Tips for Drilling a Water Well in Sandy Soil

Drilling a water well in sandy soil can present its own set of challenges. Sandy soil is loose and prone to collapse, making it difficult to maintain drilling stability and prevent the walls of the well from caving in. However, with the right techniques and equipment, it is possible to successfully drill a water well in sandy soil.

1. Use a Casing

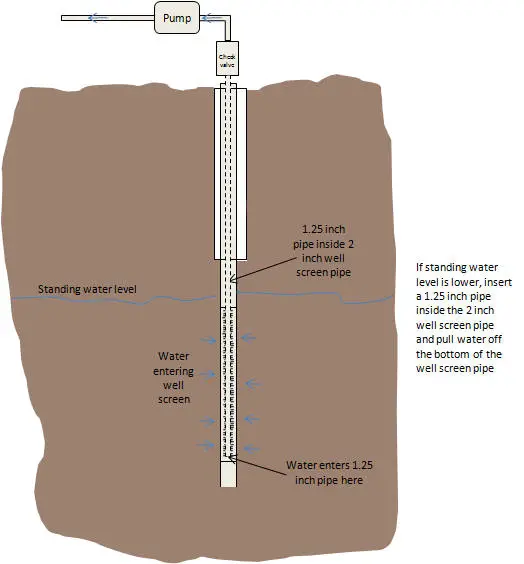

Using a casing is essential when drilling in sandy soil. A casing is a pipe that is inserted into the hole as drilling progresses. It helps to stabilize the well walls and prevent them from collapsing. The casing can also provide a pathway for the water to flow into the well.

2. Choose the Right Drilling Method

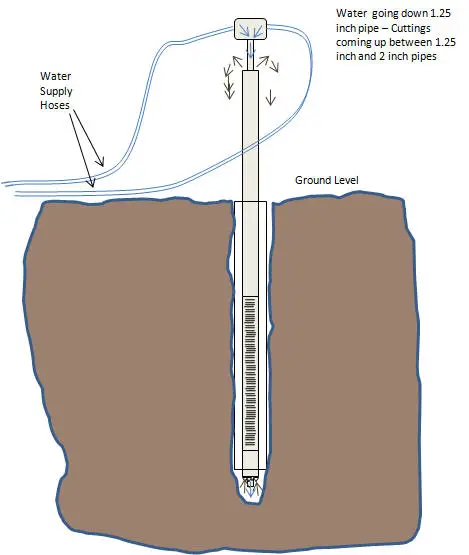

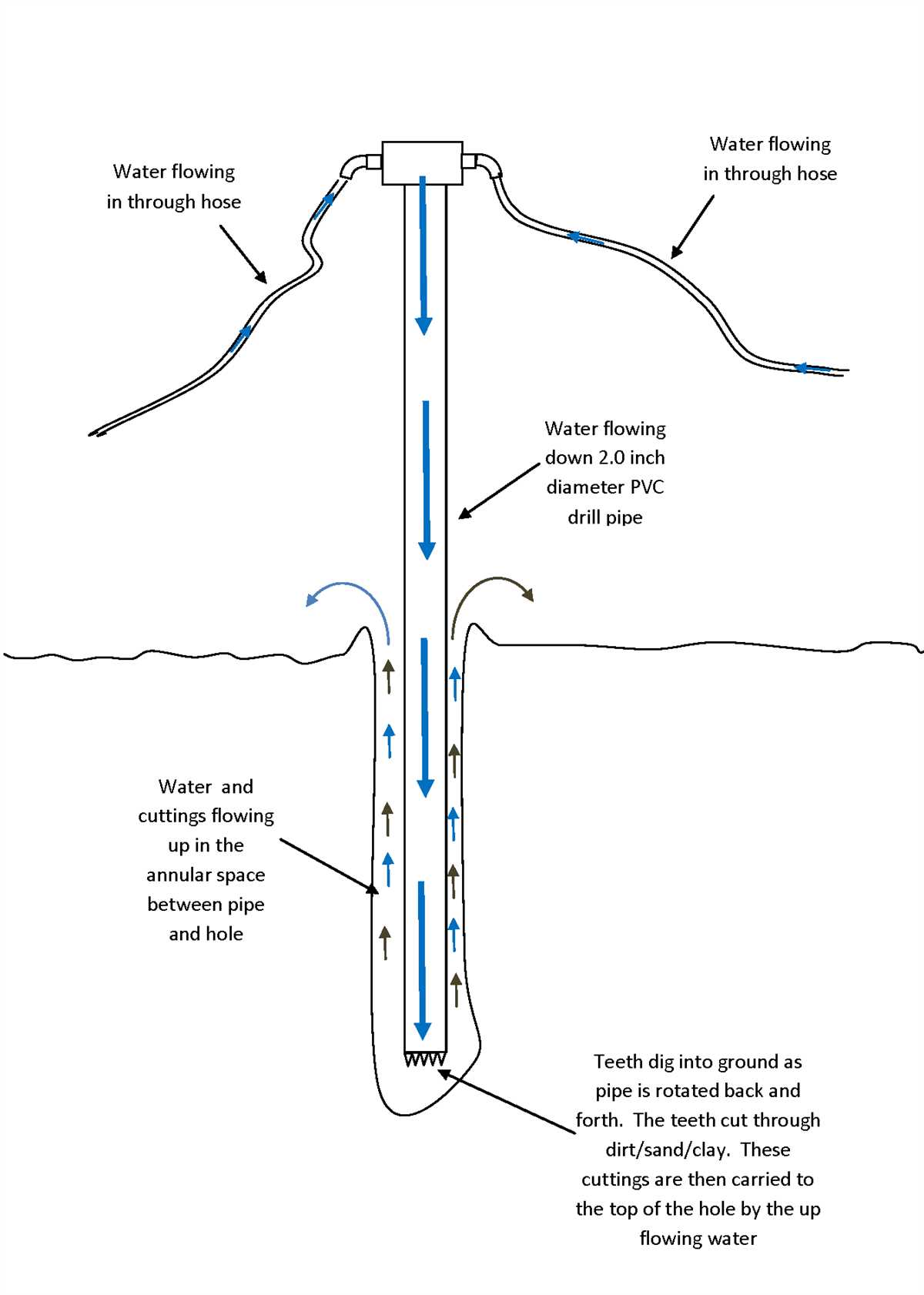

When drilling in sandy soil, it is important to choose the right drilling method. Rotary drilling is often recommended for sandy soil as it allows for the use of drilling fluid, which helps to stabilize the well walls. This method involves rotating a drill bit while simultaneously pumping drilling fluid into the hole to remove cuttings and provide support.

3. Monitor the Water Table

Monitoring the water table is crucial when drilling a well in sandy soil. Sandy soil tends to have a high water table, which means that the water level is close to the surface. It is important to drill deep enough to reach a stable water source. This can be done by using a water level indicator to measure the depth of the water table and adjust the drilling accordingly.

4. Secure the Wellhead

Once the well has been drilled, it is important to secure the wellhead to prevent contamination and ensure the safety of the water supply. The wellhead should be properly sealed to prevent the entry of surface contaminants and pests. It is also important to install a well cap or cover to protect the well from physical damage and prevent unauthorized access.

By following these tips, it is possible to successfully drill a water well in sandy soil. Proper planning, equipment, and techniques are key to ensuring the stability and effectiveness of the well. It is also important to consult local regulations and guidelines to ensure compliance with any drilling or water sourcing requirements.

Choosing the Right Equipment

When drilling a water well in sandy soil, it is important to choose the right equipment to ensure a successful drilling process. The equipment you need will depend on the depth and size of the well you are planning to drill.

1. Drilling Rig

A drilling rig is the main equipment used for drilling a water well. It is important to choose a drilling rig that is suitable for sandy soil conditions. Look for a rig that has enough power to penetrate the sandy soil easily and can handle the required drilling depth.

2. Drill Bit

The drill bit is the component of the drilling rig that actually cuts into the ground. For drilling in sandy soil, it is recommended to use a tricone bit or a drag bit. These types of bits are designed for drilling in softer formations like sand. They have a smooth cutting action that is more effective in sandy soil compared to other types of drill bits.

3. Casing

After drilling the well, casing is used to line the hole and prevent it from collapsing. In sandy soil, it is important to use a casing that has a high tensile strength to withstand the pressure of the surrounding sand. PVC casing is commonly used for water wells in sandy soil, as it is lightweight, durable, and resistant to corrosion.

4. Pump

A pump is used to extract water from the well once it is drilled. When choosing a pump for a well in sandy soil, consider the flow rate and the depth of the well. Look for a pump that is capable of handling the sandy soil and can provide the desired flow rate for your water needs.

5. Other Equipment

In addition to the main drilling equipment, there are other tools and equipment that may be required for drilling a water well in sandy soil. These include drill rods, drill collars, drilling fluids, and basic hand tools. It is important to have the necessary equipment and tools to properly handle the drilling process and ensure a successful completion of the well.

By choosing the right equipment for drilling a water well in sandy soil, you can ensure a smooth and successful drilling process. Consider the specific requirements of your project and consult with professionals if needed to make the best equipment choices.

Understanding the Soil Composition

Before drilling a water well in sandy soil, it is important to understand the composition of the soil. Sandy soil is composed of a large amount of sand particles, which are large, gritty, and have a low ability to retain water. This can present challenges when drilling a well, as the sandy soil can collapse or erode easily.

Silt and Clay Content:

In addition to sand, sandy soil may also contain small amounts of silt and clay particles. Silt particles are smaller than sand particles and feel smooth to the touch. Clay particles are even smaller and often sticky or plastic-like in texture. Understanding the silt and clay content of the soil can help in determining the appropriate drilling techniques and equipment.

Water Permeability:

One of the main characteristics of sandy soil is its high permeability. The large spaces between the sand particles allow water to infiltrate quickly, but they also make it easy for the water to drain away. This means that sandy soil does not retain water well, which can be challenging when drilling a well.

Challenges for Drilling in Sandy Soil

Drilling a water well in sandy soil can present several challenges:

- Instability: Sandy soil is prone to collapse or erode, making it difficult to maintain a stable borehole. Special tools and techniques, such as casing and drilling mud, may be required to stabilize the well.

- Low Water Retention: Due to its high permeability, sandy soil does not retain water well. This means that the well may need to be deeper or have a larger diameter to ensure an adequate water supply.

- Risk of Contamination: The high permeability of sandy soil also means that contaminants can easily infiltrate the water supply. It is important to take steps to prevent contamination, such as proper well construction and regular testing.

Drilling Techniques for Sandy Soil

To address the challenges of drilling in sandy soil, various techniques can be used:

- Use of Casing: Casing is a common technique used to stabilize the well in sandy soil. Casing is a metal or plastic pipe that is inserted into the borehole to prevent collapse and erosion.

- Drilling Mud: Drilling mud, also known as drilling fluid, is a mixture of water, clay, and other additives. It is used to lubricate and cool the drill bit, as well as to stabilize the borehole walls in sandy soil.

- Well Development: After drilling a well in sandy soil, it is important to properly develop the well to maximize water production. This may involve techniques such as air-lifting or surging to remove fine sediment and improve water flow.

By understanding the composition of sandy soil and using appropriate drilling techniques, it is possible to successfully drill a water well in sandy soil.

Preparing the Work Area

Before you start drilling a water well in sandy soil, it is important to prepare the work area to ensure a smooth and efficient drilling process. Here are some steps to follow:

1. Clear the area

Remove any obstacles or debris from the site where you plan to drill the well. This includes rocks, trees, bushes, and any other objects that may hinder the drilling process.

2. Mark the drilling spot

Using stakes or markers, designate the exact spot where you intend to drill the well. This will help you maintain precision and accuracy during the drilling process.

3. Assess the surrounding area

Take a look at the area surrounding the drilling spot to ensure there are no underground utilities or structures that could be affected by the drilling process. It is important to avoid damaging any existing infrastructure.

4. Obtain necessary permits

Check with your local government or water authority to determine if you need any permits or approvals before drilling a well. Some areas require permits to ensure compliance with environmental regulations and to protect water resources.

5. Plan for water disposal

Consider how you will dispose of the water that is extracted during the drilling process. Sandy soil can have a high water table, so you may need to install a sump pump or have a plan in place for proper water disposal to prevent flooding or environmental damage.

6. Ensure safety measures

Prioritize safety by ensuring you have the necessary safety equipment and tools. This may include gloves, safety glasses, ear protection, and a hard hat. It is also important to have a first aid kit on hand in case of any accidents or injuries.

7. Secure necessary equipment

Make sure you have all the equipment and tools necessary for drilling a well in sandy soil. This may include a drill rig, drill bits, pipes, and a pump. It is important to have all the equipment ready before starting the drilling process.

8. Plan for waste disposal

Consider how you will dispose of the waste materials generated during the drilling process. This may include soil, sand, and rock fragments. Proper waste disposal is important to ensure minimal environmental impact.

By following these steps and preparing the work area properly, you can ensure a safer and more effective drilling process when drilling a water well in sandy soil.

Ensuring Proper Well Depth

1. Research the groundwater level

Before drilling a well in sandy soil, it is essential to research the groundwater level in your area. This information can be obtained from local government agencies or professional well drillers. Understanding the depth at which groundwater is typically found will help determine the required well depth.

2. Consider the well yield

The well yield refers to the amount of water that a well can supply. It is important to ensure that the well depth is sufficient to provide an adequate water supply for your needs. Factors such as the number of people in your household and any potential irrigation needs should be taken into account when determining the required well depth.

3. Consult a professional well driller

Working with an experienced well driller is crucial to ensuring proper well depth. They will have the knowledge and expertise to assess the specific conditions of your sandy soil and determine the appropriate well depth. A professional well driller can also provide guidance on any additional considerations, such as the installation of a casing or gravel pack, to prevent sand infiltration.

4. Consider local regulations

Local regulations may have specific requirements regarding the minimum well depth in sandy soil. It is important to consult these regulations to ensure that your well complies with all necessary guidelines. Local authorities or professional well drillers can provide information on any specific requirements in your area.

5. Regular maintenance and monitoring

Once the well is drilled to the appropriate depth, it is essential to regularly maintain and monitor its performance. This includes periodic water testing to ensure water quality and regular checks on the water level to ensure that it remains at a sufficient level. Regular maintenance and monitoring will help ensure that your well continues to provide a reliable water supply.

6. Consider professional inspection

After drilling the well, it is a good idea to have it professionally inspected to ensure that it has been constructed properly and meets all necessary standards. A professional inspection can help identify any potential issues or deficiencies early on, allowing for timely repairs or adjustments to be made.

By following these tips and guidelines, you can ensure that your well in sandy soil is drilled to the appropriate depth and provides a reliable water supply for your needs.

Using the Correct Drilling Techniques

1. Selecting the proper drill bit

Choosing the right drill bit is crucial when drilling a water well in sandy soil. A carbide-tipped or diamond-tipped bit is recommended for sandy formations as they provide increased durability and cutting efficiency. These bits are designed to maintain their sharpness and stay intact when drilling through abrasive materials like sand.

2. Ensuring proper stabilization

Drilling in sandy soil can be challenging due to its loose and unstable nature. To prevent the borehole from collapsing during the drilling process, it is important to use stabilizing fluids such as bentonite or polymers. These fluids help to keep the sandy soil together and provide temporary support to the borehole walls.

3. Managing water flow

Water is essential during the drilling process to remove cuttings and cool the drill bit. However, in sandy soil, excessive water flow can cause the formation to become unstable and collapse. It is important to carefully manage the water flow by controlling the drilling speed and adjusting the flow rate to maintain stability.

4. Implementing proper casing techniques

Casing is important in sandy soil to prevent the borehole from caving in and to maintain water quality. Installing a steel or PVC casing can provide structural support and prevent the sandy soil from collapsing into the well. The casing should be carefully sealed and grouted to prevent any influx of unwanted materials.

5. Regularly checking and maintaining equipment

Regular equipment maintenance is vital to ensure efficient drilling in sandy soil. The drill rig should be inspected for any wear and tear and repaired or replaced as necessary. The drill bit should also be checked frequently and replaced if it is no longer cutting effectively. This will help to minimize downtime and ensure smooth drilling operations.

6. Hiring experienced drilling professionals

Drilling a water well in sandy soil can be a complex and challenging process. It is essential to hire experienced drilling professionals who have a thorough understanding of the unique characteristics of drilling in sandy formations. Their expertise will ensure that the correct drilling techniques are used to successfully complete the well.

Conclusion

Using the correct drilling techniques is crucial when drilling a water well in sandy soil. By selecting the proper drill bit, ensuring proper stabilization and water flow, implementing proper casing techniques, regularly checking and maintaining equipment, and hiring experienced drilling professionals, the drilling process can be carried out efficiently and effectively, resulting in a successful water well in sandy soil.

Monitoring Water Quality

Monitoring the quality of your well water is essential to ensure the safety and health of those who use it. Sandy soil presents unique challenges when it comes to water quality, as contaminants can easily seep through the loose soil and into the water source. Here are some important tips for monitoring the water quality in sandy soil:

Regular Testing

It is important to have your well water tested regularly by a certified laboratory. The testing should include analysis for common contaminants such as bacteria, nitrates, and other harmful substances. Regular testing will help you catch any issues with water quality early on and take appropriate actions to address them.

Keep Records

Maintain a logbook of the test results from each water quality analysis. This will help you track any changes in the water quality over time and identify potential sources of contamination. It will also serve as a valuable resource for future reference and comparison.

Inspect and Clean Well Components

Regularly inspect and clean the well components, including the well casing and storage tanks, to prevent the accumulation of debris, bacteria, or other contaminants. Cleaning should be done according to the manufacturer’s guidelines or with the help of a professional if necessary.

Safeguard the Well

Protecting the well from potential sources of contamination is crucial. Ensure that the well is properly constructed and sealed to prevent surface water from entering the well. Keep a safe distance between the well and potential sources of contamination, such as septic systems, livestock areas, or chemical storage.

Educate Yourself

Stay informed about potential risks and issues associated with water quality in sandy soil. Understand the local geology, nearby land uses, and potential sources of contamination in your area. This knowledge will help you make informed decisions regarding well maintenance and water treatment.

Consider Treatment Options

If water quality issues are detected, consider water treatment options that are suitable for sandy soil conditions. Depending on the specific contaminants present in the water, treatment methods such as filtration, disinfection, or reverse osmosis may be necessary to ensure the safety and quality of the water.

Consult with Experts

If you are unsure about how to monitor or address water quality concerns in sandy soil, consult with experts such as hydrogeologists, well drillers, or water treatment professionals. They can provide valuable guidance and support to ensure the protection of your well water.

By carefully monitoring the water quality in sandy soil, you can ensure that your well water remains safe and clean for drinking, cooking, and other household uses.

Maintaining the Well

Once your well is drilled and operational, it’s important to keep up with regular maintenance to ensure its longevity and efficient performance. Here are some tips for maintaining your well:

1. Regular Inspection

Periodically inspect your well for any signs of damage or wear. Look for cracks in the casing, leaks, or any other abnormalities. Address any issues promptly to prevent further damage.

2. Test Water Quality

Regularly test the quality of your well water to ensure it is safe for consumption. Test for common contaminants such as bacteria, nitrates, and heavy metals. If you notice any changes in taste, odor, or appearance of the water, consider conducting additional tests.

3. Maintain Vegetation

Keep vegetation and landscaping away from the well to prevent roots from causing damage to the casing or compromising the integrity of the well. Trim any overhanging branches to minimize the risk of debris entering the well.

4. Keep Records

Maintain a record of all maintenance activities and test results for future reference. This will help you identify any patterns or issues that may arise over time and assist in troubleshooting if any problems occur.

5. Insulate Pipes

In colder climates, insulate the pipes leading to and from the well to prevent freezing during winter. Freezing pipes can lead to blockages and potentially damage the well system.

6. Prevent Contamination

Take steps to prevent contamination of your well water. Avoid storing hazardous substances near the well and ensure proper disposal of waste or chemicals away from the well area. Regularly inspect the well cap to ensure it is secure and prevent any entry of debris or pests.

7. Periodic Well Flushing

Consider periodically flushing your well to remove any accumulated sediment or bacteria. Consult with a professional well contractor for guidance on the appropriate frequency and procedure for well flushing.

8. Stay Informed

Stay informed about any changes in local regulations or guidelines for well maintenance. Keep up with education and training opportunities to improve your understanding of proper well maintenance techniques.

Remember, regular maintenance and timely repairs are essential to keep your well functioning properly. By following these tips, you can ensure the longevity and reliability of your well.

Consulting Professionals

When drilling a water well in sandy soil, it is important to consult with professionals who have experience in this type of terrain. These professionals can provide valuable insights and guidance to ensure that the drilling process is executed effectively and efficiently.

Here are some professionals you should consider consulting when drilling a water well in sandy soil:

1. Geotechnical Engineers

Geotechnical engineers specialize in understanding the properties of soil. They can assess the composition and characteristics of the sandy soil in your area, which can help you determine the most suitable drilling methods and equipment.

2. Hydrologists

Hydrologists study how water moves through the earth’s surface and subsurface. They can analyze the hydrological conditions in your area, including the presence of underground water sources, to determine the ideal location for drilling a water well.

3. Well Drillers

Well drillers are professionals who specialize in drilling water wells. They have the expertise and equipment necessary to drill wells in different types of soil, including sandy soil. Consulting with well drillers can help you understand the specific challenges and considerations associated with drilling in sandy soil.

4. Environmental Specialists

Environmental specialists can provide valuable insights on the potential environmental impacts of drilling a water well in sandy soil. They can help you navigate any regulatory requirements or permits that may be necessary for your drilling project.

5. Local Authorities

Consulting local authorities, such as water management districts or municipalities, is important to ensure compliance with any regulations or permits related to drilling a water well. They can provide guidance on any specific requirements or restrictions that may apply in your area.

In conclusion, consulting professionals who have expertise in drilling and the specific characteristics of sandy soil can greatly enhance the success of your water well drilling project. Their knowledge and guidance can help you make informed decisions and mitigate any potential challenges that may arise during the drilling process.

FAQ:

What are the challenges of drilling a water well in sandy soil?

Drilling a water well in sandy soil presents several challenges. Sandy soil is loose and unstable, making it difficult to maintain the integrity of the well hole. Additionally, sandy soil is permeable, meaning water can easily flow through it, potentially contaminating the well water. Finally, sandy soil may not provide enough structural support for the well casing, which can lead to collapse or failure of the well.

What equipment is needed for drilling a water well in sandy soil?

Drilling a water well in sandy soil requires several pieces of equipment. A drilling rig or drill bit is needed to create the well hole. A pump is also required to remove water and drill cuttings from the well. A casing pipe is necessary to line the well hole and provide structural support. Additionally, specialized drilling fluids may be used to stabilize the sandy soil and prevent collapse.

Are there any specific techniques for drilling a water well in sandy soil?

Yes, there are some specific techniques that can be used when drilling a water well in sandy soil. One technique is to use drilling fluids, such as bentonite or polymers, to stabilize the loose soil and prevent collapse. Another technique is to drill a smaller diameter hole initially and then gradually increase the size as the well is drilled deeper. This can help to maintain stability and prevent cave-ins. Additionally, it may be necessary to install a screen or gravel pack around the well casing to prevent sand from entering the well.

What precautions should I take when drilling a water well in sandy soil?

When drilling a water well in sandy soil, it is important to take certain precautions. Firstly, you should ensure that the drilling site is free from any potential contaminants, as sandy soil is prone to contamination. It is also important to monitor the drilling process closely and make sure the well hole is properly supported to prevent collapse. Additionally, testing the well water regularly for quality and potential contaminants is essential to ensure the safety of the water supply.

Video: