which can be dangerous if they come into contact with your eyes or skin. Before starting the drilling process, make sure to wear safety goggles, gloves, and other appropriate protective gear. This will reduce the risk of injuries and ensure a safe working environment.

By following these tips, you can make drilling through hard steel a more manageable and efficient task. Remember to choose the right drill bit, use lubrication, work at a slow and steady pace, secure the workpiece, and wear proper safety gear. With the right approach, you can achieve great results and successfully complete your drilling project.

Choosing the Right Drill Bit

When it comes to drilling hard steel, using the right drill bit is essential. The type of drill bit you choose can greatly affect the efficiency and success of your drilling project. Here are some factors to consider when selecting a drill bit for drilling hard steel:

1. Material

The material of the drill bit is crucial when drilling hard steel. Look for drill bits made from high-speed steel (HSS), cobalt, or carbide. These materials are specifically designed to withstand the high temperatures and pressures encountered when drilling into hard steel.

2. Coating

Coating the drill bit with a protective layer can enhance its performance and durability. Look for drill bits that are coated with materials like titanium nitride (TiN), titanium carbonitride (TiCN), or black oxide. These coatings reduce friction and heat generation, prolonging the life of the drill bit.

3. Bit Type

There are different types of drill bits suitable for drilling hard steel, including twist bits, step bits, and cobalt bits. Twist bits are the most common and versatile option for general-purpose drilling. Step bits are ideal for drilling larger holes, as they have multiple cutting edges. Cobalt bits are specifically designed for drilling hard materials like stainless steel and cast iron.

4. Size and Shank

Consider the size of the hole you need to drill and choose a drill bit that matches it. Most drill bits come in a range of sizes, from 1/16 inch to 1 inch or larger. Additionally, ensure that the drill bit has a shank that fits your drill’s chuck size. Common shank sizes are 1/4 inch and 3/8 inch.

5. Speed and Feed Rate

When drilling into hard steel, it is important to use the correct speed and feed rate. Consult the manufacturer’s recommendations for the specific drill bit you are using. Using low speeds and applying steady pressure will help prevent overheating and ensure a more controlled drilling process.

6. Cooling and Lubrication

Drilling hard steel generates a significant amount of heat. To prevent overheating and prolong the life of the drill bit, it is crucial to use cooling and lubrication. Apply a cutting fluid or lubricant to the drilling area to reduce friction and dissipate heat. This will also help prevent the drill bit from binding and breaking.

By considering these factors and choosing the right drill bit, you can improve the efficiency and success of your drilling project on hard steel. Remember to wear appropriate safety gear and follow good drilling practices for optimal results.

Using Lubrication

When drilling through hard steel, using a lubricant can greatly improve the drilling process. Lubrication helps reduce friction and heat, making it easier to drill through the tough material and extending the life of the drill bit.

There are various types of lubricants that can be used for drilling hard steel, including cutting oils, tapping fluids, and lubricating greases. The choice of lubricant depends on the specific drilling application and the type of steel being drilled.

Benefits of Using Lubrication

Using lubrication when drilling hard steel offers several benefits:

- Reduced Friction: Lubricants create a barrier between the drill bit and the steel, reducing friction and preventing excessive wear on the cutting edges of the bit. This allows the bit to stay sharp and maintain its cutting efficiency.

- Cooling Effect: Lubrication helps dissipate heat generated during the drilling process. Hard steel can quickly build up heat, which can damage both the bit and the workpiece. By using a lubricant, the heat is absorbed and dispersed, keeping the drilling area cooler and minimizing the risk of heat-related issues.

- Improved Chip Evacuation: Lubrication helps facilitate the removal of metal chips from the drilling area. Without lubrication, chips can get stuck in the flutes of the drill bit, impeding the drilling process and potentially causing the bit to bind or break. Lubricating the drill bit helps flush away the chips, ensuring smooth and uninterrupted drilling.

- Extended Tool Life: By reducing friction and heat, using lubrication can significantly extend the life of drill bits when drilling hard steel. The lubricant acts as a protective layer, reducing wear and tear on the cutting edges and allowing the bit to maintain its sharpness for a longer period of time.

Choosing the Right Lubricant

When selecting a lubricant for drilling hard steel, it is important to consider the specific requirements of the drilling operation. Factors to consider include:

- Type of Steel: Different types of steel may require different types of lubricants. For example, stainless steel may benefit from a specific cutting oil, while carbon steel may perform well with a general-purpose tapping fluid.

- Drilling Application: The type of drilling operation being performed can also influence the choice of lubricant. For example, deep hole drilling may require a lubricant with better heat dissipation properties, while a lubricating grease may be more suitable for a slower speed drilling operation.

- Environmental Considerations: It is important to consider any environmental regulations or restrictions when choosing a lubricant. Some lubricants may contain hazardous materials or require special disposal methods.

Consulting with a steel drilling expert or referring to the manufacturer’s recommendations can help ensure the selection of the most suitable lubricant for the specific drilling application.

Application Methods

When applying lubrication for drilling hard steel, there are different methods that can be used:

- Brushing: For smaller drilling operations, a brush can be used to apply the lubricant directly onto the drill bit and the drilling area. This method allows for precise application and control.

- Flooding: In larger drilling operations or when drilling through thick steel plates, flooding the drilling area with lubricant may be necessary. This involves using a pump or a dispenser to flood the area with a continuous flow of lubricant.

- Misting: Misting is a method where the lubricant is atomized into tiny droplets and sprayed onto the drilling area. This method is often used for drilling operations that require a large volume of lubricant.

The method chosen depends on the size of the drilling operation, the accessibility of the drilling area, and the desired level of lubrication.

Clean-Up

After drilling is complete, it is important to properly clean and remove any residual lubricant from the drilling area. Leaving lubricant on the surface can attract dirt, dust, and debris, which can affect the performance of the drilled hole or potentially lead to corrosion.

Using a mild solvent or a degreaser can help remove any remaining lubricant. Wiping the area with a clean cloth or using compressed air can aid in the cleaning process.

By properly using lubrication when drilling hard steel, it is possible to enhance the drilling process, improve tool life, and achieve better drilling results.

Applying Proper Pressure

Applying the right amount of pressure when drilling hard steel is crucial for achieving successful results. Too much pressure can cause the drill bit to break or become dull, while too little pressure can result in slow progress and inefficient drilling.

Here are some tips for applying proper pressure when drilling hard steel:

- Start with a pilot hole: Before drilling the main hole, it’s recommended to start with a smaller pilot hole. This will help provide better guidance for the drill bit and reduce the amount of force needed to penetrate the steel.

- Use lubrication: Applying lubrication, such as cutting oil or metal coolant, can help reduce heat and friction during the drilling process. This, in turn, can make it easier to apply the right amount of pressure without causing excessive wear on the drill bit.

- Progress gradually: When drilling hard steel, it’s important to proceed slowly and steadily. Pushing too hard too fast can cause the drill bit to overheat and lose its effectiveness. Take your time and allow the drill bit to do the work.

- Monitor the drill bit: Keep an eye on the drill bit as you drill. If you notice excessive smoking, burning, or a change in the sound, it could be a sign that you’re applying too much pressure. Adjust accordingly to prevent damage to the drill bit or workpiece.

- Have extra drill bits on hand: Drilling hard steel can quickly wear down drill bits, especially if too much pressure is applied. It’s always a good idea to have spare bits available, so you can easily replace them if needed.

- Use a proper drill bit: Make sure you’re using the right type of drill bit for drilling hard steel. High-speed steel (HSS) or cobalt drill bits are often recommended for this task. They are designed to withstand the high temperatures and hardness of steel, providing better performance and durability.

By following these tips and applying proper pressure, you can increase your chances of drilling hard steel successfully and efficiently.

Optimizing Drill Speed

When drilling hard steel, it is important to optimize the drill speed to achieve the best results. Here are some tips to help you drill through hard steel more efficiently:

1. Selecting the Right Drill Bit

Choosing the right drill bit is crucial for drilling hard steel. High-speed steel (HSS) or cobalt drill bits are recommended for drilling through hard steel. These materials are designed to withstand the high friction and heat generated during drilling, ensuring better performance and longer bit life.

2. Using the Correct Drill Speed

Drill speed is an essential factor in successfully drilling hard steel. The optimal speed can vary depending on the type and thickness of the steel, as well as the size of the drill bit. It is generally recommended to start drilling at a slower speed and gradually increase it until you find the optimal speed for your specific application.

Refer to the manufacturer’s recommendations for the recommended drill speed for the specific material and drill bit you are using. Following these guidelines will help prevent overheating and premature wear of the drill bit.

3. Lubricating the Drill Bit

Using a lubricant while drilling can significantly improve the drilling process by reducing friction and heat buildup. Apply a cutting oil or lubricating fluid to the drill bit and the surface of the steel. This will not only help prolong the life of the drill bit but also make the drilling process smoother and more efficient.

4. Applying Consistent Pressure

Applying consistent pressure while drilling is important to maintain control and prevent damage to the drill bit. Use a steady and moderate force when drilling through hard steel, avoiding excessive pressure that can cause the bit to break or wear out prematurely.

Remember to periodically release the pressure to clear away metal shavings and allow the drill bit to cool down. This will help maintain a steady drilling speed and prevent overheating.

5. Cooling Down the Drill Bit

Hard steel can generate a significant amount of heat during the drilling process. To prevent overheating and premature wear, it is important to cool down the drill bit regularly. You can do this by dipping the drill bit in a coolant or water bath between drilling sessions.

Conclusion

By optimizing the drill speed when working with hard steel, you can achieve cleaner and more efficient drilling results. Remember to choose the appropriate drill bit, use the correct drill speed, lubricate the bit, apply consistent pressure, and cool down the drill bit to maximize performance and prolong the life of the bit.

Using a Pilot Hole

A pilot hole is a small hole drilled into the hard steel surface before drilling the actual hole. This technique is used to guide the drill bit and prepare the steel for drilling.

Benefits of using a pilot hole:

- Accuracy: The pilot hole helps in achieving more precise and accurate drilling results by providing a starting point for the drill bit.

- Prevents wandering: When drilling into hard steel, the drill bit can easily wander or slip. The pilot hole acts as a guide, preventing the bit from drifting off and ensuring a straight hole.

- Reduced heat and friction: The pilot hole allows for better heat dissipation and reduces friction during the drilling process. This helps prevent the drill bit from overheating or getting stuck in the steel.

Steps to use a pilot hole:

- Mark the drilling spot: Use a marker or a center punch to mark the exact spot where you want to drill the hole.

- Select the right drill bit: Choose a smaller drill bit than the final desired hole size. The diameter of the pilot hole should be approximately 1/4 to 1/2 the diameter of the final hole.

- Secure the steel surface: Clamp or secure the steel surface to prevent it from moving during drilling.

- Start drilling the pilot hole: Position the drill bit on the marked spot and apply firm but controlled pressure. Begin drilling at a slow speed to create the pilot hole.

- Clear the debris: Periodically remove the accumulated debris from the pilot hole using compressed air or a brush to maintain visibility and prevent the drill bit from getting clogged.

- Switch to the larger drill bit: Once the pilot hole is created, carefully switch to the larger drill bit to continue drilling the final hole.

Important tips:

- Ensure the pilot hole is straight and centered to achieve accurate drilling.

- Use cutting oil or lubricant to reduce friction and prolong the life of the drill bits.

- Apply consistent pressure and avoid excessive force to prevent the drill bit from breaking or damaging the steel surface.

- Use a cutting fluid or coolant to keep the drill bit and steel surface cool during the drilling process.

| Advantages | Steps | Tips |

|---|---|---|

| Accuracy | Mark the drilling spot | Ensure the pilot hole is straight |

| Prevents wandering | Select the right drill bit | Use cutting oil or lubricant |

| Reduced heat and friction | Secure the steel surface | Apply consistent pressure |

Using a Drilling Jig

When drilling hard steel, using a drilling jig can greatly improve your accuracy and efficiency. A drilling jig is a specialized tool that helps hold the workpiece securely in place and guides the drill bit to ensure precise drilling. Here are some tips on how to use a drilling jig effectively:

1. Choose the Right Jig for the Job

There are different types of drilling jigs available, so make sure you select the one that is suitable for the specific task and size of your workpiece. Some jigs are designed for drilling holes of different diameters, while others are adjustable to accommodate various size workpieces.

2. Securely Clamp the Jig

Before you start drilling, securely clamp the drilling jig to your work surface using C-clamps or a bench vise. This will prevent the jig from moving during the drilling process and ensure accuracy. Make sure the jig is properly aligned and level before proceeding.

3. Mark the Hole Locations

Measure and mark the hole locations on your workpiece using a center punch or a sharp awl. Marking the hole locations will help guide the drill bit and prevent it from slipping or wandering. Use a ruler or a square to ensure accurate spacing between the holes.

4. Use the Correct Drill Bit

Choose the right drill bit for drilling hard steel. High-speed steel (HSS) or cobalt bits are usually recommended for drilling through tough materials like hardened steel. Ensure that the drill bit is sharp and properly sized for the holes you need to drill.

5. Apply Cutting Fluid

To reduce heat and friction, apply cutting fluid to the drill bit and workpiece. This will help prolong the life of the drill bit and prevent it from overheating. Apply cutting fluid periodically during the drilling process to keep the drill bit cool.

6. Start Drilling Slowly

When you start drilling, begin at a slow speed to prevent the drill bit from wandering or jumping. Applying too much pressure can cause the drill bit to break or damage the workpiece. Gradually increase the drilling speed as you go deeper into the material.

7. Use Pecking Technique

When drilling hard steel, it can be helpful to use a pecking technique. This involves drilling a short distance, then lifting the drill bit out of the hole to remove chips and cool down the drill bit. Repeat this process until you complete the hole.

8. Clean and Deburr

After drilling the holes, clean off any metal shavings and burrs left behind. Use a deburring tool or a file to remove any sharp edges or burrs around the drilled holes.

By following these tips and using a drilling jig, you can improve the accuracy and efficiency of drilling hard steel. Remember to always wear appropriate safety gear, such as safety glasses and gloves, when working with power tools.

Monitoring Heat

When drilling hard steel, it is important to monitor the heat that is generated during the drilling process. Excessive heat can cause the drill bit to become dull and can result in poor performance and shorter tool life.

Why is monitoring heat important?

Monitoring heat is important because it can help prevent damage to the drill bit and ensure that the drilling process is efficient and effective. If the heat generated is not controlled, it can lead to increased wear on the drill bit and even cause it to break.

How to monitor heat

- Use a temperature monitoring device: There are various temperature monitoring devices available on the market that you can use to measure the heat generated during drilling. These devices can give you real-time data on the temperature and help you make adjustments as needed.

- Check for discoloration: When drilling hard steel, you can also check for discoloration on the metal surface. If you notice any darkening or bluing, it is an indicator that excessive heat is being generated. In such cases, it is important to take breaks and allow the drill bit to cool down.

- Feel the heat: Another simple way to monitor heat is by feeling the heat on the drill bit. If the bit becomes uncomfortably hot to touch, it is a sign that excessive heat is being generated. Again, take breaks to allow the drill bit to cool down.

- Use lubrication: Using a lubricant while drilling can help reduce friction and heat buildup. Lubricants help cool down the drill bit and the material being drilled, making the drilling process more efficient and effective.

By monitoring the heat generated during the drilling process, you can ensure that the drill bit stays sharp and performs optimally. Taking necessary precautions and making adjustments as needed will help prolong the life of the drill bit and improve the overall drilling experience.

Ensuring Safety

Drilling hard steel can be a dangerous task if proper safety measures are not taken. Here are some important tips to ensure your safety while drilling:

1. Wear Protective Gear

Always wear personal protective equipment (PPE) when drilling hard steel. This includes safety glasses or goggles to protect your eyes from flying metal chips or particles, gloves to protect your hands, and earplugs or earmuffs to protect your hearing.

2. Use Clamps or Vises to Secure the Workpiece

When drilling hard steel, it is important to secure the workpiece firmly. Use clamps or vises to hold the steel in place to prevent it from moving or spinning while drilling. This will reduce the risk of accidents and ensure more accurate drilling.

3. Use the Correct Drill Bit

Choose the right drill bit specifically designed for drilling hard steel. Using the wrong drill bit can cause the bit to slip or break, leading to accidents or damage to the workpiece. Carbide or cobalt drill bits are often recommended for drilling hard steel.

4. Start with a Pilot Hole

Drilling hard steel can be challenging. To make the process easier and reduce the risk of skidding or the drill bit wandering, start by drilling a pilot hole. A pilot hole serves as a guide and helps to create a starting point for the drill bit.

5. Use Proper Technique

When drilling hard steel, use a steady and consistent drilling motion. Apply firm, but not excessive, pressure on the drill to prevent it from slipping or jamming. Avoid using excessive force, as it can lead to broken drill bits or damage to the workpiece.

6. Cool the Drill Bit

Drilling hard steel generates heat that can reduce the effectiveness and lifespan of the drill bit. To prevent overheating, use a cooling agent such as cutting oil or lubricant. Apply the cooling agent to the drill bit periodically to keep it cool and prevent it from getting too hot.

7. Work in a Well-Ventilated Area

Drilling hard steel can produce dust, debris, and potentially harmful particles. Make sure to work in a well-ventilated area or use a dust collection system to remove and control the dust. Breathing in these particles can be hazardous to your health.

By following these safety tips, you can significantly reduce the risk of accidents and ensure a safer drilling experience when working with hard steel.

FAQ:

What are some tips for drilling hard steel?

When drilling hard steel, it is important to use a sharp drill bit. A dull drill bit can cause the drill to overheat and wear out quickly. It is also helpful to use a slower drilling speed and apply steady pressure to avoid damaging the drill bit or the steel. Using cutting fluid or lubricant can help to reduce heat and friction during the drilling process. Additionally, it is recommended to use a drill press or a sturdy hand drill to ensure stability and accuracy.

What type of drill bit should I use for drilling hard steel?

For drilling hard steel, it is best to use a cobalt or carbide drill bit. Cobalt drill bits are known for their hardness and ability to withstand high temperatures. Carbide drill bits, on the other hand, have a high resistance to wear and can maintain their sharpness for longer. Both types of drill bits are specifically designed for drilling through hard materials like steel.

Can I use a regular drill for drilling hard steel?

While it is possible to use a regular drill for drilling hard steel, it is not recommended. Regular drills may not have enough power or torque to effectively drill through hard materials. Additionally, they may not provide the necessary stability and control needed for accurate drilling. It is better to use a drill specifically designed for heavy-duty applications or a drill press for drilling hard steel.

What should I do if my drill bit becomes dull while drilling hard steel?

If your drill bit becomes dull while drilling hard steel, it is important to stop drilling and replace the dull bit with a sharp one. Continuing to use a dull drill bit can cause the drill to overheat and wear out quickly, and it can also lead to poor drilling results. It is recommended to have spare drill bits on hand when drilling hard steel to avoid interruptions in the drilling process.

Are there any safety precautions I should take when drilling hard steel?

Yes, there are several safety precautions to consider when drilling hard steel. It is important to wear safety glasses or goggles to protect your eyes from flying debris. It is also recommended to wear gloves to protect your hands from cuts and to provide a better grip on the drill. When drilling, make sure to secure the steel properly to prevent it from moving or vibrating during the drilling process. Additionally, be mindful of the heat generated and avoid touching the drill bit or the drilled steel immediately after drilling.

Video: